December 2022

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DECEMBER <strong>2022</strong><br />

>>> • WINTER WORKING • SKILLS SUPPORT • BATTEN AWARENESS • TOTAL TALK • >>>

WestWood Liquid Technologies Limited<br />

31 Morris Road, Nuffield Industrial Estate,<br />

Poole, Dorset BH17 0GG<br />

Phone: +44 800 808 5480<br />

www.westwood-uk.com<br />

Liquid Applied<br />

Waterproofing Systems<br />

Car Parks<br />

Flat Roofs<br />

Metal Roofs<br />

Gutters<br />

Roof Terraces Balconies<br />

Liquid Applied<br />

Waterproofing Systems<br />

Car Parks<br />

Flat Roofs<br />

Metal Roofs<br />

Gutters<br />

Roof Terraces<br />

Balconies<br />

WESTWOOD <strong>2022</strong>.indd 1

Editor’s Comment<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

As we approach the end of another tricky year for the roofing sector and<br />

wider construction industry, there’s a general feeling that the challenge<br />

around the supply of materials is beginning to settle – albeit from a<br />

particularly disruptive high point in <strong>2022</strong>.<br />

Indeed, the latest Product Availability Statement from the Construction<br />

Leadership Council’s Product Availability working group, states availability<br />

of building materials and products is at “its best since pre-pandemic levels<br />

last seen at the end of 2019.” However, as highlighted in NFRC’s latest<br />

State of the UK Roofing Industry report for Q3 <strong>2022</strong>, challenges around<br />

pricing and skills continue to persist. The report shows three quarters of<br />

firms (75 per cent) reported seeing costs rise compared to the previous<br />

quarter, and 51 per cent of firms reported greater difficulty finding the<br />

operatives and staff with the right skills to meet increasing workloads. You<br />

can view the full survey findings at www.total-contractor.co.uk.<br />

Continuing the focus on skills and recruitment, Ruth Scarrott, NFRC’s Head<br />

of Careers, discusses the new programme of support NFRC can offer<br />

roofing employers to help recruit and retain operatives. As Ruth explains in<br />

her article on page 12: “I urge contractors who are recruiting, now or in the<br />

future, to get in touch to see how the ECO project can benefit them.”<br />

Elsewhere in this issue Matthew Catterall of Taylors Solicitors provides the<br />

second part of his focus on selling a roofing business (p14); we put the<br />

questions to Rob Ward of RLW Roofing (p32); plus we talk winter project<br />

planning and safety with Kris Hallee of WernerCo on page 60.<br />

So read on for all this and much more!<br />

Have a lovely break over Christmas!<br />

Matt<br />

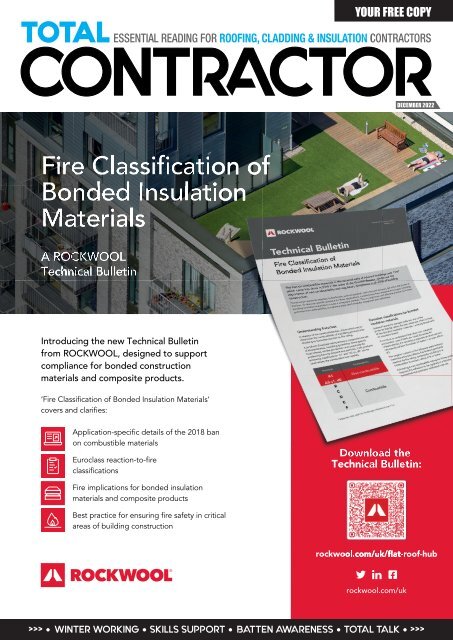

Front cover courtesy of ROCKWOOL UK. Lisa Stephens explains how to<br />

specify insulation for flat roofs to meet modern design, comfort and<br />

safety requirements on page 56.<br />

FOLLOW US @TOTCONTRACTORUK<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

Commercial Manager: Jake Roxborough<br />

DD: 01892 732 047<br />

Mob: 07956 133314<br />

Email: jakeroxborough@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

Supported by:<br />

40

Contents<br />

3 KEY FEATURES<br />

32<br />

16 BATTEN AWARENESS<br />

Daniel Redfern of Marley says roofers need to<br />

be alert to the continuing issue of counterfeit<br />

and substandard roofing batten entering the UK<br />

market<br />

32 TOTAL TALK: ROB WARD<br />

We put the questions to Rob Ward, MD of RLW<br />

Roofing, discussing his career, challenges<br />

within the sector, key projects he’s been<br />

involved with, and his long affiliation with the<br />

Sika Sarnafil system<br />

46 MATERIAL SELECTION<br />

Simon Walker of SIG Zinc & Copper explains why<br />

regulation changes and cost pressures mean<br />

the choice of material and substrate is key to<br />

the success of metal cladding projects<br />

46<br />

FURTHER READING<br />

24 SUBSTRATE SUCCESS<br />

Wallbarn’s Julian Thurbin discusses the crucial role of<br />

substrates and benefits of modular green roof systems<br />

34<br />

34 TOP CLASS WATERPROOFING<br />

Carl Bailey of Elevate discusses modular school building<br />

projects and why EPDM systems are so well suited<br />

38 FIRE STANDARDS FOCUS<br />

Flex-R’s Ben Midwinter explains why checking fire test<br />

certifications is key as supply challenges persist<br />

40 ASK A. PROCTOR GROUP<br />

The team discuss whether you need an airspace<br />

between insulation and underlay in pitched roofs<br />

56 COVER STORY: ROCKWOOL UK<br />

Lisa Stephens explains how to specify insulation for flat<br />

roofs to meet modern design and safety requirements<br />

59 QI BY QI COLUMN<br />

The Quantum Insulation team discuss the impact of<br />

insulation fire performance reclassification<br />

4 TC DECEMBER <strong>2022</strong>

REGULARS<br />

12 NFRC ROOFING TALK<br />

Ruth Scarrott discusses a new programme to<br />

support roofing businesses in the recruitment<br />

and retention of new staff<br />

14 ASK THE SOLICITOR<br />

Matthew Catterall of Taylors Solicitors looks at<br />

the steps to take and pitfalls to avoid once you’ve<br />

found a buyer for your roofing business<br />

18 PERFECTLY PITCHED<br />

Roofing consultant John Mercer discusses the<br />

considerations to make when choosing the type<br />

of roof covering for pitched roof projects<br />

54 KNAUF INSULATION<br />

TECH TALK<br />

Bradley Hirst explains what you need to know<br />

about insulating warm flat roofs<br />

INDUSTRY NEWS<br />

06 SKILLS ON SHOW<br />

Which talented roofer walked away with the top prize<br />

at this year’s SkillBuild final?<br />

10 WHAT A YEAR<br />

Sarah Spink of LRWA and Carrie Blackshaw of Minster give<br />

their thoughts on <strong>2022</strong>, plus look ahead to 2023<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

16<br />

TOTAL<br />

CLADDING<br />

46<br />

TOTAL<br />

INSULATION<br />

54<br />

We hear about Hambleside Danelaw’s Dryseal training course on page 8.<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

