Panels & Furniture Asia November/December 2022

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.panelsfurnitureasia.com<br />

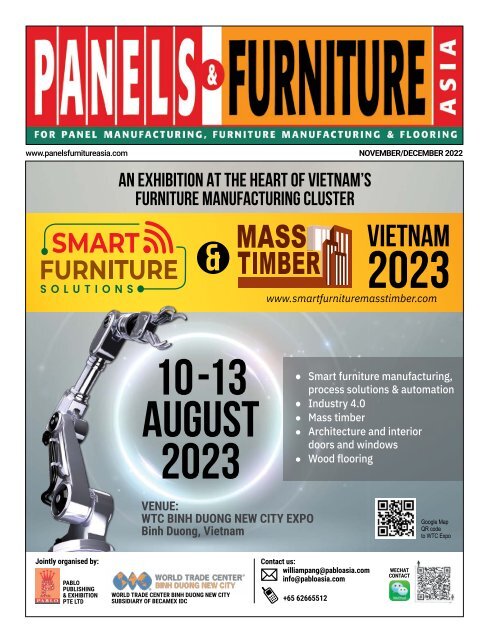

AN EXHIBITION AT THE HEART OF VIETNAM’S<br />

FURNITURE MANUFACTURING CLUSTER<br />

NOVEMBER/DECEMBER <strong>2022</strong><br />

VIETNAM<br />

2023<br />

www.smartfurnituremasstimber.com<br />

10-13<br />

AUGUST<br />

2023<br />

● Smart furniture manufacturing,<br />

process solutions & automation<br />

● Industry 4.0<br />

● Mass timber<br />

● Architecture and interior<br />

doors and windows<br />

● Wood flooring<br />

VENUE:<br />

WTC BINH DUONG NEW CITY EXPO<br />

Binh Duong, Vietnam<br />

Google Map<br />

QR code<br />

to WTC Expo<br />

Jointly organised by:<br />

PABLO<br />

PUBLISHING<br />

& EXHIBITION<br />

PTE LTD<br />

WORLD TRADE CENTER BINH DUONG NEW CITY<br />

SUBSIDIARY OF BECAMEX IDC<br />

Contact us:<br />

williampang@pabloasia.com<br />

info@pabloasia.com<br />

+65 62665512<br />

WECHAT<br />

CONTACT

Simple – we handle all the complexities that go into hardwoods to make<br />

life easier for you. Natural – we manufacture and supply only sustainable, high-quality<br />

products that breathe life into your work. Hardwoods – from harvest to delivery,<br />

we set the standard for what the hardwoods experience should be.<br />

nwh.com

Find your supplier here!<br />

These companies can supply you with exceptional<br />

hardwoods from Canada<br />

cambiumex.com<br />

canamlumber.com<br />

buchandel.com<br />

caspencer.com<br />

commonwealthplywood.info<br />

boisdv.ca dzdhardwood.com champeau.com bjvoyer.com<br />

pfmes.ca nordamhardwoods.com primewood.com rlumber.ca<br />

simonlussier.com<br />

vexco.com<br />

To know more about East Canadian Hardwood<br />

species, you are invited to visit our website.<br />

quebecwoodexport.com/en/products/hardwood-lumber/<br />

@QuebecWoodExport @QuebecWoodExport Quebec Wood Export Bureau

CANADIAN HARDMAPLE

CONTENTS<br />

CONTENTS<br />

PANELS & FURNITURE ASIA (ISSUE 6)<br />

<strong>November</strong> / <strong>December</strong> <strong>2022</strong><br />

08<br />

Editor’s Note<br />

10<br />

News<br />

Market Report<br />

16<br />

Global economic slowdown overshadows near-term<br />

market outlook<br />

Environmental Report<br />

18<br />

The role of an independent auditor in forest<br />

management<br />

20<br />

Innovative recycling and upcycling for furniture and<br />

furnishings: Giving plastic waste a new life<br />

In Person<br />

24<br />

“Delivering added value to our customers”: Teknos<br />

expands to Vietnam<br />

Product Highlight<br />

27<br />

Greater sustainability with Dieffenbacher’s CPS+<br />

continuous press system<br />

28<br />

Automated spray coating<br />

30<br />

woodCommander 5: Simpler, faster and<br />

more cost-efficient production<br />

Panel Manufacturing<br />

32<br />

<strong>2022</strong>: A year rich in achievements<br />

<strong>Furniture</strong> Manufacturing<br />

34<br />

Defect detection in batch-size-one production<br />

37<br />

Ways to improve the quality of edgebanding<br />

40<br />

The role of Malaysian <strong>Furniture</strong> Council in improving<br />

sustainability<br />

42<br />

Advanced woodworking solutions pay off<br />

with Jager and HOMAG<br />

Materials<br />

44<br />

On market diversification and educating new<br />

markets: A conversation with AHEC<br />

Flooring<br />

48<br />

New herringbone technology:<br />

One panel type for simpler production<br />

Recycling<br />

50<br />

From wood to resource: Market updates in<br />

times of challenges<br />

16<br />

42<br />

Structural Elements<br />

53<br />

Little Finlandia<br />

Columnists<br />

56<br />

Reasons for solid wood doors prone to warping and<br />

loosening<br />

60<br />

How sustainable is palm wood?<br />

Show Review<br />

64<br />

IFMAC & WOODMAC <strong>2022</strong><br />

66<br />

VietnamWood <strong>2022</strong><br />

67<br />

Calendar of Events<br />

68<br />

List of Advertisers<br />

6 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

ALL KINDS OF WOOD<br />

Whether you are looking for American, European, or<br />

Tropical wood species, we have something for you. With<br />

our new catalogues, we have made an easy overview<br />

for you to explore the many species in our range.<br />

Check out our website to browse the newest catalogues<br />

from Global Timber and see for yourself.<br />

Global Timber is an international company with more than 40 years of experience in the hardwood industry. The<br />

company consists of the head office in Denmark and a sales office in Malaysia with a total of about 35 employees.<br />

