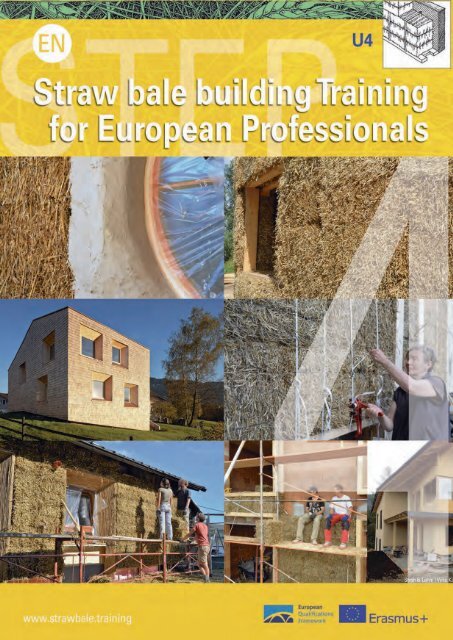

STEP U4 Handbook 2019 ENGLISH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1

2

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INDEX<br />

<strong>U4</strong><br />

TIME<br />

PAGE<br />

<strong>U4</strong> Learning Outcome 5<br />

<strong>U4</strong> Session 1 : Design and Planning ca. 6 hrs. 7<br />

Info: Thermal Insulation Composite Systems in Relation 8<br />

Info: Design and Planning: Details (Foundation/Windows) 1 2<br />

Tips: Planning-Checklist Wrapping 1 4<br />

001 -1 4 Hybrid Foundation, 002-1 5 Perimeter-Insulation, 003-1 6 Drainage,<br />

004-1 7 Roof Overhang, 005-1 8 Windows and Doors, 006-1 9 Scaffolding<br />

<strong>U4</strong> S2: Constructions 2 days 21<br />

Info: Wrapping-Konstruktionssysteme 22<br />

Tipps: Konstruktionssysteme 24<br />

007-24 CUT centered, 008-25 CUT outside, 009-26 Binding Bales to the Wall,<br />

01 0-27 Spanning Bales down, 011 -28 Spanning Bales to the Wall, 01 2-29 Pallette-<br />

Hybrid-Constructions, 01 3-30 Cage for Bale Layers, 01 4-31 Drop Nose, 01 5-32 Direct<br />

Plaster, 01 6-34 Cladding, 01 7-35 Glass Facade<br />

<strong>U4</strong> S3: Prefab-Constructions 1 day 37<br />

Info &Tipps: Wrapping-Prefab-Systems 38<br />

01 8-38 system/haus/bau / ASBN, 01 9-39 Jules Ferry Residence / Bet Gaujard,<br />

020-41 Complemedis / Werner Schmidt, 021 -42 Straw/Reed-Facade by Kengo Kuma<br />

Ass., 022-42 Waseda University Students: A-Recipe-To-Live-Straw-House,<br />

023-43 Enterprise Centre of University East Anglia: Prefab Straw-Reed-Facade,<br />

024-43 Schelfbauhütte: Montage System for Straw Bale-Wrapping,<br />

025-44 School Montreuil and Issy les Moulineux: Exterior Modular Straw Bale<br />

Facade, 027-45 Make your City Smart! / Paul Schulz, TU Vienna, 027-46 Calculation<br />

Building Costs<br />

<strong>U4</strong> S4: Alternatives to Straw Bales ca. 2 hrs. 49<br />

Info &Tipps: Natural NAWARO-Alternatives 49<br />

023-47 Inject Straw Fibres, 024-48 Straw Mats, 025-49 Reed Mats<br />

Credits and Impress 52<br />

3

4

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

LEARNING OUTCOMES<br />

<strong>U4</strong><br />

Level 3 (ECVET credit points: 1 5) / Level 4 (12)<br />

Knowledge<br />

Skills<br />

Trainees know …<br />

• about the existing national building<br />

regulations related to straw bale building.<br />

• the specific problems organizing a wrapping<br />

straw bale building site and their solutions<br />

(weather protection, safety, logistics).<br />

• the symbols to be able to understand plans<br />

and construction drawings.<br />

• new and historical wall-constructions and<br />

their impact on wrapping (horizontal moisture<br />

barrier, position ofwindows, consistence of<br />

plaster, roofoverhang).<br />

• the different methods and techniques of<br />

wrapping, their requirements, advantages and<br />

disadvantages.<br />

• the necessity and the techniques to avoid and<br />

to close gaps (between bales and between<br />

bales and construction).<br />

• other bio-sourced insulation materials, that<br />

can be used additionally in straw bale<br />

building.<br />

• different fixings and their characteristic and<br />

the suitable methods of compressing.<br />

• different wrapping techniques and their<br />

requirements related to schedule, planning,<br />

budget and resources.<br />

• about techniques and construction details for<br />

the adjacent building elements (ceiling, walls,<br />

floor- and roofplates) avoiding cold bridges.<br />

• techniques to manufacture the additive base<br />

plate for straw isolation avoiding cold bridges.<br />

• the reasons and the techniques to prepare the<br />

substrate with a plane and gap free surface.<br />

Trainees can …<br />

• control the quality ofexisting constructions in<br />

relation to its suitability for wrapping straw<br />

constructions.<br />

• handle the tools and machines which are used<br />

in wrapping construction.<br />

• apply different wrapping and retrofitting<br />

methods professionally.<br />

• resize and fix the bales and kompress them if<br />

needed.<br />

• fix the bales on an existing wall and fill gaps<br />

with straw or another suitable sustainable<br />

insulation material in order to produce a<br />

continuous layer of insulation avoiding cold<br />

bridges.<br />

• make a lasting connection between the<br />

wrapping and the existing construction.<br />

• read and understand the symbols of plans<br />

and construction drawings.<br />

• make supportive wooden structures and<br />

posts and lintels for the openings.<br />

• give advice to others, who make the plinth<br />

wall and other requested details.<br />

• prepare the substrate for following crafts<br />

(plaster, cladding, air- and wind tightness) or<br />

execute it in accordance with them (level and<br />

shave the straw surface, fix the plaster ground<br />

on wooden construction elements).<br />

Competence<br />

Trainees can …<br />

• organize and attend the building site at all stages and adapt the working process, the use oftools and<br />

adequate techniques related to straw bale wrapping (planning, preparation, execution, additional crafts).<br />