08<br />

60<br />

DECEMBER <strong>2022</strong> TC 5

Industry News<br />

LRWA STRENGTHENS<br />

ITS BOARD<br />

The Liquid Roofing and Waterproofing<br />

Association (LRWA) has<br />

appointed Cathal Quinn<br />

as a co-opted Board<br />

member.<br />

As Managing Director of<br />

MOY, a specialist in waterproofing<br />

systems for roofs, Cathal (pictured) has more<br />

than 18 years’ construction experience. As a<br />

co-opted LRWA Board member, he will be<br />

using his industry knowledge and experience<br />

to help the association deliver its aims.<br />

He said: “MOY has been an LRWA member for<br />

more than a decade. I’ve always been<br />

impressed by the association’s proactive<br />

approach which has seen it continually evolve,<br />

helping to raise our industry’s profile as well<br />

as product and installation standards.<br />

“It’s a privilege to be invited to join the Board<br />

and have the opportunity to help build on the<br />

LRWA’s success. There are several areas<br />

which I’m keen to support, including<br />

promoting roofing as an attractive career for<br />

young people, and educating specifiers,<br />

contractors and distributors on why, when and<br />

where to use liquid waterproofing.<br />

“As part of this aim, promoting best practice<br />

and complying with new and changing<br />

legislation is key. The LRWA has done a<br />

fantastic job in giving our sector a voice in the<br />

wider construction industry by working closely<br />

with organisations like the Construction<br />

Products Association (CPA) to help influence<br />

high level issues.<br />

“I’d like to help the LRWA keep this<br />

momentum going, so that we can continue to<br />

promote competency across the supply chain<br />

and highlight its importance, especially during<br />

specification.”<br />

www.lrwa.org.uk<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

ROOFING SKILLBUILD WINNER ANNOUNCED<br />

Jordan Maley (pictured), an apprentice<br />

calculation and measurement skills.<br />

at South Lanarkshire College, has<br />

SkillBuild is the largest multi-trade<br />

been awarded the Gold Medal in the<br />

competition in the UK for construction<br />

Roof Slating and Tiling competition at<br />

trainees and apprentices, and competitors<br />

SkillBuild <strong>2022</strong>.<br />

are tested on their technical abilities, time<br />

A total of seven talented slating and tiling<br />

management, character, and commitment.<br />

apprentices competed this year at the competition,<br />

It is organised by CITB, with the Roof Slating and<br />

which was held at Edinburgh College from 15 to<br />

Tiling competition delivered by NFRC. Roofing<br />

17th November. Each had earned their spot in the<br />

materials were contributed by BMI, CUPA PIZARRAS,<br />

competition at the regional qualifiers held at<br />

Hambleside Danelaw, Proctor Roofshield, Midland<br />

colleges across the country earlier in the year.<br />

Lead, SR Timber and SIG Roofing.<br />

The result follows Jordan’s success a year ago<br />

Matt Timby, a member of the judging panel for the<br />

when he took victory at the inaugural Great British<br />

Roof Slating and Tiling competition, said: “The<br />

Slate Off. The judges said that his SkillBuild<br />

competitors were set a challenging task which<br />

victory reflected ‘his accuracy and natural ability’,<br />

was designed to take them out of their comfort<br />

reporting that the competitors were given a<br />

zone. Each competitor took the task head on and<br />

‘testing design within the slating task which<br />

came out with extremely good results.”<br />

Jordan took on extremely well’, producing an<br />

impressive and well finished project.<br />

He added: “It was great to see them all apply<br />

themselves with such determination. They should<br />

Jacob Blight, a student at South Devon College,<br />

all hold their heads high as shining ambassadors<br />

was awarded the silver medal, and Kyran<br />

for the industry. I wish them all the best in their<br />

Sharlotte, of Leeds College of Building, was<br />

future careers.”<br />

awarded bronze. Kyran was also the winner of the<br />

‘stretch test’ – an additional challenge set to test www.nfrc.co.uk<br />

ECO+ CAN’T BE CONSIDERED ‘JOB DONE’<br />

Following the launch of the<br />

Executive of the FMB (left),<br />

Government’s £1 billion<br />

said: “I welcome any move to<br />

ECO+ scheme, which it says<br />

improve the UK’s leaky and<br />

will see hundreds of<br />

draughty homes and make<br />

thousands of homes across<br />

them cheaper to heat. ECO+ is<br />

the country receive new<br />

a step in the right direction,<br />

home insulation, the Federation of Master targeting a much wider section of homeowners,<br />

Builders has stated the support for<br />

but it must not be considered ‘job done’ by the<br />

homeowners to make their homes warmer and Government. I’m also cautious about rollout of the<br />

cheaper to heat is welcome, but this shortterm<br />

focus on single measures must be negotiable to avoid a repeat of failures [such as]<br />

scheme; consultation with industry is non-<br />

followed by a long-term comprehensive plan the Green Homes Grant Scheme, and we must<br />

to retrofit all of the UK’s 28 million leaky and ensure that installation is of the highest quality.<br />

energy inefficient homes.<br />

Ultimately, to give homeowners and the industry<br />

confidence, we need a broader whole-house<br />

Discussing the ECO+ scheme, following the<br />

approach to retrofit, rather than a piecemeal policy.”<br />

launch by Business and Energy Secretary Grant<br />

Shapps on 28th November, Brian Berry, Chief www.fmb.org.uk<br />

6 TC DECEMBER <strong>2022</strong>

SPEED AND<br />

SIMPLICITY,<br />

BY DESIGN.<br />

Introducing the new Siderise CT<br />

Cavity Tray.<br />

A unique trilateral design that’s flush-fitting, fully aluminium<br />

wrapped and pre-filled with non-combustible stonewool, making<br />

it incredibly quick and easy to install as well as A2-s1,d0 rated.<br />

Its exclusive design* is engineered for use with Steel Framing<br />

Systems and blockwork inner leaves without hot works, screwing<br />

or chamfering, whilst corners are easily cut on-site. Backed by<br />

forty-five years of cavity barrier innovation, full site support<br />

services and our market leading inspection app, Siderise CT<br />

Cavity Tray is another innovation to help make projects easier.<br />

Your Workmanship. Our Ingenuity. Swift Installation.<br />

Discover more at Siderise.com<br />

CERTIFICATE 21/5978<br />

*Patent pending

Industry News<br />

Hambleside Danelaw says training can be completed at<br />

its facility in Northampton or in Northern Ireland.<br />

DRYSEAL TRAINING<br />

Hambleside Danelaw conducts regular<br />

training sessions for contractors who<br />

want to become approved to install<br />

Dryseal, the flat roofing system<br />

manufactured from GRP.<br />

The manufacturer says Dryseal has been a<br />

contractor favourite for years and is<br />

manufactured in accordance with ISO 9001<br />

Quality and ISO 14001 Environmental<br />

standards, and is additionally approved by the<br />

British Board of Agrément (BBA).<br />

Dryseal’s Business Development Manager,<br />

Dan Addley, explained that the course is a<br />

“good mix of interactive practical and<br />

classroom learning that can be tailored to<br />

meet the knowledge base of the individuals on<br />

the Dryseal course.” He continued: “Over the<br />

two-day course, attendees learn all aspects of<br />

the Dryseal system including laying of the field<br />

areas, trim installation, the detailing required<br />

on corners, upstands etc., how to correctly mix<br />

catalyst, how to apply the top coat, and most<br />

importantly safe ways of working.<br />

“Where needed, advice can be given on<br />

estimating and how to correctly work out which<br />

components are needed for the installation.<br />

“Overall, I would highly recommend anyone<br />

wishing to further their roofing knowledge to<br />

attend one of our courses.”<br />

Find out more about Dryseal’s approved<br />

contractor training on 01327 701 900 or visit<br />

www.hambleside-danelaw.co.uk<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

WRAPTITE EXCELS ON OFFSITE PROJECT<br />

The Wraptite external air<br />

quality of the system from<br />

barrier system from A. Proctor<br />

installation to build and<br />

Group has been selected as<br />

completion. Wraptite is an<br />

part of a new zero carbon<br />

excellent quality product, and<br />

affordable homes project at<br />

the self-adhesive backing gives<br />

New Ferry on the Wirral.<br />

a very neat finish.<br />

The project at Windsor Close in New Ferry is a “The technical team at the A. Proctor Group<br />

new development of three-bedroomed terraced supported us throughout and provided<br />

houses to be constructed by Property<br />

comprehensive condensation risk analysis reports<br />

Development Group Starship at its off-site at the outset.<br />

manufacturing facility in Deeside.<br />

“The spacious 1,200ft² homes offer the lowest<br />

The superior airtightness performance of the running costs of any property in the immediate<br />

Wraptite membrane from the A. Proctor Group is area and deliver more affordable living for local<br />

the perfect solution, delivering significant benefits people. These Carbon Zero homes provide over<br />

to the combination of in-factory manufacture and 105m² of modern, affordable living space and<br />

on-site housing construction.<br />

were installed in seven days, ready for internal<br />

Karl Ventre, Director at Starship, explained why<br />

fit-out.<br />

Wraptite was chosen to achieve the airtightness “Starship’s unique panelised model means that a<br />

solution and how it benefits off-site construction. new home can be delivered and installed<br />

