Waste disposal cooler installation and operating instructions

Waste disposal cooler installation and operating instructions

Waste disposal cooler installation and operating instructions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

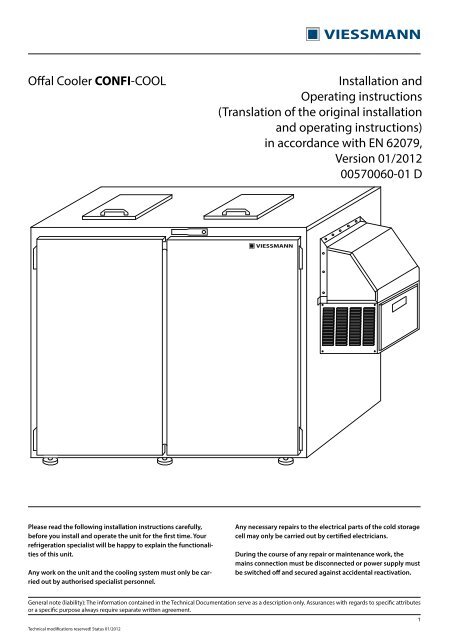

Konfiskatkühler CONFI-COOL<br />

Offal Cooler CONFI-COOL<br />

Please read the following <strong>installation</strong> <strong>instructions</strong> carefully,<br />

before you install <strong>and</strong> operate the unit for the first time. Your<br />

refrigeration specialist will be happy to explain the functionalities<br />

of this unit.<br />

Montage- Installation und <strong>and</strong><br />

Betriebsanleitung<br />

Operating <strong>instructions</strong><br />

00570060-01 D<br />

(Translation of the original <strong>installation</strong><br />

<strong>and</strong> <strong>operating</strong> <strong>instructions</strong>)<br />

in accordance with EN 62079,<br />

Version 01/2012<br />

00570060-01 D<br />

Any necessary repairs to the electrical parts of the cold storage<br />

cell may only be carried out by certified electricians.<br />

Any work on the unit <strong>and</strong> the cooling system must only be car-<br />

During the course of any repair or maintenance work, the<br />

mains connection must be disconnected or power supply must<br />

be switched off <strong>and</strong> secured against accidental reactivation.<br />

ried out by authorised specialist personnel.<br />

Lesen Sie bitte diese Montageanleitung vor Montagebe- Alle Arbeiten an der elektrischen Anlage der Kühlzelle lasginn<br />

bzw. vor der Erstinbetriebnahme sorgfältig durch. sen Sie bitte nur von Elektro-Fachkräften vornehmen. Der<br />

Ihre Kältefachfirma General note (liability): erklärt The information Ihnen gern contained die Funktion in the Technical der Documentation Netzstecker serve as a muss description bei diesen only. Assurances Arbeiten with herausgezogen regards to specific attributes und<br />

or a specific purpose always require separate written agreement.<br />

Anlage und weist Sie in die Bedienung ein. gegen Wiedereinstecken gesichert sein bzw. die Netzspannung<br />

muss abgeschaltet und gegen Wiedereinschal- 1<br />

Technical modifications reserved! Status 01/2012<br />

Alle Arbeiten am Gerät und der Kühlanlage müssen von ten gesichert sein.<br />

D

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

2<br />

Adresse:<br />

Produkt:<br />

Modellbezeichnung:<br />

Hof, 01. December 2011<br />

EG Konformitätserklärung<br />

Viessmann Kältetechnik AG<br />

Schleizer Straße 100<br />

95030 Hof/Saale<br />

Germany<br />

Konfiskatkühler<br />

CONFI-COOL<br />

Das Produkt entspricht den Anforderungen der folgenden Europäischen Richtlinien:<br />

2004/108/EG EMV-Richtlinie<br />

2006/42/EG Maschinenrichtlinie<br />

Durch Anwendung der folgenden St<strong>and</strong>ards wurde die Einhaltung der Richtlinien nachgewiesen:<br />

