Panels & Furniture Asia January/February 2018

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WOOD CLINIC 63<br />

Fig. 3: The heart wood of Kapur contains<br />

crystalline resin that is as white as borneol.<br />

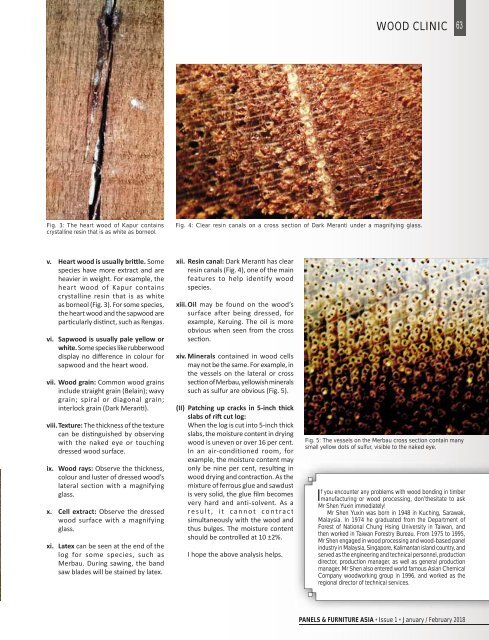

Fig. 4: Clear resin canals on a cross section of Dark Meranti under a magnifying glass.<br />

v. Heart wood is usually brile. Some<br />

species have more extract and are<br />

heavier in weight. For example, the<br />

heart wood of Kapur contains<br />

crystalline resin that is as white<br />

as borneol (Fig. 3). For some species,<br />

the heart wood and the sapwood are<br />

particularly distinct, such as Rengas.<br />

vi. Sapwood is usually pale yellow or<br />

white. Some species like rubberwood<br />

display no difference in colour for<br />

sapwood and the heart wood.<br />

vii. Wood grain: Common wood grains<br />

include straight grain (Belain); wavy<br />

grain; spiral or diagonal grain;<br />

interlock grain (Dark Meranti).<br />

viii. Texture: The thickness of the texture<br />

can be distinguished by observing<br />

with the naked eye or touching<br />

dressed wood surface.<br />

ix. Wood rays: Observe the thickness,<br />

colour and luster of dressed wood’s<br />

lateral section with a magnifying<br />

glass.<br />

x. Cell extract: Observe the dressed<br />

wood surface with a magnifying<br />

glass.<br />

xi. Latex can be seen at the end of the<br />

log for some species, such as<br />

Merbau. During sawing, the band<br />

saw blades will be stained by latex.<br />

xii. Resin canal: Dark Meranti has clear<br />

resin canals (Fig. 4), one of the main<br />

features to help identify wood<br />

species.<br />

xiii. Oil may be found on the wood’s<br />

surface after being dressed, for<br />

example, Keruing. The oil is more<br />

obvious when seen from the cross<br />

section.<br />

xiv. Minerals contained in wood cells<br />

may not be the same. For example, in<br />

the vessels on the lateral or cross<br />

section of Merbau, yellowish minerals<br />

such as sulfur are obvious (Fig. 5).<br />

(II) Patching up cracks in 5-inch thick<br />

slabs of ri cut log:<br />

When the log is cut into 5-inch thick<br />

slabs, the moisture content in drying<br />

wood is uneven or over 16 per cent.<br />

In an air-conditioned room, for<br />

example, the moisture content may<br />

only be nine per cent, resulting in<br />

wood drying and contraction. As the<br />

mixture of ferrous glue and sawdust<br />

is very solid, the glue film becomes<br />

very hard and anti-solvent. As a<br />

result, it cannot contract<br />

simultaneously with the wood and<br />

thus bulges. The moisture content<br />

should be controlled at 10 ±2%.<br />

I hope the above analysis helps.<br />

Fig. 5: The vessels on the Merbau cross section contain many<br />

small yellow dots of sulfur, visible to the naked eye.<br />

f you encounter any problems with wood bonding in timber<br />

Imanufacturing or wood processing, don’thesitate to ask<br />

Mr Shen Yuxin immediately!<br />

Mr Shen Yuxin was born in 1948 in Kuching, Sarawak,<br />

Malaysia. In 1974 he graduated from the Department of<br />

Forest of National Chung Hsing University in Taiwan, and<br />

then worked in Taiwan Forestry Bureau. From 1975 to 1995,<br />

Mr Shen engaged in wood processing and wood-based panel<br />

industry in Malaysia, Singapore, Kalimantan island country, and<br />

served as the engineering and technical personnel, production<br />

director, production manager, as well as general production<br />

manager. Mr Shen also entered world famous <strong>Asia</strong>n Chemical<br />

Company woodworking group in 1996, and worked as the<br />

regional director of technical services.<br />

PANELS & FURNITURE ASIA • Issue 1 • <strong>January</strong> / <strong>February</strong> <strong>2018</strong>