Our employees all have extensive experience from the wood industry.<br />

Per Friis Knudsen<br />

pfk@globaltimber.dk +60 111 429 7073<br />

www.asia.globaltimber.net

FROM THE EDITOR<br />

Standing together<br />

in solidarity<br />

Times are bad. This seems to be the<br />

consensus not only in the industry, but across<br />

the world. Amid inflation and rising interest<br />

rates, factories are not seeing as much orders<br />

as before, unlike earlier this year. Everybody<br />

is a little cautious and hesitant at doing<br />

business. Michael Snow, executive director<br />

of the American Hardwood Export Council<br />

(AHEC), predicts we are looking at least “six<br />

months of difficult trading conditions” (p.44).<br />

With less than two months left in the year,<br />

it is a bit of a downer to end things so<br />

bleakly. One can make the case that the<br />

global economy is definitely getting better.<br />

Trade exhibitions are back in full run, and<br />

many companies got to reconnect with<br />

old customers or meet new customers in<br />

Vietnam (p.66) or Indonesia (p.64). Likewise,<br />

CMC Texpan got to unveil new products and<br />

showcase their portfolio at the recent Xylexpo<br />

exhibition in October (p.32). A slow economy<br />

also does not stop businesses from growing.<br />

Teknos has opened a new commercial and<br />

competence centre in Vietnam (p.24), and<br />

both HOMAG and Unilin have released new<br />

technologies this year, in machinery software<br />

(p.30) and flooring (p.48) respectively.<br />

But for every little achievement we<br />

celebrate, something pulls us back. The<br />

market slowdown is one, but other global<br />

events continue to haunt us — be it the<br />

Russia-Ukraine conflict, the aftereffects of<br />

COVID-19, or climate change. With COP27<br />

in the horizon, it is time to think about<br />

sustainability measures, especially as a<br />

forestry-related industry that has huge<br />

impact in net-zero emissions. <strong>Furniture</strong> and<br />

panel manufacturers can consider applying<br />

to forest certification schemes (p.40), or try<br />

alternative wood-based materials, such as<br />

palm wood (p.60).<br />

There is no quick solution to solve market<br />

woes or climate change, and it is near<br />

impossible to sit back leisurely, knowing<br />

we still have to salvage the business in such<br />

tough times. But if everybody is mired<br />

in the same situation, perhaps we can<br />

stand together in solidarity and comfort<br />

each other. And hopefully, a new year<br />

brings new prospects: When there are new<br />

opportunities, the wood and woodworking<br />

industry will rise up again.<br />

YAP SHI QUAN | EDITOR<br />

PANELS &<br />

FURNITURE ASIA<br />

PABLO SINGAPORE<br />

Publisher<br />

William Pang • williampang@pabloasia.com<br />

Editor<br />

Yap Shi Quan • shiquan@pabloasia.com<br />

Business Development Manager<br />

Pang YanJun • yanjun@pabloasia.com<br />

Graphic Designer<br />

Goh Meng Yong • mengyong@pabloasia.com<br />

Circulation Manager<br />

Shu Ai Ling • circulation@pabloasia.com<br />

PABLO BEIJING<br />

General Manager<br />

Ellen Gao • pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Editor<br />

Kresly Shen • pabloshanghai@163.net<br />

HEAD OFFICE<br />

PABLO PUBLISHING &<br />

EXHIBITION PTE LTD<br />

3 Ang Mo Kio Street 62, #01-23, Link@AMK,<br />

Singapore 569139<br />

Tel : +65 6266 5512<br />

Email: info@pabloasia.com<br />

www.panelsfurnitureasia.com<br />

Company Registration No: 200001473N<br />

Singapore MICA (P) No: 105/12/2021<br />

REGIONAL OFFICES (CHINA)<br />

PABLO BEIJING<br />

Tel : +86 10 6509 7728<br />

Email : pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Tel : +86 21 5238 9737 / 36<br />

Email : pabloshanghai@163.net<br />

let's connect!<br />

@panelsfurnitureasia<br />

All rights reserved. Views of writers do not necessarily reflect the views of the<br />

Publisher. No part of this publication may be reproduced in any form or by any<br />

means, without prior permission in writing from the Publisher and copyright<br />

owner. Whilst every care is taken to ensure accuracy of the information in<br />

this publication, the Publisher accepts no liability for damages caused by<br />

misinterpretation of information, expressed or implied, within the pages of<br />

the magazine. All advertisements are accepted on the understanding that the<br />

Advertiser is authorised to publish the contents of the advertisements, and in<br />

this respect, the Advertiser shall indemnify the Publisher against all claims<br />

or suits for libel, violation of right of privacy and copyright infringements.<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> is a controlled-circulation magazine with two issues<br />

a year. It is mailed free-of-charge to readers who meet a set of criteria. Paid<br />

subscription is available to those who do not fit our terms of control. Please<br />

refer to subscription form provided in the publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