“We have specified this product within our system anywhere a refuse collection vehicle can fit, with<br />

offering for the last three years, and it has always no special arrangements or unnecessary<br />

performed well and helped contribute to good disruption to the community.”<br />

airtightness test results.<br />

A. Proctor says the Wraptite air barrier system<br />

“The self-adhesive membrane is easily applied in offers a safer and simplified membrane system,<br />

the factory, bonded externally to the substrate, and it is a fully self-adhered vapour permeable air<br />

and ensures that the membrane is held firmly in barrier certified by the BBA.<br />

place, even during transportation, maintaining the<br />

www.proctorgroup.com<br />

The latest Construction Product Availability Statement from John Newcomb, CEO of the<br />

Builders Merchants Federation and Peter Caplehorn, CEO of the Construction Products<br />

Association, both co-chairs of the Construction Leadership Council’s Product Availability<br />

working group, states that “product supply continues to improve, with availability of building<br />

materials and products overall now at its best since pre-pandemic levels last seen at the<br />

end of 2019.”<br />

The statement continues: “There is a plentiful supply of timber in the UK and prices have reduced<br />

for popular groups such as CLS; however, log prices in Europe and North America are still strong<br />

and production is being reduced to reflect demand in the UK and Europe. This could lead to gaps in<br />

the supply chain if demand rises suddenly but should not be a major issue if demand continues at<br />

current levels.”<br />

The statement also cautions that: “Inflationary pressures rather than availability present the main<br />

challenges for energy intensive products such as glass, concrete, cement, PIR, plasterboard and<br />

bricks.” View the full statement at www.constructionleadershipcouncil.co.uk<br />

8 TC DECEMBER <strong>2022</strong>

Handrails:- EasyGuard<br />

free-standing Guardrails<br />

*CurveyGuard – an aesthetically pleasing curved rail.<br />

*EasyGuard – raked or straight legs dependant on<br />

application. *FoldGuard – folding handrail.<br />

Trip hazard reduction – long thin base-plates with<br />

Counterweights used on un-secured ends only. Placed at 2m<br />

centres maximum to enable use for leading edge protection.<br />

Galvanised or powder coated finish. Protective mats 5mm<br />

bonded to the base plates.<br />

Standards – Exceeds Class A EN13374- Class A; For<br />

leading edge protection HSE/SR 15, September 1988.<br />

Nationwide delivery or contract installation. – Free material<br />

quantifying service – info@safetyworksandsolutions.co.uk<br />

Ladders:- Easy Fit<br />

Compliant to both BS/EN 5395 and 14122 –<br />

To comply with the standards for<br />

permanent ladders all mild steel then hot<br />

dipped galvanised to BS/EN 1461.<br />

All typical ladders bespoke – email<br />

info@safetyworksandsolutions.co.uk for a<br />

survey check sheet.<br />

Easy Fit, all ladder components are Easy<br />

to assembly; in manageable parts Easy to<br />

handle and install.<br />

Rest Platforms and ladders with special<br />

fixing requirements; solutions provided by<br />

Safetyworks in house.<br />

(All components for British Standard<br />

compliant ladders require steel components<br />

with timber and aluminium recommended<br />

for temporary use only)<br />

HANDRAILS<br />

-<br />

LIFELINES<br />

-<br />

WALKWAYS<br />

-<br />

FALL GUARDS<br />

-<br />

FLEXIDECK<br />

-<br />

DEMARKATION<br />

-<br />

LADDERS<br />

-<br />

STEELWORK<br />

-<br />

Tel: 01487 841400<br />

www.safetyworksandsolutions.co.uk

Industry News<br />

CARRIE BLACKSHAW,<br />

FIRE PROTECTION<br />

SALES DIRECTOR,<br />

MINSTER<br />

“<strong>2022</strong> has seen a great<br />

deal of growth in the<br />

fire protection market.<br />

Changes in legislation and the newly<br />

revised Building Safety Act have meant that<br />

demand for fire protection products has<br />

continued to strengthen, whilst awareness<br />

and understanding of the issues<br />

surrounding installation have also<br />

continued to improve.<br />

“In order to meet this growing demand, at<br />

Minster we have spent the past 12 months<br />

strengthening and enhancing our fire<br />

protection offering, creating a specialist<br />

division focussed on providing customers<br />

with the products and solutions needed to<br />

meet more stringent building regulations.<br />

Headed up by myself, we are also able to<br />

provide customers with technical support if<br />

required, helping to ensure that greater<br />

standards of competence are being upheld in<br />

the construction of safer buildings.<br />

“We’ve seen sales of fire protection solutions<br />

increase by almost 50% during the last 12<br />

months, a figure which can be attributed to<br />

both our improved capabilities and the<br />

heightened demand that exists in the<br />

marketplace.<br />

“The strategic changes we have implemented<br />

during the last 12 months mean that as we<br />

look ahead to 2023, we are now well placed to<br />

make the most of the opportunities the<br />

current environment presents. Whilst the<br />

overall outlook for the construction industry<br />

appears to be difficult, remediation projects<br />

present a real opportunity for contractors with<br />

re-cladding and fire protection installations<br />

required on a large scale, nationwide.”<br />

www.minsteronline.co.uk<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

END OF YEAR COMMENTS...<br />

SARAH SPINK,<br />

LRWA CEO<br />

“This year saw a lot of<br />

uncertainty in the construction sector. We’ve<br />

experienced unprecedented political upheaval<br />

which has weakened the economy, and the<br />

energy crisis has impacted us all. Issues with<br />

product availability has driven prices up,<br />

which is partly down to the impact of the war<br />

in Ukraine. But across the entire sector, trade<br />

associations have never known a period of<br />

change like it, especially following the twoyear<br />

pandemic.<br />

“The impact of the Grenfell tragedy is still ongoing<br />

in terms of building safety issues. In response,<br />

new legislation has come into force and the<br />

introduction of competency standards for<br />

construction. This year, trade associations have<br />

also been lobbying hard to minimise the impact of<br />

the transition from CE to UKCA marking.<br />

“As an association, the LRWA had a strong year.<br />

We experienced almost a 38 per cent growth in<br />

membership, with 26 new members,<br />

reinforcing the need for specialist<br />

trade associations to represent our<br />

sector at higher levels, especially<br />

during difficult periods.<br />

“We were also thrilled to bring back<br />

face-to-face events like the LRWA Awards<br />

and Gala in March, which recognises the<br />

impressive skills and strengths of all those who<br />

work in our sector. But it’s not just events, we’ve<br />

managed to meet in-person to continue our work<br />

within the various working groups the LRWA is<br />

involved in.<br />

“As well as the success of the <strong>2022</strong> Awards,<br />

which was our biggest yet, we also raised more<br />

than £10K for LandAid in our Virtual Charity<br />

Challenge. The roofing sector surpassed all our<br />

expectations as we came together to help end<br />

youth homelessness; something which seems<br />

“The LRWA remains<br />

optimistic for 2023.<br />

Historically, the sector<br />

performs well in an<br />

economic downturn<br />

driven by a focus on<br />

refurbishing existing<br />

buildings, rather than<br />

investment in new<br />

build”<br />

even more important as we live through a cost-ofliving<br />

crisis.<br />

“Looking ahead to 2023, construction output is<br />

forecast to fall by 3.9 per cent, following a rise of<br />

two per cent in <strong>2022</strong>. This is mainly due to the<br />

impact of a wider economic recession,<br />

exacerbated by the effect of the government’s<br />

‘Mini Budget’ in October <strong>2022</strong>, and the<br />

consequent fallout from recent political<br />

uncertainty.<br />

“However, the LRWA remains optimistic<br />

for 2023. Historically, the sector<br />

performs well in an economic<br />

downturn driven by a focus on<br />

refurbishing existing buildings,<br />

rather than investment in new<br />

build. And as an Association, we will<br />

continue to work closely with contractors,<br />

specifiers and manufacturers to provide them<br />

with the latest technical guidance and a voice in<br />

the issues that matter the most.”<br />

www.lrwa.org.uk<br />

LOOKOUT FOR MORE<br />

SECTOR COMMENTS<br />

AND OPINIONS IN OUR<br />

JANUARY 2023 ISSUE!<br />

10 TC DECEMBER <strong>2022</strong>

oof<br />

lantern<br />

10%<br />

NEW TRADE<br />

CUSTOMER<br />

DISCOUNT<br />

QUOTE CODE:<br />

TCK01<br />

glazed in<br />

seconds<br />

faster<br />

to fit<br />

Supply & install the multi-award-winning aluminium Korniche Roof Lantern.<br />

Fitted in minutes, glazed in seconds. The strongest lantern in class, available<br />

up to 3x2.5m in four glass panels and a maximum size of 6x4m<br />

Delivering the best products, with the best<br />

service, at the best price<br />

Contact Made for Trade for a Kwikquote today<br />

madefortrade.co | sales@madefortrade.co | 01642 610799<br />

*Discount applies to all trade customers and applied to the first, single item purchase only of the Korniche Roof Lantern

