June 2022

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

JUNE <strong>2022</strong><br />

>>> • VENTILATION • LOW PITCH ROOFS • PART L • TOOLS & WORKWEAR • >>><br />

TC Frontcover Wraptite project indd 1 17/05/<strong>2022</strong> 09:27:55

WWW.FALLARREST.COM<br />

Fall Arrest is a website designed to<br />

provide information appertaining to fall<br />

protection and prevention. The site will<br />

aid clients, architects, surveyors alike with<br />

information and provide solutions that<br />

we can offer. These offerings include full<br />

design under CDM. Fall Arrest partners<br />

with leading and trusted suppliers &<br />

manufacturers within the industry.<br />

We can assist you in the design, supply,<br />

installation & recertification of fall protection<br />

equipment as well as the supply of highly<br />

engineered personal fall protective equipment<br />

through our partners www.harnesses.co.uk.<br />

info@fallarrest.com • www.fallarrest.com

Editor’s Comment<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

This month sees the updated version of Part L of the Building<br />

Regulations come into force, and as the focus on energy efficiency in<br />

buildings increases, the changes are expected to prompt an increase<br />

in interest in solar PV from homeowners and housebuilders.<br />

With this mind, Marley has put together a handy guide explaining how to<br />

make solar work for you and your business. Free with this issue, the useful<br />

guide is packed with content to help you and your team upskill to make the<br />

most of the sector’s push for sustainability and increased demand for solar<br />

PV installations, including the low-down on the changes to Part L, all you<br />

need to know about MCS accreditation and training, as well as a real-life<br />

case study with one of the contractors Marley has supported and helped to<br />

diversify their offering and make the profitable move into solar.<br />

Kingspan Insulation has also taken steps to support operatives with the<br />

changes to Part L, as the manufacturer has announced its ToolBox Talks<br />

onsite training service which helps customers ensure their work meets the<br />

new requirements. Jonathan Ducker, Head of Regulatory Affairs, discusses<br />

how the changes will impact project teams and goes into more detail about<br />

the benefits of the Toolbox Talks support service on page 48.<br />

Elsewhere in this issue, we get a roofing contractor’s perspective on the<br />

current challenges and opportunities within the sector as we put the<br />

questions to Old Plean Roofing on page 12; James Talman of the NFRC<br />

looks back on a tricky first half of <strong>2022</strong> for the roofing sector (page 14); and<br />

John Mercer discusses the key considerations when installing low pitch<br />

roofs on page 18. So read on for all this and much more!<br />

Matt<br />

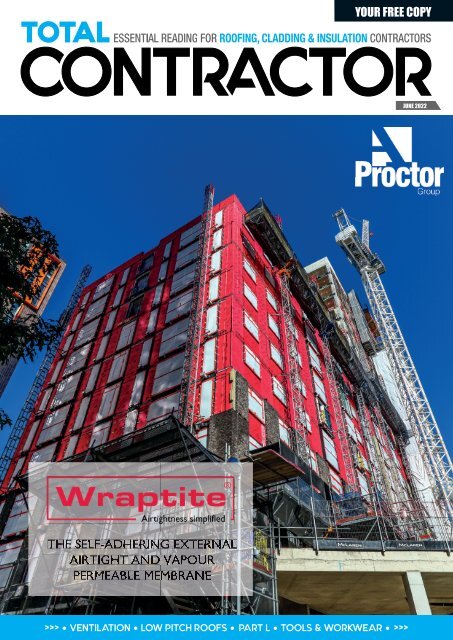

Front cover courtesy of the A. Proctor Group. Read<br />

the company’s latest Ask the A. Proctor Group feature on<br />

page 38. www.proctorgroup.com<br />

FOLLOW US @TOTCONTRACTORUK<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

Commercial Manager: Jake Roxborough<br />

DD: 01892 732 047<br />

Mob: 07956 133314<br />

Email: jakeroxborough@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

Supported by:<br />

T CK<br />

01<br />

*Discount applies to all trade customers and applied to the<br />

first, single item purc<br />

chase only of the Korniche Bifolding Door<br />

b i-folding<br />

doors<br />

Delivering the<br />

b est products,<br />

with the best service,<br />

at the best price<br />

C<br />

f<br />

q y<br />

madefortrade.co<br />

sales@madefortrade.co<br />

01642 610799<br />

ARTICULATED<br />

FU ULL BEARING<br />

ROLLERS<br />

A SMOOTH<br />

GLIDE<br />

EVERY TIME

Contents<br />

3 KEY FEATURES<br />

48<br />

12 TOTAL TALK<br />

Mark and Fiona Thornton of Old Plean Roofing<br />

answer our questions and give their<br />

perspective on sector challenges and<br />

opportunities, plus explain why roofers should<br />

be better regulated...<br />

16 THE NATURAL CHOICE<br />

SIG UK’s Ged Ferris looks at the benefits of<br />

natural slate when it comes to roofing, and<br />

explains why he feels this ancient building<br />

material has such a bright future<br />

48 IT’S GOOD TO TALK<br />

Jonathan Ducker of Kingspan Insulation explains<br />

how the manufacturer’s new Toolbox Talks<br />

service can help operatives meet the new Part L<br />

requirements for projects<br />

16<br />

FURTHER READING<br />

20 DON’T COMPROMISE<br />

Rob Cookson of Marley explains why the cheaper option<br />

is never the better option when it comes to battens<br />

26<br />

22 ROOF STRUCTURES<br />

Charlie Cannon of Beesley & Fildes advises on selecting<br />

the most appropriate timbers for roofing projects<br />

24 BACK TO BASICS<br />

Paul Lambert looks at the ventilation requirements for<br />

cold and warm pitched roofs<br />

26 SAFETY AT HEIGHT<br />

Gurjeev Bola of Werner answers the key questions for<br />

contractors when it comes to working at height<br />

38 ASK THE A. PROCTOR GROUP<br />

Do you need MVHR to achieve good airtightness in<br />

buildings? the experts at A. Proctor Group discuss...<br />

60 POWERED UP<br />

Makita UK’s Kevin Brannigan looks at the tools that can<br />

help roofers increase efficiency and work more safely<br />

4 TC JUNE <strong>2022</strong>

REGULARS<br />

14 NFRC ROOFING FOCUS<br />

James Talman looks back on the first half of <strong>2022</strong><br />

and explains how NFRC is working to help ease<br />

the pressure on roofers<br />

18 PERFECTLY PITCHED<br />

In his latest column, pitched roofing consultant<br />

John Mercer looks at the key considerations for<br />

roofers when constructing low pitch roofs<br />

44 KNAUF INSULATION<br />

TECH TALK<br />

Bradley Hirst provides his top tips for insulating<br />

suspended timber floors<br />

49 QI BY QI<br />

The experts at QI look at the factors currently<br />

influencing market pricing<br />

INDUSTRY NEWS<br />

06 Q1 <strong>2022</strong> SURVEY RESULTS<br />

NFRC’s latest sector survey shows contractors have had<br />

to raise their tender prices, but workloads are strong<br />

08 THE EXTENT OF TOOL THEFT<br />

A tool has been stolen every 17 minutes since March 2021<br />

according to Direct Line business insurance<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

16<br />

TOTAL<br />

CLADDING<br />

36<br />

TOTAL<br />

INSULATION<br />

44<br />

Pictured: Gavin Crane has been<br />

appointed the first CEO of Band<br />

of Builders, the fast-growing<br />

construction sector charity<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