EMV:<br />

EN 55014-1:2006+A1:2009<br />

EN 55014-2:1997+A2:2008<br />

EN 61000-3-2:2006+A1:2009+A2:2009<br />

EN 61000-3-3:2008<br />

MRL: EN ISO 12100:2010<br />

EN 60335-2-89:2010 in Verbindung mit<br />

EN 60335-1:2002+A11:2004+A1:2004+A12:2006+<br />

Corr. 2006 + A2:2006+Corr.2007-01+Corr. 2007-<br />

02+A13:2008+Corr.2009+Corr.2010+A14:2010<br />

Für die Zusammenstellung der technischen Unterlagen ist bevollmächtigt:<br />

Name: Wilhelm Heidt<br />

Adresse:<br />

Viessmann Kältetechnik AG<br />

Schleizer Straße 100<br />

95030 Hof/Saale<br />

Germany<br />

Dipl.-Kfm. Armin Luczkowski (Vorst<strong>and</strong>)<br />

Technical modifications reserved! Status 01/2012

Table of Contents<br />

1. Operating Instructions 4<br />

1.1 Purpose of the document 4<br />

1.2 Visualisation of safety <strong>instructions</strong> 4<br />

2. Safety notices <strong>and</strong> warnings 4<br />

2.1 Intended use 4<br />

2.2 Reasonably foreseeable misuse 5<br />

2.3 Damage arising frominappropriate use 5<br />

2.4 Conversions or modifications 5<br />

2.5 Spare <strong>and</strong> wear parts/ auxiliary materials 5<br />

2.6 Risks arising from working with the<br />

CONFI‑COOL 5<br />

2.7 Technical safety 5<br />

2.8 Intended Use 6<br />

2.9 Residual risk 6<br />

2.10 Obligations of the <strong>operating</strong> company 6<br />

2.11 Personal protection equipment 6<br />

2.12 Obligations of the <strong>operating</strong> personnel 6<br />

2.13 Qualifications of the <strong>operating</strong> personnel 7<br />

2.14 Safety <strong>and</strong> protective devices 7<br />

2.15 Machine designation 7<br />

3. Description 8<br />

3.1 Function description 8<br />

3.2 Excerpt from our warranty terms 8<br />

3.3 Technical specifications of the <strong>cooler</strong> 8<br />

4. Unpacking 9<br />

4.1 Unpacking <strong>and</strong> h<strong>and</strong>ling 9<br />

4.2 Scope of delivery CONFI-COOL 9<br />

4.3 Disposal of the packaging material 9<br />

5. Installation 10<br />

5.1 Before starting the assembly 10<br />

5.2 Mounting the <strong>cooler</strong> corpus 10<br />

5.3 Installation of external <strong>cooler</strong> 11<br />

6. Dimensions CONFI‑COOL<br />

for 120 l containers 13<br />

7. Dimensions CONFI‑COOL<br />

for 240 l containers 14<br />

8. Startup 15<br />

9. What if? 15<br />

10. OPERATION 16<br />

10.1 Prerequisites for operation 16<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

10.2 Defrosting 16<br />

10.3 Condensate 16<br />

11. Changing cold storage temperatures<br />

(without heating unit for winter months) 17<br />

12. Changing cold storage temperatures<br />

(without heating unit for winter months) 17<br />

13. Maintenance <strong>and</strong> Cleaning 18<br />

13.1 Before cleaning 18<br />

13.2 Cleaning the device 18<br />

14. Removal, final Decommissioning 19<br />

14.1 Disposal of the used appliance 19<br />

15. Liability 19<br />

16. Fault Detection & Elimination 20<br />

17. Energy Conservation/ Environmental<br />

Consciousness 20<br />

18. Wear & Spare Parts List 21<br />

18.1 Seals 21<br />

18.2 Spare parts 21<br />

18.3 Miscellaneous 21<br />

19. Verdrahtungsplan CONFI‑COOL<br />

without heating unit for winter months 22<br />

20. Verdrahtungsplan CONFI‑COOL without<br />

heating unit for winter months 3<br />

3

MANUFACTURER<br />

VIESSMANN Kältetechnik AG<br />

Schleizer Straße 100<br />

95030 Hof/Saale<br />

Tel.: +49 (0)92 81 / 81 4-0 - Fax: +49 (0)92 81/ 81 4-2 69<br />

info@vkag.de - www.vkag.de<br />

FORMAL INFORMATION AbOUT ThE OPERATING<br />

INSTRUCTIONS<br />

Document No.: 00570060-01D<br />

Creation Date: 01.01.2012<br />

Last Revision: 01/2012<br />

© Copyright VIESSMANN KÄLTETECHNIK AG, 2011.<br />

All rights reserved.<br />

Reprints, also in part, only permitted in agreement with<br />

VIESSMANN KÄLTETECHNIK AG.<br />

1. Operating Instructions<br />

1.1. PURPOSE OF ThE DOCUMENT<br />

These <strong>operating</strong> <strong>instructions</strong> describe the <strong>installation</strong>,<br />

