Dental Asia May/June 2022

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BEHIND THE SCENES<br />

Since these braces were fabricated in-office<br />

at a much lower price point than traditional<br />

aesthetic brackets, this will also enable a<br />

cost-effective transition to in-office clear<br />

aligners. Clear aligners will then facilitate<br />

additional expansion movements, molar<br />

uprighting, and occlusion detail. Since this<br />

patient was missing a lower incisor, utilising<br />

3D orthodontic simulation software will<br />

idealise the position of the lower arch with<br />

the missing lower incisor.<br />

After logging into the Braces On Demand<br />

platform and ordering the desired bracket<br />

prescription, a 3D file is sent directly to<br />

Form 3B via the Remote Print feature. If<br />

the printer already has a resin tank, build<br />

platform and the correct Denture Resin<br />

cartridge inserted, the print job will start<br />

automatically once the upload is received.<br />

After printing is completed, the build<br />

platform containing the printed brackets<br />

is removed from the printer and, using a<br />

squeeze bottle filled with isopropyl alcohol,<br />

the parts are lightly rinsed to remove excess<br />

resin. A paper towel can also be used to<br />

remove any additional resin released from<br />

the printed appliances.<br />

The newly rinsed build platform is then<br />

placed into the Form Wash post-processing<br />

unit for 10 minutes, where it is gently<br />

agitated in an alcohol bath. After the Form<br />

Wash, the parts are dried using compressed<br />

air to remove residual alcohol from the<br />

surface.<br />

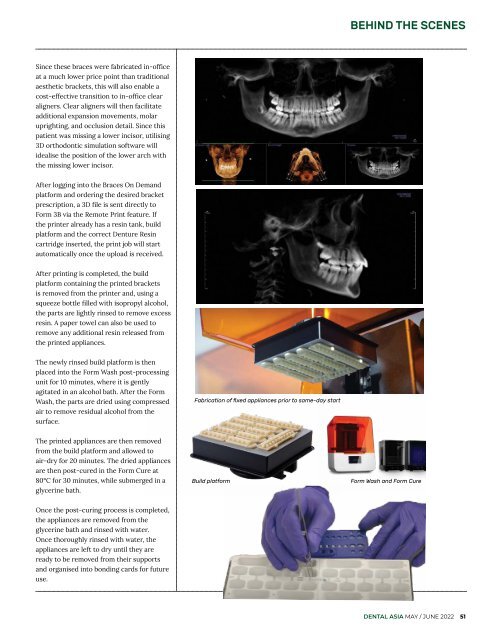

Fabrication of fixed appliances prior to same-day start<br />

The printed appliances are then removed<br />

from the build platform and allowed to<br />

air-dry for 20 minutes. The dried appliances<br />

are then post-cured in the Form Cure at<br />

80°C for 30 minutes, while submerged in a<br />

glycerine bath.<br />

Build platform<br />

Form Wash and Form Cure<br />

Once the post-curing process is completed,<br />

the appliances are removed from the<br />

glycerine bath and rinsed with water.<br />

Once thoroughly rinsed with water, the<br />

appliances are left to dry until they are<br />

ready to be removed from their supports<br />

and organised into bonding cards for future<br />

use.<br />

DENTAL ASIA MAY / JUNE <strong>2022</strong> 51