10<br />

60<br />

JUNE <strong>2022</strong> TC 5

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

IOR STUDENT OF THE<br />

YEAR ANNOUNCED<br />

The Institute of Roofing<br />

(IoR) has named Ruth<br />

Evans as its Student<br />

of the Year.<br />

Ruth (pictured left with<br />

Kay Rose, right, CEO of the<br />

IoR) is an Internal Sales Manager for Polyroof<br />

and was presented with the award for achieving<br />

a distinction in the IoR’s Associate Course.<br />

Accredited by the Awarding Body of the Built<br />

Environment (ABBE), the IoR says its Associate<br />

Course is designed to help people progress in<br />

the roofing industry, especially those aiming to<br />

step up into supervisory or managerial roles.<br />

Participants gain knowledge on a range of<br />

areas, including project management, law,<br />

surveying and estimating, tendering and<br />

procurement, roof safety, and sustainability.<br />

Speaking about her achievement, Ruth said:<br />

“I am very surprised and happy to receive this<br />

award as there were many other welldeserving<br />

candidates. When I joined Polyroof<br />

seven years ago, I had no roofing experience. I<br />

had been working in a technical role in the<br />

chemicals sector for 12 years and decided to<br />

have a complete career change after time<br />

away with a young family. Although I had<br />

transferable skills and qualifications, these<br />

were not directly associated with the roofing<br />

industry. Taking part in the Associate Course<br />

has enabled me to gain a recognised<br />

qualification in roofing, helping me to further<br />

develop my career and providing existing and<br />

potential clients with confidence in my<br />

expertise. I have gained a lot of valuable<br />

knowledge, including a much broader<br />

overview of the roofing industry and an<br />

appreciation of applications that I am not<br />

directly involved in day to day.”<br />

For further info on the Associate Course,<br />

email: admin@instituteofroofing.org<br />

RISING COSTS PROMPT TENDER PRICE INCREASES<br />

The latest State of the Roofing Industry survey<br />

from NFRC (National Federation of Roofing<br />

Contractors) and Glenigan has revealed that a<br />

balance of 73 per cent of roofing and cladding<br />

contractors raised their tender prices in Q1 of<br />

<strong>2022</strong>. This is said to be an increase on a<br />

balance of 61 per cent in Q4 of 2021.<br />

Consequently, NFRC says clients seeking to have<br />

roof work done will be faced with higher prices,<br />

as contractors compensate for their costs rising.<br />

The survey of NFRC members also revealed that a<br />

balance of 90 per cent of respondents said that<br />

material prices had risen compared to Q4 of 2021.<br />

This is alongside a balance of 61 per cent of firms<br />

reporting that labour costs had increased.<br />

NFRC has also stated that responses related to<br />

the impact of the Russian invasion of Ukraine<br />

also indicated that energy costs are placing a<br />

burden on contractors, with 18 per cent noting an<br />

impact, whilst increased fuel prices were also<br />

noted.<br />

Despite these challenges, the survey shows<br />

roofers and cladders remained in demand. The<br />

survey points to increased enquiries for<br />

contractors across the UK, and shows workloads<br />

grew for the sixth consecutive quarter since the<br />

survey began, in late 2020. NFRC says this<br />

continued, steady pipeline of work meant that on<br />

balance contractors felt optimistic about the next<br />

twelve months.<br />

However, the survey also indicated that shortages<br />

of both materials and labour are still affecting<br />

many contractors, with NFRC saying this is<br />

possibly exacerbating price inflation as demand<br />

outstrips supply.<br />

The survey shows material shortages eased<br />

slightly from Q4 of 2021 but remained a<br />

significant challenge, as 29 per cent had difficulty<br />

in securing concrete roof tiles, and 26 per cent<br />

experienced the same with clay roof tiles. In a<br />

period of fresh government incentivisation of<br />

energy efficiency measures, the survey shows<br />

The Q1 <strong>2022</strong> survey shows that whilst challenges remain<br />

around pricing and lead times on materials, contractors are<br />

optimistic regarding workloads for the next 12 months.<br />

that one in five (20 per cent) reported that<br />

insulation was difficult to obtain – indicating no<br />

improvement on Q4.<br />

As skills shortages remain rife across the<br />

industry, with the Q1 survey seeing a balance of<br />

59 per cent of contractors reporting a worsened<br />

landscape when they sought suitable labour, the<br />

survey shows over a third (36 per cent) reported<br />

difficulty recruiting slaters and tilers, whilst<br />

22 per cent struggled to bring on built-up felt<br />

roofers, and 15 per cent said the same regarding<br />

cladders.<br />

James Talman, NFRC CEO, said: “With cost<br />

pressures weighing heavily on contractors, it is<br />

unsurprising that so many must raise their prices.<br />

Clients will need to be aware that work on their<br />

roofs will cost more. It is essential that there is<br />

close collaboration between suppliers,<br />

contractors and clients to ensure the burden of<br />

this inflation is fairly shared.”<br />

He added: “Despite these challenges, demand for<br />

work has remained strong, meaning contractors<br />

are right to remain hopeful in <strong>2022</strong>, and<br />

accordingly gain confidence to invest in skills.”<br />

Allan Wilén, Economics Director at Glenigan,<br />

commented on the results of the survey: “Roofing<br />

contractors’ workload grew firmly during the first<br />

quarter. New enquiries also improved, and firms<br />

expect a further strengthening in workload over<br />

the next 12 months. The rise in workload and<br />

expectations is despite disruption and cost<br />

pressures from labour and material shortages.”<br />

www.nfrc.co.uk<br />

6 TC JUNE <strong>2022</strong>

TAKE YOUR<br />

ROOFING BUSINESS<br />

TO THE NEXT LEVEL WITH NFRC<br />

Technical advice, the industry quality stamp and fantastic<br />

profile-raising opportunities—for all roofing disciplines<br />

NFRC sets the highest<br />

standards for work across<br />

all roofing and cladding<br />

disciplines. But we’re much<br />

more than the industry’s quality<br />

assurance stamp. Membership<br />

of the trade association offers<br />

contractors and suppliers a<br />

range of powerful technical<br />

and commercial advantages.<br />

These include a profile on our website<br />

and directory listing, making your<br />

business easier for clients to find. Plus<br />

exclusive access to technical support and<br />

updates, an exclusive health and safety<br />

app, and advice on training provision.<br />

For suppliers, key benefits include<br />

numerous opportunities to engage with<br />

roofing contractors all over the country.<br />

And as the voice of the roofing sector,<br />

NFRC makes our members’ views<br />

heard where it matters most. We work<br />

with government, standards bodies<br />

and training providers to promote the<br />

interests of the industry, and of the<br />

construction market as a whole.<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC trade<br />

membership benefits<br />

WHAT BEING AN NFRC MEMBER MEANS FOR YOU<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC supplier<br />

membership benefits<br />

EXCLUSIVE ACCESS TO OUR ROOFING<br />

CONTRACTOR MEMBERS<br />

Call 020 7638 7663 or visit<br />

nfrc.co.uk/TCbenefits to request our<br />

benefits brochure—and find out more<br />

about what NFRC membership can do<br />

for your business.<br />

NFRC GROUP ALSO INCLUDES<br />

Competent Person Scheme:<br />

self-certify roof refurbishment<br />

to Building Regs<br />

Roofing operatives<br />

competency accreditation<br />

Promoting roofing as a<br />

skilled profession and<br />

offering career advice<br />

UK’s premier event for the<br />

roofing industry<br />

Recognising best roofing<br />

training standards<br />

Supporting hardship, training/<br />

upskilling, volunteering<br />

and environment<br />

Contractors with knowledge,<br />

skills and experience of<br />

heritage roofing systems

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

TOOLS STOLEN EVERY<br />

17 MINUTES The A. Proctor Group, synonymous with<br />

FURTHER LEARNING WITH PROCTOR GROUP<br />

A tool has been stolen from a<br />

tradesperson every 17 minutes in<br />

England, Wales and Northern Ireland<br />

since March 2021, according to new<br />

analysis of police force data from Direct<br />

Line business insurance.<br />

In total, the analysis shows 31,161 tools<br />

were stolen, the majority of which (17,370)<br />

were taken by thieves breaking into vehicles.<br />

technically advanced thermal, acoustic and<br />

membrane solutions for the construction<br />

industry, has introduced a RIBA-Approved<br />

CPD seminar titled “Building Refurbishment,<br />

Systems for Retrofit & Conservation.”<br />

Aimed at architects, specifiers and contractors,<br />

attendees will receive technical advice from A.<br />

Proctor Group technical experts, providing the<br />

latest guidance on British and European<br />

Standards, compliance with Building<br />

Direct Line business insurance points out this<br />

Regulations, and learning on how to maximise • Introduction to PAS 2035 design framework<br />