workings, operation <strong>and</strong> maintenance of the offal <strong>cooler</strong><br />

CONFI-COOL. It furthermore provides information about<br />

the safe <strong>and</strong> efficient h<strong>and</strong>ling of the device.<br />

1.2 VISUALISATION OF SAFETy INSTRUCTIONS<br />

Safety <strong>instructions</strong> are marked with a pictogram <strong>and</strong> a signal<br />

word. The signal word describes the severity of the impending<br />

hazard.<br />

WARNING<br />

Possibly impending risk for<br />

life <strong>and</strong> limb of personnel<br />

(severe injury or death).<br />

CAUTION<br />

Possibly dangerous situation<br />

(minor injury or damage<br />

to material assets).<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

4<br />

IMPORTANT<br />

Requires a certain behaviour<br />

or task to ensure safe<br />

h<strong>and</strong>ling of the device.<br />

NOTE<br />

Tips for operation or particularly<br />

useful information.<br />

2. Safety notices <strong>and</strong> warnings<br />

The offal <strong>cooler</strong> CONFI-COOL complies with safety requirements.<br />

Inappropriate use of the device may, however, result<br />

in personal injury <strong>and</strong> material damage.<br />

Read the <strong>operating</strong> <strong>instructions</strong> carefully before commissioning<br />

the device. It contains important information on<br />

the <strong>installation</strong>, safety, use <strong>and</strong> maintenance of the device.<br />

Compliance will help protect from injury <strong>and</strong> damage to<br />

the device.<br />

Store the <strong>operating</strong> <strong>instructions</strong> <strong>and</strong> pass on the document<br />

to any later owner!<br />

2.1 INTENDED USE<br />

The offal <strong>cooler</strong> CONFI-COOL is intended solely for the<br />

cooling of organic waste. Any other use is not permitted<br />

<strong>and</strong> may be hazardous, s. section 3.2.<br />

Intended use includes:<br />

n Compliance with all <strong>instructions</strong> in<br />

these <strong>operating</strong> <strong>instructions</strong><br />

n Compliance with the inspection<br />

<strong>and</strong> maintenance schedule<br />

n The exclusive use of original parts<br />

Personnel, who due to their physical, sensory or mental<br />

ability, or their inexperience or ignorance are unable to operate<br />

the device safely must not use this device without the<br />

supervision <strong>and</strong> instruction by a responsible person.<br />

IMPORTANT<br />

Only use this device as intended <strong>and</strong> in impeccable<br />

technical condition! The manufacturer<br />

shall not accept liability for any damage due to unintended<br />

use or incorrect operation.<br />

Technical modifications reserved! Status 01/2012

2.2 REASONAbLy FORESEEAbLE MISUSE<br />

Any other use than the one specified under 'Intended use'<br />

or any use beyond that intended use shall be considered<br />

'inappropriate use', e.g.:<br />

n Use of the CONFI-COOL in connection with the cooling<br />

of non-packaged/ open food or medication<br />

2.3 DAMAGE ARISING FROM INAPPROPRIATE USE<br />

n The operator/ specialist dealer/ refrigeration<br />

specialist is solely responsible<br />

n The manufacturer shall not accept any liability<br />

NOTE:<br />

Inappropriate use may result in risks <strong>and</strong> hazards.<br />

Inappropriate uses are e.g. exceeding of the threshold<br />

values set for st<strong>and</strong>ard device operation, s. page 8,<br />

Section "Technical data".<br />

2.4 CONVERSIONS OR MODIFICATIONS<br />

Arbitrary conversions or modifications to the device shall<br />

result in the invalidation of any liability <strong>and</strong> warranty<br />

responsibilities of the manufacturer!<br />

The electromagnetic behaviour of the device may be<br />

impaired by unauthorised additions or modifications of any<br />

kind. You should therefore not carry out any modifications<br />

or additions to the device without firdt consulting the<br />

manufacturer <strong>and</strong> having received his permission in writing.<br />