• coordinate and communicate the special needs of wrapping constructions with other professionals.<br />

• explain different methods ofwrapping with straw with reference to advantages and disadvantages.<br />

• select good quality bales for wrapping and supervise the whole wrapping process during the<br />

construction period.<br />

5

6

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

SESSION PLAN S1<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning<br />

Objectives:<br />

Trainer:<br />

Trainees ...<br />

… have the ability to read and understand architectural plans and<br />

construction drawings.<br />

… know different structural options.<br />

… know the advantages and disadvantages of every solution.<br />

Skills:<br />

Make a building schedule<br />

Organize and finish the work according to schedule<br />

Make a cutting list<br />

Calculate the building costs<br />

Methods:<br />

Theory<br />

Practice<br />

Lecture/talk<br />

Explanations<br />

Practice<br />

Organization:<br />

Basics of architectural plans and construction drawings<br />

Different structural options, characteristics and bale<br />

requirements<br />

Advantages and disadvantages of different techniques<br />

How to prepare a building schedule<br />

How to make a cutting list<br />

Calculation of building costs (material, labour etc.)<br />

Study and develop a case-study comparing the results with<br />

other trainees.<br />

Prepare a case study for every group of trainees (2–3 persons), study it<br />

in order to be able to compare it with the results of the participants.<br />

Place:<br />

Classroom<br />

Duration:<br />

3 days<br />

Equipment:<br />

Beamer<br />

Flip chart<br />

Documents:<br />

Info sheets:<br />

I1 Drawing basics<br />

I2 Characteristics of<br />

different options<br />

I3 Drawings of pros and<br />

cons<br />

Text sheets:<br />

X1 Drawing basics<br />

X2 Characteristics of the<br />

different options<br />

X3 Organization of building<br />

site and schedule<br />

Exercise sheets:<br />

E1 Make a building schedule<br />

E2 Cutting list<br />

E3 Calculating material and<br />

costs<br />

E4 Drawing construction<br />

details<br />

Evaluation:<br />

Multiple choice<br />

7

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION) INFO 1<br />

<strong>U4</strong>-S1-I1 : Thermal Insulation Composite System<br />

<strong>U4</strong><br />

U-Wert: 0,1 32 W/m 2 K<br />

PEI n.e.: >1 9 kWh/m²<br />

U-Wert: 0,1 28 W/m 2 K<br />

PEI n.e.: >23 kWh/m²<br />

U-Wert: 0,1 78 W/m 2 K<br />

PEI n.e.: >1 3 kWh/m²<br />

U-Wert: 0,1 73 W/m 2 K<br />

PEI n.e.: >1 3 kWh/m²<br />

U-Wert: 0,1 74 W/m 2 K<br />

PEI n.e.: >1 33 kWh/m²<br />

Straw Bales with Direct Limeplaster<br />

Bale density ca. 1 00 kg, complete 38,5 cm thick<br />

Surface: shaving, stuffing, plastering<br />

Wrapping-System: Material Price/m2 (AT)<br />

Straw Bales: around € 1 0,00 - 1 7,40/m2 (cert.)<br />

Constr. with/out window box: € 1 3,05 - 36,50/m2<br />

Lime plaster 2,5 cm, mesh, Rabolin: € 1 0,00/m2<br />

Material-Price complete: € 33,05 - 63,90/m2<br />

Straw Bales with ventilated Cladding<br />

Bale density ca. 90 kg, complete 45 cm thick<br />

Wrapping-System: Material Price/m2 (AT)<br />

Straw Bales: around € 1 0,00 - 1 7,40/m2 (cert.)<br />

Constr. with/out window box: € 1 3,05 - 36,50/m2<br />

diffusion open facadeboard (DWD): € 8,46/m2<br />

Batten, Counterbatten, Cladding: € 40,00/m2<br />

Material-Price complete: € 71,51 - 102,36/m2<br />

Naporo Hempmat + Capatect Facade<br />

20 cm Hemp Board/Mat, complete 21 cm<br />

Wrapping-System: Material Price/m2 (AT)<br />

Hempmat (Naporo): 24,91 - 41 ,52/m2<br />

Screw dowel, filler, plaster base, fibre glass<br />

mesh, CarboPorPlaster: € 24,80/m2<br />

+/-Windowbox with Insulation: € 23,45/m2<br />

Material-Price complete: € 50,00 - 89,77/m2<br />

Mini-StrawBales, Woodfibreb., Lime-Directplaster<br />

26 cm Straw, 4 cm SteicoProtect, compl. 32,5 cm<br />

Wrapping-System: Material Price/m2 (AT)<br />

Straw Bales: around € 8,00 - 11 ,20/m2 (cert.)<br />

Constr. with/out window box: € 1 3,05 - 36,50/m2<br />

diffusion open facadeboard: € 1 3,1 8/m2<br />

Lime plaster 2,5 cm, mesh: € 8,70/m2<br />

Material-Price complete: € 43,00 - 69,58/m2<br />

to compare: Baumit WDVS EPS-F<br />

1 8 cm EPS-F, complete ca. 20 cm<br />

Wrapping-System: Material Price/m2 (AT)<br />

EPS-F (Polystyrol-Insulation): 22,60/m2<br />

Adhesive filler, fibre glass mesh, primer,<br />

Silikat Top: € 1 7,09/m2<br />

+/-Windowbox with Insulation: € 23,45/m2<br />

Material-Price complete: € 40,00 - 63,14/m2<br />

8<br />

Prices: baustrohballen.at/sonnenklee.at/frischeis.at/haeuser-in-wolle.com/bauschilf.at/hagebau.at