growing problem is unsurprisingly hitting<br />

performance and avoid potential failures.<br />

tradespeople hard financially, as with the<br />

• Reducing condensation risks in pitched roof<br />

average value of a stolen tool costing £3,852,<br />

there has been £80 million worth of<br />

equipment taken over the last year,<br />

compounding the issues for tradespeople<br />

trying to bounce back from the pandemic.<br />

Building Refurbishment, Systems for Retrofit &<br />

Conservation Iain Fairnington, Technical<br />

Director, commented: “This session provides an<br />

overview of the factors to consider in<br />

refurbishment and conservation projects,<br />

refurbishment.<br />

The CPD serves the following RIBA Core<br />

Curriculum areas:<br />

• Design, construction, and technology<br />

including the basics of building physics as<br />

Alison Traboulsi, Product Manager at Direct<br />

• Legal, regulatory, and statutory compliance<br />

related to hygrothermal design. It also provides<br />

Line business insurance, commented: “At a<br />

an overview of the standards, regulations and • Knowledge level: General Awareness.<br />

time when people are facing serious cost of<br />

frameworks involved in designing for retrofit<br />

living challenges, heartless criminals are<br />

Iain Fairnington concluded: “Our CPDs have<br />

and conservation.”<br />

taking away the livelihoods of hardworking<br />

proved invaluable to professionals involved in<br />

tradespeople. It is not just the value of the<br />

tools stolen, theft can cause big delays on site,<br />

By the end of the session, Iain says attendees<br />

will have gained a greater understanding of:<br />

the design and construction of buildings.<br />

Through the CPD series, we aim to provide<br />

causing huge additional costs and causing<br />

technically accurate learning based on best<br />

• The retrofit and conservation considerations<br />

serious scheduling headaches. We urge those<br />

practices, innovation, and project examples to<br />

considering purchasing second-hand tools to<br />

question the provenance to limit opportunities<br />

• Knowledge of hygrothermal material<br />

properties and good design practice<br />

help individuals make informed choices when<br />

specifying product solutions for their projects.”<br />

for criminals to dispose of stolen goods.”<br />

• Introduction to hygrothermal assessment Book a CPD at www.ribacpd.com<br />

www.directlineforbusiness.co.uk/smallbusiness-insurance/tradesman<br />

standards<br />

www.proctorgroup.com<br />

MCRMA EXPANDS CPD OFFERING WITH CAVITY BARRIER FOCUS<br />

The Metal Cladding & Roofing Manufacturers<br />

Association (MCRMA) has added a new CPD<br />

module to its online CPD programme.<br />

stop and a cavity barrier; the regulations that<br />

apply to the different countries of the UK and the<br />

types of cavity barriers used in ventilated<br />

anticipated 60-120 minutes of professional<br />

development, and following successful completion<br />

of the CPD, a certificate is available for immediate<br />

rainscreen facades.<br />

download. All modules have been accredited by the<br />

The CPD module, ‘Cavity barriers for ventilated<br />

CPD Certification Service. The CPDs are available to<br />

rainscreen façades’, sets out to consider the key There are now 16 approved CPDs available on the<br />

anyone seeking to develop their knowledge and<br />

questions about cavity barriers and offers MCRMA website. The course material is studied<br />

skills within the metal building envelope sector.<br />

guidance for their correct specification, including offline with an online assessment component to<br />

an understanding of the difference between a fire verify knowledge. The modules represent an Find out more: www.mcrma.co.uk/online-cpds/<br />

8 TC JUNE <strong>2022</strong>

oof<br />

lantern<br />

10%<br />

NEW TRADE<br />

CUSTOMER<br />

DISCOUNT<br />

QUOTE CODE:<br />

TCK01<br />

glazed in<br />

seconds<br />

faster<br />

to fit<br />

Supply & install the multi-award-winning aluminium Korniche Roof Lantern.<br />

Fitted in minutes, glazed in seconds. The strongest lantern in class, available<br />

up to 3x2.5m in four glass panels and a maximum size of 6x4m<br />

Delivering the best products, with the best<br />

service, at the best price<br />

Contact Made for Trade for a Kwikquote today<br />

madefortrade.co | sales@madefortrade.co | 01642 610799<br />

*Discount applies to all trade customers and applied to the first, single item purchase only of the Korniche Roof Lantern

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

VISIBLE BENEFITS<br />

WITH SNICKERS!<br />

Whether its dusk,<br />

dawn or dark,<br />

Snickers<br />

Workwear has a<br />

superior range of<br />

Hi-Vis protective<br />

wear for both<br />

men and women<br />

to ensure comfort, safety and certified<br />

protection.<br />

The latest additions to the Hi-Vis range are<br />

the new Stretch Work Trousers made from<br />

the innovative Sorona sustainable<br />

performance fibre.<br />

Sorona delivers both environmental benefits<br />

and great performance. This recyclable, biobased<br />

fibre offers exceptional softness for<br />

maximum comfort, as well as excellent<br />

durability to help extend the lifetime of a<br />

garment.<br />

The new Hi-Vis Work Trousers with Sorona<br />

also offer long-lasting elasticity for ease of<br />

movement. Snickers Workwear says Sorona<br />

is also quick-drying, breathable and soft to<br />

the touch for optimal comfort and workday<br />

performance.<br />

With advanced designs, high-tech fabrics<br />

and performance reflection features, all<br />

Snickers Workwear Hi-Vis protective wear<br />

has durable colour-fast protection that it<br />

says will last through wash after wash,<br />

retaining shape, comfort and protection<br />

levels throughout the life of the garments.<br />

Added to which, Snickers Workwear High-<br />

Vis garments can be custom-profiled to<br />

ensure ‘stand out’ coverage for your<br />

corporate brand.<br />

www.snickersworkwear.co.uk<br />

More on workwear and tools from page 60<br />

Band of Builders has appointed its first Chief Executive Officer (CEO)<br />

as part of ambitious plans to significantly increase the registered<br />

charity’s ability to help members of the UK construction industry<br />

who are battling illness or injury.<br />

The charity says it has appointed Gavin Crane, its former Chair of<br />

the Board of Trustees, into the newly created role as it looks to build<br />

on its solid foundations to expand its scope, reach and influence<br />

within the construction industry.<br />

Mr Crane explained that his first challenge is to map out the strategy and direction of the charity<br />

for the next 5–10 years as it looks to build on its three cornerstones of providing practical support<br />

by completing projects, offering financial help to tradespeople facing hardship, and making<br />

wellbeing services readily accessible to anyone in the construction industry who is in crisis.<br />

“In its simplest form, the new CEO role will mean ensuring that more people support Band of<br />

