CEAC-2021-02-February

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Since installation and the commencement of operation, there’s<br />

only been one slight hitch.<br />

“I’d say the biggest issue was the evaporator that we had to have<br />

replaced, which came down to the manufacturer,” Domina says,<br />

indicating that they simply took the replacement in stride.<br />

In addition to the chillers, they added the new replacement<br />

evaporator pump and two new condenser pumps, both on<br />

frequency drives. According to Leitner and Clarke’s team, this<br />

was a no-brainer. “Especially efficiency-wise, and everything,”<br />

Leitner says. “It offers rebates for more efficient equipment and<br />

everything, so they were able to get a significant rebate for doing<br />

the replacement this way as opposed to something that wasn’t as<br />

efficient.”<br />

“These pumps are Armstrongs,” Leitner continues. “They call<br />

them smart pumps. They don’t need differential pressure switches<br />

down the line. They handle everything right at the pump. The<br />

pump — it’s got configurations in the drive, and sensors, and<br />

figures everything out right at the pump, rather than having<br />

to throw something downline. It’s the first time I’ve used these<br />

pumps. We’ve used them at the company quite a bit, but this<br />

is the first job that I was able to use these pumps on [a job], so<br />

they worked out real good. Real nice pumps.”<br />

For more information about how you can best outfit your building<br />

with modular chiller units, feel free to contact Air Comfort<br />

Sales Engineer Scott Leitner at leitners@aircomfort.com.<br />

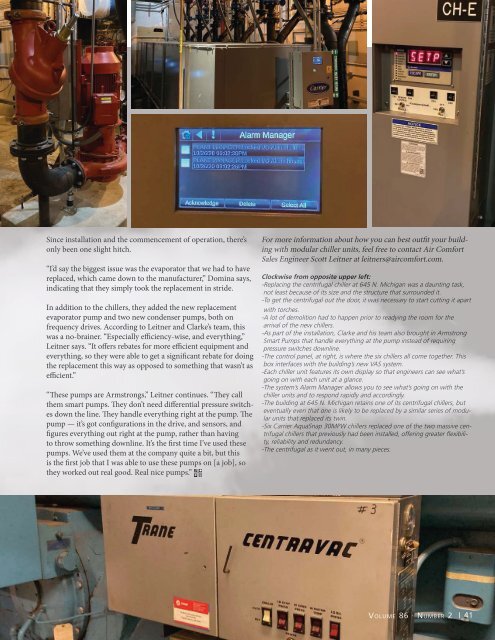

Clockwise from opposite upper left:<br />

-Replacing the centrifugal chiller at 645 N. Michigan was a daunting task,<br />

not least because of its size and the structure that surrounded it.<br />

-To get the centrifugal out the door, it was necessary to start cutting it apart<br />

with torches.<br />

-A lot of demolition had to happen prior to readying the room for the<br />

arrival of the new chillers.<br />

-As part of the installation, Clarke and his team also brought in Armstrong<br />

Smart Pumps that handle everything at the pump instead of requiring<br />

pressure switches downline.<br />

-The control panel, at right, is where the six chillers all come together. This<br />

box interfaces with the building’s new VAS system.<br />

-Each chiller unit features its own display so that engineers can see what’s<br />

going on with each unit at a glance.<br />

-The system’s Alarm Manager allows you to see what’s going on with the<br />

chiller units and to respond rapidly and accordingly.<br />

-The building at 645 N. Michigan retains one of its centrifugal chillers, but<br />

eventually even that one is likely to be replaced by a similar series of modular<br />

units that replaced its twin.<br />

-Six Carrier AquaSnap 30MPW chillers replaced one of the two massive centrifugal<br />

chillers that previously had been installed, offering greater flexibility,<br />

reliability and redundancy.<br />

-The centrifugal as it went out, in many pieces.<br />

Volume 86 · Number 2 | 41