Waste to Energy: Harnessing the fuel in organic waste to create a business opportunity for a recycling-based society and system

To generate a feasible amount of methane to support a digester, it is estimated that 10 to 12 tons/d, with 8-10% contamination and 80% of the contamination being bioplastics, can produce about 70 Nm3/h of biogas. This is the amount of biogas needed to produce 200 kg/day of hydrogen, which is the smallest commercially available packaged system. The greenhouse gas emission (GHG) for IngeoTM is currently 1.3 kg CO2 eq./kg polymer compared to approx. 3.2 kg CO2 eq./kg polymer for PET. Therefore, implementing anaerobic digestion for PLA can reduce around 942.5 kg - 1132 kg per day of CO2 equivalent emissions. A total of 1 ton per day of undigested bioplastic with 30% of total solids will be sent to landfills; 3 tons per day of dewatered digestate cake can be utilized for composting, and Class A fertilizer can be produced. The research on anaerobic degradation of biopolymers is still in its infancy. Therefore, this report has discussed different pre-treatment alternatives to treat PLA such as physical, chemical, and thermal treatments. This report suggests on-site segregation benefits of the current solid waste management scenario in the commercial sector of Plano, Texas. Organic waste generated from a cafeteria of the commercial sector in Plano caused an environmental impact on landfills. This report consists of a description of existing scenarios and possible pre-treatment alternatives for bioplastic degradation generated from the commercial sector. Harshada Pednekar was a graduate research analyst in the Hunt Institute while studying for a masters degree in environmental engineering from SMU's Lyle School of Engineering

To generate a feasible amount of methane to support a digester, it is estimated that 10 to 12 tons/d, with 8-10% contamination and 80% of the contamination being bioplastics, can produce about 70 Nm3/h of biogas. This is the amount of biogas needed to produce 200 kg/day of hydrogen, which is the smallest commercially available packaged system. The greenhouse gas emission (GHG) for IngeoTM is currently 1.3 kg CO2 eq./kg polymer compared to approx. 3.2 kg CO2 eq./kg polymer for PET. Therefore, implementing anaerobic digestion for PLA can reduce around 942.5 kg - 1132 kg per day of CO2 equivalent emissions.

A total of 1 ton per day of undigested bioplastic with 30% of total solids will be sent to landfills; 3 tons per day of dewatered digestate cake can be utilized for composting, and Class A fertilizer can be produced. The research on anaerobic degradation of biopolymers is still in its infancy. Therefore, this report has discussed different pre-treatment alternatives to treat PLA such as physical, chemical, and thermal treatments. This report suggests on-site segregation benefits of the current solid waste management scenario in the commercial sector of Plano, Texas. Organic waste generated from a cafeteria of the commercial sector in Plano caused an environmental impact on landfills. This report consists of a description of existing scenarios and possible pre-treatment alternatives for bioplastic degradation generated from the commercial sector.

Harshada Pednekar was a graduate research analyst in the Hunt Institute while studying for a masters degree in environmental engineering from SMU's Lyle School of Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

22<br />

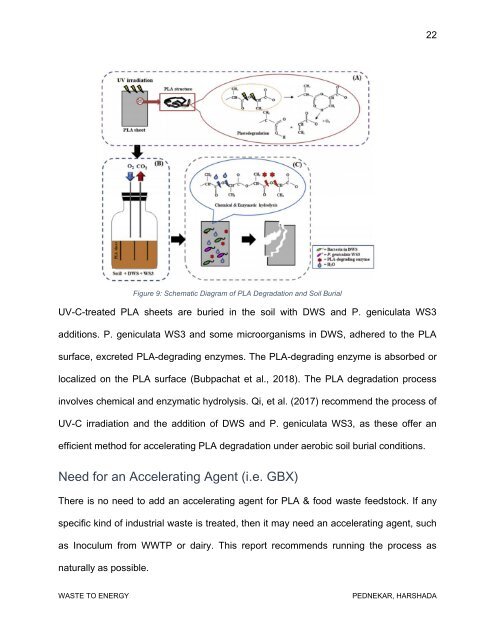

Figure 9: Schematic Diagram of PLA Degradation <strong>and</strong> Soil Burial<br />

UV-C-treated PLA sheets are buried <strong>in</strong> <strong>the</strong> soil with DWS <strong>and</strong> P. geniculata WS3<br />

additions. P. geniculata WS3 <strong>and</strong> some microorganisms <strong>in</strong> DWS, adhered <strong>to</strong> <strong>the</strong> PLA<br />

surface, excreted PLA-degrad<strong>in</strong>g enzymes. The PLA-degrad<strong>in</strong>g enzyme is absorbed or<br />

localized on <strong>the</strong> PLA surface (Bubpachat et al., 2018). The PLA degradation process<br />

<strong>in</strong>volves chemical <strong>and</strong> enzymatic hydrolysis. Qi, et al. (2017) recommend <strong>the</strong> process of<br />

UV-C irradiation <strong>and</strong> <strong>the</strong> addition of DWS <strong>and</strong> P. geniculata WS3, as <strong>the</strong>se offer an<br />

efficient method <strong>for</strong> accelerat<strong>in</strong>g PLA degradation under aerobic soil burial conditions.<br />

Need <strong>for</strong> an Accelerat<strong>in</strong>g Agent (i.e. GBX)<br />

There is no need <strong>to</strong> add an accelerat<strong>in</strong>g agent <strong>for</strong> PLA & food <strong>waste</strong> feeds<strong>to</strong>ck. If any<br />

specific k<strong>in</strong>d of <strong>in</strong>dustrial <strong>waste</strong> is treated, <strong>the</strong>n it may need an accelerat<strong>in</strong>g agent, such<br />

as Inoculum from WWTP or dairy. This report recommends runn<strong>in</strong>g <strong>the</strong> process as<br />

naturally as possible.<br />

WASTE TO ENERGY<br />

PEDNEKAR, HARSHADA