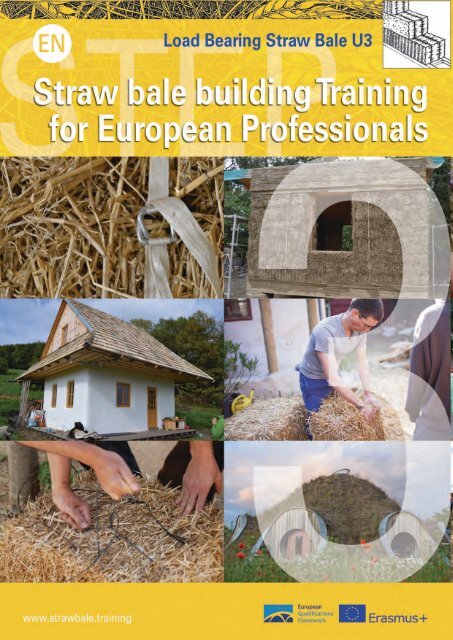

STEP U3 Handbuch ENGLISH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1

2

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

CONTENTS<br />

<strong>U3</strong><br />

TIME<br />

PAGE<br />

<strong>U3</strong> Learning Outcome 5<br />

<strong>U3</strong> Session 1 : Design & Planning 5 hrs 7<br />

Info presentation 1 : Design Basics 8<br />

Info presentation 2: Drawing Basics 1 0<br />

Tips: Load-Bearing SBB Pros 001 -1 2 and Cons 002-1 3 1 2<br />

Weather Protection I 003-1 4, Weather Protection II 004-1 5<br />

Organization of the Building Site – Planning 005-1 6, Preparatory Works 006-1 7,<br />

Building Schedule 007-1 8/1 9, Cutting List 20, Estimating Costs 21<br />

<strong>U3</strong> Session 2: Construction & Statics 2 days 23<br />

Info 1 : Construction – Overview and Examples 24<br />

Tips: Bales and Walls Dressing Bales 008-26, Notching Bales 009-27, 26<br />

Compressing Walls with Trucker Straps 01 0-28, with Car Jacks 011 -29<br />

Info 2: Statics (Virko Kade) 38<br />

Info 3: Compression & Settlement 42<br />

Info 4: Legislation 44<br />

Info 5: Characteristics of the Planning Process 45<br />

Info 6: Remarks on Building Physics 46<br />

<strong>U3</strong> Session 3: Tools & Practice 1 day 32<br />

Tips: Tools Splitting Bales with Bale Needles 01 2-32, Hedge Saws 01 3-33,<br />

Persuader 01 4-34, Gap Filler 01 5-35<br />

Info 2: Strings and Knots 36<br />

Appendix: Statics House Fliri (Peter Braun) 49<br />

Credits and Impressum 52<br />

3

4

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

LEARNING OUTCOMES<br />

<strong>U3</strong><br />

Level 3 (ECVET credit points: 1 5) / Level 4 (12)<br />

Knowledge<br />

Skills<br />

Trainees know …<br />

• about the existing national building<br />

regulations related to straw bale building.<br />

• the specific problems organising a load<br />

bearing straw bale building site and their<br />

solutions (weather protection, safety, logistics).<br />

• the symbols to be able to understand plans<br />

and construction drawings.<br />

• the necessity and the techniques to avoid and<br />

to close gaps (between bales and between<br />

bales and construction).<br />

• the reasons and the techniques to fill in straw<br />

in the required density and the specific<br />

methods of compressing and their application.<br />

• the techniques to fix the bales in the<br />

construction (corner detail).<br />

• the techniques to adapt the straw bales layers<br />

to the requirements of load bearing straw bale<br />

building.<br />

• the pros and cons of the load bearing<br />

technique and its requirements related to<br />

schedule, planning, budget, and resources.<br />

• the details for adjacent building elements<br />

(floor and roof plates, ring-beam and openings)<br />

according to load-bearing straw bale building.<br />

• the details for openings (windows, doors) and<br />

for intersections (chimneys, pipes, wires).<br />

• the reasons and the techniques to prepare the<br />

substrate with a plane and gap free surface.<br />

Trainees can …<br />

• control the quality ofexisting constructions in<br />

relation to its suitability for load bearing straw<br />

bale building.<br />

• handle the tools and machines which are used<br />

generally on straw bale building sites and for<br />

simple wood constructions.<br />

• choose appropriate bales for the load bearing<br />

techniques, resize, reknot and fix the bales<br />

together.<br />

• adjust the bales to the length of the<br />

construction elements in a suitable assembly.<br />

• do basic carpentry to make additional<br />

wooden construction aids in order to erect<br />

straight walls.<br />

• compress the assembled bales in different<br />

techniques in an adequate way.<br />

• fill gaps and holes with straw in a required<br />

compression.<br />

• fabricate base and top ring beam and fill it<br />

with insulation material and fix it adequately.<br />

• calculate building costs related to the straw<br />

bale constructions.<br />

• prepare all surfaces for the successive crafts<br />

people (plaster, cladding, wind- and air<br />

tightness) or execute these tasks in mutual<br />

agreement.<br />

• assemble the supporting wooden structures<br />

and the frames for openings.<br />

Competence<br />

Trainees can …<br />

• organize and attend the building site at all stages and adapt the working process, the use oftools and<br />

adequate techniques related to straw bale building (planing, preparation, execution, additional crafts).<br />