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION) INFO 1<br />

<strong>U4</strong>-S1-I1 : Thermal Insulation Composite System<br />

<strong>U4</strong><br />

Source: u-wert.net, infos without warranty<br />

9

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION) INFO 1<br />

<strong>U4</strong>-S1-I1 : Thermal Insulation Composite Systems in Relation<br />

<strong>U4</strong><br />

10

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION) INFO 1<br />

<strong>U4</strong>-S1-I1 : Thermal Insulation Composite Systems in Relation<br />

<strong>U4</strong><br />

11

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO 2<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning<br />

1 2

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO 2<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning<br />

1 3

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

Task:<br />

Calculate PEI<br />

of this foundation<br />

per m<br />

1 4<br />

001<br />

Insulated Hybrid Foundation:<br />

Concrete or not Concrete?<br />

In order not to have to build with organic, moisture-sensitive materials in the splash<br />

area, we have to somehow overcome the 30 cm - with a base or auxiliary<br />

foundation. In general, this is made of concrete, although we don't have much loads<br />

except a plastered straw ball wall. What actually speaks against concrete? Concrete<br />

is an artificial mixture of cement, sand or gravel and water. Usually. further additives<br />

are used. The required energy expenditure for the production of concrete depends<br />

essentially on the composition of the concrete. The component with the highest<br />

energy content is the cement. Furthermore, a distinction is made between reinforced<br />

and unreinforced concrete. The reinforcement degree has a significant influence on<br />

the production energy PEC (transport concrete C20 / 25: PEI: 31 5 kWh / m3, λ = 2.0 W<br />

/ mK, concrete blocks: PEI: 379 kWh / m3, λ = 1 ,35W / mK).<br />

Advantages Concrete: High compressive strength, good sound insulation, good fire<br />

protection, good moisture protection, high thermal mass, any shape<br />

Disadvantages Concrete: poor thermal insulation, aging process, "composite<br />

building material".<br />

Thermoblock-Bricks have an even higher primary energy content (perlite filled)<br />

Brick S, Poroton: PEI: 484 kWh / m3, λ = 0.09-0.11 W / m.K)<br />

One possibility is to reduce the proportion of concrete as much as possible and to<br />

use mineralic, insulating building materials instead. However, their properties are<br />

also very different: perlite (PEI: 1 87 kWh / m3, λ = 0.06 W / mK), foam glass (PEI: 224<br />

kWh / m3, λ = 0.07 W / mK), Leca (PEI: 850 kWh / m3, λ = 0.035 W / mK) as well as<br />

XPS have a higher primary energy content than concrete (PEI: 548 kWh / m3, λ = 0.1 6<br />

W / mK) ) Solution: 1 5 cm concrete blocks with perlite or foam glass. Thus, the<br />

primary energy content remains justifiable.<br />

Source ofallValues for PEC und λ:TU Munich

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

002<br />

Foamglass-gravel and Cork<br />

Perim.insulation instead of XPS<br />

Are there any ways to prevent concrete and XPS in the wrapping foundation and<br />

perimeter insulation? The starting price for comparison is: € 9.74 / m.<br />

If we take a single-storey building (3 m high), we have a static load of straw bales<br />

(1 00 kg / m3 = 1 08 kg / and lime plaster (1 400 kg / m3 = 1 05 kg), thus total of 227 kg /<br />

m foundation. This is comparatively little load. Furthermore, these wrapping loads<br />

are not carried completely by the foundation, but partly by the wall and the roof<br />

rafter (suspended construction). And the 6 cm foot threshold distributes the unequal<br />

loads.<br />

Now we know that foam glass e.g. is suitable as a capillary, heat-insulating and loadbearing<br />

layer under ground level. 30-40 cm foam glass gravel around the house are<br />

enough (price at 50 cm depth € 11 ,70 - 1 5,70 / m). In order to overcome the 30 cm<br />

above ground level, Mirapor proposes so-called wall bags. Foam glass could also be<br />

filled into gabions (30 x 30 x 30 cm: € 8.95) or as in the case of the Earthbags<br />

(Calearth), filled into PP sandbags (€ 0,83, 4 rows of á 40 x 60 cm = € 6.46 / mm).<br />

Another alternative is cork as perimeter insulation. Cork should not be placed<br />

directly on the damp ground, but it can bridge the 30 cm on top of foam-glass gravel<br />