2.5 SPARE AND WEAR PARTS/ AUxILIARy MATERIALS<br />

The use of spare <strong>and</strong> wear parts from third-party<br />

manufacturers may cause risks <strong>and</strong> hazards. Only use<br />

original parts or parts that have been authorised for use<br />

by the manufacturer. The spare parts list can be requested<br />

from VIESSMANN KÄLTETECHNIK AG.<br />

The manufacturer shall not accept any liability for damage<br />

resulting from the use of spare <strong>and</strong> wear parts as well as<br />

auxiliary material not authorised by the manufacturer.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

2.6 RISkS ARISING FROM WORkING WITh ThE<br />

CONFI‑COOL<br />

The use of the CONFI-COOL may lead to risks <strong>and</strong> impairments:<br />

n For life <strong>and</strong> limb of the operator or third parties<br />

n For the device itself<br />

n For other material assets<br />

Knowledge of the safety <strong>and</strong> <strong>operating</strong> <strong>instructions</strong> contained<br />

in this document form the basis for safe <strong>and</strong> errorfree<br />

operation of the device.<br />

IMPORTANT<br />

The <strong>operating</strong> <strong>instructions</strong> must be stored at<br />

the <strong>operating</strong> location of the device at all times!<br />

The <strong>operating</strong> <strong>instructions</strong> must be freely accessible<br />

for <strong>operating</strong> <strong>and</strong> maintenance personnel. General <strong>and</strong><br />

local regulations regarding accident prevention <strong>and</strong><br />

environmental protection must be complied with.<br />

2.7. TEChNICAL SAFETy<br />

Check the device for any visible damage prior to <strong>installation</strong>.<br />

Do not commission a device with any visible or other<br />

damage. A damaged device may endanger your personal<br />

safety!<br />

WARNING<br />

A damaged mains supply line for the<br />

CONFI-COOL must be replaced by the<br />

manufacturer/ your authorised dealer prior to<br />

commissioning to prevent any danger.<br />

The <strong>cooler</strong> contains the coolant tetrafluorethane (R134a).<br />

Tetrafluorethane is a colourless, almost odourless gas <strong>and</strong><br />

other than CFCs has no destructive effect on the ozone<br />

layer. In accordance with the Kyoto Protocol, however, it<br />

must not be released into the environment!<br />

In addition to the <strong>operating</strong> noise of the compressor, other<br />

flow sounds may occur in the entire cooling cycle. These<br />

effects are unfortunately unavoidable, but have no adverse<br />

effect on the performance of the device.<br />

Ensure that no part of the cooling cycle is damaged during<br />

transport or <strong>installation</strong> of the device.<br />

5

In case of damage:<br />

n Avoid open flames or sources of ignition.<br />

n Pull the mains plug.<br />

n Ventilate the room in which the device is installed for<br />

several minutes.<br />

n Notify customer service.<br />

Safe operation of the device can only be guaranteed if it was<br />

installed <strong>and</strong> connected in accordance with the <strong>operating</strong><br />

<strong>instructions</strong>.<br />

Make sure to compare the connection data (voltage <strong>and</strong><br />

frequency) on the type plate with those of the local grid<br />

before connecting the device.<br />

The data must match in order to avoid any damage to the<br />

device. Please contact customer service if you have any<br />

doubts.<br />

The device must not be connected to the mains grid via extension<br />

cables or multiple socket strips, as these would not<br />

guarantee the necessary safety (e.g. danger of overheating).<br />

Electric safety of the device can only be guaranteed if an<br />

approved protective conductor (earthing) system is installed.<br />

It is of utmost importance that this basic safety requirement<br />

is met. In case of doubt, ensure that a certified<br />

electrician verifies the <strong>installation</strong> on site. The manufacturer<br />