Builders, so we can help more people,” said Mr Crane.<br />

“It’s a very exciting time to be part of Band of Builders because the charity is gaining huge<br />

momentum, which is all down to the commitment of so many of our base of volunteers, who give<br />

their time generously to support the charity and its activities. It’s also down to the benefactors<br />

and sponsors who have given us significant financial support – in many cases making us their<br />

official charity partner. The board of trustees has ambitious plans for the growth of the charity,<br />

and the creation of this role is a huge statement of intent. I’m looking forward to being at the<br />

heart of taking Band of Builders to the next level.”<br />

As well as being tasked with building more strategic partnerships and developing more<br />

fundraising opportunities, Mr Crane also has a wider-reaching ambition to be a positive voice<br />

on issues affecting the construction industry, such as apprenticeships, the skills gap, inclusion<br />

and gender discrimination.<br />

www.bandofbuilders.org<br />

MGMA CONTINES TO GROW<br />

The Metal Gutter Manufacturers Association<br />

(MGMA) has welcomed two new member<br />

companies to the Association: Weatherfast<br />

Limited and JPM Pressbrake Sections<br />

Limited.<br />

Weatherfast Limited, based in Great Barr,<br />

Birmingham, produce the WeatherFOLD gutter<br />

liner system which has been developed to fold<br />

with ease into any existing gutter, and once<br />

welded the system becomes seamless allowing<br />

water to flow freely towards outlets, whilst the<br />

steel base enables the liner to be easily<br />

maintained by simply brushing out.<br />

JPM Pressbrake Sections Limited, based in<br />

Dudley, is one of the largest fabricators of single<br />

skin and insulated composite gutters. The<br />

company also produces fascia gutters and all<br />

ancillary items such as stop ends, outlets,<br />

corners, weirs and rainwater pipes.<br />

The MGMA currently has 16 members and says<br />

membership is open to all companies who<br />

manufacture and market metal rainwater<br />

systems, and to those companies who provide a<br />

range of professional support services to the<br />

metal rainwater systems industry.<br />

www.mgma.co.uk<br />

Above: Gavin Crane has been<br />

appointed the first CEO of Band<br />

of Builders.<br />

10 TC JUNE <strong>2022</strong>

i-folding<br />

door<br />

15%<br />

GLAZED IN<br />

SECONDS<br />

INTRODUCTORY<br />

DISCOUNT *<br />

DISCOUNT CODE<br />

TCK02<br />

FIT FASTER<br />

CLIP BEAD<br />

Patented clip bead delivering the fastest glazing time.<br />

Trickle vents positioned in frame - no need for extenders! Full bearings and<br />

stainless steel hardware for the smoothest glide every time. All with a 10 year<br />

manufacturer’s warranty.<br />

Delivering the best products, with the best<br />

service, at the best price<br />

Contact Made for Trade for a Kwikquote today<br />

madefortrade.co | sales@madefortrade.co | 01642 610799<br />

*<br />

Discount applies to all trade customers and applied to the first, single item purchase only of the Korniche Bifolding Door | *Korniche Bi-folding<br />

door price is based on 5-5-0 configuration 3750 x 2000 , stock colour, delivered. Unglazed. Price is correct at point of publishing. Delivery<br />

restrictions apply. Product specification and prices may be subject to change without prior notice.

Total Talk: Old Plean Roofing<br />

“ROOFERS SHOULD BE BETTER<br />

REGULATED & HELD ACCOUNTABLE”<br />

We put the questions to Mark and Fiona Thornton who run Old Plean Roofing, a family<br />

firm based in Stirling, discussing current market trends, challenges and opportunities,<br />

the perennial problem of recruiting skilled workers, why roofers should be better<br />