(price at 1 0 cm thickness and 30 cm height: 1 2,53 / m). A lime-cement plaster with<br />

glass fiber mesh ensures that this auxiliary foundation does not settle. But: without<br />

guarantee!<br />

1 5

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

1 6<br />

003<br />

Advantages and Disadvantages<br />

of Drains in Restoration<br />

In the restoration and clearing of old building cellars no drainages are generally<br />

found. This has its good reason in building the floors of these basements. In many of<br />

the cellars, for example, only a loose brick is laid in the Wilhelminian era, which does<br />

not have any kind of sealing against the ground. If foundations are built, they are<br />

usually water-permeable and in no way waterproof concrete. On the outside, the<br />

floor materials were again installed in a slightly compressed manner, so that at the<br />

base of the walls only capillary moisture - ie soil moisture, which could not be<br />

removed by drainage - is present. If the soil situation remains the same, the<br />

installation of a drainage tube would be completely ineffective, since a drainage pipe<br />

only drains water in liquid form.<br />

The installation of a drainage system with leachable granules, drainage plates and<br />

drainage pipes on the exterior walls and foundations would considerably impair<br />

these cellar constructions. Water would permanently flew into the open-pore and<br />

leachable drainage package next to the basement, which would lead to continuous<br />

water input and damage on walls and foundations. In particular, the soil moisture<br />

present to date under the basement floor would convert to a moisture saturation of<br />

the soil, which could not be relieved by a functional drainage at the exterior side of<br />

the walls.<br />

Respecting this, drains in old buildings are not purposeful and usually senseless,<br />

especially since a drainage in water-bearing soil layers would only bring about a<br />

reduction in the water amount. (Source: trockenlegung-hannover.de/drainagen)

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

004<br />

Is there enough Roof-Overhang<br />

lateral and on gable-side?<br />

Roof overhang lateral: the distance from the façade to the respective eaves (drip<br />

edge); Roof overhang at the gable-side (Ortgang) beyond the façade.<br />

While the extension of the lateral roof overhang is relatively simple, static<br />

calculations are mandatory when the roof overhang on the gable-side is extended.<br />

The administrative background has also to be added to the effort. When you renew<br />

the roof overhang at the gable side, you will have to obtain a building permit. In<br />

addition, building laws define a minimum distance to adjacent areas and also to the<br />

road. Finally, in many cases the neighbors will also have to confirm their agreement<br />

in writing.<br />

This also means that you need a structural engineer or architect who can design and<br />

sign the appropriate blueprints before submitting them to the building authorities<br />

for approval.<br />

Please check, before you cover an outer insulation, the roof overhang on all sides,<br />

for the wrapping with straw you need in the minimum case 36 to 40 cm on all sides.<br />

If this space is not available, it is advisable to think about thinner thermal insulation<br />

layers (for example with 26 cm minibales, flakes or other insulation) (see page 8 or<br />

tip 01 3). Or you extend the roof unconventionally: with a short extra roof under the<br />

main roof above the wrapped straw bale wall. This could be covered for example<br />

with a metal sheet (roofer / plumber, see picture on the upper right).<br />

17

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

005<br />

Solid Boxes carry the (new)<br />

Windows and Doors:<br />

If windows are left in the existing wall (e.g. because they still correspond to the<br />

thermal insulation standard), a thermal bridge is created because the straw bale<br />

wrapping insulation is completely open here. Windows are always the weak point in<br />

any house (8 - 1 2 cm wood or plastic frame has a significantly worse insulation<br />

value than 36 cm straw). In this case, the window frames must be massively<br />

insulated (outside), but this usually causes a problem (from the wall to the window<br />

wing it is usually not more than 5-6 cm).<br />

So windows are ideally removed and placed in the insulation area. Sturdy boxes (the<br />

larger the window or the (terrace) door, the more solid) are used for this purpose,<br />

which are pushed into the cavities after removal and are laterally fixed (and<br />

insulated). Concrete formwork panels meet these requirements better than OSB and<br />

are cheaper than natural three-layer panels. In addition, their impregnation provides<br />

a double rain protection (window sill). On the front, they are attached to our hybrid<br />

posts. The window sill is slightly sloped (2 °) and because the additional 40 cm<br />

insulation layer greatly reduces the amount of sunlight the box can also be beveled<br />

outwards (45 °). It is simpler, however, to extend the box only 1 8 cm to the center of<br />

the straw bale (where the windows are then installed at the front edge of the box)<br />

and the angle before is produced by cutting the bales (alligator / hedge trimmer).<br />

1 8

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S1 : Design and Planning-Checklist<br />

006<br />

Safety and Efficiency:<br />

Do we need a Scaffolding?<br />

Anyone who has lifted a 1 4 kg strawbale on a ladder standing in front of a wall and<br />

does not have the muscles of Arnold Schwarzenegger can sing a song of it: a<br />

scaffolding helps not only to save energy (and to not leave the motivation), it also<br />

helps to maintain the quality of the installation. Bales need to be compressed<br />

downwards with your weight (feet) or the persuader (wooden hammer) and with<br />

additional flakes to close the gaps to the adjacent bale, they must also be installed<br />

as flush as possible in a level with the neighboring bales ( so that we get a flat<br />

surface for the subsequent plaster). We are talking about quality work, which can<br />

only be done on a safe scaffolding. In single-storey houses, you may work perfectly<br />

with a few stable bucks and scaffolding boards. Or a smaller sliding aluminum<br />

scaffolding (which can be rented easily and cheaply, e.g. at geruestverleih.at: € 70, - /<br />

week). In two-storey buildings it is advisable to have a scaffolding erected by a<br />

scaffolding builder or master builder, as it can be used also by other craftsmen (e.g<br />

plasterers and roofers). Saving money here can ultimately become more expensive<br />

as not only the motivation of the straw bale builders or helpers is decreasing but<br />

also the workload during the post-processing of the wall increases massively. in a<br />

new building the bales can be infilled from inside, in wrapping also the plastering is<br />

carried out exclusively from the outside. So please do not save money on the wrong<br />