shall not accept any liability for damages caused by the<br />

lack of or the malfunction of a protective conductor system<br />

(e.g. electrocution).<br />

Installation <strong>and</strong> maintenance aor repair work must only be<br />

carried out by personnel authorised by the manufacturer.<br />

Improper <strong>installation</strong> <strong>and</strong> maintenance or repair work may<br />

result in significant hazards to the operator, for which the<br />

manufacturer shall not accept any liability.<br />

Any repairs during the warranty period must only be carried<br />

out by a customer service authorised by the manufacturer.<br />

Any repairs carried out by third parties during that<br />

time shall void the device warranty.<br />

The device must be disconnected from the mains power<br />

supply before any <strong>installation</strong> or maintenance work is carried<br />

out. The device will only be disconnected from the<br />

mains power supply, when one of the following conditions<br />

is met:<br />

n The mains power plug is unplugged from the wall socket.<br />

Never pull on the connection cable. Disconnect the device<br />

only by pulling the actual power plug.<br />

n The mains power fuse has been deactivated.<br />

Only use OEM parts to replace defective components. The<br />

manufacturer shall guarantee the safety requirements for<br />

original spare parts only.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

6<br />

2.8 INTENDED USE<br />

CONFI‑COOL is designed for use with a specific climate<br />

class (SN: ambient temperatures between +10 <strong>and</strong> +32 °C,<br />

max. humidity 75 %).<br />

Only open doors as long as necessary, as otherwise the<br />

cooling chamber temperature will rise. Excessive cooling<br />

chamber temperatures will result in increased energy<br />

consumption, longer condenser run times, <strong>and</strong> in extreme<br />

cases an emergency shut-down of the cooling system by<br />

way of the safety elements.<br />

Never cover the air inlet <strong>and</strong> air outlet openings. Faultless<br />

airflow can otherwise not be guaranteed. Energy consumption<br />

would increase <strong>and</strong> component damage can not be<br />

excluded.<br />

Do not treat the door seals with oils or greases. This would<br />

result in porosity of the seals over time.<br />

NOTE<br />

The manufacturer shall not accept liability for damage<br />

due to non-compliance with safety notices or<br />

warnings.<br />

2.9 RESIDUAL RISk<br />

The device was manufactured in accordance with the state<br />

of technology <strong>and</strong> recognised safety st<strong>and</strong>ards.<br />

2.10 ObLIGATIONS OF ThE OPERATING COMPANy<br />

Only personnel must be permitted to work on the device,<br />

who<br />

n are familiar with the basic regulations for<br />

work safety <strong>and</strong> accident prevention<br />

n have received induction training<br />

for working on the device<br />

n have read <strong>and</strong> understood the <strong>operating</strong> <strong>instructions</strong><br />

Compliance with the requirements outlined in the EC directive<br />

for the use of work equipment 2007/30/EC is m<strong>and</strong>atory.<br />

2.11 PERSONAL PROTECTION EqUIPMENT (PPE)<br />

We recommend using the following PPE for <strong>installation</strong>/ removal<br />

tasks in connection with the device:<br />

n Protective gloves<br />

Technical modifications reserved! Status 01/2012

n Safety boots<br />

2.12 ObLIGATIONS OF ThE OPERATING PERSONNEL<br />

Prior to starting work, all personnel tasked with working on<br />

the device must<br />

n take note of the basic regulations for work<br />

safety <strong>and</strong> accident prevention<br />

n read <strong>and</strong> comply with the information provided in the<br />

chapter on safety in these <strong>operating</strong> <strong>instructions</strong><br />

