Water & Wastewater Asia January/February 2022

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HOTSEAT<br />

if needed. To successfully manage the<br />

The reinforced construction of the<br />

challenges of wastewater treatment,<br />

peristaltic hose and its use of rubber<br />

the pump’s hose and inserts need<br />

compositions – such as natural rubber,<br />

to offer the highest level of material<br />

ethylene propylene diene monomer<br />

compatibility, while also being able to<br />

(EPDM), Buna-N, and more – that<br />

reliably deliver the millions of pumping<br />

have been specially designed for the<br />

cycles that are required during their<br />

stresses within the peristaltic hose<br />

lifetimes.<br />

allow for the optimum lifecycle and<br />

performance.<br />

A critical consideration when<br />

selecting the hose material<br />

For more than two decades,<br />

is its “fatigue resistance”.<br />

peristaltic hose pump technology<br />

This trait defines how resistant to<br />

– as epitomised by the standard-<br />

failure the hose material is as it runs<br />

setting operation of the Abaque<br />

through its millions of pumping cycles.<br />

Peristaltic Hose Pump family – has<br />

solid-laden slurries, and waterthin,<br />

shear-sensitive and viscous<br />

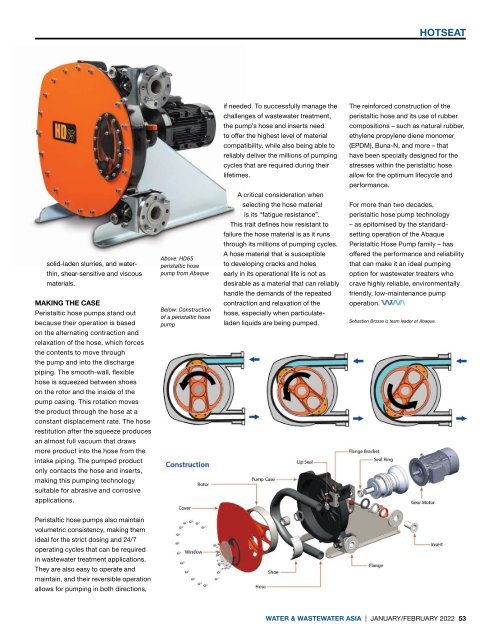

Above: HD65<br />

peristaltic hose<br />

pump from Abaque<br />

A hose material that is susceptible<br />

to developing cracks and holes<br />

early in its operational life is not as<br />

offered the performance and reliability<br />

that can make it an ideal pumping<br />

option for wastewater treaters who<br />

materials.<br />

desirable as a material that can reliably<br />

crave highly reliable, environmentally<br />

MAKING THE CASE<br />

Peristaltic hose pumps stand out<br />

because their operation is based<br />

on the alternating contraction and<br />

Below: Construction<br />

of a peristaltic hose<br />

pump<br />

handle the demands of the repeated<br />

contraction and relaxation of the<br />

hose, especially when particulateladen<br />

liquids are being pumped.<br />

friendly, low-maintenance pump<br />

operation.<br />

Sebastien Brosse is team leader at Abaque.<br />

relaxation of the hose, which forces<br />

the contents to move through<br />

the pump and into the discharge<br />

piping. The smooth-wall, flexible<br />

hose is squeezed between shoes<br />

on the rotor and the inside of the<br />

pump casing. This rotation moves<br />

the product through the hose at a<br />

constant displacement rate. The hose<br />

restitution after the squeeze produces<br />

an almost full vacuum that draws<br />

more product into the hose from the<br />

intake piping. The pumped product<br />

only contacts the hose and inserts,<br />

making this pumping technology<br />

suitable for abrasive and corrosive<br />

applications.<br />

Peristaltic hose pumps also maintain<br />

volumetric consistency, making them<br />

ideal for the strict dosing and 24/7<br />

operating cycles that can be required<br />

in wastewater treatment applications.<br />

They are also easy to operate and<br />

maintain, and their reversible operation<br />

allows for pumping in both directions,<br />

WATER & WASTEWATER ASIA | JANUARY/FEBRUARY <strong>2022</strong> 53