regulated and held accountable for their actions, and so much more…<br />

Can you tell us a bit about Old<br />

Plean Roofing and the types of<br />

projects you get involved with…<br />

Old Plean Roofing is a family firm –<br />

we’re based in Stirling and are proud to<br />

be members of NFRC, the Guild of<br />

Master Craftsmen and the trading<br />

standards Buy with Confidence scheme.<br />

Currently we employ a team of five<br />

office-based staff and eight on-site<br />

operatives. We specialise in flat and<br />

pitched roofing and take on a whole<br />

range of projects including roof rebuilds<br />

and repairs and maintenance contracts.<br />

What was your path into construction and<br />

to your current position?<br />

Mark – I began treading my path in 1986 starting<br />

as a labourer in a large roofing firm and<br />

progressing slowly through the ranks to<br />

Construction Manager. In the mid-2000s, I<br />

decided to follow a different path and worked for<br />

a couple of well-known construction companies<br />

in technical roles, however, I kept returning to<br />

roofing. Starting Old Plean Roofing was therefore<br />

a natural progression. I am passionate about<br />

raising standards in roofing and seeing roofers<br />

trained and upskilled.<br />

Fiona – My background is in counselling which<br />

is a bit different to roofing! I now manage all the<br />

office based activities; a normal day can include<br />

sorting out PPE, chatting to clients or filling out<br />

tender documents. Every day is different and<br />

though it can be a bit stressful, work is never<br />

dull.<br />

Mark Thornton (front row, right) with the Old Plean Roofing team.<br />

“How do we move<br />

forward? Incentivise<br />

and train”<br />

You must have worked on some difficult<br />

projects over the years; does one in<br />

particular stand out?<br />

Plenty of projects spring to mind – particularly<br />

those which throw you a curve ball! However, one<br />

that is high up on the list is a local project where<br />

we were replacing the flat roof only to discover<br />

that it was not only the roof which needed to be<br />

replaced but so did most of the timbers. For years<br />

the void had not been insulated resulting in<br />

condensation build-up. We tackled this one<br />

professionally though, as always, and ensured<br />

the building remained fully water-tight at all<br />

times.<br />

What about difficult customers – do you<br />

get many of these and how do you deal<br />

with them?<br />

We work very closely with all our clients<br />

and usually get the job over the line<br />

without much difficulty. However, as we<br />

all know, issues out of our control will<br />

arise whether it be disruption due to<br />

weather or difficulty in getting materials<br />

to site. Communication is therefore key<br />

to the relationship and we strive to keep<br />

our clients informed throughout the quote<br />

and project process.<br />

Tell us about a current project<br />

you’re working on…<br />

At the moment we have several projects<br />

on the go across the Central Scotland area. In<br />

particular we have recently just started a large<br />

re-roof outside Falkirk for a domestic customer<br />

which includes replacing the fascia, soffit and<br />

gutters around the property. We are also carrying<br />

out repairs and maintenance at a large<br />

commercial property in Stirling.<br />

You seem like a company who won’t cut<br />

corners and feel strongly about how the<br />

sector is perceived by homeowners and<br />

customers. Unfortunately we still hear a<br />

lot about rogue roofers – do you feel more<br />

can be done to target individuals and<br />

companies who rip customers off? and if<br />

so, should it be coming from the industry<br />

or Government?<br />

We have always felt that roofers should be better<br />

regulated so they can be held accountable for<br />

their actions, and we have had to follow up on so<br />

many jobs where rogue roofers have left carnage<br />

in their wake. Government needs to do more to<br />

combat this.<br />

12 TC JUNE <strong>2022</strong>

With this in mind, the NFRC has launched<br />

the RoofCERT accreditation scheme which<br />

longer-term will hopefully promote<br />

roofers who have best practice and the<br />

customers’ interests at heart – are you<br />

aware of the RoofCERT scheme and is it<br />

something you will adopt for your<br />

business and team?<br />

Mark – I am a huge advocate of RoofCERT and<br />

was involved early on during my time as Roof<br />

Training Manager for the Single Ply Roofing<br />

Association. It is a fantastic scheme which needs<br />

to be utilised more – particularly here in<br />

Scotland.<br />

Moving on from this – the skills issue and<br />

attracting new entrants to the sector is a<br />

perennial problem which appears to be getting<br />

worse rather than better. How are you finding<br />

things with regards to recruiting workers, and<br />

what more do you think needs to be done to<br />

attract new entrants to roofing and the wider<br />

construction industry?<br />

It is extremely difficult to attract and recruit<br />

suitable workers. The industry as a whole is<br />

experiencing this. How do we move forward?<br />

Incentivise and train. Pump more money into roof<br />

training groups to allow them to offer more<br />

substantial training at a cost that is more<br />

affordable. We should also enforce small<br />

businesses and one-man bands to train and<br />

achieve qualifications in their roofing discipline.<br />

Issues around supply of materials such as<br />

roof tiles and timber are well<br />

documented, often leading to longer lead<br />

times and some price rises – has this<br />

been your experience and if so, how have<br />

you adapted to ensure projects run<br />

smoothly?<br />

The issue of long lead times has hit the<br />

construction industry hard. Projects are being<br />

pushed back or even put on the back burner. I’m<br />

quite hopeful this will change in time, however,<br />

it’ll likely be 18 months before any change will be<br />

recognised.<br />

“I am a huge advocate of RoofCERT – It is a<br />

fantastic scheme which needs to be utilised<br />

more – particularly here in Scotland”<br />

What have you learned about your<br />

business from working throughout the<br />

pandemic – has it impacted the way<br />

you’ll approach work, the supply chain<br />

and the types of projects you might get<br />

involved with going forward?<br />

Everyone needs a roofer, pandemic or not. We<br />

approach each and every client with empathy and<br />

work hard to ensure we deliver on our promise,<br />

whatever that may be.<br />

Online reviews appear to play a much<br />

bigger part in a homeowner / customer’s<br />

decision making process these days; what<br />

is your opinion of online reviews – are<br />

they a blessing or a curse for roofers?<br />

They certainly have a place but we find that word<br />

of mouth referrals are still the main source of the<br />

majority of our enquiries.<br />

“Price is a big driver in<br />

today’s market,<br />

especially now as the<br />

cost of living is rising”<br />

Is price the main driver for projects in<br />

today’s market?<br />

Price is a big driver in today’s market, especially<br />

now as the cost of living is rising. However, we<br />

have found that an honest and systematic<br />

approach to each of our clients means that cost<br />

usually takes a back seat.<br />

What’s the most satisfying thing about<br />

your job?<br />

The lovely people we get to meet on a daily<br />

basis. Each one has a different story to tell and<br />

we are proud to add our little chunk of life to<br />

theirs.<br />

And the most frustrating?<br />

Having to let people down because of situations<br />

out of our control – the biggest one being the<br />

weather!<br />

What’s your most important tool, either in<br />

the office or on site?<br />

Our operatives on site. They are continually<br />

complimented for their knowledge, expertise and<br />

for being extremely polite and quiet!<br />

Following what has been a challenging<br />

period for roofing and the wider<br />

construction industry, are there reasons<br />

to be optimistic going forward?<br />

Yes, definitely. People continue to need roofers<br />

and contractors and we’re getting lots of<br />

enquiries and are extremely busy. We know we<br />

will face future challenges – particularly in the<br />

labour market and that’s something we aim to<br />

combat by investing in training our staff.<br />

It’s also likely we will hit a recession in the<br />

coming months which could be a cause for<br />

concern but generally we are optimistic about the<br />

future.<br />

What can we expect from Old Plean<br />

Roofing in the coming years?<br />

We will continue to offer the same reliable and<br />

transparent service as we have always done as<br />

we strive to become the roofing builder and<br />

maintenance contractor of choice in Central<br />

Scotland. We also plan to expand our<br />

maintenance and repairs division and offer new<br />

services.<br />

Contact Old Plean Roofing:<br />

01786 811 033<br />

www.oldpleanroofing.co.uk<br />

@oldpleanroofing<br />

JUNE <strong>2022</strong> TC 13

NFRC Roofing Talk<br />

CHALLENGES PERSIST BUT NFRC IS<br />

WORKING TO EASE THE PRESSURE<br />

James Talman, NFRC’s CEO, takes a look back at the first half of <strong>2022</strong>, which has<br />

presented a number of obstacles for roofers and the wider industry to contend with,<br />

and outlines some of the work NFRC has been been putting in to support the sector...<br />