place. Additionally the construction site becomes much safer.<br />

1 9

20

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

SESSION PLAN S2<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

Objectives:<br />

Trainer:<br />

Trainees ...<br />

… know different structural options of wrapping and retrofitting<br />

and their characteristics and bale requirements.<br />

… know how to fix the bales, to stabilize the system and all the<br />

different techniques.<br />

… know the different options to compress the bales within the<br />

systems.<br />

… know the details of the connections: foundation, corners,<br />

windows, doors, roof etc.<br />

… know how to prepare the different surfaces for plastering.<br />

Skills:<br />

Execute wrapping and retrofitting construction methods<br />

Use of different compression and fixing techniques<br />

Organize and finish the work according to schedule<br />

Execute good connection details<br />

Knowledge of how to maintain integrity of the insulation<br />

Prepare different surfaces for plastering<br />

Methods:<br />

Theory<br />

Practice<br />

Practice on different wrapping and retroffiting systems<br />

Different structural options of wrapping and retrofitting and<br />

their characteristics and bale requirements<br />

Fixing the bales with different techniques<br />

Compressing bales within different systems<br />

Advantages and disadvantages of wrapping and retrofitting<br />

techniques<br />

Details of connections: foundation, corners, windows and<br />

doors, roof, etc.<br />

Preparing different surfaces for plastering<br />

Study and develop a case-study comparing the results with<br />

other trainees.<br />

Place:<br />

Workshop or building-site<br />

and classroom<br />

Duration:<br />

5 days<br />

Equipment:<br />

Beamer (projector)<br />

Bales<br />

Structure or model to work<br />

on with tools<br />

Documents:<br />

Info sheets:<br />

I1 Wrapping<br />

I2 Retroffiting<br />

I3 Details<br />

Text sheets:<br />

X1 Wrapping<br />

X2 Retroffiting (Best<br />

building practice)<br />

Power point:<br />

P1 Ex. Wrapping<br />

P2 Ex. Retrofitting<br />

Evaluation:<br />

Multiple choice<br />

Organization:<br />

Preparation of a structure to be wrapped or retrofitted, preparation of a structure to demonstrate<br />

different construction details.<br />

Order enough bales, prepare tools for measuring, cutting, adjusting bales, fixing, compressing.<br />

Order all the material needed for preparing the plastering.<br />

21

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO S2<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

22

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO S2<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

23

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

007<br />

CUT-Hybrid-Construction:<br />

centered - for direct plastering<br />

If the surface of the straw bale wall is directly plastered, the posts (usually planks<br />

2.5 x 1 5 cm are enough to hold the bales) are placed in the center. The back of our<br />

construction thus forms the wall of the old stock. The bale is simply pushed against<br />

the existing wall (on edge). If the wall is directly plastered, care must be taken when<br />

filling the bales to form a flat surface on the outer side (ie connect to the adjacent<br />

bales without gaps). In order to prevent the bales from slipping or falling out in<br />

hybrid constructions (where they are not clamped between the boards and the wall)<br />

they are fixed (nailed or screwed) after each row by battens (2.5 x 2.5 cm). Predrilling<br />

especially helps when the battens are nailed. This (5 m long) batten is entered in the<br />

bale (laid halm side) by cutting the straw on the surface with a bread knife or a wide,<br />

stable cutter. This additional 36 cm insulation (approx. 39 cm thickness incl. plaster)<br />

brings your house to low-energy standard. Alternatively, 26 cm miniballs can also be<br />

used (28.5 cm total thickness).<br />

24

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

008<br />

CUT-Hybrid-Construction:<br />

outside - for (Timber-)Cladding<br />

If the front of the bales is to be planked with diffusion-open boards (for example, for<br />

a ventilated wooden facade), we place the posts (2.5 x 1 5 cm or better 4 x 1 5 cm)<br />

flush with the front of the 6 cm thick wooden base. In this case, we do not need<br />

battens to fix the bales, since they are clamped between the wall and the boards<br />

(diffusion-open 1 6 mm DWD). If the wall is slightly sloped, our Wrapping wall should<br />

also be slightly sloped, just like in the assembly of a insulation composite system,<br />

which is usually not levelled. Otherwise, it must also be stuffed after each row, since<br />

crevices in the dewpoint area lead to convection and thus condensation. Please<br />

check the exact bale thickness before installing the hybrid posts, there are also bales<br />

which differ by the standard size 36 cm (about 34 cm thick). The bale density does<br />

not have to be as high (from 85 kg / m3) as with direct plasters (1 00 kg) and when<br />

stuffing, it is enough to fill the holes just in such a way that holes disappear, the<br />

straw doesn#t have to be well anchored. Contrary to the direct plaster, since the<br />

boards also hold loose straw. However, overhanging straw should be cut off,<br />

especially along the stands (hedge trimmer), so that the straw does not slide<br />

between the post and the board during assembly. Since here the individual rows are<br />

not fixed with battens (which also fix the distance of the stands), it is important to<br />

ensure that the posts / planks do not bend during the filling (especially at the<br />

corners). And it is advisable to fix the stands at least after each storey (2,5-3 m) on<br />

the wall.<br />

25

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

009<br />

Binding<br />

Straw Bales on the Wall<br />

Before the CUT hybrid construction was invented and adapted for wrapping, bales<br />

were attached to the walls with cords. New connecting cords were knotted on the<br />

two bale cords and these were then fixed to the wall (dowels and eyelets). This does<br />

not just sound like a lot of work, it is. In addition, there are other disadvantages of<br />

this (outdated) technique: the cords intersect the bales and deform them, fixing<br />

dowels in old walls can be a real challenge, the strings remain as in the load bearing<br />

straw bale technique on the bale, which makes shaving much harder (or impossible).<br />