NFRC Roofing Talk<br />

SUPPORTING CONTRACTORS TO<br />

RETAIN NEW STARTERS<br />

Ruth Scarrott, NFRC’s Head of Careers, introduces a new programme that can help<br />

contractors recruit and retain new staff with tailored support during their first six<br />

months in the industry.<br />

Ensuring that the roofing and cladding<br />

industry is a respected, desirable and<br />

rewarding career choice is a key strategic<br />

objective for NFRC, and we are delighted to<br />

have been awarded the CITB’s England<br />

Construction Opportunities (ECO) commission,<br />

to deliver tailored support to roofing industry<br />

employers to recruit and retain the workforce<br />

they need.<br />

Having more support available to new entrants<br />

when entering into employment increases the<br />

likelihood of their retention. We know that firms in<br />

our industry can sometimes find it difficult to hold<br />

on to someone during those first few months of<br />

employment; our latest State of the Roofing<br />

Industry survey showed that almost one in three<br />

contractors has struggled with retaining new<br />

starters recently – that’s after the challenge of<br />

recruiting someone! – and over half of firms<br />

reported in the third quarter of the year that<br />

obtaining staff was getting more difficult.<br />

Once a new starter is in their role, firms need to<br />

make sure they have the support they need to stay<br />

and flourish in that job, especially if they are new<br />

to the industry and will be facing brand new<br />

challenges.<br />

The purpose of the ECO project is to support new<br />

entrants and their employers to sustain<br />

employment from job start to six months in.<br />

Involvement in the project gives new employees<br />

support in the workplace through job coaching,<br />

mentoring, employer engagement, peer and<br />

buddy systems or other measures – as well as<br />

support for the employer to recruit, and to make<br />

sure the new starter is site-ready.<br />

“We know that<br />

firms in our<br />

industry can<br />

sometimes find it<br />

difficult to hold on<br />

to someone during<br />

those first few months<br />

of employment”<br />

The scheme will help NFRC to:<br />

• Support roofing employers to recruit and retain<br />

‘new or returning to the industry’ employees in a<br />

wide range of roles, including on-site jobs as well<br />

as supervisors, designers, project managers and<br />

office support staff.<br />

• Guide the employer through the recruitment<br />

and interview stages.<br />

• Link up organisations supporting candidates to<br />

employers looking to recruit – these include the<br />

Department for Work and Pensions and other<br />

community partners.<br />

• Source site-readiness training for the new<br />

employee if required.<br />

• Guide the employer through accessing CITB<br />

“I urge contractors who<br />

are recruiting, now or<br />

in the future, to get in<br />

touch to see how the<br />

ECO project can benefit<br />

them”<br />

Left: Ruth Scarrott is NFRC’s Head of Careers:<br />

“The purpose of the ECO project is to support<br />

new entrants and their employers to sustain<br />

employment from job start to six months in.”<br />

grants for ongoing employment<br />

support for the new employee.<br />

• Offer in-work advice and support to both<br />

employer and employee.<br />

The skills shortage in our industry is not a new<br />

challenge, but it needs to be tackled –<br />

especially as a high proportion of people in our<br />

industry are due to retire within the next ten<br />

years, and as we have a lack of diversity in the<br />

workforce.<br />

I urge contractors who are recruiting, now or in<br />

the future, to get in touch to see how the ECO<br />

project can benefit them. It is a fantastic<br />

mechanism to give both employers and new<br />

employees targeted and appropriate support to<br />

aid employee retention and development,<br />

whichever role you want to recruit a new starter<br />

into. Even though the project has ‘England’ in its<br />

name, we are able to help employers in Scotland<br />

too.<br />

If you are looking for information and support but<br />

this isn’t the right opportunity for you right now,<br />

there is more help on offer. The NFRC Roofing<br />

Careers Service is a free resource for employers<br />

and those considering or seeking a career in the<br />

roofing and cladding industry.<br />

Visit www.nfrc.co.uk/careers to find out more.<br />

Contact NFRC<br />

www.nfrc.co.uk<br />

@TheNFRC<br />

12 TC DECEMBER <strong>2022</strong>

Ask the Solicitor<br />

SELLING-UP PART 2: YOU’VE FOUND<br />

A BUYER, SO WHAT NEXT?<br />

In the second part of his focus on selling a roofing business, Matthew Catterall,<br />

Corporate Partner at Taylors Solicitors, explains the steps to take once you’ve found a<br />

buyer for your business, including what you should expect and the pitfalls to be<br />

cautious about...<br />

Following on from last month’s article in which<br />

we discussed how to prepare for the sale of<br />

your business, this month we examine what<br />

to expect once a buyer has been found.<br />

The offer<br />

As we discussed last month, it is important to be<br />

clear about your objectives on a sale, and the<br />

sale price is likely the most important aspect of<br />

your considerations.<br />

Once a willing buyer has been found, they will<br />

usually provide an ‘indicative’ offer based on the<br />

limited information that has been provided to them<br />

up to that point as part of the marketing process.<br />

There are several key considerations that need to<br />

be reviewed (as well as the total consideration<br />

payable).<br />

Will the consideration be payable in a lump sum<br />

on completion, or spread out?<br />

In the simplest deals, the buyer will pay a fixed<br />

amount of cash for your company, in full, on<br />

completion. However, in today’s market, most<br />

buyers will want to spread the cost of payment<br />

over an extended period, typically two to three<br />

years. These payments are known as ‘deferred<br />

consideration’.<br />

Where you have deferred consideration, there are<br />

a number of further issues to consider:<br />

1. How much will I have in my pocket on ‘day<br />

one’? Depending on your reasons for sale and<br />

your plans for the future, you will need to ensure<br />

that the amount paid on completion is sufficient<br />

to cover your immediate plans, be that paying off<br />

About the author: Matthew Catterall is a Corporate Partner at Taylors Solicitors. For more information about preparing your<br />

business for sale or indeed the sale process itself, contact Matthew via 07748 633149 or matthew.catterall@taylors.co.uk<br />