• co-ordinate and communicate the special needs of load-bearing construction with other professionals.<br />

• explain different methods ofload-bearing construction with reference to advantages and disadvantages.<br />

• inspect and select good quality bales for load-bearing construction during the whole building process.<br />

• control the general quality of the bales during the whole building process.<br />

5

6

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1<br />

<strong>U3</strong><br />

<strong>U3</strong>-S1 : Design and Planning<br />

Objectives:<br />

Trainees …<br />

… have the ability to read and understand architectural plans and<br />

construction drawings<br />

… know different structural options<br />

… know the dis-/advantages of every solution<br />

Knowledge and Skills:<br />

- Making a building schedule<br />

- Organization and execution of the work within schedule<br />

- Making a cutting list<br />

- Calculation of the building costs<br />

Methods:<br />

- Lecture/Talk<br />

- Explanations<br />

- Practice<br />

Trainer:<br />

Location:<br />

Classroom<br />

Duration:<br />

8 hours<br />

Equipment:<br />

Projector, Flipchart<br />

Theory<br />

Practice<br />

Basics of architectural plans and construction drawings<br />

Different structural options, characteristics and bale<br />

requirements<br />

Advantages and disadvantages of different techniques<br />

How to prepare a building schedule<br />

How to make a cutting list<br />

Calculate the building costs (material, labour, etc)<br />

Study and develop a case-study comparing the results with<br />

other trainees<br />

Unterlagen:<br />

Info Sheets:<br />

I1 Drawing basics<br />

Text Sheets:<br />

X1 Straw bale and<br />

legislation<br />

X2 Advantages and<br />

disadvantages of loadbearing<br />

X3 Characteristics of<br />

different options<br />

X4 Organisation of building<br />

site and schedule<br />

X5 Design basics<br />

Evaluation:<br />

Practical Test<br />

Organisation:<br />

Prepare a case study for every group of trainees (2–3 persons), study it in<br />

order to be able to compare it with the results of the participants.<br />

Final:<br />

Multiple Choice<br />

Oral Test<br />

7

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S1 – DESIGN – INFO 1<br />

<strong>U3</strong>-S1-I1 : Design Basics<br />

<strong>U3</strong><br />

8

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S1 – DESIGN – INFO 1<br />

<strong>U3</strong>-S1-I1 : Design Basics<br />

<strong>U3</strong><br />

9

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S1 – DESIGN – INFO 1<br />

<strong>U3</strong>-S1-I1 : Design Basics<br />

<strong>U3</strong><br />

Understanding Architectural Plans<br />

Architectural drawings are a way of<br />

representing three dimensional shapes in two<br />

dimensions. When drawn accurately and to<br />

scale they can be used for a variety of<br />

purposes; from calculating quantities of<br />

materials needed to helping workers to<br />

construct the building to the right size and<br />

shape with doors and windows in the correct<br />

positions.<br />

Plan View:<br />

The plan view is the most basic drawing and is a “top-down” view of all or part of the building. Various<br />

information is shown in plans. A floor plan is typically used to show layouts of rooms, stairs, doors and<br />

windows and can be visualized as what you’d see if you looked down after cutting through the building at<br />

about eye level (1 500 mm above finished floor level), with everything above the cut removed. Typically a<br />

separate floor plan is included for each floor in the building. Other plans may show specific parts of the<br />

building, e.g. sole plate plan, bale plans, wall plate plan.<br />

10

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S1 – DESIGN – INFO 1<br />

<strong>U3</strong>-S1-I1 : Design Basics<br />

<strong>U3</strong><br />

Elevations:<br />

Elevations are views of the front, back and sides of the building. Elevations are used to convey an impression<br />

of how the building will look from outside but are also used to show positions and dimensions of doors and<br />

windows, roof pitch and sometimes detail such as external finishes etc.<br />

Sections:<br />

Sections are used to show additional information. A section is, a bit like a plan view, a slice through the<br />

building. Sections are generally a vertical slice through the building and are typically used to show detail on<br />

the roof construction, room heights, foundations etc. A “cross-section” is a section through the shorter axis of<br />

a building, whereas a “long section” is a section along the longer axis. Sometimes several sections will be<br />

needed, especially where different parts of the building are different heights, have different roof<br />

construction/pitch etc. Large scale sections are often used to provide construction detail on specific parts of<br />

the building.<br />

Conventions and Good Practice:<br />

It is good practice to include scale bars on scaled drawings so<br />

that any distortions in scale (when printing, photocopying,<br />

converting between digital file types, etc) can be easily<br />

identified. The scale bars should be checked before measuring<br />

off drawings.<br />

Where sections are included they are normally marked on the plans<br />

and elevations with a line and arrows. The line shows where the<br />

building is “sliced”, the arrows point in the direction of view. Each<br />

section is typically allocated a letter, and this letter appears by the<br />

arrows at each end of the section line.<br />

11

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

001<br />

Advantages of the<br />

Load-Bearing Technique<br />

• Load-bearing construction uses less timber than other straw bale building<br />

methods, with straw carrying the structural loads.<br />

• Less timber means fewer thermal bridges compared to framed constructions.<br />