As we pass the halfway point of <strong>2022</strong>, it’s<br />

useful to reflect on the progress we’ve made<br />

in the year so far. In the first six months of<br />

the year – which many hoped would bring relief<br />

from the continued consequences of the Covid-19<br />

pandemic – contractors have faced a number of<br />

challenges to contend with, including rapid cost<br />

inflation, ongoing poor material availability and<br />

labour shortages, new regulation and an end to<br />

the red diesel rebate, to name just a few. NFRC is<br />

intent on supporting members and the wider<br />

industry to weather the storm, and below I have<br />

outlined a small selection of the work we have<br />

kickstarted in the first half of <strong>2022</strong>, responding to<br />

both longstanding and emerging challenges.<br />

Meeting the skills challenge<br />

It will not be news to anyone that roofing,<br />

cladding and the wider construction industry face<br />

a skills challenge. As an industry we struggle to<br />

find the people with the right skills to do the job,<br />

and NFRC’s quarterly State of the Roofing Industry<br />

survey, which we have compiled since late 2020,<br />

has consistently confirmed this, with firms<br />

struggling to recruit in roles from slaters and<br />

tilers, to built-up felt roofers to estimators. CITB<br />

estimated in 2021 that the industry needed<br />

217,000 new workers over the following five years<br />

to plug the gap. As demand persists, we run the<br />

risk of cowboys taking on work that should be<br />

done by someone with the appropriate skills.<br />

<strong>2022</strong> began with a key move from NFRC on this<br />

front, with the launch of the NFRC Careers<br />

Service, a resource available to anyone online at<br />

nfrc.co.uk/careers, targeted at those seeking to<br />

enter the industry and employers looking to<br />

attract, recruit and retain new talent.<br />

NFRC members also have access to our<br />

Head of Careers – Ruth Scarrott, who<br />

can aid firms in improving their offer<br />

to candidates, help demystify the<br />

processes of recruiting new people,<br />

and support the development of training<br />

and upskilling provision.<br />

In recent weeks, the NFRC Charitable Trust has<br />

also made available a dedicated Inclusion Fund,<br />

with funding available for member companies to<br />

provide insight and improve diversity in the<br />

sector through insight days, site visits and online<br />

activities. This is to engage people from diverse<br />

backgrounds in learning about careers and<br />

opportunities in roofing, raising the profile of the<br />

industry as a career choice. NFRC members can<br />

express their interest via the NFRC website. This<br />

initiative will contribute further to our efforts to<br />

make the industry more accessible, so that we<br />

can attract as much talent as possible.<br />

Helping the industry find its feet on<br />

sustainability<br />

The end of 2021 saw the release of Future (P)roof,<br />

a report commissioned by the NFRC Charitable<br />

Trust and conducted by the University of<br />

Southampton, to explore the role of our rooftops in<br />

fighting the effects of climate change and helping<br />

to ensure our buildings can stand up to warmer,<br />

wetter weather. We have followed this up in <strong>2022</strong><br />

with a number of new and continued initiatives.<br />

One new initiative is the NFRC Sustainability<br />

Group, made up of knowledgeable and<br />

enthusiastic individuals from both NFRC trade<br />

and supplier member organisations, aiming to<br />

tackle key challenges that businesses face in<br />

James Talman, CEO of NFRC.<br />

terms of sustainability and their<br />

environmental impact, currently<br />

emphasising the issue of waste.<br />

NFRC has also recently gained<br />

representation on the City of London’s<br />

Skills for a Sustainable Skyline Taskforce, and will<br />

be contributing to work on meeting the need for<br />

green skills in the capital.<br />

Facing mounting pressures is easier when<br />

there’s help on hand<br />

Numerous challenges from inflation, to heavy<br />

workloads and not enough workers, to a wave of<br />

new regulations, can take their toll on firms, and<br />

many individuals have felt considerably under<br />

pressure, whether that’s physically, mentally or<br />

financially.<br />

NFRC saw the need to help, and in March<br />

launched a partnership with ARAG, offering<br />

members a free legal, tax and HR helpline. From<br />

contract disputes to corporation tax, they are on<br />

hand to assist. There is also a counselling<br />

helpline for member companies and their<br />

employees – an important part of the service, as<br />

Mates in Mind reported in February this year that<br />

a third of construction workers say they<br />

experience an elevated level of anxiety every day.<br />

As an industry we find ourselves still facing a host<br />

of challenges, but NFRC is doing everything it can<br />

to make sure that businesses and individuals in<br />

roofing are well equipped to face them.<br />

Contact NFRC<br />

www.nfrc.co.uk<br />

@TheNFRC<br />

14 TC JUNE <strong>2022</strong>

Handrails:- EasyGuard<br />

free-standing Guardrails<br />

*CurveyGuard – an aesthetically pleasing curved rail.<br />

*EasyGuard – raked or straight legs dependant on<br />

application. *FoldGuard – folding handrail.<br />

Trip hazard reduction – long thin base-plates with<br />

Counterweights used on un-secured ends only. Placed at 2m<br />

centres maximum to enable use for leading edge protection.<br />

Galvanised or powder coated finish. Protective mats 5mm<br />

bonded to the base plates.<br />

Standards – Exceeds Class A EN13374- Class A; For<br />

leading edge protection HSE/SR 15, September 1988.<br />

Nationwide delivery or contract installation. – Free material<br />

quantifying service – info@safetyworksandsolutions.co.uk<br />

Ladders:- Easy Fit<br />

Compliant to both BS/EN 5395 and 14122 –<br />

To comply with the standards for<br />

permanent ladders all mild steel then hot<br />

dipped galvanised to BS/EN 1461.<br />

All typical ladders bespoke – email<br />

info@safetyworksandsolutions.co.uk for a<br />

survey check sheet.<br />

Easy Fit, all ladder components are Easy<br />

to assembly; in manageable parts Easy to<br />

handle and install.<br />

Rest Platforms and ladders with special<br />

fixing requirements; solutions provided by<br />

Safetyworks in house.<br />

(All components for British Standard<br />

compliant ladders require steel components<br />

with timber and aluminium recommended<br />

for temporary use only)<br />

HANDRAILS<br />

-<br />

LIFELINES<br />

-<br />

WALKWAYS<br />

-<br />

FALL GUARDS<br />

-<br />

FLEXIDECK<br />

-<br />

DEMARKATION<br />

-<br />

LADDERS<br />

-<br />

STEELWORK<br />

-<br />

Tel: 01487 841400<br />

www.safetyworksandsolutions.co.uk

Natural Slate<br />

ANCIENT SLATE: A MATERIAL<br />

FOR THE FUTURE<br />

Ged Ferris, Category Manager at SIG UK, sees a buoyant future for that most ancient<br />

building material – natural slate.<br />

Natural slate is a metamorphic rock formed<br />

from layers of clays or volcanic ash,<br />

transformed over millenia by heat and<br />

pressure. It’s first confirmed use as a roofing<br />

material dates back to the Roman era. Now this<br />

most ancient material is set for a major revival as<br />

it is a perfect fit for an industry that is rapidly<br />

adopting more sustainable building practices.<br />

In just about every sector from food to fashion we<br />

are waking up to an understanding that<br />

the most sustainable products are<br />

likely to be those that take the<br />

least processing. In the<br />

building sector, the<br />

immediate challenge is to<br />

move the whole construction<br />

process towards net zero –<br />

reducing the embodied carbon of<br />

building materials as much as possible.<br />

Slate takes very little energy to produce. It’s a<br />

mined product and the majority of its carbon<br />

footprint comes from its transport, rather than its<br />

production. The Inventory of Carbon and Energy,<br />

an independent database at the University of<br />

Bath, has compared natural slate with other tiling<br />

options and concluded that while there is a large<br />

variation in the embodied carbon of natural<br />

roofing slates, it will be approximately 16% that<br />

of other roofing materials.<br />

Many of the major housebuilders have stated<br />

their intention to be zero carbon by 2050 and are<br />

already putting pressure on their supply chains to<br />

make a positive contribution. While energy<br />

intensive product manufacturers work on<br />

reducing the impact of their processes, slate<br />

already ticks this particular box.<br />

Equally significant is a growing focus on the<br />

Above: Summer Lake Development, The Cotswolds – credit Fosse Specialist Roofing.<br />

Left: Windsor Court Care Home in Malvern – credit Lawrence Baker. Both images feature SIGA Slate.<br />

principle of circularity in<br />

construction. Advocates point<br />

out that natural resources are<br />

finite and that single-use materials<br />

are simply not sustainable. In the most<br />

extreme model, buildings are viewed as active<br />

warehouses for products. When the building has<br />

had its time, the products are dismantled and<br />

used to create the next structure.<br />

It's a vision for the future and we are a way off<br />

yet, but natural slate turns out to be ahead of its<br />

time. The material itself has excellent resistance<br />

to weather, with the best quality slates lasting<br />

hundreds of years. When a slate roof needs<br />

replacing it is often the fixings or felt that are<br />

causing the problem. Slates can easily be<br />

reclaimed and used again. There is already a<br />

market for reclaimed slates and some<br />

commentators estimate that as much as 5% of<br />

roofing slate in use today may have come from<br />

another roof.<br />

And finally, there is the combination with solar<br />

technology. As we move towards the extreme<br />

“When a slate roof<br />

needs replacing it is<br />

often the fixings or felt<br />

that are causing the<br />

problem”<br />

energy efficiency requirements of the Future<br />

Homes Standard, new homes will effectively need<br />

to include renewable technology to meet the<br />

emissions performance targets. Solar PV panels<br />

will undoubtedly be a big part of the mix and<br />

integrating the panels into a roof finished with<br />

dark grey tiles provides a consistent appearance.<br />

For all these reasons, we are expecting to see<br />

sales of natural slate performing strongly. SIG<br />

Roofing has a number of options with our various<br />

ranges of natural slate coming from quarries in<br />

the UK, Spain, Canada and Brazil.<br />

Contact SIG Roofing<br />

www.sigroofing.co.uk<br />

@SIGRoofing<br />

16 TC JUNE <strong>2022</strong>

UK DISTRIBUTOR OF<br />

Superior, long-lasting waterproofing membranes<br />

FOR THE BEST IN SINGLE PLY MEMBRANES<br />

- WE’VE LITERALLY GOT IT COVERED.<br />

Discover more at www.alwitra.co.uk<br />

01202 785200 sales@alwitra.co.uk www.alwitra.co.uk<br />

UK Head Office Unit 9-11 Fleets Industrial Estate, Willis Way, Poole, Dorset BH15 3SU