Scan to subscribe<br />

to PFA’s enewsletter<br />

8 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

Steel Belts for the Wood and Laminate industry<br />

Our endless Steel Belts offer highest quality, optimum strength<br />

and a long lifetime. Additionally, our worldwide service<br />

network supports you 24/7 - especially when it is urgent.<br />

Exceptional operating<br />

characteristics<br />

Global technical<br />

support and service<br />

Berndorf Band GmbH<br />

T: +43 2672 800 0<br />

E: band@berndorf.co.at<br />

www.berndorfband-group.com<br />

Ultimate strength<br />

and durability<br />

Steel Belts | Belt Systems | Worldwide Service

NEWS<br />

TEKNOS EXPANDS<br />

TO VIETNAM WITH<br />

NEW COMMERCIAL<br />

AND COMPETENCE<br />

CENTRE<br />

The opening ceremony of Teknos’s new centre in Dong Nai, Vietnam<br />

Teknos has announced the opening of its new<br />

commercial and competence centre with a<br />

technical application laboratory, training and<br />

warehouse facilities in Dong Nai province,<br />

Vietnam.<br />

According to the company, Vietnam is an<br />

important growth market for them, and to be<br />

close to their customer, they have invested<br />

in and are committed to the region and their<br />

existing and future customers. The new office<br />

opened on 13 Sep <strong>2022</strong>.<br />

The local staff will now be able to provide<br />

local services, from sampling and pre-line<br />

trial testing, to training, colour matching and<br />

optimised logistical services, thus reducing lead<br />

times and offering the ability to provide fit-forpurpose<br />

logistical support.<br />

Customers in Vietnam will also have access to<br />

Teknos’s range of products. The waterborne<br />

and UV products will be imported from<br />

Malaysia, the nearest Teknos production<br />

site in the region. Accessibility to additional<br />

products is also ensured and can come from<br />

the company’s factories in Finland, Germany,<br />

Denmark or China.<br />

“The decision to establish the new service<br />

centre in <strong>Asia</strong>-Pacific supports our growth<br />

plans. Vietnam was a logical choice for us as our<br />

Vietnamese export business has grown steadily<br />

over the past years,” said Paula Salastie, CEO of<br />

Teknos and owner of Teknos Group.<br />

“We want to meet customers where they are<br />

located to be able to enhance our collaboration<br />

and support them with faster response time<br />

and tailored solutions and services.<br />

“This will also enhance our sustainability<br />

as it reduces the emissions from logistics.<br />

Our team in Vietnam plays a crucial role in<br />

broadening our global development and<br />

service network. Our model will always<br />

be working in close cooperation with our<br />

customers, building a stronger relationship,<br />

by providing them with sustainable coating<br />

solutions.”<br />

Wanda Smith, managing director of Teknos<br />

Malaysia, who is also taking care of the South<br />

East <strong>Asia</strong> region, leads the new Teknos Vietnam<br />

set-up, looking after the sales, customer<br />

support, technical service and warehouse<br />

functions.<br />

“It is an exciting time to mark this milestone<br />

and start a new chapter in this region to be<br />

closer to our Vietnamese customers,” said<br />

Smith.<br />

The new office is located at Nhon Trach<br />

Industrial Zone III – Phase 2, Hiep Phuoc<br />

town, Nhon Trach district, Dong Nai province.<br />

It has a total area of about 650m 2 , branded<br />

with the blue and green Teknos corporate<br />

colour scheme, and consists of an office space,<br />

meeting room, technical application laboratory<br />

and warehouse.<br />

Teknos will continue to invest and grow in<br />

Vietnam, with a mid-term of three to five<br />

years expansion plan to become a secondary<br />

production site and gain better control over<br />

lead time and reduce the dependence on<br />

imports to meet the growing local demand.<br />

As such, the Vietnamese expansion will be able<br />

to support the export to other South East <strong>Asia</strong>n<br />

or <strong>Asia</strong>-Pacific countries, complementary to<br />

Teknos’s Malaysia plant.<br />

For more information about Teknos’s new<br />

centre, flip to page 24. P<br />

SIEMPELKAMP AND SMARTECH TO COLLABORATE<br />

ON AI TECHNOLOGY FOR WOOD-BASED PANEL INDUSTRY<br />

Siempelkamp and Smartech have<br />

announced a partnership to work on artificial<br />

intelligence (AI) for the wood-based panel<br />

industry, particularly for manufacturers of<br />

engineered wood products.<br />

“We believe our collaboration with Smartech<br />

will drive the next generation of wood-based<br />

panel manufacturing. We look forward to<br />

working together to bring to the market<br />

the most cutting-edge technology with a<br />

massive impact for our customers,” said<br />

Gregor Bernardy, head of Manufacturing<br />

Executive System (MES) and Industrial IT<br />

Solutions from Siempelkamp Logistics &<br />

Service.<br />

“Siempelkamp is a global leader in<br />

supplying press lines to the wood-based<br />

panel industry and we are excited to be<br />

working together. Technology is the key to<br />

better growth and a better future. The synergy<br />

between Siempelkamp and Smartech will drive<br />

the market with a game-changing solution,”<br />

said Hanoch Magid, CEO of Smartech.<br />

Smartech is a specialist in smart factories, with<br />

experience in transforming existing production<br />

lines into autonomous, data-driven and<br />

sustainable assets. P<br />

10 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

NEWS<br />

EUMABOIS APPOINTS NEW PRESIDENT<br />

Luigi De Vito, the president of Acimall and<br />

division director of SCM, has become the<br />

president of Eumabois recently, succeeding<br />

past president Jürgen Köppel.<br />

Eumabois is a European association<br />

dedicated to promoting European<br />

woodworking machinery industry regionally<br />

and internationally. De Vito was the previous<br />

vice-president of the association since 2016.<br />

The board of director was also renewed, with<br />

new members being Wolfgang Rohner from<br />

IMA Schelling, Daniel Bucher from Striebig,<br />

and Ismet Toktas from AES Group. Outgoing<br />

members include Samuel Hänni from<br />

Lamello, and Mustafa Sabri Erol from Törk<br />

Makine. P<br />

Handover between Juergen Koeppel (left)<br />

and Luigi De Vito (right)<br />

De Vito commented in his inaugural<br />

speech as the new president: “I want to<br />

express my best wishes to the new board<br />

of directors that will be in office for the<br />

next three-year term. My heartfelt thanks<br />

go to all the outgoing board members I<br />

have worked with and who, in recent years,<br />

have contributed to bringing Eumabois to<br />

its current levels of quality and influence<br />

worldwide.<br />

“Finally, a very special thanks goes to Jürgen<br />

Köppel, the years spent together have been<br />

fuelled by a strong spirit of collaboration and<br />

mutual esteem, and I can say that I am very<br />

proud of the work done together and of the<br />

results achieved.”<br />

Köppel, in his farewell speech, said: “I<br />

am very pleased that such top-class<br />

representatives of our industry are<br />

supporting at European level and are<br />

thus driving our common European ideas<br />

worldwide.<br />

“European woodworking machines and<br />

tools are setting trends worldwide and<br />

this leading position needs to be secured<br />

and expanded with the support of our<br />

federation.<br />

“I would like to thank everyone who has<br />