“In today’s market, most buyers will want to<br />

spread the cost of payment over an extended<br />

period, typically two to three years. These<br />

payments are known as ‘deferred consideration’”<br />

the mortgage, buying that holiday home in the<br />

South of France or taking that well deserved<br />

round-the-world trip!<br />

2. Tax. No-one likes to pay it, but knowing your<br />

obligations in advance is important to prevent a<br />

shock when the bill arrives. Deferred<br />

consideration creates an additional twist in that,<br />

while you have yet to receive the money,<br />

depending on how the deferred consideration is<br />

structured (which is beyond the scope of this<br />

article and for your tax professionals to advise<br />

properly on), the usual position is that HMRC will<br />

assume you will receive all the money, and your<br />

next tax return will account for the tax on the<br />

whole consideration, not just the amounts already<br />

received. While this means that as and when you<br />

receive your deferred consideration you have<br />

already paid the tax on it, it will reduce the<br />

amount immediately available to you after<br />

completion.<br />

3. How strong is the buyer? When it comes to<br />

deferred consideration, you should effectively look<br />

at it as if you are lending money to the buyer, so<br />

thought should be given as to whether that money<br />

14 TC DECEMBER <strong>2022</strong>

has any likelihood of being repaid. You cannot<br />

guarantee the future performance of the business<br />

you have just sold (especially under new<br />

ownership) nor the wider performance of the<br />

buyer’s business, so care should be taken to<br />

ensure the buyer has sufficient ‘fat on its back’ to<br />

pay the deferred consideration. This is especially<br />

important where the buyer is a new company with<br />

no trading history.<br />

4. What about security? Where there is a<br />

significant amount of deferred consideration (say,<br />

more than 20-30 per cent of the total), you<br />

should consider pushing for security over (at the<br />

very least) the business and assets you have<br />

sold, but also the assets of the buyer and, if<br />

available, the wider group of the buyer.<br />

How is the consideration calculated?<br />

There are an enormous number of ways a buyer<br />

will seek to price a transaction, which will depend<br />

on the nature of both the target and buyer<br />

businesses, funding arrangements and market<br />

conditions. While there will often be a ‘headline<br />

price’, buyers will often seek to introduce<br />

‘adjustment mechanisms’ that change how much<br />

money is paid. This is also why it is very<br />

important to engage a suitable qualified,<br />

independent advisor to walk you through the<br />

options and how that will affect the ‘bottom line’<br />

in your pocket.<br />

Some of the most common of these are:<br />

1. Cash-free, Debt-free: As the name suggests,<br />

the price is adjusted having regard for how much<br />

free cash (which is added to the price) and debt<br />

(which is deducted from the price) is in the target<br />

business. Buyers will want to keep a ‘normalised’<br />

amount of working capital in the business, which<br />

is not a straightforward exercise and can often<br />

lead to a nasty surprise when final consideration<br />

calculations are circulated if not dealt with early.<br />

2. Net Assets: As a buyer is often basing the offer<br />

on historic accounts, they will want to ensure that<br />

the net asset position at completion is the same<br />

level as the point in time their offer is based on –<br />

the buyer will do a ‘reckoning up’ exercise after<br />

“Tax. No-one likes to pay it, but knowing your<br />

obligations in advance is important to prevent a<br />

shock when the bill arrives”<br />

completion and there will be an adjustment to the<br />

purchase price based on whether the actual net<br />

asset position at completion is above or below a<br />

set target.<br />

3. Earn-out: This is a form of consideration that<br />

is based upon the future performance of the<br />

business after completion. It is typically used if<br />

the business to be sold is on an upward trajectory<br />

in terms of development, so that the seller can<br />

get the benefit of having built it to that position,<br />

but is selling prior to benefiting from the potential.<br />

An earn-out can add significant consideration,<br />

but needs to be carefully negotiated with regard<br />

to how the business is run after completion (for<br />

example, so that profits that would otherwise<br />

come into the business are not diverted to the<br />

buyer, which would mean the seller doesn’t get<br />

credit, or the buyer making major ‘management<br />

charges’ to artificially depress the profits on<br />

which the earn-out payments are calculated).<br />

The wider sales process<br />

Once the headline terms of the sale are agreed,<br />

the technical work begins, which in brief<br />

comprises:<br />

1. A full ‘due diligence’ exercise by the buyer on<br />

the target company, which will involve the seller<br />

(and their advisors) responding to detailed<br />

queries on the legal, financial, tax and<br />

commercial aspects of the business.<br />

2. The drafting of the transaction documents,<br />

which implement the main deal terms, but will<br />

include ‘warranties’ (essentially contractual<br />

promises) to be given by the seller as to the<br />

nature and state of the target company.<br />

3. A ‘disclosure’ exercise in which statements are<br />

made by the seller against the warranties referred<br />

to above so that no claims can be brought against<br />

the seller for breach of those warranties.<br />

If you follow the advice given in part one of this<br />

series, the due diligence and disclosure exercises<br />

should be smooth sailing, so again I urge you to<br />

engage early with your professional advisors<br />

when considering a sale.<br />

Contact Taylors Solicitors<br />

01254 297900<br />

www.taylors.co.uk<br />

@taylorslawfirm<br />

DECEMBER <strong>2022</strong> TC 15

Roofing Battens<br />

BE ALERT TO COUNTERFEIT<br />

BATTENS<br />

Daniel Redfern, Marketing Manager at Marley, discusses the continuing problem<br />

concerning the influx of counterfeit roofing battens on the market, and explains what<br />

roofing contractors should be aware of when purchasing and installing batten...<br />

Worryingly, there has been a significant<br />

influx of counterfeit roofing battens<br />

entering the market recently, with the<br />

consequences of using them already being felt.<br />

Indeed, both the NFRC and Timber Development<br />

UK have issued warnings to their members to<br />

highlight this issue.<br />

A perfect storm<br />

Exceptionally high demand for treated timber,<br />

combined with shortages and supply chain issues<br />

brought about by the pandemic and Brexit, along<br />

with the war in Ukraine, has created a perfect<br />

storm allowing an abundance of sub-standard<br />

roofing battens to enter the UK market. Whilst<br />

coloured, stamped and sold as BS 5534<br />

compliant, they are in fact, counterfeit.<br />

Know your battens<br />

Daniel Redfern, Marketing Manager at Marley,<br />

explained: “It has always been important that<br />

roofers understand what they’re buying when it<br />

comes to battens. Cheaper and often inferior<br />

battens may carry imperfections that can cause<br />

breakages and lead to accidents on site,<br />

especially since being weight bearing, battens are<br />

used as a step ladder whilst a contractor is<br />

working on the roof.<br />

“Moreover, with site safety being of paramount<br />

importance, and the safety of the team being the<br />

ultimate responsibility of the contractor, choosing<br />

to compromise on the quality of a safety-critical<br />

product on a roof, such as battens, could well be<br />

a costly – and avoidable – mistake.”<br />

Greater threat<br />

Daniel continued: “The problem of cheaper<br />

battens is one issue but counterfeit<br />

battens present a much greater threat<br />

to contractors who may unwittingly<br />

fit them believing they are, in fact,<br />

using the genuine article. It is<br />

therefore crucial that contractors check<br />

and check again on site and are 100%<br />

certain about the provenance of their<br />

battens.<br />

“Remember, using non-compliant<br />

battens of inferior quality to certified<br />

roofing battens will not only compromise<br />

safety on site, but will also reduce the longevity of<br />

the roof and may result in the roof having to be<br />

stripped and re-roofed should the battens prove<br />

to be sub-standard.”<br />

Don’t be caught out<br />

Daniel and the team at Marley say roofers should<br />

take responsibility for fully inspecting their battens<br />

on site, immediately rejecting them if there are any<br />

discrepancies. They point out that there are some<br />

simple checks to use to help avoid any issues:<br />

Essential markings: According to BS 5534, all<br />

graded battens should be clearly marked with<br />

supplier details, size, species and relevant<br />

standard. Although not required by BS 5534, it is<br />

recognised best practice to also display third<br />

party certification i.e. BBA.<br />

Size: Check the thickness of the batten –<br />

BS 5534 states that a batten should be 25 mm<br />

thick with a tolerance of – 0/+3 mm. Look out<br />

for equally and consistently sized battens.<br />

Knots: BS 5534 states that the sum of both faces<br />

should be no more than the width i.e. 38 mm/50<br />

mm. Where knots are visible on both sides of a<br />

batten or are excessively large, it<br />

should not be used.<br />

Colour: Although intended as a<br />

useful visual aid, colour is no<br />

guarantee of compliance, so check<br />

other markers.<br />

Rot: Due to their treatment, BS 5534<br />

graded battens do not rot. Battens<br />

with any sign of rot should be<br />

discarded.<br />

Documentation: Either delivered to site or<br />

available via the merchant, all BS 5534 graded<br />

battens will carry the correct documentation<br />

which should always be requested by<br />

contractors.<br />

Genuine quality with JB Red battens<br />

Whilst counterfeit battens are causing a real<br />

issue throughout the industry, Daniel says<br />

roofers can rely on Marley’s JB Red roofing<br />

battens.<br />

He explained: “Produced from slow-grown<br />

timber, JB Red battens are stringently tested and<br />

graded using our dedicated roof batten scanning<br />

line – Goldeneye. Treated with MicroPro<br />

preservative to give a 60-year service life, JB<br />

Red battens are fully BS 5534 compliant and are<br />

currently the only UK machine-graded batten<br />

available to the roofing industry with BBA<br />

certification.”<br />

Find out more about Marley JB Red Battens<br />

www.marley.co.uk/roofing-batten/<br />

jb-red-batten<br />

01283 722222<br />

16 TC DECEMBER <strong>2022</strong>

Building<br />

the future<br />

as Elevate<br />

FIRESTONE ROOFING, WALL AND LINING SYSTEMS ARE NOW ELEVATE<br />

Our name may be changing, but the same people,<br />

products and standards you trust will remain.<br />

Scan QR code below to see all the ways we’ve evolved to Elevate,<br />

a new brand of the Holcim Building Envelope division.