• Load-bearing is a very simple form of construction and for the most part uses<br />

only three basic skills: notching bales (around fixing posts for doors and windows),<br />

splitting bales and dressing bales.<br />

• The structural loading of the bales helps keeping the straw in place.<br />

Load-bearing technique with big bales:<br />

• High insulation value (U-value) of the walls (esp. with bales on edge)<br />

• Fast montage of the walls (with crane)<br />

1 2

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

002<br />

Disadvantages of the<br />

Load-Bearing Technique<br />

• Unlike framed constructions (which can support a roof that works as weather<br />

protection), load-bearing is potentially more vulnerable to weather damage,<br />

unless some form of temporary roof or cover can be built.<br />

• Pre-fabrication off-site is not possible.<br />

• Because the straw is part of the buildings structure, repairs of any damage in it<br />

are more difficult compared with repairing damaged straw in timber frame constructions.<br />

•The lack of a frame means more care must be taken when building and compressing<br />

to ensure an even, level wall height.<br />

• Compressing the bales requires higher skill levels than placing them.<br />

• Load-bearing has no general building control approval in many countries.<br />

• Potential moisture issue with dew point between straw and external render.<br />

Load-bearing technique with big bales:<br />

• Relatively large floor areas necessary for walls<br />

• Montage only with crane<br />

1 3

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

003<br />

Weather Protection in<br />

Load-Bearing Building Technique<br />

In a wet climate like that of the U.K, protection against adverse weather needs to be<br />

factored into the build. On a small build it may simply be a case of covering over the<br />

works on a daily basis with temporary protection until the roof has been built and<br />

waterproofed. However, normally this approach is far from ideal and can lead to a<br />

stressful and vulnerable build process.<br />

Alternative solutions include:<br />

• Scaffolding with protective sheeting, (including a sheeted roof on “flyover”<br />

scaffold trusses).<br />

• The permanent roof structure can be built temporarily propped to provide protection.<br />

This can be done either by building the roof at height on a temporarily<br />

propped wall plate …<br />

• … or by building the roof on the floor below, craning it to height and propping<br />

in place.<br />

1 4

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

004<br />

Alternative Solutions<br />

for Weather Protection<br />

In either case, the propped roof should be approximately 1 50mm above its intended<br />

final position to allow the insertion of the uncompressed bales. Provision should be<br />

made for lowering the propped roof to allow for bale compression (e.g. by using<br />

Acrow props).<br />

Below: Temporary propping detail with prop screwed into side of wall plate. Note the<br />

chock screwed into the side of the prop to help support the wall plate.<br />

Whichever approach is taken, secondary bale protection should also be used (e.g.<br />

covering the tops of unroofed bale walls with secured tarpaulins, roofing felt etc).<br />

1 5

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

1 6<br />

005<br />

Organization of the Building Site:<br />

Planning Process<br />

Some processes may take unexpectedly long periods of time and some materials<br />

need to be ordered well in advance of when they’re actually required on site. By<br />

working out a schedule in advance and identifying any potential “bottlenecks”, work<br />

on site is much more likely to run smoothly, minimising unexpected delays. The<br />

schedule should include the following items:<br />

Design work: This is very open-ended – time will depend on the approach. Designs<br />

can be arrived at very quickly or can be the result of years of careful consideration<br />

and gradual evolution of ideas. It is worth spending time at the design stage to get<br />

the concepts right – it’s much easier to work out ideas on paper (or the digital equivalent)<br />

rather than doing and redoing work on site.<br />

Planning permission: In some countries it will take at least eight weeks for a decision<br />

to be made even in the most straight-forward planning applications. Controversial<br />

ones may take much, much longer. Bear in mind that there is no guarantee an application<br />

will be approved. Some types of work do not require planning permission<br />

(e.g. Permitted Development), although in some cases a notification procedure must<br />

still be followed. Check with the Local Planning Authority (LPA) for clarification. In<br />

some cases, additional approvals may also be required (Conservation Area or Listed<br />

Building consents, ...).<br />

Building Regulations Approval: is usually required in addition to planning permission.<br />

Approval may take from 5–8 weeks, although sometimes site work is permitted<br />

before formal approval is issued.

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

006<br />

Organization of the Building Site:<br />

Preparatory Works<br />

Time should be allowed for works that need to take place before straw work can<br />

begin. This could involve:<br />

• site clearance<br />

• excavation to level<br />

• excavation and construction of foundations<br />

• ground floor structure, including any services beneath (waste pipes, new gas,<br />

water and electricity connections)<br />

• sole plate and upright fixing posts<br />

• temporary weather protection (propped roof or similar)<br />

• security fencing<br />

• secure storage on site (tools & equipment, straw bales etc)<br />

• access, parking, delivery, covered working area etc.<br />

17

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S1 – TIPPS<br />

<strong>U3</strong><br />

007<br />

Organization of the Building Site:<br />

Building Schedule<br />

Many natural materials are seasonal and sourcing may need to be done a long time<br />

in advance or at a particular time of year. Straw is baled in August so to have bales<br />

made a certain way and available in May, it may be necessary to talk to a local farmer<br />

the summer before. Coppicing of hazel for stubs and pins stops at the end of<br />