supported me in my work, especially I want<br />

to thank Luigi De Vito, because in the past<br />

six years of working together, he, as a former<br />

competitor, has become a strong comradein-arms<br />

and friend.”<br />

Besides the change in presidency, the new<br />

vice-president was also appointed, with<br />

Frederik Meyer from HOMAG group taking<br />

charge.<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 11

NEWS<br />

HOMAG UNVEILS<br />

DRILLTEQ H-308<br />

FOR ASIAN MARKETS<br />

HOMAG has launched DRILLTEQ H-308,<br />

which features the latest in drilling<br />

technology in terms of efficiency and speed,<br />

designed and developed for <strong>Asia</strong>.<br />

According to HOMAG, DRILLTEQ H-308 is<br />

distributed exclusively in <strong>Asia</strong>, since the<br />

region requires a flexible machine to deliver<br />

diverse orders.<br />

Previously, manufacturing firms had to<br />

manually adjust their machines with each<br />

change in the cut, drilling and pattern. The<br />

DRILLTEQ H-308 does away with these timeconsuming<br />

steps.<br />

In summary, the machine offers flexibility<br />

for high variant diversity as well as<br />

efficiency when series production is<br />

needed. Work interruptions are also<br />

lessened, resulting in faster processes and<br />

greater efficiency.<br />

The DRILLTEQ H-308 is suitable for firms that<br />

produce 200-300 pieces a day.<br />

The high-speed<br />

processing unit of<br />

DRILLTEQ H-308<br />

(Image: HOMAG)<br />

“TWO-IN-ONE” DRILLING MACHINE<br />

The DRILLTEQ H-308 includes six-sided<br />

processing, enabling the machine to drill six<br />

sides of the working piece simultaneously.<br />

The machine also operates on two working<br />

fields that can be fed by an operator at the<br />

same time, offering a two-in-one machine. As<br />

one field is working on one panel, the other<br />

field can prepare for further processing of the<br />

workpiece.<br />

Meanwhile, its upgraded variant, the<br />

DRILLTEQ H-310, provides the same functions<br />

but can be connected in a fully automatic line<br />

and can be controlled by a computer or robot.<br />

As such, the processing time is reduced, and<br />

there is greater availability and flexibility in<br />

production.<br />

“The possibility of using two working fields<br />

at the same time, thus doubling loading the<br />

machine, is fully in line with the wishes and<br />

needs of the <strong>Asia</strong>n market,” said Gordon Wu,<br />

product development head of HOMAG.<br />

The DRILLTEQ H-308 also possesses a spindle<br />

clamp that can perform precise depth in<br />

drilling, ensuring reliable quality due to high<br />

repeat accuracy. It is equipped with four<br />

computer numerical controlled (CNC) clamps<br />

to hold the workpieces firmly and precisely.<br />

It can handle workpieces with dimensions of<br />

250-2,500mm in length and 60-1,250mm in<br />

width.<br />

HOMAG reported that the woodWOP software<br />

is also included in the machine, enabling<br />

fast and intuitive operation and the ability to<br />

create individual sub-programmes. It also has<br />

greater programming security by providing<br />

3D images of the workpieces as well as the<br />

processing and clamping equipment. P<br />

ARAUCO APPROVES<br />

NEW MDF LINE AT MEXICO<br />

Arauco’s board of director has approved<br />

the construction of a new medium-density<br />

fibreboard (MDF) line in the city of Zitácuaro,<br />

Mexico.<br />

According to Arauco, this construction project<br />

will be an investment of US$235m and<br />

incorporates operational, environmental and<br />

safety technology. The project is expected to<br />

begin operating during Q2 2025.<br />

Arauco is a producer of wooden boards in<br />

Mexico. This project is expected to add about<br />

300,000m 3 of MDF production per year, half<br />

of which would be melamine coated to meet<br />

the growing demand of Mexico’s furniture,<br />

construction, and interior decorating industries.<br />

The plant will create jobs for 220 new<br />

employees. Additionally, it strives to<br />

promote a circular economy model,<br />

driving small local forestry producers<br />

and protecting the surrounding<br />

ecosystem.<br />

Back in May, Arauco also announced an<br />

investment to expand their thermally<br />

fused lamination (TFL) operations at their<br />

particleboard plant in Grayling, Michigan, US.<br />

The new lamination line will be Arauco’s third<br />

TFL line at Grayling and will increase the mill’s<br />

lamination capacity more than 50% in support<br />

of Arauco’s Prism TFL decorative surface<br />

product offering. P<br />

The new MDF line at<br />

Mexico (Image: Arauco)<br />

12 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

NEWS<br />

ZIEGLER GROUP STARTS WOOD FIBRE<br />

INSULATION BOARD PRODUCTION<br />

WITH NEW DIEFFENBACHER PLANT<br />

A complete wood fibre insulation board (WFIB)<br />

plant provided by Dieffenbacher for Ziegler<br />

Group’s site in Grafenwöhr, Bavaria, Germany,<br />

is up and running less than one year after<br />

construction began.<br />

Dieffenbacher’s scope of supply for the complete<br />

plant included a fibre dryer, a EVOjet M 2.0<br />

gluing system, the forming station and<br />

forming line with pre-press, a CSS continuous<br />

steam press system, the raw board handling<br />

system, electrics, automation, and the<br />

MyDIEFFENBACHER digital service platform.<br />

“We are very pleased that our new<br />

Dieffenbacher WFIB plant had such a rapid<br />

and successful start,” said Andreas Sandner,<br />

commercial managing director at Ziegler<br />

Group.<br />

According to Dieffenbacher, the line for<br />

rigid WFIB began production on 30 Aug<br />

<strong>2022</strong>. Ziegler Group placed its order with<br />

Dieffenbacher on 1 Apr 2021, but the<br />

construction only began five months later in<br />

September due to a change of location from<br />

the town of Bärnau, 50km west to Grafenwöhr,<br />

on a short notice.<br />

“We never would have been able to achieve<br />

this record-breaking construction and<br />

completion time without the full cooperation<br />

of our partners. In this case, especially<br />

Dieffenbacher,” said Sandner.<br />

“The change of location and the procurement<br />

crisis during the pandemic made this feat all<br />

the more remarkable. Our thanks go to the<br />

entire Dieffenbacher team, who overcame<br />

Production of the first board in Ziegler Group’s new<br />

Dieffenbacher WFIB plant in Grafenwöhr,<br />

Bavaria, Germany<br />

huge challenges to meet our requirements for<br />

product quality and energy efficiency.”<br />

In addition to the WFIB plant just completed,<br />

Ziegler Group commissioned Dieffenbacher to<br />

supply another fibre dryer for flexible insulation<br />

mat production at the Grafenwöhr site.<br />

Construction began in June, and the 10-tonne/h<br />

capacity dryer should have started operations<br />

in October. P<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 13

NEWS<br />

FUTURE HEIRLOOMS:<br />

NEW DESIGN COLLABORATION<br />

IN AMERICAN RED OAK<br />

NOW OPEN<br />

All seven pieces of<br />

Future Heirlooms<br />

(Image: Sarah de Pina)<br />

Future Heirlooms, a design collaboration by<br />

South African cooperative Always Welcome and<br />

the American Hardwood Export Council (AHEC),<br />

is now open at Always Welcome Viewing Rooms<br />

in Sandton, Johannesburg, South Africa.<br />

The project, which was initially announced in<br />

July <strong>2022</strong>, will remain at its current location until<br />

<strong>November</strong> <strong>2022</strong>, and will then move to the new<br />