Perfectly Pitched<br />

ROOF COVERING CHOICE:<br />

THE KEY CONSIDERATIONS<br />

Following on from his recent series of articles on different roof shapes, John Mercer looks at<br />

the considerations when choosing the most appropriate roof covering for roof structures...<br />

In my recent series of articles, I have<br />

discussed various roof shapes, from the<br />

seemingly straightforward gable-to-gable roof,<br />

through to more complicated shapes such as<br />

hipped and mansard roofs, to curved roofs.<br />

Presented with a roof structure, how do we go<br />

about deciding on the best and most appropriate<br />

roof covering? This decision is of course influenced<br />

to a large degree by the surrounding roofscapes<br />

and local preferences. But we must also consider<br />

the technical aspects of a roof design to<br />

determine an appropriate roof product.<br />

The most obvious example is curved<br />

roofing. It is almost always the case<br />

that double lapped plain tiles or<br />

slates must be used on a curved roof<br />

slope. Although having said that, I have<br />

seen fixed gauge traditional clay pantiles used<br />

to great effect on a roof with an eyebrow window.<br />

Now there’s a challenge for you! Experienced<br />

pantilers tend to prefer non-interlocking clay<br />

pantiles for use on uneven old roofs, as the lack<br />

of interlocks means the tiler, by careful<br />

manipulation of the headlap and side lap, can to<br />

a degree compensate for variations in the roof.<br />

Cost<br />

Cost is obviously a big consideration when<br />

deciding on a roof covering. Double lapped plain<br />

tiles tend to be more expensive than single<br />

lapped tiles to purchase and to install. I have<br />

come across many examples of proposed curved<br />

roofs that have then been constructed as a series<br />

of flat, faceted slopes, to enable the use of single<br />

lapped tiles. This can be fine, but the necessary<br />

junctions – valleys on a concave slope and hips<br />

on a convex slope – can introduce a risk of<br />

failure, either right from the start, or at a future<br />

Left: John Mercer. Above: image shows Condron Double Pantiles.<br />

date as materials weather and<br />

degrade. Junctions on the concave side,<br />

which are really a form of valley, must be<br />

designed and constructed to account for the<br />

relative shallow angles at which the roof slopes<br />

on a faceted roof meet.<br />

Rafter length and pitch<br />

A roof should be designed with the type of roof<br />

covering in mind. Long rafter lengths combined<br />

with a low pitch should be avoided wherever<br />

possible. Tile manufacturers give maximum<br />

recommended rafter lengths for their products,<br />

with guidance on increasing the roof pitch for long<br />

rafter lengths. When using single lapped tiles,<br />

consider the complexity and size of roof features<br />

such as dormer windows. Large tiles may look out<br />

of place on small roof slopes or very short rafter<br />

lengths, therefore it may be worth considering the<br />

use of medium format tiles.<br />

Roof systems should not discharge water in point<br />

loads from a higher roof slope onto lower roof<br />

areas, or into a junction such as a side abutment.<br />

If practical, break up the roof into smaller sections.<br />

For example, allow the upper roof to shed directly<br />

into a gutter rather than onto a lower roof.<br />

Features such as raking verges can look<br />

architecturally interesting, but remember that if<br />

the rake is such that water will run off it, then it<br />

is really a sloping eaves and will require a gutter<br />

system. If the rake is the other way, then it is<br />

really a sloping mono-pitch roof, and so needs a<br />

top edge weathering system.<br />

Detailing junctions<br />

With regards to detailing junctions, use the<br />

appropriate weathering system for the tile or<br />

slate. For example, at side abutments slates and<br />

plain tiles require soakers, cover flashings are<br />

generally used with single lapped profiled tiles<br />

and secret gutters or proprietary soakers with flat<br />

single lapped tiles.<br />

Underlay considerations<br />

Something that is not always understood or<br />

sometimes not even totally accepted is that the<br />

underlay layer should act as a second line of<br />

defence against snow, rain, or dust driven<br />

18 TC DECEMBER <strong>2022</strong>

through the slates or tiles, as well as making the<br />

building weathertight before the tiles are<br />

installed. Lay the underlay with a drape between<br />

rafters and consider the use of nail tape and<br />

counterbattens, particularly at low roof pitches.<br />

Nail tape seals between the underlay, battens,<br />

and counterbattens to prevent water ingress. The<br />

counterbattens encourage air flow within the<br />

batten cavity and provide a gap for any water to<br />

flow under the tile battens.<br />

Ensure the underlay is weathertight at junctions<br />

such as side abutments, valleys and around roof<br />

windows and chimneys, and is properly<br />

supported at the eaves, with adequate fall behind<br />

the fascia or tilt fillet. If water can pool behind the<br />

fascia, it will inevitably leak into the structure.<br />

There are different types of permeable underlays,<br />

all with their own methods of installation. Some<br />

air-permeable underlays can be used without<br />

additional ventilation; most vapour permeable<br />

underlays require a level of additional ventilation<br />

when used in a cold roof structure, i.e., where the<br />

“The importance of<br />

obtaining a roof tile<br />

manufacturer’s<br />

written fixing<br />

specification cannot<br />

be over-emphasised”<br />

insulation is laid across a horizontal ceiling –<br />

check with the manufacturer.<br />

Fixing specifications<br />

A final word on fixing; the importance of obtaining<br />

a roof tile manufacturer’s written fixing<br />

specification cannot be over-emphasised. As well<br />

as making sure that the roof is secure and<br />

installed in compliance with BS 5534, site<br />

supervisors and inspectors may want to see the<br />

specification. Obtain the fixing specification<br />

before tendering for the work so that the method<br />

of installation, such as nailing and clipping, can<br />

be factored into the tender price.<br />

In summary:<br />

• Choose the most appropriate roof covering,<br />

with decisions based on locality, compatibility<br />

with the roof design and, of course, cost. Ensure<br />

the manufacturer’s recommendations can be<br />

complied with.<br />

• Ensure roof junctions are detailed to suit the<br />

roof tile type. Avoid shedding water from one<br />

roof slope onto a lower slope in point loads such<br />

as from a fall pipe or lower end of a valley.<br />

• Install the underlay to make certain it acts as<br />

a watertight layer. Follow the underlay<br />

manufacturer’s recommendations for<br />

installation and condensation control.<br />

• Always obtain a written roof tile fixing<br />

specification from the tile manufacturer before<br />

work commences and, ideally, as a guide to<br />

tendering.<br />

Contact John Mercer<br />

www.johnmercerconsultant.co.uk<br />

Johnmercer 3<br />

For further r<br />

inform<br />

ation<br />

or a hire quotation call<br />

01858 412 100<br />

Email: sales@cookerhire.com<br />

www.cookerhire.com

Pitched Roofs<br />

DRY VERGE SYSTEMS: QUALITY<br />

PRODUCTS ARE KEY TO SUCCESS<br />

The team at Manthorpe Building Products discuss the guidance around dry fix roofing<br />

products and explain why specifying and installing quality products is crucial to a pitched<br />