March, so sourcing them can be difficult if left until the summer.<br />

Even for more “mainstream” materials, there can often be a considerable delay between<br />

ordering and arrival on site. Whilst many components are often available “offthe-shelf”<br />

or at short notice (e.g. regular softwood timber sizes like 1 00x50mm for<br />

sole plates or OSB sheets), it is good practice to source more unusual components,<br />

especially those required to seal the building from the elements (to make it “wind<br />

and watertight”) and check how long they will take to arrive so they can be ordered<br />

in plenty of time. Such materials would include doors and windows, materials for<br />

the roof structure (trusses or cut roof materials), the roof covering and external<br />

render or cladding.<br />

If a lime render is to be used externally, the build should ideally be scheduled so the<br />

lime is applied early enough in the year that it has time to carbonate well before the<br />

first frosts.<br />

1 8

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

BULDING SCHEDULE<br />

<strong>U3</strong><br />

1 9

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

CUTTING LIST<br />

<strong>U3</strong><br />

20

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

ESTIMATING COSTS<br />

<strong>U3</strong><br />

21

22

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S2<br />

<strong>U3</strong><br />

LOAD-BEARING CONSTRUCTION<br />

Objectives:<br />

Trainees know…<br />

… different structural options for load-bearing construction and<br />

their characteristics and bale requirements<br />

… how to fix the bales, to stabilize the system and all the different<br />

techniques<br />

… different options for compressing the bales<br />

… details for how to connect with other building elements;<br />

foundations, corners, windows, doors, roof, etc.<br />

… how to prepare different surfaces for plastering<br />

Competences and Skills:<br />

- Building with load-bearing straw bales<br />

- Using different compression and fixing techniques<br />

- Organization and execution of the work within the schedule<br />

- Executing good connection details<br />

- Maintaining integrity of the insulation<br />

- Preparing different surfaces for plastering<br />

Methods:<br />

Theory<br />

Practice<br />

- Theory and practice of load-bearing construction<br />

Different structural options for load-bearing, their<br />

characteristics and bale requirements.<br />

Fixing the bales, and different techniques<br />

Compressing bales within different systems<br />

Details of connections: foundation, corners, windows and<br />

doors, roof, etc.<br />

Preparing different surfaces for plastering<br />

Study and develop a case-study comparing the results with<br />

other trainees.<br />

Fixing the bales, and different techniques<br />

Compressing bales within different systems<br />

Preparing different surfaces for plastering<br />

Trainer:<br />

Location:<br />

Workshop or building-site<br />

and classroom<br />

Duration:<br />

1 8 hours<br />

Equipment:<br />

Projector<br />

Straw Bales<br />

Structure of model<br />

to work on<br />

Tools<br />

Documents:<br />

Info Sheets:<br />

I1 Dressing bales<br />

I2 Details<br />

Text sheets:<br />

X1 Load-bearing<br />

(Best building practice)<br />

Presentation:<br />

Examples Load-bearing<br />

Evaluation:<br />

Practical Test<br />

Final:<br />

Multiple Choice<br />

Oral Test<br />

Organisation:<br />

Prepare load-bearing build, prepare structure to demonstrate different construction details.<br />

Order bales, prepare tools for measuring, cutting, adjusting bales, fixing, compressing.<br />

Order all the material needed for preparing for plastering.<br />

23

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S2 – INFO 1<br />

LOAD-BEARING CONSTRUCTION<br />

<strong>U3</strong><br />

24

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING SESSION S2 – INFO 1<br />

LOAD-BEARING CONSTRUCTION<br />

<strong>U3</strong><br />

25

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S2<br />

<strong>U3</strong><br />

008<br />

Preparing and<br />

Dressing Bales<br />

Left; bale to be dressed and joint between undressed bales<br />

Right; “dressed” bale and joint between dressed bales<br />

It is good practice to inspect and dress bales before use; checking the bale has been<br />

kept dry and is free from seed heads etc. Bales tend to bulge up in the middle of the<br />

end face and drop away towards the corners.<br />

“Dressing” the bale involves flattening off the ends to allow bales to meet more<br />

snugly. Straw can be slid under the strings, moving straw from the high points in the<br />

centre to the lower parts at the sides and corners.<br />

Dressing bales gives a much better junction between bales, improving thermal performance<br />

and minimizing work later (reduces need to stuff gaps etc). Dressing bales<br />

can be most easily done by a pair of people working together as shown below.<br />

The bale can be held in place by the two people pushing against it from opposite sides<br />

with one lower leg each.<br />

Both hands should be made like garden claws; palms held flat, fingers splayed<br />

slightly apart and angled down and back towards them.<br />

Both ends of the bale should be dressed before the bales are laid or worked further<br />

(e.g. split, notched etc).<br />

26

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S2<br />

<strong>U3</strong><br />

009<br />

Notching Bales<br />

Where a straw bale wall meets a post (for example at window and door openings, at<br />

junctions with other materials etc) bales will need to be notched. This improves airtightness<br />

and minimizes draughts and also helps make the wall rigid.<br />

There are two sizes of notch that may be required. Where two bales will meet at the<br />

post, one on each side, each bale should be “half-notched”: the depth of the notch in<br />

each bale should be equivalent to half the diameter of the post (for a 1 00mm / 4” post<br />

this would mean a 50mm deep notch). This typically occurs beneath a window.<br />

Beside windows and doors, the post will be entirely recessed into the straw with a<br />

“full notch” – 1 00mm deep notch for a 1 00mm / 4” post.<br />

The process is very simple. For a 50mm notch a piece of 1 00×50mm / 4×2” timber is<br />

laid across the centre of the bale where the notch is to go. An old saw is used to cut<br />

the straw using the timber as a guide. After the first few strokes to mark the cut, the<br />

timber should be removed and the saw angled slightly outwards as it will naturally<br />

tend angle inwards, resulting in a “V”-shaped cut if unchecked. Once one side of the<br />

cut is done, the wood should be replaced before removing the saw blade so the<br />

timber can again be used as a guide for a cut the other side. The depth and size of the<br />

cut should be checked using the guide timber. When the notch is the right depth and<br />

shape, the timber should sit snugly inside it with the top of the timber flush with the<br />

surface of the bale.<br />

For a full notch, the process is identical but using a 1 00×1 00m / 4×4” guide timber.<br />