Always Welcome Heritage House in Cape Town in<br />

January 2023.<br />

For this project, a group of seven South African<br />

designers from three provinces across the<br />

country have created a series of works that not<br />

only anticipates the future of sustainable design,<br />

but also explores their own heritage and the<br />

story of South Africa’s design legacy.<br />

Created in American red oak by hardwood<br />

furniture designer-manufacturers Houtlander<br />

and timber importers BOS Timbers, the seven<br />

pieces are a celebration of material and memory,<br />

and ask questions about current approaches to<br />

the environment.<br />

The seven pieces were crafted by various design<br />

studios and designers, such as Dokter and Misses,<br />

MashT Design Studio, TheUrbanative, Kumsuka,<br />

Kalki Ceramics, Joe Paine in partnership with<br />

Nathan Gates, and Nøde Studio.<br />

Under the mentorship of the Always Welcome<br />

team, the designers were asked to create an<br />

object or a piece of furniture that encapsulates<br />

the themes of sustainability, longevity and<br />

quality.<br />

“We need to end our current throwaway culture<br />

and we need to use materials that have a low<br />

environmental impact. These issues should<br />

affect all our day-to-day decision-making,” said<br />

Roderick Wiles, regional director of AHEC.<br />

“Designers, especially, have a huge influence<br />

on how products are planned and with what<br />

materials. This project was the perfect platform<br />

for us to work with accomplished South African<br />

designers and makers, while also helping<br />

them to work with an abundant, versatile and<br />

beautiful, yet lesser-known American hardwood<br />

species.”<br />

For the designers, the project has offered<br />

an opportunity to explore alternative<br />

manufacturing methods and American red oak<br />

itself.<br />

Commenting on her participation in the project,<br />

Thabisa Mjo, founder of Johannesburg-based<br />

product and furniture design group MashT<br />

Design Studio, said: “The material intrigued<br />

me from the outset of Future Heirlooms. I<br />

became fascinated by the seemingly endless<br />

possibilities of American red oak itself that,<br />

coupled with Houtlander’s special ability to<br />

work with timber, set my imagination alight and<br />

I just had to see what could be made.”<br />

The American red oak arrived for the project<br />

at the South African port of Durban was also<br />

carbon negative. AHEC reported that just<br />

about 1.3m 3 of American red oak were used<br />

to make all seven pieces, with the finished<br />

pieces being made up just under 1m 3 of wood<br />

after manufacturing.<br />

For their lifetime, these seven furniture pieces<br />

will keep around 1,069kg of CO2e out of the<br />

atmosphere.<br />

Wiles concluded: “Such is the size of the US<br />

hardwood forest resource and so dominant<br />

in the forest is red oak at roughly 18% of the<br />

total resource, that all the red oak lumber<br />

used to make the seven designs would have<br />

been replaced in the US hardwood forest<br />

through natural regeneration in just 1.35<br />

seconds.<br />

“With the world facing the ever-increasing<br />

impacts of climate change and of overconsumption<br />

of high-impact materials, the<br />

emphasis needs to shift to the environmental<br />

merits of making more use of what nature is<br />

growing.<br />

“Through this collaboration, we hope the<br />

designers and manufacturer learnt a lot<br />

about a beautiful and sustainable material<br />

while also demonstrating the beauty of a<br />

widely available, yet under-utilised American<br />

hardwood species.” P<br />

14 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

NEWS<br />

MTC INKS MOU WITH THAILAND’S<br />

TIMBER ASSOCIATIONS<br />

In a move to enhance ASEAN member countries’ competitiveness as a<br />

region, the Malaysian Timber Council (MTC) has signed a Memorandum<br />

of Understanding (MoU) with the Thai Hevea Wood Association (THA)<br />

and the Wood Processing Industry Club at The Federation of Thai<br />

Industries (FTI) in Songkhla, Thailand.<br />

The MoU, which was signed by Muhtar Suhaili, CEO of MTC, Nikorn<br />

Likhitwangphanit, president of THA, and Akarin Vongapirat, chairman<br />

of FTI Wood Processing Industry Club, will help to promote the<br />

development of the Malaysian and Thailand timber trade as well as<br />

establish timber trade standardisation between the two countries.<br />

The MoU also included promotional activities for MTC’s upcoming<br />

Malaysian Wood Expo (MWE) to encourage participation from Thai<br />

timber industry players in the fair.<br />

In 2021, Malaysia was one of the top five major timber export<br />

destinations for Thailand’s major timber products, especially for<br />

sawntimber. According to MTC, Malaysia was the largest export country<br />

for Thailand’s sawntimber which amounted to US$44.3m. Thailand also<br />

exported $7.8m worth of wooden furniture and $10m worth of plywood<br />

to Malaysia in 2021.<br />

MAT MOISTENING<br />

INNOVATION MAT MOISTENING<br />

AT WORK<br />

INNOVATION AT WORK<br />

Bottom moistening<br />

on forming belt<br />

Bottom moistening<br />

on forming belt<br />

WEKO-FLUID-APPLICATION-SYSTEM<br />

WEKO-FLUID-APPLICATION-SYSTEM<br />

Top moistening<br />

on mat surface<br />

Top moistening<br />

on mat surface<br />

The MoU signing was followed by a B2B matching session between 19<br />

timber companies from Malaysia and 15 companies from Thailand.<br />

“We need to strengthen our business ties and help escalate each other’s<br />

imports and exports in international markets,” Muhtar said, adding that<br />

the MoU was prompted during an earlier market visit to Bangkok in April<br />

this year.<br />

“Both MTC and FTI came up with the idea of organising a Rubberwood<br />

Sourcing Mission from Malaysia to the Songkhla province which is the<br />

second-largest rubber producer in Thailand with 330,240 hectares of<br />

planted area.”<br />

Sourcing and augmenting raw material supply for local timber-based<br />

manufacturers is one of MTC’s top priorities, and Thailand’s rubberwood<br />

is sought after. MTC has started reaching out to its trade partners within<br />

ASEAN to revive business and trade relationships that were halted due<br />

to the COVID-19 pandemic.<br />

According to MTC, this year alone the council has visited Singapore<br />

in March, Thailand in April, Vietnam in June, Indonesia in July and is<br />

scheduled for a visit to the Philippines in <strong>November</strong>. P<br />

IMPROVE YOUR BOARDS QUALITY<br />

IMPROVE YOUR BOARDS QUALITY<br />

YOUR BENEFITS<br />

• Increase your press speed<br />

YOUR BENEFITS<br />

• Higher surface density<br />

• Improved Increase your bending press strength speed<br />

• Less Higher or no surface sanding density<br />

• Longer Improved sanding bending tool strength lifetime<br />

• Smoother Less or no surface sanding for<br />

• easy Longer laquering sanding tool lifetime<br />

• Smoother surface for<br />

easy laquering<br />

Productivity<br />

and Quality<br />

Productivity<br />

and Quality<br />

www.weko.net<br />

www.weko.net<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 15

MARKET REPORT<br />

Global economic slowdown<br />

overshadows near-term<br />

market outlook<br />

By Judd Johnson, editor,<br />

Hardwood Market Report Publications<br />

Most countries in the world are<br />

experiencing slower economic growth or<br />

economic contraction. Certainly, those<br />

with global influence are performing at<br />

less-than-optimal rates.<br />

For instance, the US is contending with<br />

a 40-year high rate of inflation and a<br />

tightened monetary policy by the federal<br />

government. Included are significantly<br />

higher interest rates to commercial<br />

and consumer borrowers. Also, the<br />

US GDP has marked two consecutive<br />

quarters of contraction, which is one<br />

measure of recession. In contrast, the US<br />

manufacturing sector is still expanding,<br />

according to its Purchasing Managers’<br />

Index (PMI) readings of over 50, which<br />

is another barometer that indicates<br />

the US economy is not in recession.<br />

But recession or no recession, the US<br />

economy is waning.<br />

Europe’s economy is also suffering from<br />

tightened oil and gas supplies extending<br />

from Russia’s war on Ukraine. This is<br />

affecting both business and consumer<br />

activity, and the impacts will become<br />

more severe during winter.<br />

China has earned recognition as<br />

the world’s manufacturing hub. But<br />

the manufacturing sector of China’s<br />

economy has contracted five of the<br />

past seven months, based on the<br />

government’s manufacturing PMI<br />

report. Also, China’s economic growth<br />

in <strong>2022</strong> has relied heavily on increased<br />

exports of goods and services, which<br />

climbed from 21% of the overall<br />

economy in 2021 to 36% of China’s<br />

economy midway through this year.<br />

China’s domestic consumerism created<br />

a great deal of economic growth prior to<br />

COVID-19, but has slowed substantially.<br />

COVID-19 and Russia’s war on Ukraine<br />

are key contributors to present<br />

economic challenges. There also have<br />

been policy missteps by world leaders<br />

that exacerbated existing problems<br />

and risks, however well-intended those<br />

policies might have been.<br />

Putting all the causes aside — and there<br />

are many — one ramification facing the<br />

forest and wood products industries<br />

from the economic slowdown is reduced<br />

consumerism in all major markets<br />

around the world. Specifically at risk<br />

are housing sales and sales of nonessential,<br />

big-ticket items, such as home<br />

furnishings.<br />

AN UNNECESSARY REALITY<br />

The frustrating part of this potential<br />

outcome is that the marketplace<br />

had prepared for housing and home<br />

16 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

MARKET REPORT<br />

have affected production capacity<br />

utilisation and the product mix of<br />

sawn lumber and timbers. That said,<br />

continued financial strain could alter the<br />

production make-up by acquisitions and<br />

attrition of sawmill companies.<br />

COVID-19 and subsequent pressures have affected production capacity utilisation and the<br />

product mix of sawn lumber and timbers<br />

furnishing sales to increase. There is<br />

pent-up consumer demand in markets<br />

held back by government lockdowns<br />

to control the spread of COVID-19 and<br />

delayed deliveries of goods. There also<br />

is increasing demand in other markets.<br />

It is an important distinction that<br />

demand is not the same as the ability or<br />

inability to fulfil demand.<br />

In particular, the US has a large and<br />

growing population of young people<br />

that extends in ages from 40 years<br />

and younger. Over half of the total US<br />

population falls within this age group,<br />

which means there can be tremendous<br />

consumer buying power for homes and<br />

home furnishings for many years to<br />

come.<br />

financial stress for almost three years.<br />

The historic rise in prices that occurred<br />

in 2021 did create profits for sellers,<br />

but not for long. Rapidly rising costs of<br />

replacement goods and materials cut<br />

into profit margins and left companies<br />

exposed with high-cost inventories<br />

when sales prices began to fall.<br />

TIME AGAIN FOR TRANSITION<br />

In the case of US hardwood sawmill<br />

production capacity, there has been<br />

no measurable change since the<br />

early recovery phase from the Great<br />

Recession. However, changes caused<br />

by COVID-19 and subsequent pressures<br />

This pattern of business is similar<br />

to that which began in Q4 2018 and<br />

carried over to the start of 2020, as<br />

the pandemic emerged. There was<br />

evidence of tighter supplies of US grade<br />

hardwood in H2 2019, and there was a<br />

growing sense of optimism then about<br />

improved business heading into 2020.<br />

Yes, COVID-19 was unforeseen and<br />

changed the marketplace. But before<br />

then, US hardwood lumber supplies<br />

were corrected.<br />

And they are correcting now, again. P<br />

Hardwood Market Report (HMR)<br />

is the leading source of pricing<br />

and market information for North<br />

American hardwoods. It has<br />

provided reliable, expert analysis<br />

of pricing and market trends to<br />

hardwood companies throughout<br />

the world since 1922. Sample copies<br />

and subscription services for HMR<br />

and all other HMR publications are<br />

available online at www.hmr.com.<br />

Non-essential items<br />

like home furnishings<br />

are at risk of reduced<br />

consumerism<br />

from the economic<br />

slowdown<br />

While wood products manufacturing<br />

and distribution can support increased<br />

product demand at present, companies<br />

involved in these businesses cannot<br />

stand by idly and indefinitely while<br />

waiting for a non-responsive customer<br />

base to re-engage.<br />

First, supplies will adjust to present<br />

market conditions. That is happening<br />

now, even if results from production and<br />

inventory cutbacks are not yet evident.<br />

In time, and without improvement<br />

in economies and consumer activity,<br />

manufacturing and distribution<br />

capacities will contract. The reality<br />

is that businesses have been under<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 17