roofing project’s success.<br />

With the publication of BS 8612 in 2018,<br />

the UK roofing industry finally got a<br />

British Standard for its dry fix roofing<br />

products. Prior to its publication, dry fix products<br />

had been used in the UK for over 40 years, but<br />

their design, manufacture and installation had<br />

been largely unregulated.<br />

There are many advantages to dry fix, such as<br />

being essentially maintenance-free. No matter<br />

how well a contractor installs a mortar<br />

bedded verge, ridge, or hip, eventually<br />

the elements and natural building<br />

settlement will erode the mortar,<br />

making it ineffective. By contrast, dry fix<br />

systems can cope with settlement by<br />

allowing a degree of movement in the surrounding<br />

materials. During installation, mortar work may<br />

be ruined if it rains or there is a frost before it has<br />

had time to set. As soon as a dry fix system is<br />

installed, it is ready to face the elements.<br />

Requirements of dry verge<br />

BS 8612 sets out specific requirements for dry<br />

verge systems; they must remain durable and<br />

perform the following technical functions – 1)<br />

resist predicted wind loads; 2) close the gap<br />

between the tiles/slates and wall or bargeboard<br />

top; 3) drain any water from the roof away from<br />

the gable wall; and 4) act as one of the fixings for<br />

the roof tiles or slates.<br />

The Standard provides test methods to determine<br />

the resistance of a dry verge system to horizontal<br />

and vertical wind loads. The methodology can be<br />

used by manufacturers to ensure that a dry verge<br />

system will resist predicted wind loads and<br />

provide a secure fixing for itself and be one of the<br />

two required fixings for the verge tiles.<br />

Images: Manthorpe linear verge units.<br />

For verge systems to be<br />

compliant with BS 8612, they<br />

must prevent rainwater from the roof<br />

running down the gable wall which can<br />

lead to staining and mould growth on the wall.<br />

This is particularly important where there is no<br />

fascia, and the dry verge is installed directly<br />

against the gable wall.<br />

Manthorpe expertise<br />

At Manthorpe Building Products we specialise in dry<br />

fix roofing products. The company has been<br />

developing innovative building products for the<br />

construction industry for over 30 years and has<br />

extensive experience in the use of plastics, as well<br />

as the expertise to develop and manufacture<br />

virtually all our products in-house and continues to<br />

invest heavily in new technology and production<br />

processes. All Manthorpe dry verge products have<br />

been independently tested at the Building<br />

Research Establishment (BRE) to ensure they fully<br />

comply with and, in many cases, go beyond the<br />

requirements of the relevant British Standards.<br />

Dry verge products<br />

At Manthorpe we offer several systems in our<br />

SmartVerge range. The Linear Dry Verge System<br />

provides a secure mechanical fixing solution for<br />

many types of roof coverings including Fibre<br />

Cement Slates, Natural Slates, and Interlocking<br />

Plain Tiles. The Linear Verge Units can be easily<br />

fitted to the verge of the roof in succession and<br />

preserve the continuous line of the verge,<br />

providing a neat and attractive finish to the verge,<br />

as well as draining moisture away from the gable<br />

wall to prevent staining. The system is available<br />

in Slate Grey, Black, Terracotta and Dark Brown to<br />

compliment any roof design.<br />

For a stepped appearance to the dry verge<br />

system, i.e. to carry the tile coursing through to<br />

the verge edge, The SmartVerge Ambidextrous dry<br />

verge system provides an attractive finish to the<br />

verge detail of a roof for most makes and profiles<br />

of interlocking tiles laid between a batten gauge<br />

of 255 mm to 345 mm. Being comprised of<br />

individual verge units, one per tile course, the<br />

‘stepped’ appearance of the roof tiles is<br />

preserved. The dry verge units provide a neat<br />

capping over each tile in succession, and once<br />

fitted they are weatherproof and maintenance<br />

free. The ambidextrous design of the system allows<br />

the units to be used on either side of the verge,<br />

making it ideal for roofers and stockists wishing to<br />

minimise their stock of dry verge components.<br />

For those wishing to preserve the stepped<br />

appearance of the roof tiles whilst maintaining a<br />

continuous line on the underside of the verge, at<br />

Manthorpe we offer two versions of the<br />

SmartVerge Handed Dry Verge System. The verge<br />

units are supplied handed to suit left and righthand<br />

roof verges, with the original version being<br />

available in PVCu and suitable for tile gauges<br />

Continued on page 22<br />

20 TC DECEMBER <strong>2022</strong>

ORDER ONLINE 24/7.<br />

FIXFAST AT YOUR FINGERTIPS.<br />

You can now get quick quotes and place express orders<br />

online 24/7 at Fixfast.com. And with everything organised in a<br />

new dedicated ‘projects’ area, it’s never been easier to get the<br />

support you need from us. Try Fixfast.com today.<br />

W: fixfast.com l T: +44 1732 882387 l E: sales@fixfast.com

Pitched Roofs<br />

Continued from page 20<br />

from 280 mm to 345 mm. A polypropylene<br />

version is also available, again with handed verge<br />

units, providing even more flexibility in tile gauge<br />

with adjustment from 255 to 345 mm.<br />

Both the Ambidextrous and the Handed dry verge<br />

systems incorporate special features to ensure that<br />

water is drained away from the wall to prevent<br />

staining. The verge units are available in a range of<br />

colours to complement any roof design.<br />

The SmartVerge Interlocking Plain Tile<br />

Verge system is a recent addition to<br />

the Manthorpe dry verge range. The<br />

system is designed especially for<br />

use with interlocking plain tiles, with a<br />

batten gauge range from 173mm to<br />

190mm. The ambidextrous design of the verge<br />

units means they can be installed on left and<br />

right-hand verges. Manufactured from UV<br />

stabilised polypropylene, the verge units are<br />

available in Grey, Black, Terracotta, Brown, and<br />

Antique Red to complement any colour of roof tile.<br />

Images: The SmartVerge Ambidextrous dry verge system provides an attractive<br />

finish to the verge detail of a roof.<br />

The unique design of the verge units<br />

means that the upper flange always<br />

lays perfectly flat on the roof tile,<br />

eliminating any potential tile ‘kick up’ in the<br />

tile course above and increasing the effective<br />

drainage angle of the lower flange, thus improving<br />

the rate of water runoff from the verge and away<br />

from the wall.<br />

For all our Manthorpe SmartVerge systems, angled<br />

or round ridge end caps<br />

are available to protect the<br />

end of the ridge and eaves<br />

closures, secure the first verge unit and<br />

prevent access for birds and large insects.<br />

Contact Manthorpe Building Products<br />

01773 303 000<br />

www.manthorpebp.co.uk<br />

Email: mbp.care@manthorpebp.co.uk<br />

PLAIN TILES DELIVER FOR COASTAL PROJECT<br />

BMI Redland’s Plain Tiles have helped Redland concrete Plain Tile in a<br />

would have to be installed<br />

provide a stunning transformation to a Slate Grey colour was said to be<br />

securely.<br />

private home refurbishment in Kent. the natural choice.<br />

With a unique roof design, the<br />

Located on a clifftop overlooking the sea, The<br />

Keep, private home, was going through a total<br />

renovation which included a whole new roof.<br />

There were two main challenges<br />

for this project, the first being the<br />

details of the roof itself. With over<br />

Grasby team needed to take<br />

particular care throughout the<br />

project. With the installation of<br />

8,000 tiles to be installed over the pitched roof, as the eyebrow window, the team had to create a<br />

With a unique roof design that incorporated a large<br />

well as flat roof sections for the back dormer, timber bough by soaking the battens, bending it into<br />

chimney and an eyebrow window detail (see<br />

Grasby Roofing needed to ensure the attention to a semi-circle and using a mitre saw to cut it where<br />

image), as well as some flat sections, Grasby<br />

detail was maintained throughout the project. This needed. Working with Grasby Roofing over a period<br />