Please contact the manufacturer directly (s. page 4) in case<br />

of any unanswered questions.<br />

2.13 qUALIFICATIONS OF ThE OPERATING PERSONNEL<br />

We ask that the following tasks only be carried out by relevantly<br />

trained personnel:<br />

n Transport/ removal<br />

n Commissioning<br />

n roubleshooting <strong>and</strong> error correction during maintenance<br />

n Setup, equipment<br />

n Maintenance<br />

n Disposal/ recycling<br />

2.14 SAFETy AND PROTECTIVE DEVICES<br />

Description of safety <strong>and</strong> protective devices:<br />

n Protective earthing of all metal components on the device<br />

n Illuminated main switch<br />

n Drip protection on the device exterior<br />

n Overheating protection on the condenser<br />

n Protective switch to prevent excessive<br />

voltage intake of the condenser<br />

n Protective cover over the fan<br />

NOTE<br />

The device must only be operated in its fully connected/<br />

complete state, as only then all protective<br />

<strong>and</strong> safety devices will be fully operational.<br />

Comm<strong>and</strong> devices for a machine stop in case of emergency<br />

The following comm<strong>and</strong> devices for a machine stop in case<br />

of emergency are installed on the device:<br />

n Device main switch<br />

n Mains connection plug<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

Warning devices<br />

The following warning devices are installed on the <strong>cooler</strong>:<br />

n Cooling chamber over/ under temperature via thermostat<br />

optional<br />

Actions in case of defective safety <strong>and</strong> protective devices:<br />

Defective safety <strong>and</strong> protective devices may result in the<br />

following hazardous situations:<br />

In this case:<br />

n switch off the <strong>cooler</strong> immediately<br />

n secure against unauthorised reactivation<br />

n disconnect from mains power supply<br />

2.15 MAChINE DESIGNATION<br />

Warning signs are attached to the <strong>cooler</strong> with regards to<br />

the following residual risks, which cannot be eliminated<br />

structurally:<br />

Vor dem Öffnen des Gehäuses Netzstecker ziehen!<br />

Nicht mit Spritzwasser reinigen!<br />

Nicht in den Lüfterbereich hineinfassen!<br />

Disconnect from mains before opening!<br />

Do not spray with water when cleaning!<br />

Keep h<strong>and</strong>s out of fan area!<br />

Mettre l’appareil hors tension avant de l’ouvrir!<br />

Ne pas nettoyer l’appareil au jet d’eau!<br />

Ne pas mettre les mains dans le ventilateur!<br />

Take note of all signage on the CONFI-COOL:<br />

n Warnings<br />

n Safety notices<br />

n Other designations<br />

n Type plate<br />

7

3. Description<br />

3.1. FUNCTION DESCRIPTION<br />

The offal <strong>cooler</strong> CONFI-COOL is designed exclusively for<br />

the cooling of organic waste at room temperatures between<br />

+2 <strong>and</strong> +20 °C.<br />

The CONFI-COOL is a device of climate class 'SN', which<br />

is specified for ambient temperatures between +10 <strong>and</strong><br />

+32 °C.<br />

In the case of outdoor <strong>installation</strong>s it must be ascertained<br />

that the construction brief includes a protective housing<br />

(self contained construction) for the offal <strong>cooler</strong> against the<br />

elements (snow, rainwater, high winds, etc.).<br />

The CONFI-COOL is powered by a cooling system filled<br />

with R134A.<br />

Permanent air circulation effects an even temperature <strong>and</strong><br />

air distribution throughout the interior of the <strong>cooler</strong> corpus.<br />

The heat drawn from the cooled goods is expelled through<br />

the fin package. At the same time, the water withdrawn<br />

due to the undercutting of the dew point is reintroduced<br />

into the ambient air via an integrated condensation evaporation<br />

unit.<br />

The <strong>cooler</strong>s are controlled via a thermostat, which utilises<br />

the recirculated air in the cooling chamber as measur<strong>and</strong>.<br />

The evaporator is defrosted by way of a cyclically controlled<br />

deactivation of the condenser via the thermostat.<br />

3.2 ExCERPT FROM OUR WARRANTy TERMS<br />

We shall not accept any liability for damages as a result of<br />

inappropriate or improper use, faulty assembly or commissioning<br />

by the buyer or third parties, natural wear, faulty<br />

or negligent treatment, chemical or electro-chemical <strong>and</strong><br />

electrical influences not attributable to us, from non-compliance<br />

with the assembly, <strong>operating</strong> <strong>and</strong> maintenance <strong>instructions</strong>,<br />

from improper modifications or repair work carried<br />

out by the buyer or third parties, <strong>and</strong> from effects of<br />

parts of third party origin.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