ENVIRONMENTAL REPORT<br />

The role of an<br />

independent auditor<br />

in forest management<br />

By Yap Shi Quan<br />

As forests are increasingly subjected to harmful causes,<br />

whether natural or man-made, the need to preserve and<br />

protect them arises. Auditing is one such way. Forest<br />

Practices Board, a forest watchdog organisation based in<br />

British Columbia, Canada, explains what auditing in forestry<br />

comprises, and how it contributes to healthier forestlands.<br />

Forestlands are depleting across the world.<br />

Regardless of whether it is due to natural causes<br />

like climate change, or man-made causes like<br />

illegal logging or deforestation, forests need to<br />

be preserved if businesses want to maintain the<br />

global consumption of timber used for wood<br />

and non-wood products, or simply, to protect<br />

our environment. Timber certification systems<br />

have been implemented to ensure that timber<br />

is harversted ethically and legally. But is it<br />

adequate?<br />

Another way is through auditing. Darlene<br />

Oman, director of corporate performance from<br />

Forest Practices Board (FPB), explained what<br />

auditing comprises: “During a forestry audit,<br />

[our] board examines timber harvesting, road<br />

construction, maintenance and deactivation,<br />

silviculture activities, such as replanting<br />

and tending of new forests, and wildfire<br />

preparedness and prevention, as well as<br />

operational plans related to these activities.”<br />

FPB is a watchdog organisation based in British<br />

Columbia (BC), Canada that provides oversight<br />

of both forest companies and government<br />

agencies. It ensures that forest planning and<br />

practices in BC are sound, and that the public’s<br />

interests in the forests are being served.<br />

According to Oman, their auditors in BC check<br />

for compliance with legislation, specifically<br />

with the Forest and Range Practices Act<br />

and the Wildfire Act. The Forest and Range<br />

Practices Act sets out BC government’s<br />

objectives for how the province’s forests<br />

should be managed, and the Wildfire Act aims<br />

to prevent wildfire caused by industrial activity<br />

in the forests.<br />

Oman continued: “Inspections take place in<br />

the field and plans and permits are reviewed<br />

in the office. Examples of practices audited are<br />

18 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

ENVIRONMENTAL REPORT<br />

1<br />

2<br />

Legend<br />

1 The trend<br />

of warmer<br />

temperatures<br />

and drought<br />

have subjected<br />

BC forests to<br />

stressors<br />

2 BC forests cover<br />

approximately 57<br />

million hectares<br />

and are used for<br />

different activities<br />

checking reserves left along streams to<br />

protect fish habitat and water quality,<br />

ensuring roads and bridges are safe<br />

for industrial use and are not causing<br />

soil erosion or landslides, checking the<br />

number and quality of replanted trees,<br />

and ensuring that any fire hazards from<br />

slash and debris are treated to reduce<br />

the risk of wildfire.”<br />

THE STATE OF BC FORESTS<br />

Currently, BC’s forests are “generally<br />

very healthy”, but the trend of warmer<br />

temperatures and drought have<br />

subjected their forests to stressors,<br />

according to Oman. In the last 10-20<br />

years, insect infestations and wildfires<br />

have caused damage to millions of<br />

hectares of BC’s forested lands.<br />

The forests in BC cover approximately<br />

57 million hectares and are used for<br />

different activities. For instance, about<br />

20 million hectares are available for<br />

timber harvesting and the forest<br />

industry harvests about 1%, or 200,000<br />

hectares each year. The forests also<br />

provide forage for ranchers to graze<br />

cattle, and are important for the tourism<br />

and recreation sectors. Furthermore,<br />

forests are important to indigenous<br />

lives. BC is home to about 200<br />

indigenous nations, each with their own<br />

unique language, dialect, and traditions.<br />

The government is committed to<br />

implementing the United Nations<br />

Declaration on the Rights of Indigenous<br />

Peoples — a framework that aims to set<br />

standards on maintaining the rights<br />

and dignity of indigenous people<br />

globally — by involving indigenous<br />

nations in decisions about the<br />

management of BC’s forestlands.<br />

In 2021, BC passed legislation that<br />

enshrines this commitment in law.<br />

INDEPENDENCE<br />

As an independent auditor, FPB is<br />

responsible for holding governments<br />

and businesses accountable,<br />

ensuring that all forestry policies<br />

and legislations are abided. The<br />

organisation assures the public<br />

that forest companies follow legal<br />

requirements to protect forest values,<br />

and that the government is enforcing<br />

any forest-related legislation.<br />

This independence is what separates<br />

FPB from other certification or<br />

auditing bodies — it is not directed<br />

by the government or market forces,<br />

and hence key to gaining the public’s<br />

trust in their findings and policy<br />

recommendations: “Having an<br />

independent third party that provides<br />

this assurance builds public trust in the<br />

stewardship of BC’s public forests.”<br />

FPB has audited various woodworking<br />

businesses in the past, including<br />

Interfor, a forest products producer<br />

based in North America, and<br />

Kalesnikoff, a mass timber and lumber<br />

manufacturer. From these audits, FPB<br />

will make policy recommendations<br />

to the government, so that any harm<br />

done to forestlands from industrial<br />

and woodworking activities can be<br />

mitigated.<br />

As Oman explained: “Over the years,<br />

the board has made a number of<br />

recommendations to the government<br />

to improve the forest management<br />

system in BC. The government<br />

recently introduced amendments to<br />

the legislation that would address<br />

a number of our recommendations,<br />

such as a new forest landscape<br />

planning requirement, maps that<br />

showed the public the location of new<br />

logging roads and cut blocks, and<br />

giving government managers greater<br />

authority to direct forest companies if<br />

their activities might cause harm to the<br />

environment.”<br />

Indeed, in that sense, FPB is more<br />

answerable to the public and the<br />

forestlands. With a stronger forest<br />

management and stewardship,<br />

ensuring no long-lasting harm to the<br />

ecosystems, a stronger forest industry<br />

will emerge as well — contributing<br />

to a more regular revenue flow for<br />

companies producing forest-related<br />

products. To that end, the board<br />

encourages all companies to “comply<br />

with the Forest and Range Practices<br />

Act and the Wildfire Act and to<br />

follow best management practices in<br />

planning and designing their forestry<br />

operations”, so that the public remains<br />

confident in the management of BC<br />

forests. P<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 19

ENVIRONMENTAL REPORT<br />

Innovative recycling and<br />

upcycling for furniture<br />

and furnishings: Giving<br />

plastic waste a new life<br />

By Ken Hickson<br />

Wood used by<br />

Roger&Sons to<br />

repurpose airline<br />

seats and galley<br />

carts<br />

There is a fair chance that plastic<br />

will get back into “my good books”.<br />

Particularly if I find a few more examples<br />

of where ocean-bound plastic is being<br />

put to good use. Like being turned into<br />

furniture or textiles for furnishing, or<br />

even panels for boats or buildings.<br />

Admittedly, my preference is for wood<br />

— everywhere — in furniture and fittings<br />

and even in complete built structures.<br />

But I must admit I am looking much<br />

more closely as plastic gets recycled<br />

more and can be turned into an object<br />

to admire and use. Sometimes in<br />

combination with wood.<br />

I saw this for myself when I went to the<br />

launch of the new global headquarters<br />

of Archwey in Singapore recently.<br />

Archwey is a holding company for<br />

various brands that innovate materials,<br />

including Arch & Hook.<br />

Not only did Sjoerd Fauser, the CEO of<br />

Archwey make a seemingly outlandish<br />

