Water & Wastewater Asia May/June 2019

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

34 | FROM THE GROUND<br />

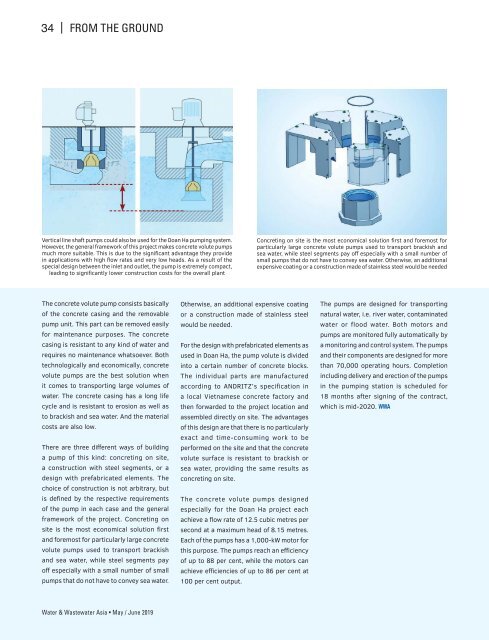

Vertical line shaft pumps could also be used for the Doan Ha pumping system.<br />

However, the general framework of this project makes concrete volute pumps<br />

much more suitable. This is due to the significant advantage they provide<br />

in applications with high flow rates and very low heads. As a result of the<br />

special design between the inlet and outlet, the pump is extremely compact,<br />

leading to significantly lower construction costs for the overall plant<br />

Concreting on site is the most economical solution first and foremost for<br />

particularly large concrete volute pumps used to transport brackish and<br />

sea water, while steel segments pay off especially with a small number of<br />

small pumps that do not have to convey sea water. Otherwise, an additional<br />

expensive coating or a construction made of stainless steel would be needed<br />

The concrete volute pump consists basically<br />

of the concrete casing and the removable<br />

pump unit. This part can be removed easily<br />

for maintenance purposes. The concrete<br />

casing is resistant to any kind of water and<br />

requires no maintenance whatsoever. Both<br />

technologically and economically, concrete<br />

volute pumps are the best solution when<br />

it comes to transporting large volumes of<br />

water. The concrete casing has a long life<br />

cycle and is resistant to erosion as well as<br />

to brackish and sea water. And the material<br />

costs are also low.<br />

There are three different ways of building<br />

a pump of this kind: concreting on site,<br />

a construction with steel segments, or a<br />

design with prefabricated elements. The<br />

choice of construction is not arbitrary, but<br />

is defined by the respective requirements<br />

of the pump in each case and the general<br />

framework of the project. Concreting on<br />

site is the most economical solution first<br />

and foremost for particularly large concrete<br />

volute pumps used to transport brackish<br />

and sea water, while steel segments pay<br />

off especially with a small number of small<br />

pumps that do not have to convey sea water.<br />

Otherwise, an additional expensive coating<br />

or a construction made of stainless steel<br />

would be needed.<br />

For the design with prefabricated elements as<br />

used in Doan Ha, the pump volute is divided<br />

into a certain number of concrete blocks.<br />

The individual parts are manufactured<br />

according to ANDRITZ’s specification in<br />

a local Vietnamese concrete factory and<br />

then forwarded to the project location and<br />

assembled directly on site. The advantages<br />

of this design are that there is no particularly<br />

exact and time-consuming work to be<br />

performed on the site and that the concrete<br />

volute surface is resistant to brackish or<br />

sea water, providing the same results as<br />

concreting on site.<br />

The concrete volute pumps designed<br />

especially for the Doan Ha project each<br />

achieve a flow rate of 12.5 cubic metres per<br />

second at a maximum head of 8.15 metres.<br />

Each of the pumps has a 1,000-kW motor for<br />

this purpose. The pumps reach an efficiency<br />

of up to 88 per cent, while the motors can<br />

achieve efficiencies of up to 86 per cent at<br />

100 per cent output.<br />

The pumps are designed for transporting<br />

natural water, i.e. river water, contaminated<br />

water or flood water. Both motors and<br />

pumps are monitored fully automatically by<br />

a monitoring and control system. The pumps<br />

and their components are designed for more<br />

than 70,000 operating hours. Completion<br />

including delivery and erection of the pumps<br />

in the pumping station is scheduled for<br />

18 months after signing of the contract,<br />

which is mid-2020. WWA<br />

<strong>Water</strong> & <strong>Wastewater</strong> <strong>Asia</strong> • <strong>May</strong> / <strong>June</strong> <strong>2019</strong>