Stahlwerk Thüringen GmbH a modern steel production site with ...

Stahlwerk Thüringen GmbH a modern steel production site with ...

Stahlwerk Thüringen GmbH a modern steel production site with ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

The continuous casting machine<br />

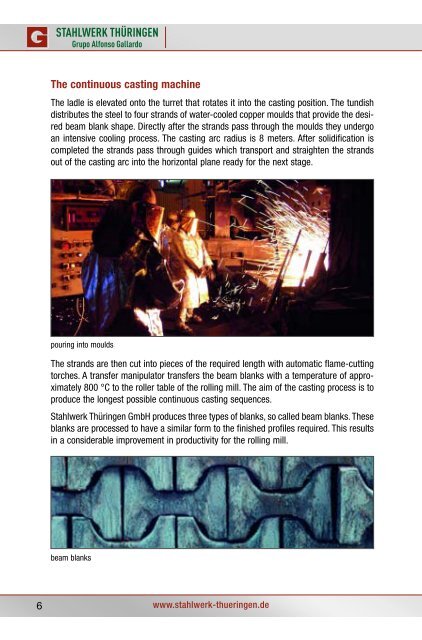

The ladle is elevated onto the turret that rotates it into the casting position. The tundish<br />

distributes the <strong>steel</strong> to four strands of water-cooled copper moulds that provide the desired<br />

beam blank shape. Directly after the strands pass through the moulds they undergo<br />

an intensive cooling process. The casting arc radius is 8 meters. After solidification is<br />

completed the strands pass through guides which transport and straighten the strands<br />

out of the casting arc into the horizontal plane ready for the next stage.<br />

pouring into moulds<br />

The strands are then cut into pieces of the required length <strong>with</strong> automatic flame-cutting<br />

torches. A transfer manipulator transfers the beam blanks <strong>with</strong> a temperature of approximately<br />

800 °C to the roller table of the rolling mill. The aim of the casting process is to<br />

produce the longest possible continuous casting sequences.<br />

<strong>Stahlwerk</strong> <strong>Thüringen</strong> <strong>GmbH</strong> produces three types of blanks, so called beam blanks. These<br />

blanks are processed to have a similar form to the finished profiles required. This results<br />

in a considerable improvement in productivity for the rolling mill.<br />

beam blanks<br />

www.stahlwerk-thueringen.de