12” x 37” Gap Bed Lathe - Harbor Freight Tools

12” x 37” Gap Bed Lathe - Harbor Freight Tools

12” x 37” Gap Bed Lathe - Harbor Freight Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPEED AND POWER CONTROLS<br />

rn your lathe on and off, and control its speed and direction from the main control panel.<br />

Switch<br />

speed And pOwer cOntrOLs<br />

he power switch You can to turn<br />

SPEED lathe the on machine and AND off POWER and ON. control Push<br />

CONTROLS<br />

speed the switch and direction again to from turn the main control panel.<br />

turn your lathe on and off, and control its speed and direction from the main control panel.<br />

e OFF.<br />

the power switch<br />

dicator Light (D) will be on when the machine is running.<br />

er Switch<br />

1. Turn the Emergency Stop Switch (C) clockwise; the Indicator<br />

h mergency, the power you switch can<br />

Light<br />

to stop turn the<br />

(D) will<br />

the machine<br />

light<br />

machine by<br />

up. The<br />

ON. pressing<br />

Spindle<br />

Push<br />

will<br />

the the<br />

not<br />

switch Emergency<br />

turn without<br />

again Stop<br />

operating<br />

to turn<br />

). ine OFF. the Control Lever (V).<br />

Indicator Light (D) will be on ��<br />

when the machine is running.<br />

n emergency, 2. you The can Press stop the Switch machine (A) is used by pressing to run the the spindle Emergency temporarily Stop to<br />

(C).<br />

allow the gears to engage when changing speed gears. When<br />

you release the switch, the spindle will stop.<br />

��<br />

Fig.7 Power Switch.<br />

Direction Controls 3. In an emergency, you can stop the machine by pressing the<br />

Emergency Stop Control (C).<br />

ot change the settings of these controls if the motor is running.<br />

Fig.7 Power Switch.<br />

Fig.7 Power Switch.<br />

the speed and direction controls<br />

nd Direction power before Controls changing these settings.<br />

Note: Do not change the settings of these controls if the motor is running.<br />

o Spindle not change Speed<br />

Shut the can<br />

OFF settings be controlled<br />

the power of these before controls by setting<br />

changing if the the<br />

these motor Speed<br />

settings. is Control running. knobs (G) and (H). Refer<br />

t F on the the power Headstock before to changing the right these of the settings. knobs to determine the proper setting for the desired<br />

The Spindle Speed can be controlled by setting the Speed Control knobs (G) and (H).<br />

ation he Spindle speed. Speed Nine Refer can speeds to be the controlled are chart possible on the by Headstock setting from the 64 to Speed the to right 1500 Control of rpm. the knobs knobs The to direction (G) determine and (H). the may proper Refer be<br />

using art on Direction the Headstock Control setting to for the (F). the right desired of the spindle knobs rotation to determine speed. Eighteen the proper speeds setting are possible for the from desired 72 to<br />

rotation speed. Nine 1600 RPM. speeds The are direction possible may be from controlled 64 to using 1500 Direction rpm. The Control direction (F). may be<br />

d using Direction<br />

Quick change<br />

Control<br />

Gearbox<br />

(F).<br />

nge Gearbox<br />

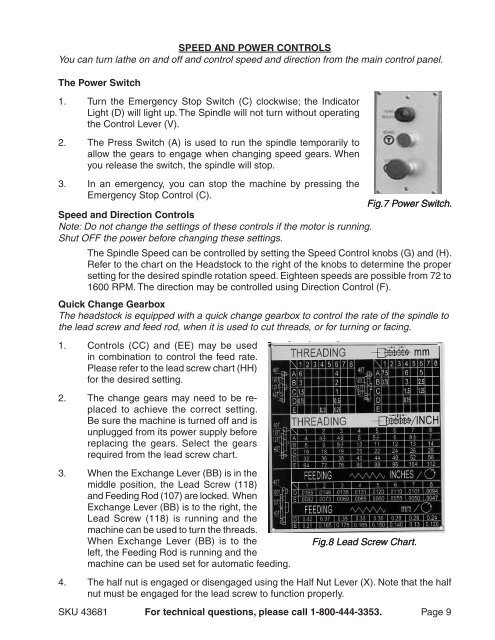

The headstock is equipped with a quick change gearbox to control the rate of the spindle to<br />