Care should be taken to avoid the strings either being accidentally cut or slipping into<br />

the notch. Notching can be carried out much quicker and more accurately using<br />

machines such as alligator or shark saws.<br />

27

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S2<br />

<strong>U3</strong><br />

010<br />

Straw Bale Walls:<br />

Compressing with Trucker Straps<br />

Currently the most widely used method is to squeeze the straw using trucker straps<br />

with a ratchet fixing.<br />

These are typically passed under the sole plate, around the straw and over the wall<br />

plate, as shown in the picture. The straw can then be compressed between the two<br />

plates by tightening the straps. Straps are placed on each side of each door and<br />

window opening, at each corner and at regular intervals elsewhere. Straps are<br />

positioned so that alternate straps have their ratchets on opposite sides<br />

of the wall (the straps tend to compress more on the ratchet side of the wall so<br />

alternating helps to even out the compressive pressures).<br />

28

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S2<br />

<strong>U3</strong><br />

011<br />

Straw Bale Walls:<br />

Compressing with Car Jacks<br />

This method can only be used where there is a suitably braced, robust<br />

surface to set the jacks against. The most common use is to compress bales under or<br />

above a window. A temporary 1 00x1 00mm beam can be securely fixed between the<br />

upright fixing posts as a jacking point. A permanent 1 00x1 00mm beam can be<br />

rebated into the top of the highest bale below the window (or the soffit of the lowest<br />

bale above) and pushed using the jacks to compress the straw. When fully<br />

compressed the permanent beam is fixed into place and the temporary one<br />

removed.<br />

29

30

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

SESSION S3<br />

<strong>U3</strong><br />

TOOLS FOR LOAD-BEARING STRAW BALE BUILDING<br />

Objectives:<br />

Trainees know …<br />

… the tools and machines used on the straw bale building site<br />

… specific problems of straw bale building site organization<br />

… how to solve any technical problem conveniently<br />

Competences and Skills:<br />

- To handle tools and machines which are used in load bearing<br />

straw bale construction<br />

Methods:<br />

Demonstration<br />

explanation<br />

practice<br />

Trainer:<br />

Location:<br />

Workshop or building-site<br />

Duration:<br />

4 hours<br />

Equipment:<br />

Tools<br />

Theory<br />

Specific problems of straw bale building site organization<br />

Unterlagen:<br />

Info Sheet:<br />

I1 Tools<br />

Text Sheet:<br />

X1 Building Site<br />

Evaluation:<br />

Practical Test<br />

Practice<br />

Handling the tools, visiting building site<br />

Final:<br />

Multiple Choice<br />

Oral Test<br />

Organisation:<br />

Looking for an appropriate building-site in the surroundings or preparing different tools and material for<br />

the demonstration<br />

31

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S3<br />

<strong>U3</strong><br />

TOOLS FOR LOAD-BEARING STRAW BALE BUILDING<br />

01 2<br />

Splitting Straw Bales<br />

with Bale Needles<br />

Bale needles may be useful or even indispensable for load-bearing straw bale walls<br />

(in this case each new row of bales needs half-bales). In the infill-technique, the bales<br />

are compressed more easily with adding flakes between two plates. Bales can<br />

also be compressed to a certain density by simply rebinding it with strings,<br />

depending on the strength you tear, or with screw clamps. But as bale needles are<br />

connected to straw bale building like the halms to the bale, let's look at these tools.<br />

Actually a pointed wooden stick with two holes at the top is enough for their<br />

function (since there are two new cords needed –- one for the right, one for the left<br />

bale part). There are also combined bale needles (which are connected to a<br />

bar/handle, which pull all four cords through the bale at the same time (two upper<br />

and two lower – instead of the two existing cords). After you pulled your strings<br />

through the bale, the cords are knotted to each half-bale. There are special knots, as<br />

they are known from sailing. After you rebound your halfs, the original two cords are<br />

removed, thereby maintaining the density of the bale. If you took the right strings on<br />

the right half bale you can divide your bale (otherwise, if strings are crossed, you<br />

have two connected half-bales). So you can definitely say that some straw balers<br />

make a science out of a simple thing.<br />

32

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S3<br />

<strong>U3</strong><br />

TOOLS FOR LOAD-BEARING STRAW BALE BUILDING<br />

01 3<br />

Straw Bale Tools: Shaving<br />

Surfaces with Hedge Saws<br />

We do not only want to squeeze a few protruding stalks with hedge saws, in most<br />

cases we want a plane surface to save plaster and to avoid different drying times,<br />

even if bales are slightly differently thick or bulged or not exactly installed plane.<br />