The first layer of bales is attached to the base plate with small spikes (also as in loadbearing<br />

straw bale construction). Pointed 2.5 x 2.5 cm battens with a length of<br />

approx. 20 cm fit into a 3 cm drill hole in base wood, to prevent bales from slipping.<br />

The advantage of this technique (some argue with the continuous insulation area) is<br />

not clear on closer inspection, since hybrid posts (1 " planks) affect the total<br />

insulation value of the wall far less than e.g. remaining cavities, which are then filled<br />

with clay or COB or lime plaster. Of course, no "planking" for a wooden facade can<br />

be attached to this "construction", it can only be "plastered" directly. The technique is<br />

a mixture with or, rather, a relic of load bearing straw bale building, where bales<br />

have still been laid flat (47 - 50 cm bale thickness). Since we know that flat bales<br />

have a way worse insulation value than bales on edge, this technique is actually<br />

superfluous (unless wood is not available).<br />

26

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

010<br />

Down-spanning<br />

Straw Bales in the Wall<br />

The down-spanning of straw bales also comes from load-bearing construction<br />

technology. Admittedly, it compresses the bales quite good, thus closing up fairly<br />

reliably gaps between the bale rows. The packaging tapes, which are used for this<br />

purpose and are clamped with a packing tong, remain in the wall and - similar to the<br />

cords (tip 09) - are a hindrance when shaving the walls. Also the wood consumption<br />

does not really decrease compared to the CUT technique, because instead of the<br />

stands a massive, at least 6 cm thick and 36 cm wide, wooden top plate hinders the<br />

bales before constriction. As well the base plate has to be doubled so that the tape<br />

can be pulled through. And again, the wrapping tapes are guided through eyelets,<br />

which are fastened to the old stock wall every 50 - 1 00 cm. In the case of bad bales,<br />

this technique may have advantages due to the stronger compression with the<br />

packaging tong (and possibly precompression with truck straps). In case of good<br />

bales, the technique as well as the binding with cords to the wall (tip 009) is actually<br />

only one big disadvantage compared to hybrid CUT construction.<br />

27

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

011<br />

Straw Bales<br />

spanned to the Wall<br />

Jakub Wihan, the Czech strawball builder, who has worked with amazonnails for a<br />

long time, is the inventor of this optimized fixing technique, which is still used today<br />

in Slovakia (Boris Hoechel demonstrates the technique). Bbales are installed here<br />

again on edge, after the second row, a wrapping tape is placed on the straw bales<br />

and guided through two eyelets attached to the wall. On the front, 2 strips or round<br />

wood are threaded through the cords and formed into an "H" with an approx. 50 cm<br />

wide spacing board. As soon as further rows of bales have been piled up, the<br />

wrapping tapes are now pulled over the "H" connected to the eyelets of the back<br />

wall. This H auxiliary construction presses the bales towards the wall, with sufficient<br />

tension (and not too hard bales) the wood pulls into the straw bales and forms a<br />

straight surface at the front. The advantage of this technique is that the bales are<br />

attached to the wall with pressure (tension), exactly what we mean by fixing the<br />

bales to the existing wall. And the technique is relatively fast, you only need 2<br />

eyelets per "H" and can simultaneously clamp 6-9 bales on the wall. But once again,<br />

the disadvantages of this technique are: the durable fixation depends on the 2<br />

eyelets, if they are not well anchored, the entire bale wall falls, as well as if the<br />

wrapping band tears. Also here the strings remain on the bale and hinder shaving.<br />

Finally, at least the board must be provided with a plaster ground.<br />

28

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

01 2<br />

Straw Flakes for thinner Layers<br />

mounted with Pallettes<br />

Used pallets are a favorable construction material, usually cheaper than the wood in<br />

it. In addition, we do not need Euro pallets for this technology, but the more<br />

favorable pallets with a little more space between the boards at the top. These can<br />

be filled well with bale flakes while lying backwards on the ground. Afterwards, the<br />

filled and "insulated" pallets are simply screwed to the wall, thus compressing the<br />

protruding bales again compactly. From the front (visible) cavities can be re-stuffed<br />

(therefore also the slightly larger distance between the boards is ideal). In the spaces<br />

we fill clay with a lot of straw fibers (COB), which sucks the moisture from our<br />

dewpoint area, since clay is strongly hygroscopic (water-absorbing). As with a<br />

diagonal bracing, it must be covered with reed stucco or another plaster carrier. The<br />

advantage of this technique is that it can achieve lower insulation thicknesses up<br />

from 1 5 cm (pallet thickness). Depending on the distance between the wall and the<br />

pallet, the insulation thickness can be set individually. Pallets are solidly built, even if<br />

a nail is missing or riddled, it doen't fall apart. Who once tried to break a pallet,<br />

knows how stable they are. This technology is also extremely favorable at around €<br />

1 0, - / m2 of material requirements (wooden stands, pallet, straw). By the way, we do<br />

not fix the pallets directly on the wall, but on planks which are connected between<br />

base plate and the roof by a distance of the width of the pallets (for example 1 25<br />

cm), like our CUT posts.<br />

29

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

01 3<br />

Straw Flakes for thinner Layers:<br />

building a Cage<br />

As already mentioned for the pallet wrapping technique (tip 01 2), we need a kind of<br />

cage for thinner insulation thicknesses below 26 cm (mini bales) or 36 cm (standard<br />

bales) in order to fix the bale flakes. The thickness can thus be individually adjusted<br />

from about 6 cm (for example, if the roof overhang is not sufficient for whole bales).<br />