ock<br />

hange<br />

is equipped<br />

Gearbox<br />

with a quick change gearbox to control the rate of the spindle to the<br />

the lead screw and feed rod, when it is used to cut threads, or for turning or facing.<br />

dstock and feed is equipped rod, when with it is a used quick to change cut threads, gearbox or to for control turning the or rate facing. of the spindle to the<br />

1. Controls (CC) and (EE) may be used<br />

ew ls (CC) and feed and rod, (EE) when may<br />

in combination<br />

it be is used used in<br />

to<br />

to combination<br />

control<br />

cut threads,<br />

the feed<br />

or to<br />

rate.<br />

for turning or facing.<br />

l trols the feed (CC) rate. and Please (EE) Please may refer refer be to to used the the lead in lead combination screw screw chart chart (HH) to<br />

trol or the the desired feed rate. setting. Please for the desired refer to setting. the lead screw chart<br />

ange ) for the gears desired may need setting. to be replaced in order to<br />

change gears<br />

2.<br />

may<br />

The<br />

need<br />

change<br />

to be<br />

gears<br />

replaced<br />

may need<br />

in order<br />

to be<br />

to<br />

re-<br />

e the correct setting. placed Be to sure achieve the machine the correct is turned setting.<br />

eve is unplugged the correct from setting. Be sure the machine is turned<br />

Be sure its power the machine supply is turned before off and is<br />

and is unplugged from unplugged its power from its supply power before<br />

ting to replace the gears. Select the gears supply required before<br />

mpting to replace replacing the gears. the Select gears. the Select gears the required gears<br />

he the lead lead screw screw chart. chart. required from the lead screw chart.<br />

Exchange change Lever Lever (BB) (BB) is is used used to to activate activate and and control control<br />

3. When the Exchange Lever (BB) is in the<br />

direction ection of of rotation. rotation. When When the the lever lever is is in in the the middle<br />

middle<br />

middle position, the Lead Screw (118)<br />

n, tion, the the lead lead screw screw is is parked. parked. When When the the lever lever is is to to<br />

and Feeding Rod (107) are locked. When<br />

right, ht, the the lead lead screw screw Exchange is is running, running, Lever and and (BB) the the is machine to machine the right, can can the<br />

d sed to to turn turn threads. threads. Lead When When Screw the the lever (118) lever is is is to running to the the left, left, and the the<br />

rew screw is reversed, is reversed, and machine and the the machine can machine be used may to may turn be be the used used threads. for. for.<br />

rnal or external machining When Exchange or face Lever cutting. (BB) is to the<br />

Fig.8<br />

Fig.8<br />

Lead<br />

Lead<br />

Screw<br />

Screw<br />

Chart.<br />

Chart.<br />

l or external machining or face cutting.<br />

Fig.8 Lead Screw Chart.<br />

l or external machining or face cutting.<br />

Fig.8 Lead Screw Chart.<br />

half nut is engaged left, or the disengaged Feeding Rod using is running the Half and the Nut Lever<br />

lf<br />

Note<br />

nut<br />

that<br />

is engaged<br />

the half machine or<br />

nut<br />

disengaged<br />

must can be be engaged used using set the<br />

for Half automatic the lead<br />

Nut feeding. screw<br />

Lever<br />

to function properly.<br />

ote that the half nut must be engaged for the lead screw to function properly.<br />

4.<br />

The half nut is engaged or disengaged using the Half Nut Lever (X). Note that the half<br />

nut must be engaged for the lead screw to function properly.<br />

SKU 43681 for technical questions, please call 1-800-444-3353.<br />

KU # 43681<br />

U # 43681<br />

Page 9