Even if there are customers who prefer a more organic-hunched surface, in most<br />

cases they mean slight bumps in the (hand-)plaster and not simply covering uneven<br />

bales with the plaster. The cutting of the hunches of straw bales is a long-term work,<br />

but it really becomes hard work with not really sharp hedge saws. Unfortunately<br />

sharpening is often as expensive as a new one. A tip to save energy is to pick hedge<br />

saws with a rather shorter sword (about 50–60 cm). The longer the sword, the more<br />

pressure we need to push to the bale surface, and the harder it is to shave a round<br />

wall or vault inside. In terms of strength: from 450 W, hedge trimmers are robust and<br />

strong enough. The sharpness of the knives is much more important. Hedge saws<br />

are among the very safe machines (since they cut only between the knives).<br />

Nevertheless, you can tweak neatly with hedge saws (a small cut with painful<br />

bruising is the result). It can happen when you sit on the scaffolding shaving the<br />

walls. More often, if you don't take care, you will cut the cable and cause a short<br />

circuit. Therefore, it is best to carry the cable over the shoulder. Or choose a model<br />

with battery.<br />

33

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S3<br />

<strong>U3</strong><br />

TOOLS FOR LOAD-BEARING STRAW BALE BUILDING<br />

01 4<br />

Straw Bale Tools: the Straw Bale<br />

Hammer or Persuader<br />

This wooden hammer "persuades" each bale (at least as long as it is not fixed with<br />

battens). It is a must on each straw building site and also easy to manufacture with<br />

leftover construction wood. Only the handle should be sturdy (typically hardwood).<br />

Do not screw the handle to the wooden plates too often (twice should be enough),<br />

otherwise it will break more easily at this point. The persuader should be heavy, but<br />

it is used with a swing to move the bales back into the row, or to connect the upper<br />

bale with the underlying ones well.<br />

34

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

TIPPS S3<br />

<strong>U3</strong><br />

TOOLS FOR LOAD-BEARING STRAW BALE BUILDING<br />

01 5<br />

Straw Bale Tools:<br />

Gap Filler in Two Sizes<br />

No one can fill straw bales between posts/rafters (or stack them over one another in<br />

the load-bearing straw bale building) without leaving any holes at all. This is due to<br />

the fact that bales are often rounded at the edges rather than square; on the other<br />

hand, cavities can also develop when filling (densifying) with layers. And finally it<br />

happens again and again that, for structural reasons, there is a (diagonal) squared or<br />

round wood in the insulation area, such as the planks of an intermediate ceiling. In<br />

order to fill these cavities with (loose) straw and prevent convection in the<br />

insulation layer as well as thermal bridges, we use selfmade, simple stuffing tools.<br />

Of course, you can also stuff with your hands (fingers), but I wouldn’t recommend<br />

that for larger areas. After some days you cannot move your fingers any more.<br />

Especially if the wall is to be plastered, it is important to stuff the straw in the same<br />

density as the bales nearby, so that the weight of the plaster does not pull it out<br />

again.<br />

For these purpose we need two gap fillers or "stuff sticks", made of strips of 25×25<br />

mm (1 ×1 ") for the small and 25×50 mm for the large one. So we are building a "T",<br />

which we screw together once or twice (6–8 cm screw, 5–6 mm hole pre-drill). The<br />

smaller handle has a length of 1 5 cm, the larger handle has a length of 25–30 cm,<br />

which we bevel at the top like a screwdriver (with a jigsaw or crosscut saw). Finally,<br />

we put a small notch in the middle of the "cutting edge", so that the straw to be<br />

stuffed is bundled together more effectively. Finally we take sandpaper (or a rasp)<br />

and round off all edges a little bit.<br />

35

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 2<br />

Cords and Knots<br />

<strong>U3</strong><br />

36

37

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 3<br />

STRUCTURAL BEHAVIOUR<br />

<strong>U3</strong><br />

Virko Kade:<br />

Structural Behaviour<br />

Like any other building material, straw bales react in a very specific way to forces<br />

working in on single bales or on the whole building. Settlement is as much an issue<br />

as is known from traditional wood construction. The ductility of the straw bale<br />

results in (besides good thermal and acoustic insulation) an extremely good<br />

performance withstanding earth quakes. Tests conducted in the USA showed no<br />

failure even exposed to earth quakes of the highest level!<br />

Performing our own tests, we put a weight of 35 KN (3.5 metric tons) on a small<br />

bale, which did not destroy it. Only seconds after it was almost back to it’s original<br />

size, and after five minutes it was exactly like before the test.<br />

What loads can a straw bale wall bear without collapsing?<br />

The structural engineer Bruce King, who was part of the development of the straw<br />

bale building regulations in the USA, recommends not more than 500 kg per meter<br />

of straw bale wall as upper limit and calculation base. According to the building laws<br />

in the States however, the walls are supposed to bear the loads without being<br />

plastered. We put several tons per meter on a plastered sample straw bale wall<br />

without facing structural failure. Only the wall plate was forced between the two<br />

plastered surfaces. Massive snow loads on some of “my” buildings amounted to an<br />

actual load of 1.000 kg per meter wall and more without causing any cracks in the<br />

plaster. We can learn from this, that a heavy roof truss with roof tiles doesn’t work, at<br />

least with small bales. It makes sense to construct a roof as light as possible and<br />

reinforce it with a structural partition wall as “snow insurance”. Furthermore using<br />

small bales one-storey buildings are advisable, at least with the usual Alpine snow<br />

loads in mind. The Swiss architect Werner Schmidt proved that with big bales even<br />

3.5 storeys and substantially higher snow loads can work (see appendix Statics<br />

House Fliri p. 80).<br />

38<br />

What height of a straw bale wall is legally possible?<br />

In countries with specific straw bale building regulations the condition is being<br />

upheld, that the ratio of height and width of the wall should be < 6:1. This means a<br />

maximum of eight small bales on top of each other. The actual height of the room<br />

can be varied to some extent by adjusting the height of the wooden construction at<br />

the base and of the ring beam. This very regulations recommend for small bale<br />

constructions, to keep the length of a straight wall without bracing (e.g. with<br />

partitions) below six metres. A realistic limit according to my personal experiences!

