Cooling Tower Fundamentals - SPX Cooling Technologies

Cooling Tower Fundamentals - SPX Cooling Technologies

Cooling Tower Fundamentals - SPX Cooling Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SECTION I<br />

20<br />

In point of fact, design air conditions for the<br />

example problem would not have been given to<br />

a cooling tower designer as “78°F at a 50% relative<br />

humidity”. Rather, instructions would have<br />

been to design for a “65°F wet-bulb temperature”.<br />

Only if there was a requirement to know the<br />

exact amount of evaporation, or if the selection<br />

were for something other than a normal mechanical<br />

draft cooling tower, would there have been<br />

a need to know the design dry-bulb temperature<br />

of the air, or its relative humidity.<br />

Wet-bulb temperatures are measured by<br />

causing air to move across a thermometer<br />

whose bulb (properly shielded) is encased in a<br />

wetted muslin “sock”. As the air moves across<br />

the wetted bulb, moisture is evaporated and<br />

sensible heat is transferred to the wick, cooling<br />

the mercury and causing equilibrium to be<br />

reached at the wet-bulb temperature. For most<br />

acceptable and consistent results, the velocity<br />

of the air across the wick must be approximately<br />

1000 fpm, and the water used to wet the wick<br />

should be as close as possible to the wet-bulb<br />

temperature. Distilled water is normally recommended<br />

for wetting of the wick.<br />

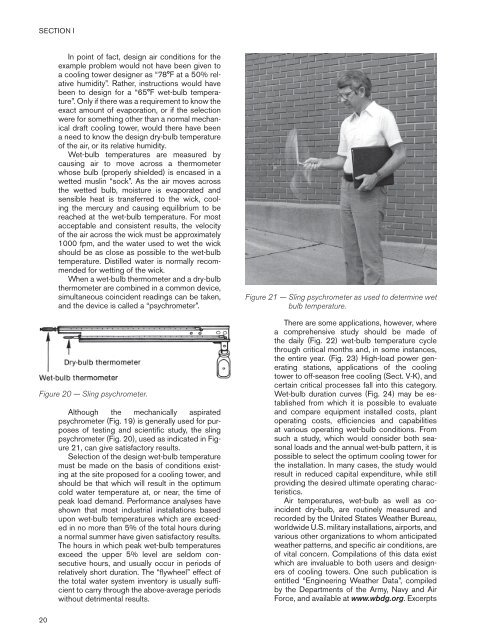

When a wet-bulb thermometer and a dry-bulb<br />

thermometer are combined in a common device,<br />

simultaneous coincident readings can be taken,<br />

and the device is called a “psychrometer”.<br />

Figure 20 — Sling psychrometer.<br />

Although the mechanically aspirated<br />

psychrometer (Fig. 19) is generally used for purposes<br />

of testing and scientific study, the sling<br />

psychrometer (Fig. 20), used as indicated in Figure<br />

21, can give satisfactory results.<br />

Selection of the design wet-bulb temperature<br />

must be made on the basis of conditions existing<br />

at the site proposed for a cooling tower, and<br />

should be that which will result in the optimum<br />

cold water temperature at, or near, the time of<br />

peak load demand. Performance analyses have<br />

shown that most industrial installations based<br />

upon wet-bulb temperatures which are exceeded<br />

in no more than 5% of the total hours during<br />

a normal summer have given satisfactory results.<br />

The hours in which peak wet-bulb temperatures<br />

exceed the upper 5% level are seldom consecutive<br />

hours, and usually occur in periods of<br />

relatively short duration. The “flywheel” effect of<br />

the total water system inventory is usually sufficient<br />

to carry through the above-average periods<br />

without detrimental results.<br />

Figure 21 — Sling psychrometer as used to determine wet<br />

bulb temperature.<br />

There are some applications, however, where<br />

a comprehensive study should be made of<br />

the daily (Fig. 22) wet-bulb temperature cycle<br />

through critical months and, in some instances,<br />

the entire year. (Fig. 23) High-load power generating<br />

stations, applications of the cooling<br />

tower to off-season free cooling (Sect. V-K), and<br />

certain critical processes fall into this category.<br />

Wet-bulb duration curves (Fig. 24) may be established<br />

from which it is possible to evaluate<br />

and compare equipment installed costs, plant<br />

operating costs, efficiencies and capabilities<br />

at various operating wet-bulb conditions. From<br />

such a study, which would consider both seasonal<br />

loads and the annual wet-bulb pattern, it is<br />

possible to select the optimum cooling tower for<br />

the installation. In many cases, the study would<br />

result in reduced capital expenditure, while still<br />

providing the desired ultimate operating characteristics.<br />

Air temperatures, wet-bulb as well as coincident<br />

dry-bulb, are routinely measured and<br />

recorded by the United States Weather Bureau,<br />

worldwide U.S. military installations, airports, and<br />

various other organizations to whom anticipated<br />

weather patterns, and specific air conditions, are<br />

of vital concern. Compilations of this data exist<br />

which are invaluable to both users and designers<br />

of cooling towers. One such publication is<br />

entitled “Engineering Weather Data”, compiled<br />

by the Departments of the Army, Navy and Air<br />

Force, and available at www.wbdg.org. Excerpts