Panels & Furniture Asia November/December 2021

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PANEL MANUFACTURING<br />

start to the core, allowing customers to<br />

make the most of small-diameter logs.<br />

The line is suitable for both hardwood<br />

and softwood. Raute’s Optimal Peeling<br />

Geometry (OPG) technology also<br />

peels veneer with good capacity and a<br />

high thickness tolerance compared to<br />

conventional spindleless lathes.<br />

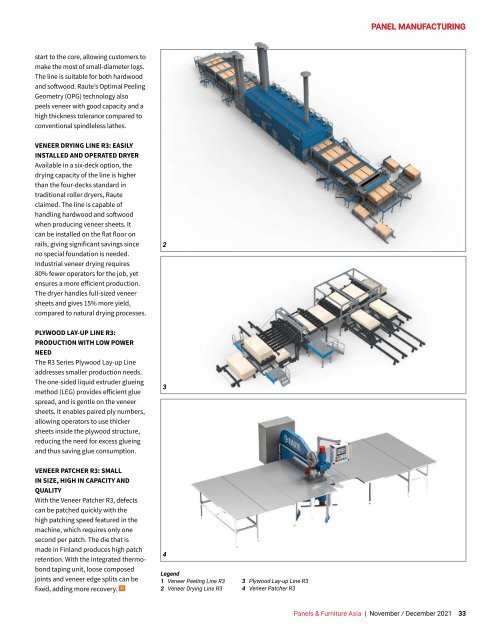

VENEER DRYING LINE R3: EASILY<br />

INSTALLED AND OPERATED DRYER<br />

Available in a six-deck option, the<br />

drying capacity of the line is higher<br />

than the four-decks standard in<br />

traditional roller dryers, Raute<br />

claimed. The line is capable of<br />

handling hardwood and softwood<br />

when producing veneer sheets. It<br />

can be installed on the flat floor on<br />

rails, giving significant savings since<br />

no special foundation is needed.<br />

Industrial veneer drying requires<br />

80% fewer operators for the job, yet<br />

ensures a more efficient production.<br />

The dryer handles full-sized veneer<br />

sheets and gives 15% more yield,<br />

compared to natural drying processes.<br />

2<br />

PLYWOOD LAY-UP LINE R3:<br />

PRODUCTION WITH LOW POWER<br />

NEED<br />

The R3 Series Plywood Lay-up Line<br />

addresses smaller production needs.<br />

The one-sided liquid extruder glueing<br />

method (LEG) provides efficient glue<br />

spread, and is gentle on the veneer<br />

sheets. It enables paired ply numbers,<br />

allowing operators to use thicker<br />

sheets inside the plywood structure,<br />

reducing the need for excess glueing<br />

and thus saving glue consumption.<br />

3<br />

VENEER PATCHER R3: SMALL<br />

IN SIZE, HIGH IN CAPACITY AND<br />

QUALITY<br />

With the Veneer Patcher R3, defects<br />

can be patched quickly with the<br />

high patching speed featured in the<br />

machine, which requires only one<br />

second per patch. The die that is<br />

made in Finland produces high patch<br />

retention. With the integrated thermobond<br />

taping unit, loose composed<br />

joints and veneer edge splits can be<br />

fixed, adding more recovery. P<br />

4<br />

Legend<br />

1 Veneer Peeling Line R3<br />

2 Veneer Drying Line R3<br />

3 Plywood Lay-up Line R3<br />

4 Veneer Patcher R3<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2021</strong> 33