claim that his company intended to<br />

“rid the world of virgin plastics”, but he<br />

showed me how it could be done. He<br />

showed me how his brand-new office<br />

has been filled with recycled plastic<br />

furniture and fittings.<br />

He started in the Netherlands by turning<br />

plastic waste into coat hangers for the<br />

fashion industry. Now he has found an<br />

efficient way of putting plastic waste,<br />

literally, through the mill, turning it into<br />

tiny pellets which can then be moulded<br />

into objects of desire.<br />

Arch & Hook has also done a lot of<br />

work for Nike, not only to make use of<br />

recycled plastic in all the sports shoes<br />

it makes, but using what he calls “the<br />

BLUE recycling process”.<br />

On top of this, retail stores themselves<br />

have become shrines to the<br />

convenience of virgin plastic — often<br />

crammed with plastic display cases,<br />

shelving, packaging and furniture that<br />

has been designed to be thrown away<br />

rather than reused.<br />

Arch & Hook’s experimentation with<br />

sustainable materials dates back<br />

to 2016, when the company started<br />

exploring a way to turn ocean-bound<br />

and post-consumer plastics into new<br />

products.<br />

20 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

ENVIRONMENTAL REPORT<br />

During London Fashion Week in<br />

September 2019, the company launched<br />

BLUE: a fully-recyclable hanger<br />

made from 100% recycled plastics<br />

predominantly sourced from four of the<br />

most polluting rivers in the world.<br />

Arch & Hook takes<br />

plastic waste<br />

through the BLUE<br />

recycling process<br />

Fauser has been quoted in media around<br />

the world as he believes “any fashion<br />

or retail company dragging its heels<br />

on eliminating virgin plastic from its<br />

business will soon be left behind. The<br />

tide is turning against single-use plastic<br />

— both in the public consciousness and<br />

now through global legislative action”.<br />

In March this year, at the Environment<br />

Assembly in Nairobi, Kenya,<br />

representatives from the United Nations<br />

(UN) Member States “endorsed a historic<br />

resolution” to combat plastic pollution.<br />

An Intergovernmental Negotiating<br />

Committee will be established this year<br />

with the aim of drafting an international<br />

legally binding agreement before 2025.<br />

This is truly significant. Rather than<br />

only focusing on waste management,<br />

the agreement will address diverse<br />

alternatives to the full lifecycle of<br />

plastic, including production, design<br />

and disposal.<br />

So, through the work of Archwey and<br />

others, we should expect to see a lot<br />

more practical uses for recycled plastic;<br />

furniture and furnishings made to last,<br />

too.<br />

We have reported before on the<br />

Singapore social enterprise, Semula,<br />

because it has been doing its best to<br />

show what can be done by recycling<br />

or repurposing plastic waste, taking<br />

it through a heating and moulding<br />

process to produce items for home and<br />

office environments.<br />

According to Jeryl Yep, co-founder<br />

of Semula, the company is still going<br />

strong whether “by design and good<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 21

ENVIRONMENTAL REPORT<br />

intentions”, taking discarded highdensity<br />

polyethylene (HDPE) bottles<br />

and turning them into “one-of-akind<br />

material which can be used as<br />

decorative claddings, fittings and the<br />

making of furniture and more”.<br />

Limited only by the imagination, Yep<br />

said Semula has to date diverted<br />

1.7 tonnes of plastic waste from<br />

the incineration plant and landfill<br />

into upcycled new plastic sheets for<br />

partners to use in commissioned<br />

projects.<br />

Semula believes strongly that only by<br />

showing how plastic waste can have<br />

commercial value can we change<br />

people’s perspective about it.<br />

“We need to reduce the overuse of<br />

finite resources,” Yep insisted. “And,<br />

instead, consider the use of nontraditional<br />

material like upcycled<br />

plastic. This takes away some of the<br />

pressure on our natural ecosystems,<br />

and through time, leads to behaviour<br />

change for a more sustainable way<br />

of living.”<br />

Semula operates and makes all<br />

its sheets locally. It works and<br />

collaborates with local fabricators<br />

and craftsmen to design and turn<br />

waste into a treasured thing of<br />

beauty. Educating businesses<br />

and creating greater awareness in<br />

the minds of the consumer is an<br />

important by-product of the work<br />

done by Semula.<br />

Working in partnership helps too, so<br />

maybe Semula and Archwey could<br />

find ways to collaborate in a similar<br />

way to what Semula has done with<br />

the woodcrafts firm, Roger&Sons.<br />

These innovative and creative people<br />

in Roger&Sons have just told us<br />

about their latest Singapore project.<br />

They now have a collaboration with<br />

the Singapore Airlines by repurposing<br />

economy class three-seaters and<br />

galley carts from retired Airbus A380<br />

planes.<br />

While they had in mind making these<br />

for airline enthusiasts, they have<br />

recreated limited-edition collectables<br />

using repurposed local wood. This<br />

upcycling collaboration features<br />

Roger&Sons’ initiative, The Local Tree<br />

Project — an effort to rehabilitate<br />

abandoned logs felled in our city.<br />

Its version of the economy class<br />

three-seater showcases local African<br />

mahogany as the material of choice,<br />

while retaining its original aluminium<br />

frames and plastic armrests.<br />

Even identifying its forms, the<br />

enterprising woodcrafters mimicked<br />

its curvatures to mould the seats for<br />

comfort. They also kept its functional<br />

seat-recline mechanism, allowing<br />

additional control for passengers’<br />

comfort.<br />

There will probably be many furniture<br />

collectors — more than just aviation<br />

enthusiasts — who would love to<br />

feature these unique “flying objects”<br />

in their homes or offices.<br />

Whether for repurposing airline<br />

seats and galley carts, largely made<br />

of plastic and metal, or producing<br />

furniture and useful objects for the<br />

home and office from ocean-bound<br />

plastic, we are seeing a desire by<br />

committed businesses to come up<br />

with a second life for what would<br />

normally be dumped.<br />

Archwey puts it this way: “We collect<br />

post-consumer and post-industrial<br />

plastic waste via blue bins and put it<br />

2<br />

through a process of technological<br />

1<br />

2<br />

3<br />

recycling, including extrusion and<br />

granulation, before transforming it<br />

into high-quality recycled pellets that<br />

can be manufactured into anything.<br />

We design for the future — and work<br />

with companies that realise that is<br />

the only option, both ethically and<br />

economically.”<br />

The trick here is making sure that<br />

materials are designed from the<br />

very beginning with their second life<br />

already in mind. That is “sustainability<br />

thinking”. That is applying the<br />

principles of a circular economy.<br />

And maybe that is the future for the<br />

built environment — inside and out<br />

— as its grapples with the challenge<br />

of producing a large share of global<br />

greenhouse gas emissions. P<br />

Legend<br />

1 Semula takes<br />

plastic bottles and<br />

turns them into<br />

coasters, plates or<br />

tiles<br />

2 Plastic recycled<br />

and used in this<br />

bar table top<br />

and stool seats<br />

for Archwey’s<br />

Singapore<br />

headquarters<br />

3 Close up of the<br />

wood treatment<br />

used for upcycled<br />

airline seats<br />

22 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

Canadian wood.<br />

Versatile and durable.<br />

Gỗ Canada.<br />

Đa dụng và bền bỉ.<br />

WESTERN HEMLOCK GỖ ĐỘC CẦN BỜ TÂY<br />

TRY CANADIAN WOOD<br />

HÃY DÙNG THỬ GỖ CANADA<br />

canadianwood.com.vn<br />

+84 (0)274 380 3609<br />

A range of high-quality certified lumber from sustainably<br />

managed forests of British Columbia, Canada.<br />

Các loại gỗ xẻ chất lượng cao được chứng nhận từ nguồn rừng trồng<br />

được quản lý bền vững của tỉnh bang British Columbia, Canada.