Perfectly Pitched<br />

LOW PITCH ROOFS<br />

Pitched Roofing Consultant John Mercer discusses the<br />

key considerations when constructing low pitch roofs.<br />

Of the many enquiries I receive, one of the<br />

most popular topics relates to low pitch<br />

roof construction. Experience has taught<br />

us that the ideal range of roof pitches for roof tiles<br />

and slates is anywhere between 30 to 50º. During<br />

rainfall or wind-driven rain spells, water is shed<br />

from one double lapped tile or slate course to the<br />

next one below, the tiles and slates having sufficient<br />

lap and pitch to prevent any sideways or upwards<br />

‘creep’ of the water through capillary action from<br />

penetrating the roof covering. Single lapped tiles<br />

perform the same function by virtue of their lap<br />

over the course below and side laps which can be<br />

either simple overlaps or more sophisticated<br />

interlocks with water bars and troughs.<br />

Although the trend in recent years is to build<br />

homes with steeper pitch roofs to provide living<br />

spaces within the roof, there are many tiles and<br />

slated roofs constructed at low pitches to reduce<br />

construction costs, for example, or reduce a<br />

building’s impact on the horizon, or very<br />

commonly, to enable the building of a home<br />

extension to fit below the upstairs windows.<br />

Roof tile manufacturers have developed and<br />

continue to develop roof tiles and associated<br />

systems that are suitable for use at low pitches.<br />

However, under certain weather conditions, water<br />

may be driven through the slating or tiling and must<br />

be captured by the underlay system and drained<br />

away to the gutter. Certainly, at low roof pitches,<br />

the risk of water ingress increases through or<br />

around the tiling, simply because everything is<br />

working closer to its limits. For example, though<br />

the individual components have been<br />

thoroughly tested and perform fine at the<br />

stated minimum roof pitch, constructing<br />

the roof with the same accuracy as<br />

that used under test conditions can<br />

be difficult. It only takes a small<br />

gap or two in the tiling where it<br />

passes over a flashing and the risk of water<br />

ingress is increased.<br />

BS 5534 states that the underlay layer should<br />

provide a continuous under-roof barrier to water,<br />

snow, and dust, and should be capable of<br />

draining any moisture that might be deposited<br />

onto the surface of the underlay to the roof<br />

drainage system. Although BS 5534 does not<br />

provide specific design details on how to<br />

construct a waterproof underlay system, it does<br />

recommend that consideration be given to sealing<br />

any penetrations through the underlay, such as<br />

nail holes, with suitable tapes or sealants.<br />

The design recommendations provided in<br />

BS 5534 are an acknowledgement that there will<br />

be occasions when rainwater finds its way<br />

through the tiling and onto the underlay, so the<br />

roof should be regarded as a system, rather than<br />

simply a collection of individual components.<br />

It is important to follow the installation<br />

recommendations given in BS 5534 and BS 8000-6<br />

for the underlay. Underlay laid unsupported, directly<br />

over the rafters or counterbattens, must be laid with<br />

a sufficient drape to enable water to run freely into<br />

the underlay troughs and under the tile battens<br />

towards the gutters. If the underlay is laid too tight,<br />

without a drape, water on the underlay will be<br />

trapped behind the tile battens and will eventually<br />

find its way through the batten nail holes in the<br />

underlay and leak into the roof structure.<br />

On low pitched roofs, rainwater is more likely to<br />

be driven through the tiling during heavy winddriven<br />

rain events, though roof design<br />

battens<br />

Counterbattens<br />

should consider other factors<br />

too. For example,<br />

manufacturers usually<br />

set a maximum rafter<br />

length for their tiles when<br />

used at the minimum<br />

recommended roof pitch. It is<br />

Nail tape<br />

Tile<br />

Summary<br />

• Observe the tile manufacturer’s<br />

recommendations on minimum roof pitch<br />

and maximum rafter length.<br />

• Avoid draining water from higher roof<br />

slopes onto a low-pitched extension roof.<br />

• Ensure the underlay is detailed correctly at<br />

junctions such as abutments and properly<br />

sealed around penetrations such as pipes and<br />

roof windows. Use adhesive tapes where<br />

necessary.<br />

• Consider the use of counterbattens with nail<br />

tape between the counterbattens and underlay<br />

to seal the nail holes through the underlay.<br />

important to observe any such restrictions by, for<br />

example, raising the roof pitch if possible, or<br />

dividing the roof into shorter sections with a<br />

gutter part way down the slope. On single storey<br />

extensions, care should be taken to avoid<br />

draining a higher roof onto the low pitch extension<br />

roof via a valley or through a gutter downpipe.<br />

Even dormer windows can pose a risk if the<br />

rainwater from the dormer roof is drained directly<br />

onto the low pitch roof.<br />

It is equally important to detail all junctions<br />

correctly when installing the underlay, with the<br />

correct turn ups at abutments and suitably<br />

sealed around penetrations such as pipes and<br />

roof windows.<br />

There are no special measures or variations to<br />

sub-roof designs that relate to roof pitch in<br />

BS 5534. However, there are methods that can be<br />

adopted to ensure the underlay is watertight. For<br />

example, consider using counterbattens between<br />

the underlay and tile battens, with a bituminous<br />

nail tape fitted between each counterbatten and<br />

the underlay (see image left). The counterbattens<br />

will ensure that there is a path for water to reach<br />

the gutters without the need for a drape, and the<br />

nail tape will seal the batten and counterbatten<br />

nail holes through the underlay.<br />

Contact John Mercer<br />

www.johnmercerconsultant.co.uk<br />

18 TC JUNE <strong>2022</strong>

THE TOTAL PACKAGE<br />

Leading building materials manufacturer, well as minimizing condensation risk by<br />

Glidevale Protect, has provided a full range of introducing natural ventilation into each building<br />

roofing, ventilation and construction products to help create healthy homes.<br />

as part of a major new social housing development<br />

Products supplied and installed on this<br />

in Belfast, which is taking a fabric first approach to<br />

development included the Protect VP300 vapour<br />

building healthy, sustainable homes.<br />

permeable pitched roofing underlay which was<br />

One of the largest mixed tenure developments to teamed with Protect Fulmetal RediRoll, a universal<br />

be constructed in Northern Ireland to date, the dry fix ventilated ridge and hip system, alongside<br />

new scheme for a leading social housing provider tile vents for the roof. Glidevale Protect also<br />

includes 244 homes, which are a mix of social supplied Protect TF200 Thermo for the external<br />

and affordable housing, a community facility, a timber frame walls – a low emissivity, insulating<br />

linear park and a children’s play park.<br />

reflective membrane and the non-reflective<br />

external breather membrane, Protect TF200, was<br />

Working with main contractor Kevin Watson<br />

used on spandrel panels. These provided weather<br />

Group, established Belfast-based roofing<br />

protection during the construction, as well as<br />

subcontractor Prentice Roofing and offsite<br />

helping to avoid interstitial condensation risk<br />

manufacturers and installers of the timber frame<br />

within the wall construction. Cavity trays,<br />

panels Leadon Timber Frame, Glidevale Protect<br />

airbricks and loft access hatches from Glidevale<br />

delivered a complete solution of products to<br />

Protect completed the project.<br />

improve thermal efficiency and airtightness, as<br />

Belfast project: The Protect VP300 underlay installation.<br />

Cornelius Ward, Director at Kevin Watson Group,<br />

said: “In order to deliver the highest quality<br />

standards to meet the client’s expectations, we<br />

like to collaborate with supply chain partners who<br />

can ensure our sub-contractors are provided with<br />

top performing building materials using a fabric<br />

first approach. Glidevale Protect’s wide breadth<br />

of solutions used on this development meant full<br />

peace of mind during the construction process,<br />

helping to create energy efficient and healthy<br />

homes.”<br />

Contact Glidevale Protect<br />

www.glidevaleprotect.com<br />

Email: info@glidevaleprotect.com<br />

For further r<br />

inform<br />

ation<br />

or a hire quotation call<br />

01858 412 100<br />

Email: sales@cookerhire.com<br />

www.cookerhire.com

Battens<br />

DON’T COMPROMISE ON QUALITY<br />

An essential component of a roof, battens are structurally important, so Rob Cookson,<br />

National Business Development Manager at Marley, says it makes sense to use the<br />

best. However, as he points out, current supply issues have meant that inferior – and<br />

crucially less safe – battens could have entered the market, so whilst some roofing<br />

battens may be slightly cheaper, Rob says they could cause problems down the line...<br />