In order to fill the bales as efficiently as possible, post distances of 36 cm, 47 - 50 cm<br />

or 72 cm are ideal.<br />

Materials which are suitable for a cage: 1 ) diffusion-open boards (DWD), see also tip<br />

025 form a wind-tight outer plane, and are especially useful when a wooden facade<br />

is to be mounted (price for DWD around € 8, - / m2). See picture above.<br />

2) 2.5 x 2.5 cm strips/battens at intervals of max. 1 0 cm have the advantage that they<br />

can be directly plastered with appropriate plaster thicknesses (2-3 cm) without<br />

plaster grounds (but with mesh). The advantage here is, as with the pallets, the<br />

filling of the interspaces with clay (when plastered with<br />

lime directly on top, we use 5-6 parts of clay and 1 part<br />

of lime) thus keeping our straw insulation layer dry as<br />

with Fachwerk-houses. See picture on the left.<br />

3) It is also possible to use bamboo, (reed) mats or<br />

similar solid materials, depending on the regional<br />

availability.<br />

30

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

01 4<br />

Break between Perimeter- and Wall<br />

Plaster: Dripping Nose<br />

To prevent moisture transport from the cement plaster in the splash water area (30<br />

cm above ground level) up to the lime plaster facade, these two plasters must be<br />

separated by a horizontal barrier. This droplet is essentially an extension of the<br />

horizontal barrier between the strip foundation and the base plate of the<br />

construction to the outside, in such a way that water can drip off (picture above left).<br />

The dripping nose is at the same time the stiffening of this metal strip. Ideally, better<br />

use zinc, aluminum or stainless steel instead of galvanized sheet, which is a few euro<br />

cheaper but not permanently rustproof, if it is not painted. The drip can be fixed on<br />

the outside of the base plate (with roofing nails) or under the foot threshold. It then<br />

stands horizontally to the outside (plaster thickness + 5 mm overhang) and then<br />

bends obliquely downwards to the dripped nose. Each tinsmith will bend such a<br />

sheet in short time in the desired length. A 5 cm strip of Steico Underfloor can be<br />

clamped above the metal (picture on the upper right). A further possibility is to cover<br />

the entire base in the splash area with metal, the drip nose is then just above ground<br />

level (Center).<br />

31

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

01 5<br />

Direct plaster on Straw Bales:<br />

rainproof and windproof<br />

Straw surfaces - properly prepared - are excellent plaster carriers. For this purpose,<br />

straw bales must be well baled (or compressed) to a minimum density of 1 00 kg /<br />

m3. The surfaces must be shaved ad levelled with the hedge trimmer and hollow<br />

spaces should be filled with as long straw as possible. It is not advisable to store the<br />

straw bales for month or years (so that the smooth but protective wax layer<br />

disappears). The surface - after shaving - is so rough that the clay and lime plasters<br />

hold on to this plaster carrier (the straw is shaved / cut off with the hedge trimmer<br />

with strong pressure). Excessed wood parts wider than 2 cm must be covered with<br />

plaster grounds (such as reed stucco, Steico Unerfloor, soft fiber board, Heraklith BM<br />

or cork) or heavily roughened (every 3 cm). Connections to window frames, doors,<br />

roundwood stands, etc. must be air- and wind-tight (tapes, apu strips, multiple<br />

plastering). Because earth- and lime plasters leadeasily to rust in metals, metals in<br />

touch with plasters must remain permanently rust-free (stainless steel, zinc,<br />

aluminum).<br />

32

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

01 6<br />

Timber Cladding on Straw Bales:<br />

Boards and Ventilation Areas<br />

The safest method of protecting straw from rain and moisture is a wooden facade.<br />

Since wood with a μ-value of > 20 (spruce dry 50, damp 20) has a moisture-braking<br />

effect, a back-ventilation is to be provided, which allows the moisture from the room<br />

air diffuse outwards. In the case of vertical ventilation areas, 3-5 cm are sufficient,<br />

horizontal ventilation areas (flat roof) should be 8-1 0 cm. They are usually built with<br />

battens and counter battens, so that the air can sweep from all sides through the<br />

ventilation area. The first lattice is always installed in the direction of the boards /<br />

planks of the wooden facade, the second is then 90 ° to it. In order for air to circulate<br />

(which practically always works by the solar radiation on the façade when the air is<br />

heated), an air inlet of at least 3 cm in width at the lower end of the wooden façade<br />

and an equally wide air outlet at the upper end has to be installed. This openings are<br />

covered with a bird protection mesh (picture on the upper right), so that no animals<br />

(eg wasps) can enter here, this perforated mesh should be relatively fine (2-3 mm).<br />

The second layer of rain protection underneath the façade then usually forms a<br />

diffusion-free, but also water-repellent, wind-proof layer: this is usually achieved<br />

with diffusion-open panels (DWD) or with a two-layered clay plaster: the second (fine<br />

plaster) layer closes the cracks of the base plaster. In order to be windproof even<br />

under the battens, it is advisable to plaster the clay over the entire area and to install<br />

the battens afterwards.<br />

33

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

017<br />

ventilated Glass Facades in front of<br />

Straw Bales: visible Straw<br />

Building physics says that a (not wind-tight) insulation layer, which is not enclosed<br />

(ie aerated), loses its thermal properties. The estimates range from half to 1 00%.<br />

Therefore an unplastered or unplanked straw bale house should not insulate at all<br />

(which is easy to check, anyone who has once built such a house knows how fast it<br />

can be warm, but it can cool down quickly when the insulation area is ventilated).<br />