IN PERSON<br />

“Delivering added<br />

value to our customers”:<br />

Teknos expands to Vietnam<br />

The new commercial and competence centre in Vietnam by<br />

Teknos promises faster response time, and solutions and services<br />

tailored to each customer. How can this customer-centric<br />

business model strengthen the value of the company?<br />

By Yap Shi Quan<br />

Teknos’s new commercial<br />

and competence centre in<br />

Vietnam<br />

OFFERING “VALUE-ADDED SERVICES”<br />

Everything a company does impacts their<br />

customers’ perceptions and decisions to keep<br />

choosing the company’s brand, solutions,<br />

products and services: This customer-centric<br />

model is one of the guiding business principles<br />

of Teknos, as declared by Paula Salastie,<br />

CEO of Teknos and owner of Teknos Group.<br />

It is also one of the various reasons why the<br />

coating solutions provider has opened a new<br />

commercial and competence centre in Vietnam<br />

in September, with the aim of enhancing their<br />

collaboration with Vietnamese customers<br />

and support them with faster response time,<br />

and tailored solutions and services of their<br />

offerings.<br />

Located in the province of Dong Nai, the new<br />

centre includes Teknos’s sales and business<br />

development, customer service, technical<br />

application and services, training, and<br />

warehouse facilities. Wanda Smith, managing<br />

director of Teknos Malaysia, elaborated: “Our<br />

local technical support and extensive global<br />

network are at our customers’ service to help<br />

find the right solution for their needs. On top of<br />

that, we train our customers, help with safety,<br />

chemistry, application, painting line processes<br />

and so on. All these can be done from either our<br />

new facility centre or at the customer’s site.”<br />

24 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

IN PERSON<br />

As a whole, Teknos offers various types of<br />

value-added services, including product<br />

development and adjustment, production<br />

line configuration or set-up, line audit,<br />

sampling and pre-line trial, colour matching,<br />

quality performance testing, on-site or<br />

virtual technical troubleshooting, and more.<br />

According to Salastie, such services are part<br />

of the company’s strategic pillar of ‘Customer<br />

Experience’, where it aims to be as close to<br />

their customers as possible by increasing<br />

customer satisfaction and creating “long-term<br />

customer relationships”. In essence, Teknos<br />

hopes to interact with them “at all stages and<br />

touchpoints of their journey, before and after<br />

they become [their] customer”.<br />

She added: “Each customer has their unique<br />

operation model and pain points. For some,<br />

this might be about energy savings, others<br />

might want to solve recycling of over-sprayed<br />

paint, or they might need to understand their<br />

contribution to greenhouse emissions. We<br />

tailor our services with close collaboration,<br />

to understand our customers better all the<br />

way to their end customer. For us, aftersales<br />

services involve following how our<br />

customers’ products develop and adapting our<br />

collaboration, so that our services suit their<br />

given circumstances.”<br />

1<br />

As mentioned by Salastie, Teknos looks at their<br />

own manufacturing footprint and emissions<br />

throughout the lifecycle of their customers’<br />

products. The company is committed to<br />

sustainability in their own processes, their<br />

customers’ journey, and in the collaborations<br />

with suppliers and other stakeholders, by<br />

practising their own strategies modelled after<br />

the United Nations’ Sustainable Development<br />

Goals (SGDs): future generation, sustainable<br />

solutions and services, people and culture, and<br />

responsible operations and supply chain. For<br />

instance, Teknos chose to open the new centre<br />

in the JSC Industrial Park because the park<br />

was equipped with sustainable infrastructure<br />

systems, including a central wastewater<br />

treatment and built-in air ventilation.<br />

2<br />

Legend<br />

1 Teknos team with the<br />

JSC team<br />

2 The reception area<br />

3 The technical<br />

application room<br />

Salastie intuited that building ESG values<br />

and after-sales services is crucial in delivering<br />

added value to their customers: “This will<br />

reinforce or reassure our customers that they<br />

have made the right choice in choosing us, and<br />

make them feel good about the Teknos brand.<br />

3<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 25

IN PERSON<br />

It plays an important role in customer<br />

satisfaction and long-lasting customer<br />

relations, generating loyal customers<br />

and increasing Teknos brand value.”<br />

WHY VIETNAM?<br />

In 2021, Vietnam contributed 36% of<br />

Teknos’s total sales revenues in the<br />

South East <strong>Asia</strong>n region, among other<br />

key markets that Teknos is located in,<br />

such as Malaysia, Thailand, Indonesia<br />

and Cambodia. This is an indicator of<br />

the company’s growing demand in the<br />

country, and hence their decision to<br />

expand into Vietnam to better support<br />

the demand. Smith commented that<br />

they are also aware Vietnam is one<br />

of the fastest growing economies in<br />

the world, with “openness to foreign<br />

investment and the Vietnamese<br />

government putting incentives in place”,<br />

attracting Teknos to invest further in the<br />

market.<br />

4<br />

5<br />

“Currently, Vietnam is already one of the<br />

leading manufacturers and exporters of<br />

furniture, including wood for indoor and<br />

outdoor purposes. With all the existing<br />

and growing opportunities in sight, we<br />

are confident that our Teknos solution<br />

offerings, be it products or services, will<br />

be able to benefit customers in Vietnam<br />

— such as our bio-based products,<br />

finishings and systems such as digital<br />

printing or embossing, and value-added<br />

services for pre- and post-purchases.”<br />

For better collaborations with their<br />

customers, Teknos chose Dong<br />

Nai province also because it is one<br />

of Vietnam’s main manufacturing<br />

centres. Smith explained that the JSC<br />

Industrial Park is most favourable in<br />

terms of geographical location for<br />

business development, investment, and<br />

transport intersections for connectivity,<br />

being close to various ports like Cai Lai<br />

and Cai Mep ports, and airports such as<br />

Tan Son Nhat airport and Long Thanh<br />

international airport. With Teknos’s<br />

waterborne and UV products imported<br />

from Malaysia, and additional products<br />

from their Finland, Germany, Denmark<br />

or China factories, customers can<br />

choose from different supply channels.<br />

Furthermore, they can have easier<br />

access to local sales and technical<br />

support team, as well as regional and<br />

global specialists for more complex<br />

projects.<br />

Following their Vietnam expansion,<br />

Teknos is planning to grow their<br />

business by penetrating existing<br />

markets in <strong>Asia</strong>-Pacific, mainly<br />

Indonesia, Thailand, Australia, Japan<br />

and New Zealand. Salastie concluded:<br />

“Currently we are managing these<br />

markets via export directly or with<br />

our distribution network. The aim<br />

is to expand our product range and<br />

services in furniture as well as to other<br />

customer areas and, as the business<br />

grows, eventually to have our own<br />

entities.” P<br />

Legend<br />

4 The technical<br />

laboratory<br />

5 Warehouse<br />

containing<br />

Teknos solutions<br />

26 <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong>

PRODUCT HIGHLIGHT<br />

Greater sustainability<br />

with Dieffenbacher’s CPS+<br />

continuous press system<br />

Environmental regulations are<br />

tightening and the cost of CO2 emissions<br />

is increasing, but with Dieffenbacher’s<br />

CPS+ continuous press system,<br />

manufacturers can balance economic<br />

and sustainability goals to build a<br />

better future for their business and the<br />

environment.<br />

Dieffenbacher’s Press Emission<br />

Control System is just one tool to help<br />

achieve that balance. It protects the<br />

environment by cleaning exhaust gases<br />

from the press through a washing<br />

process. Dust and condensable fractions<br />

of exhaust gases are bound to fine water<br />

droplets. These solid and liquid parts<br />

are separated in the system’s Inline<br />

Scrubber. In addition, pre-absorber<br />

units are available to reduce volatile<br />

organic compounds (VOC) emissions,<br />

particularly formaldehyde.<br />

Another way to balance economic and<br />

sustainability goals is to reuse heat<br />

from the press exhaust air elsewhere<br />

in the production process. When the<br />

press exhaust air is cleaned by a wet<br />

air cleaning system, for example, the<br />

Inline Scrubber in the Press Emission<br />

Control System, the process water<br />

from the wet air cleaning system cools<br />

down. The result is more effective<br />

air cleaning, as cold water can bind<br />

emissions better. The recovered<br />

low-calorific heat from the process<br />

water can then be used, for instance,<br />

to preheat the hall air inside the<br />

production building to save heating<br />

energy and costs. It can also be used<br />

to preheat the glue. This not only<br />

saves energy, but the resulting lower<br />

viscosity glue enables a more precise<br />

glue spray pattern. More consistent<br />

operations, meanwhile, produce less<br />

excess glue. These are two of the<br />

various ideas to reduce energy costs<br />

and emissions and increase profits by<br />

reusing press exhaust air, according to<br />

Dieffenbacher. P<br />

Reuse heat from<br />

the press exhaust<br />

air elsewhere in the<br />

production process,<br />

such as to preheat<br />

the glue<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>November</strong> / <strong>December</strong> <strong>2022</strong> 27

PRODUCT HIGHLIGHT<br />

Automated spray coating<br />

In carpentry and joinery services for living, working and<br />

commercial areas, carpentry company Bantli focuses on<br />

quality, customer satisfaction and innovative technology. Their<br />

automated spray coating line from Buerkle is an example of this.<br />

SEEING AND FEELING SURFACES<br />

Interior designers and furniture manufacturers<br />

face the challenge of making the looks and<br />