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 3<br />

STRUCTURAL BEHAVIOUR<br />

<strong>U3</strong><br />

39

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 3<br />

STRUCTURAL BEHAVIOUR<br />

<strong>U3</strong><br />

40

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 3<br />

STRUCTURAL BEHAVIOUR<br />

<strong>U3</strong><br />

41

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 4<br />

COMPRESSING & SETTLEMENT<br />

<strong>U3</strong><br />

Virko Kade:<br />

Compressing and Settlement<br />

In load-bearing straw bale building, the bales are usually installed “lying flat”.<br />

Because the orientation of the straw is more or less uniform thanks to the pressing<br />

process, the stems are lying on the floor or parallel to it, respectively.<br />

In principle, thus the settlement can be bigger compared to an upright installment of<br />

the bales (which is common in certain timber frame constructions), but “standing”<br />

bales are running the risk of snapping under pressure, which would lead to the wall<br />

collapsing. If the bale/stem orientation is lying flat, the stalks are pressed into one<br />

another and wedged tight. The higher the pressure, the better the stability. Soon a<br />

single bale as part of a wall construction can no longer be moved or put into a better<br />

position. Corrections should therefore be done before the compression with straps.<br />

Generally speaking, straw bales should already be compressed as much as possible<br />

during the “brick”-laying; e.g. you could chose the heaviest person at site and let<br />

him walk on the wall crest every two or three layers.<br />

Nevertheless: Be careful when fitting bales in openings that are actually too small! A<br />

bale that is too long and is nonetheless forced into place with all strength moves<br />

other bales to the side, the corners are bulging outwards, the point load on window<br />

frames can get very high and so forth.<br />

When using small bales, the wall height is already below the theoretical measure of<br />

36 cm × 8 bales only by compressing it with a persons weight. Ideally the compression<br />

should be done mostly with straps and ratchets rather than by the weight of the<br />

roof truss. Therefore the strap-compressing should be exhausted before mounting<br />

the roof truss. The amount of settlement is the result of so many variables, that it<br />

can hardly be calculated.<br />

With small bales, the difference between the actual and the theoretical measurements<br />

can be between 5 and 7 %, with jumbo bales it’s 0 to 0.5 %. The compressing<br />

of big bales yields almost no measurable results, it’s importance lies in the enabling<br />

of an even settlement. Furthermore the resistance of the bales towards roof loads is<br />

increased. And: The straps which remain below the plaster are the only statically<br />

effective bracing against wind load.<br />

42

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 4<br />

COMPRESSING & SETTLEMENT<br />

<strong>U3</strong><br />

43

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 5<br />

BUILDING LAW (IN AUSTRIA)<br />

<strong>U3</strong><br />

Virko Kade:<br />

Building Law: Legislation<br />

in Austria<br />

44<br />

The straw bale building regulations differ very much from country to country. Many<br />

countries don’t have any specific regulation at all, others only recommendations.<br />

The most precise laws are to be found in the USA, which comes with advantages<br />

and disadvantages. E.g. the so-called chicken wire has to be used flat-spread, which<br />

can cause problems in wet climates, not to speak of electromagnetic radiation etc.<br />

On the plus side the regulations provide some sort of planning security, especially<br />

with regard to load-bearing constructions. Consequently the majority of straw bale<br />

buildings in the USA are load-bearing in the making, like in several other countries,<br />

btw.<br />

In Austria there is no general building control approval including a structural<br />

calculation. The certified bales are only approved with regard to insulation<br />

properties, fire resistance and humidity. When using them for insulation purposes<br />

only, it is usually no problem to get a building approval, even insurance companies<br />

nowadays have listed straw bales as building material.<br />

If you’d like to build with structurally loaded straw bales, however, an individual<br />

authorization is required. That means, that the building control can simply give its<br />

approval “one house at a time”, ideally without the need of any further proof. It helps<br />

the cause to refer to existing buildings as well as to the ecological advantages and<br />

the high level of innovation of this building technique. Written documentation<br />

(books, brochures), that shows how far the professionalization of straw bale building<br />

has come in Europe, can also help the authorities to rethink. But it is still possible<br />

that one has to provide a structural report. In this case it’s usually of little help to<br />

quote the building laws and structural surveys of other countries; you’ll have to<br />

deliver. Which can be quite time- and money-consuming, if you find a structural<br />

engineer at all.<br />

In the past it was often enough to convince the construction site management<br />

(master builder, carpenter) to incur liability for this construction method to satisfy<br />

the building control as well. Extensive structural tests aiming for a general building<br />

control approval according to the Austrian norms would unfortunately be very<br />

expensive and require a huge effort – too big a price considering the public and<br />

trade interest, which is not overwhelmingly high.