But if the wind is hindered by a glass or Plexiglass layer (of course glass must also<br />

be ventilated, so cold air flows into the ventilation area), and according to<br />

calculations of the house of the future project "Biohof Achleitner" (20 m-long straw<br />

bale wall behind glass), the heat gain in this "glass house" is greater than the loss<br />

due to the lack of wind resistance: U-value: 0.11 4 W / m2K (plastered: 0.11 6 W / m2K).<br />

Maybe this is right for the south<br />

side ... Nevertheless, such<br />

techniques (similar to bottle<br />

walls) are at least to be<br />

questioned: for sure they serve<br />

more aesthetics than building<br />

physics.<br />

34

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

TIPS<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S2: Construction<br />

Sarah Wigglesworth´architectural office in London / Guest House in Chile, AATA Arch.<br />

35

36

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

SESSION PLAN S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

Objectives:<br />

Trainer:<br />

Trainees ...<br />

… know the tools and machines used on the straw bale building<br />

site.<br />

… know specific problems of straw bale building site organization.<br />

… know how to solve any technical problem conveniently.<br />

… know accident prevention regulations, how to recognize<br />

dangers and save working practices.<br />

Skills:<br />

Handling tools and machines which are used in straw bale<br />

construction<br />

Methods:<br />

Demonstration<br />

Explanations<br />

Practice<br />

Place:<br />

Workshop or building site<br />

Duration:<br />

4 hours<br />

Equipment:<br />

Tools<br />

Theory<br />

Practice<br />

Specific problems of straw bale building site organization<br />

Trying the tools, visiting building site<br />

Documents:<br />

Info sheets:<br />

I1 Tools<br />

I2 Building site<br />

Text sheets:<br />

X1 Tools<br />

X2 Building site<br />

Power point:<br />

P1 Tools<br />

Evaluation:<br />

Multiple choice<br />

Organization:<br />

Looking for an appropiate building-site in the surroundings; prepare different tools and materials<br />

for the demonstration<br />

37

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

01 8<br />

system/haus/bau-Module, entwickelt von C. Kastner, H. Gruber, W. Schmelz<br />

38

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

01 9<br />

Jules Ferry Residence in St. Die des Vosges (FR) von Bet Gaujard Arch.: 7stöckiger Bau<br />

39

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

Jules Ferry Residence in St. Die des Vosges (FR) by Bet Gaujard Arch.: 7storey-building<br />

40

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

020<br />

Complemedis AG, CH: Wrapping with prefabricated modules by Werner Schmidt<br />

41

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

021<br />

022<br />

Straw/Reed-Facade by Kengo Kuma, Japan; below: Waseda University Students have<br />

developed this prototype: Straw cools through evaporation in summer and heats<br />

through fermentation in winter<br />

42

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

023<br />

024<br />

Enterprise Centre/University East Anglia, UK; Schelfbauhütte in the Alte Brauerei, DE<br />

43

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

025<br />

School in Issy les Moulineux and Montreuil, FR: external mounted straw bale modules<br />

44

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

026<br />

Make Your City Smart Project by Paul Adrian Schulz: conccrete slab building with DIYstraw<br />

bale walls: social living in Vienna (Partner: ASBN);<br />

ASBN-Project InsulateGreece with a similar idea against Fuel Poverty, GR<br />

45

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

46

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO & TIPS S3<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S3: Prefab Wrapping Constructions<br />

Make Your City Smart Projekt-Calculation for the project by Paul Adrian<br />

Schulz: Materials and Work in Straw Bale Walls +/- Self-Building (DIY)<br />

47

48

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO S4<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S4: Alternatives: Straw Injection-Systems<br />

027<br />

49

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO S4<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S4: Alternatives: Straw Mats<br />

028<br />

50

<strong>U4</strong> – WRAPPING (EXTERIOR THERMAL INSULATION)<br />

INFO S4<br />

<strong>U4</strong><br />

Session Plan <strong>U4</strong>-S4: Alternatives: Reed-Mats<br />

029<br />

A) 25 cm Reed (5 Layers)<br />

U-Value: 0,208 W/m 2 K<br />

PEI n.r.: >1 7 kWh/m²<br />

€ 52,50 - 75,80/m2<br />

B) Straw, Reed-Insulation-Board, Lime-Direct Pl.<br />

26 cm Straw, 5 cm Reed Mat, complete 33,5 cm<br />

Wrapping-System: Material Price/m2 (AT)<br />

Straw Bales: around € 8,00 - 11 ,20/m2 (cert.)<br />

Constr. with/out window box: € 1 3,05 - 36,50/m2<br />

Reed insulation board (bauschilf.at): 8,47/m2<br />

Lime Plaster 2,5 cm, Mesh: € 8,70/m2<br />

Material - complete price: € 38,22 - 56,17/m2<br />

51

<strong>STEP</strong> – Straw Bale Training for European Professionals<br />

UNIT 4 – Wrapping (201 7)<br />

©/Editor/Texts/Tipps: Herbert Gruber (ASBN)<br />

Co-Workers: Helmuth Santler, BuildStrawPro-Team (Erasmus+<br />

Projekt)<br />

Design & Photos: Herbert Gruber; more Photos: Naporo (8)<br />

Hagebau (8), u-wert.net (9), Geocell (1 5, 1 6), Misapor,<br />

Kurkfabriek (1 5), Horst Danner, GrAT (22), Virko Kade (23),<br />

Kengo Kuma (36), Icons: Michael Howlett (SBUK)<br />

This <strong>Handbook</strong> bases on<br />

the <strong>Handbook</strong> by the Leonardo-<br />

Group <strong>STEP</strong> (201 5)<br />

52