As Rob Cookson, National Business<br />

Development Manager at Marley, points<br />

out: “When it comes to battens, it’s<br />

important that roofers understand what they’re<br />

buying – not all battens are the same. Cheaper<br />

and often inferior battens may carry<br />

imperfections that can cause breakages and lead<br />

to accidents on site, especially since being weight<br />

bearing, as battens are used as a step ladder<br />

whilst a contractor is working on the roof.<br />

“With site safety being of paramount importance,<br />

and the safety of the team being the ultimate<br />

responsibility of the contractor, choosing to<br />

compromise on the quality of a safety-critical<br />

product on a roof, such as battens, could well be<br />

a costly – and avoidable – mistake.’<br />

Rely on Red<br />

Critically, only battens that have been pre- or<br />

factory graded to BS 5534 can be called or used<br />

as ‘roofing battens’, such as Marley’s JB Red, a<br />

high-quality roofing batten. Marley also says it’s<br />

the only UK factory-graded batten available to the<br />

roofing industry with BBA certification.<br />

Marley says it sets the standard for graded<br />

roofing battens, and with its wealth of experience,<br />

expertise and knowledge of the roofing and timber<br />

markets, Marley says it sources the timber for its<br />

JB Red battens from its extensive network of<br />

Scandinavian saw mills.<br />

Rob continued: “Selecting the correct timber to<br />

use for roofing battens is of paramount<br />

importance. We only source slow-grown timber<br />

which ensures strength and durability, whilst our<br />

battens are cut from kiln-dried sideboards to<br />

provide maximum strength and stability, plus they<br />

Above: Marley’s Goldeneye scanner. Right: JB Red batten.<br />

are less likely to distort.”<br />

Produced at its specialist manufacturing site in<br />

Gainsborough, Marley says JB Red battens are<br />

stringently tested and graded using its state-ofthe-art,<br />

dedicated roof batten scanning line –<br />

Goldeneye.<br />

Scanning each timber batten intricately to the<br />

millimetre, Marley says Goldeneye’s computercontrolled,<br />

dedicated laser and camera grading<br />

line produces battens graded to the performance<br />

regulations of BS 5534 both quickly and<br />

accurately. The manufacturer says it is important<br />

to note that currently, many other suppliers within<br />

the UK batten market rely on visual grading only.<br />

In addition, MicroPro, a preservative treatment<br />

that protects against wood rotting, fungi and<br />

insects – and gives a 60-year desired service life<br />

– vacuums a preserving red pigment into the<br />

timber ensuring that the resulting battens are<br />

both completely protected, and also transformed<br />

to give their distinctive and easily identifiable red<br />

colour.<br />

Visibly exceeding standards<br />

Marley points out whilst JB Red completely meets<br />

the NHBC requirements for fully graded roofing<br />

battens, the red colour means that they are highly<br />

visible on site, making it easy for Local Authority<br />

Building Control, NHBC, and other inspectors to<br />

see that high-quality, pre-graded and compliant<br />

battens have been used.<br />

An easy choice<br />

Rob continued: “Our JB Red battens help to make<br />

your life on site both easier and safer. Being pregraded,<br />

no further grading on site is required,<br />

saving you time. Being red in colour, means that<br />

they are easily identifiable, making any<br />

inspector’s – as well as your – job easier.<br />

“Finally, the exceptionally high quality of<br />

manufacture at every stage – from integral<br />

strength and consistency of size to thoroughly<br />

protective treatments giving real peace of mind –<br />

makes JB Red battens an easy choice for any<br />

roofing contractor to make.”<br />

Contact Marley / JB Red<br />

www.marley.co.uk/roofing-batten/<br />

jb-red-batten<br />

01283 722222<br />

20 TC JUNE <strong>2022</strong>

Roofing underlays<br />

Ventilation solutions<br />

Expert technical support<br />

Ventilation<br />

Condensation<br />

Control<br />

Choiceiseverything<br />

With one of the most comprehensive<br />

ranges of roof underlays and ventilation<br />

solutions available in the UK and Ireland,<br />

Glidevale Protect offers tried and trusted<br />

performance for any project. When you’re<br />

creating better buildings and healthy<br />

homes, choice really is everything.<br />

Glidevale Protect is a specialist UK producer, offering<br />

ventilation solutions, condensation control and energy<br />

efficiency across the built environment.<br />

For technical guidance or to book a presentation,<br />

contact us on +44 (0)161 905 5700, email<br />

info@glidevaleprotect.com or visit<br />

www.glidevaleprotect.com/choice

Roof Structure<br />

I-BEAMS VS POSI-JOISTS: SELECTING<br />

THE RIGHT SOLUTION<br />

Charlie Cannon, Design Manager at Beesley & Fildes’ engineered timber department,<br />

advises on selecting the most appropriate timbers for roofing projects.<br />

Most roofing contractors who come to<br />

Beesley & Fildes for roofing timbers<br />

already have a clear idea of what they<br />

need, based on their own experience and an<br />

architect’s drawing. But, as a service-oriented<br />

builder’s merchant, it’s not our job to simply give<br />

them what they’ve asked for; we also provide<br />

advice to help them make informed decisions<br />

that could enable them to reduce costs, simplify<br />

the installation and achieve an improved<br />

outcome for their project.<br />

Making the right choices<br />

To a degree, the choice between i-beams and<br />

posi-joists is often based on personal preference<br />

and experience but, as trends in house design<br />

evolve, it’s important to understand the different<br />

advantages and limitations of each type of<br />

timber. Our design software enables us to create<br />

an optimised design that takes into account the<br />

structural loading, required spans and roof design<br />

so that we can present contractors with the most<br />

appropriate and cost effective solution.<br />

In basic terms, i-beams may be less expensive but<br />

the width and/or number of i-beams required to<br />

achieve larger spans can often lead to increased<br />

design and installation complexity, higher<br />

installation costs and extended programme length.<br />

The enhanced load bearing and structural<br />

strength provided by posi-joists makes them the<br />

ideal choice for larger roofs and, in particular, for<br />

roofs that feature larger spans. Increasingly, we<br />

are finding that loft spaces are being used as<br />

open plan accommodation and posi-joists enable<br />

the required spans to be achieved with smaller<br />

timber widths, working within the loading limits of<br />

the structure and avoiding any compromise to<br />

ceiling heights in the loft space or the floor below.<br />

The open structure of posi-joists also<br />

means that wiring can easily be<br />

fed through the joists, aiding<br />

speed of installation as<br />

compared to i-beams, where<br />

holes need to be drilled in the<br />

correct locations. Not only is<br />

creating apertures for building<br />

services a time-consuming addition<br />

to the programme, but it can also affect the<br />

integrity of the i-beam, which is another key<br />

consideration when selecting the best approach<br />

for their project.<br />

Reducing risk<br />

Our design service makes it easy for our<br />

customers to see how the design will be installed.<br />

And, because we supply a complete solution with<br />

all fixings and accessories included in the<br />

drawings and 3D render, (see above) it’s easy to<br />

appreciate the installation advantages that could<br />

result in time and labour cost savings.<br />

Importantly, a simplified, easier to install design<br />

with all components provided as a complete<br />

package not only offers cost advantages, it also<br />

de-risks the project. Simplification means fewer<br />

opportunities for error and detailed drawings<br />

provide a fully itemised plan for the installation,<br />

aligned to every item of timber and metalwork<br />

supplied. Moreover, because everything is<br />

supplied by Beesley & Fildes using dimensions<br />

supplied by the contractor, we offer complete<br />

Above left and right: Attic render by Beesley &<br />

Fildes; Left: Charlie Cannon, Design<br />

Manager at Beesley & Fildes.<br />

accountability for both the<br />

design and the delivered roof<br />

components, including any<br />

trusses included in the design<br />

and supplied by us.<br />

One of the challenges we sometimes face<br />

is customers who modify timbers for the roofing<br />

installation to make them fit as the installation<br />

evolves on site, as opposed to faithfully following<br />

the CAD drawings for the design. Our team is<br />

available for troubleshooting advice throughout<br />

the project and we always encourage contractors<br />

to call us before they modify anything, so that we<br />

can help them to install the roof according to the<br />

design. This is what we mean by an end-to-end<br />

service, from design through to finished<br />

installation.<br />

Genuine added value<br />

The term ‘added value’ is often over-used, but<br />

when it comes to helping contractors decide where<br />

to use i-beams or posi-joists, our knowledge and<br />

design service can help roofing contractors to<br />

manage costs and reduce risks, providing a<br />

tailored approach to meet the challenges and<br />

requirements of each specific project.<br />

Contact Beesley & Fildes<br />

www.beesleyandfildes.co.uk<br />

22 TC JUNE <strong>2022</strong>

Technical support<br />

Roofing experts on-hand to offer help and advice<br />

Assured standards<br />

Meets all British Standards and regulations<br />

High-quality components<br />

Tested for maximum performance, meaning no call backs<br />

Estimates & fixing specs on demand<br />

We’ll help you create them on site and on the go<br />

Comprehensive roof solution<br />

Easy installation with tried and tested compatible components<br />

Need a complete<br />

roof system?<br />

We’ve got you covered.<br />

With all elements brought together from a single<br />

source, you can be confident that everything<br />

will work together perfectly – and that high<br />

performance is all backed up with a 15-year<br />

system guarantee. Find your peace of mind.<br />

marley.co.uk/roofsystem

Back to Basics<br />

VENTILATION REQUIREMENTS FOR<br />

COLD & WARM PITCHED ROOFS<br />

In the latest Back to Basics column from Hambleside Danelaw, Paul Lambert discusses<br />

the ventilation requirements for cold and warm pitched roofs.<br />

Stopping condensation and moisture from<br />

developing in pitched roofing is imperative<br />

when seeking to prevent mould and damp.<br />

Approved Document C2 states that “Roofing can<br />

be designed to protect a building from<br />