Roofing knew that it wasn’t going to be<br />

included the installation of the tiles over the of four weeks, BMI Redland was responsible for the<br />

straightforward. With a north-facing seafront<br />

eyebrow window, which is a notoriously difficult supply of its concrete Plain Tile in Slate Grey, as<br />

location, the new roof had to be made to last, while<br />

tiling task. This is because the installation of well as the necessary fittings and fixtures in a full<br />

also creating a good aesthetic fit for the property<br />

eyebrow windows requires a double lapping of tiles, system solution.<br />

and surrounding location. This meant ensuring all<br />

which is a complex style of tile installation that can<br />

8,000 tiles were installed to withstand high winds<br />

Adam Grasby of Grasby Roofing explained: “When<br />

only be done on curved roofs. This particular<br />

and comply with the latest regulations.<br />

originally discussing with the client what concrete<br />

window would also need a timber bough to be<br />

plain tiles to install on the roof, it was an easy<br />

Grasby Roofing has been working with Redland tiles custom-built to size.<br />

choice. In the 20 years I have been using Redland<br />

for over 20 years, so when they were looking for the<br />

The second challenge was the location. The Keep is products, I’ve always been satisfied with the<br />

perfect tile to suit not only the location’s look, but<br />

located on a clifftop which means it is exposed to quality of tiles and fittings, and on this occasion,<br />

also the weather conditions and the ability to<br />

the elements including high winds, so the tiles it was no different.” www.bmigroup.com/uk/<br />

accommodate the detail of the roof, the BMI<br />

22 TC DECEMBER <strong>2022</strong>

TO ALL OUR CUSTOMERS, SUPPLY PARTNERS AND INDUSTRY<br />

COLLEAGUES. THANK YOU FOR YOUR CONTINUED<br />

SUPPORT THROUGHOUT THE YEAR. WE WISH YOU A MERRY<br />

CHRISTMAS & A HAPPY NEW YEAR.<br />

Unit 12B, Metcalf Drive,<br />

Altham Industrial Estate,<br />

Altham, Lancashire,<br />

England, BB5 5TU<br />

Tel 01282 930680<br />

sales@easy-trim.co.uk<br />

www.easy-trim.co.uk

Green Roofs: Substrates<br />

SUBSTRATE SELECTION<br />

By Julian Thurbin, Wallbarn Director.<br />

Precise quality, speed of installation and<br />

known performance are key factors that<br />

have made modular construction products<br />

and systems an attractive proposition.<br />

And applying this thinking to green roofs has<br />

delivered huge advantages, not least that specifiers<br />

and installers can rest assured that the system they<br />

choose will live up to expectations and the sedum or<br />

wildflowers will thrive for years to come.<br />

At Wallbarn we were an early adopter of the<br />

modular approach, developing our high<br />

performance M-Tray system to offer roofing<br />

contractors an easy, quick and clean-to-install<br />

solution that delivers an instant living roof with<br />

the bonus that the 500 mm x 500 mm trays can<br />

be lifted if access to the roof deck is required.<br />

Our multiple award-winning M-Tray is a green roof<br />

in a box, combining all the elements of a<br />

traditional roll-out solution – including substrate,<br />

plants and drainage – into carefully designed<br />

trays that click together on site. Every element of<br />

the system has been meticulously thought<br />

through, including the all-important substrate.<br />

The substrate – the material into which the green<br />

roof is planted – holds the key to a successful<br />

installation. At Wallbarn, working closely with<br />

partner company Sedum Growers and in<br />

conjunction with renowned soil scientist Susie<br />

Holmes, a specialist in horticultural growing<br />

media and soil management, we have invested<br />

heavily in developing and field testing different<br />

formulations to identify the substrate composition<br />

that works best, both in enabling plants to<br />

flourish and delivering fire performance.<br />

The result is a ‘gold standard’ compost that is made<br />

predominantly from materials sourced close to the<br />

our growing nursery in Hampshire, and matured onsite<br />

for around a year, producing a super high<br />

quality, low organic and peat-free growing medium<br />

that meets fire ratings and exceeds GRO Code<br />

guidance. It has been designed to deliver an<br />

optimum blend and supply of slow release<br />

nutrients coupled with great moisture<br />

control, enabling plants to flourish<br />

throughout the life of the roof. The mix<br />

represents a fine balancing act<br />

between the basic elements of the<br />

substrate – compost, lightweight aggregate and<br />

coir – and the need to achieve compliance with<br />

BS 8616:2019, Approved Document B, the GRO<br />

Code and the B ROOF t(4) fire rating.<br />

Composting<br />

Producing this BS-compliant substrate relies<br />

heavily on the quality of raw materials and it’s<br />

here that the greatest of care is taken, as Sedum<br />

Growers’ joint Managing Directors David Holloway<br />

and Keith Pegren know. As David explained: “For<br />

us, a lot of the commercially available Pas 100<br />

compost is of unknown quality. It might contain<br />

weeds or hormonal herbicides, which don’t<br />

breakdown in the composting process. We<br />

therefore manufacture our own on site using<br />

local, known sources of raw materials. We control<br />

the whole process from start to finish, which can<br />

take in excess of a year.”<br />

One ingredient used in the compost is discarded<br />

matter from a nearby business producing<br />

chamomile and other essential oils. This waste<br />

stream meets David and Keith’s exacting<br />

standards because they know its provenance and<br />

it has been heated to high temperatures, killing<br />

weeds etc.<br />

Other carefully selected agricultural waste is<br />

combined into the mix, which is then left to<br />

compost. “It’s quite a complex process,”<br />

explained Keith. “It has to be warm enough to kill<br />

weeds etc. so we continually check the<br />

temperature, and the chemical composition of the<br />

final compost is key. Chemicals released during<br />

the composting process create salts, which can<br />

be harmful to plants so they have to be allowed to<br />

Above: M-Tray farm sedum harvesting.<br />

Left: Substrate components.<br />

leach out. We carry out electro<br />

conductivity tests to measure salts content<br />

and only release the compost for use when it has<br />

physically cooled down sufficiently and salts are<br />

at a safe level.”<br />

To complete the Wallbarn substrate, coir and Lytag<br />

and/or Leca are combined with the compost:<br />

Coir: a lightweight, natural by-product of the<br />

coconut industry used to lighten the substrate<br />

and introduce fibres that lock in moisture and<br />

nutrients.<br />

Lytag: a lightweight ballast produced from power<br />

station waste.<br />

Leca: an expanded clay which is also a waste<br />

product and super lightweight/bulk forming. The<br />

roots of sedum and wildflowers grip the particles<br />

to bind into the substrate and support the whole<br />

green roof.<br />

The care invested in the M-Tray substrate<br />

demonstrates how at Wallbarn we go above and<br />

beyond legislation and guidance. We have been at<br />

the forefront of many industry changes and<br />

always strive to physically test ingredients to<br />

ensure they perform as we wish, using<br />

Warringtonfire for fire tests and STRI for growth<br />

tests. M-Tray exceeds all regulations by a<br />

significant degree. Our ethos is to provide<br />

customers with industry-leading, healthy green<br />

roofs that thrive throughout their lifetime, meet<br />

regulatory and industry standards and are as<br />

eco-friendly as possible.<br />

Contact Wallbarn<br />

www.wallbarn.com<br />

020 8916 2222<br />

24 TC DECEMBER <strong>2022</strong>

SOLUTIONS<br />

UNIQUE.<br />

ADAPTABLE.<br />

GUARANTEED. *<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

* THAT’S THE DANELAW DIFFERENCE<br />

Contact us or scan<br />

for all our roof pitch<br />

ventilation solutions<br />

call us: 01327 701 910<br />

email: sales@hambleside-danelaw.co.uk<br />

www.hambleside-danelaw.co.uk<br />

45+ YEARS OF ROOFING INNOVATION<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

0333 016 04275<br />

<br />

more at

i-folding<br />

door<br />

15%<br />

INTRODUCTORY<br />

DISCOUNT *<br />

QUOTE DISCOUNT<br />

CODE<br />

TCK02<br />

Delivering the best products,<br />

with the best service, at the best price<br />

Contact Made for Trade for a KwikQuote today<br />

madefortrade.co | sales@madefortrade.co | 01642 610799<br />

*Discount applies to all trade customers and applied to the first, single item purchase only of the Korniche Bi-folding Door | *Korniche Bi-folding door price is based on 7-7-0 configuration 5100 x 2000<br />