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 6<br />

<strong>U3</strong><br />

DESIGN<br />

Characteristics of Planning SBBs<br />

Each planning should take into account the specifics of the wall constructions (with<br />

regard to materials used and special features). This is particularly true in straw bale<br />

building, since the building material is not familiar to many planners and yet it<br />

requires a different way of thinking. First, of course, we should consider the bale<br />

dimensions – which are not precise and not following any industrial standard. A small<br />

bale has a fairly exact width (between 45 and 50 cm, according to the baler); the<br />

height may also vary according to the baler, but the most regular size is 36 cm.<br />

But: The bales become smaller by compression, so this height vanishes after the<br />

second or third layer. How much settlement you actually have in the end is not exactly<br />

calculable, so always calculate a bigger settlement to prevent the top beam from<br />

touching or resting on the window sill and endangering the entire statics. Stiff<br />

components such as intermediate walls or additional supports should be installed at a<br />

fixed height when the setting has been completed. Before that, work with scaffolding,<br />

e.g. threaded rods. Window sockets are designed ideally 20–30cm below the top beam<br />

and infilled later. For smaller windows that are walled in, calculate the total height of<br />

the window frame a few centimeters smaller than the theoretical bale dimension.<br />

The length has the greatest variance in straw bales. It can be set as desired in the<br />

baler, but still depends on the swath (width and stroke length of the tracks in the<br />

field) and the driving method. Even well-made small balls can have a variance on<br />

average of up to 1 0 cm or more. For a load-bearing building I calculate with a length<br />

of 1 00cm (which is regular for proper-density-bale dealers). That said: the length of<br />

small bales is not that big an issue, many of them have to be resized anyway, which<br />

can easily be done. In the case of big bales, however, it can take 20–30 min per piece<br />

(assuming crane/forklift is available).<br />

Theoretically, the length of most jumbo bales is 240cm. Although big bales are far<br />

more precise than small ones, some are still longer than others, gaps between bales<br />

occur … suddenly the wall is 20cm longer! Therefore I calculate in the planning with<br />

245cm length. Filling a gap later is definitely the least effort. Every second row,<br />

however, we still need half-bales to build properly bonded. At best you order the<br />

half-bales from the straw merchant before harvesting (some more than you need). I<br />

order with my desired length minus 5–1 0cm.<br />

In order to be able to work exactly and to facilitate window installation and plaster<br />

connections, all wooden components of the wall should be planned level with the<br />

straw surface, so both can be plastered in one layer.<br />

We should definitely focus on the following points regarding the statics:<br />

• no point loads on the top beam<br />

• avoid thrust forces on the wall crown (ring beam / top beam)<br />

• do not put loads on a blunt end wall, always arrange wooden posts here<br />

• use only the same bales for a building, preferably from the same harvest<br />

• enough additional bracing by intermediate walls (snow loads)<br />

• bearing walls (usually two): as few and as small windows as possible<br />

• max. wall length without bracing (for small bales with 50cm width): 6 metres<br />

• roof loads should be as small as possible (small bales)<br />

45

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 7<br />

BUILDING PHYSICS<br />

<strong>U3</strong><br />

Virko Kade:<br />

Remarks on Building Physics<br />

In central and northern Europe we should take into account a number of points that<br />

are less important in other parts of the world:<br />

• avoid metal parts in the straw, especially in the outer third (threaded rods, etc.)<br />

• avoid thermal bridges to ensure good insulation; furthermore, thermal bridges<br />

increase the effect of weak points<br />

• never place bales directly on concrete, always use a thermal separation<br />

• place the first row of bales always on wooden base plates (at least 5cm) in order<br />

to avoid water damage<br />

• do not use plasters which contain cement on the outside, only pure lime<br />

plasters; use clay plaster inside<br />

• interior constructive changeovers with straw walls such as partition walls,<br />

ceilings, etc. should always be sealed well, for example with plaster or clay fleece<br />

or similar<br />

• first bale layer should be above the splash water area (> 30cm)<br />

46

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING INFO 8<br />

QUESTIONS ABOUT DETAILS<br />

<strong>U3</strong><br />

Virko Kade:<br />

Questions about Details<br />

Wall bushings (pipes, cables, etc.)<br />

• Electricity and water (interior)<br />

• Chimney<br />

• Plaster preparations<br />

• Weather<br />

• Scheduling<br />

• Costs<br />

47

48

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

STRUCTURAL CALCULATION<br />

<strong>U3</strong><br />

Peter Braun / House by Arch. Werner Schmidt<br />

Load Bearing Straw Bale Building:<br />

About the Static Properties of Straw Bales<br />

Load Distribution<br />

The central bearer concentrates the load.<br />

49

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

STRUCTURAL CALCULATION<br />

<strong>U3</strong><br />

Peter Braun / House by Arch. Werner Schmidt<br />

Model: Office building of the city of Lausanne, architects collective carpe<br />

50

<strong>U3</strong> – LOAD-BEARING STRAW BALE BUILDING<br />

STRUCTURAL CALCULATION<br />

<strong>U3</strong><br />

Peter Braun / House by Arch. Werner Schmidt<br />

Deformation<br />

51

<strong>STEP</strong> – Straw Bale Training for European Professionals<br />

UNIT 3 – Load-bearing Straw Bale Construction (201 7)<br />

Editors/Tips: Herbert Gruber, Helmuth Santler (ASBN)<br />

Virko Kade, Michael Howlett; Coworks: BuildStrawPro-<br />

Team (Erasmus+ Projekt)<br />

Design & Photos: Herbert Gruber; Virko Kade, Werner<br />

Schmidt; more Photos: Werner Schmidt, provided by<br />

Architects. Illustrations/Icons: Michael Howlett (SBUK)<br />

This Handbook is based on<br />

the Handbook by Leonardo-<br />

Group <strong>STEP</strong> (201 5)<br />

52