8<br />

3.3. TEChNICAL SPECIFICATIONS OF ThE COOLER<br />

Model types<br />

Exterior dimensions<br />

(W x D x H)<br />

CONFI‑COOL / +W<br />

1 x 120 l, 2 x 120 l, 3 x 120 l<br />

1 x 240 l, 2 x 240 l, 3 x 240 l<br />

320 x 465 x 615 mm<br />

Section (W x H) 297 x 367 mm<br />

Rated voltage 230 V/ 50 Hz<br />

Fuse protection 16 A<br />

Power input 2.2 A<br />

Electric output 450 W<br />

Permitted <strong>operating</strong><br />

pressure<br />

18 bar<br />

Refrigerant R134A<br />

Refrigerant amount 0.19 kg<br />

Cooling capacity<br />

(t 0 = -10°C)<br />

520 W<br />

Ambient temperature max. +32 °C<br />

Operating noise<br />

51 dBA (measured at approx.<br />

1m distance)<br />

Weight 27 kg<br />

Electric protection type IP34<br />

Climate class SN<br />

The cooling system has been checked for proper seal.<br />

Technical modifications reserved! Status 01/2012

4. Unpacking<br />

IMPORTANT<br />

Ensure that the package containing the <strong>cooler</strong><br />

is transported in upright position at all times,<br />

as otherwise damage to the cooling system could occur,<br />

which would impede the functionality of the device.<br />

Take note of the relevant signage on the packaging!<br />

The device is always delivered individually packed in carton.<br />

Check the condition of the packaging <strong>and</strong> then the<br />

device for visual damage in the presence of the delivery<br />

driver, <strong>and</strong> have your findings verified with a signature (including<br />

a photograph, as required). Non-compliance with<br />

this condition will void any right to compensation.<br />

Please read the "Instructions in case of damage"! The "General<br />

terms for transport damages <strong>and</strong> hidden transport<br />

damages" apply.<br />

n Ensure that no lose parts remain in the packaging before<br />

<strong>disposal</strong>.<br />

n Please supply exact details of any defects (with photorück.graph,<br />

if possible), type designation <strong>and</strong> manufacturer's<br />

ID for our processing of any warranty claims.<br />

4.2 SCOPE OF DELIVERy CONFI‑COOL<br />

Pre-assembled devices:<br />

n Cooler corpus pre-assembled, incl. door(s), insertion<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

flap(s) <strong>and</strong> loading ramp(s) (depending on model)<br />

n Allen key<br />

n 1, 2 or 3 h<strong>and</strong>les for the insertion<br />

flap(s) (depending on model),<br />

incl. 2 screws for each h<strong>and</strong>le<br />

n Cooler CONFI‑COOL<br />

n Attachment screws to attach the <strong>cooler</strong><br />

to the <strong>cooler</strong> corpus<br />

n Operating <strong>instructions</strong><br />

n Key to lock the CONFI‑COOL<br />

Kit deliveries:<br />

n Base<br />

n 6 or 8 support legs (depending on model)<br />

n Left side panel with door hinge<br />

n Rear panel<br />

n Right side panel with door hinge<br />

<strong>and</strong> cut-out for the <strong>cooler</strong><br />

n Lid with insertion flap(s)<br />

n Allen key<br />

The packaging material was selected specifically with enviIhr<br />

Beitrag n 1, 2 or 3 h<strong>and</strong>les zum for insertion Umweltschutz<br />

flap(s) (dependronmental<br />

aspects in mind <strong>and</strong> is therefore recyclable.<br />

ing on model), incl. 2 screws for each h<strong>and</strong>le<br />

n 1 or 2 doors (depending on model)<br />

n Hinge pin(s) for door assembly<br />

Entsorgung der Transport- Entsorgung des Altgerätes<br />

4.1 UNPACkING AND hANDLING<br />

n Cooler CONFI‑COOL<br />

verpackung<br />

n Attachment screws to attach the cool-<br />

Elektrische und elektronische Altgeräte<br />

n Before <strong>and</strong> during the unpacking of the CONFI-COOL, or, er to the <strong>cooler</strong> corpus<br />

where the delivery is in kit form - before unpacking any n Die Verpackung schützt das Gerät vor enthalten Foam rubber vielfach stopper <strong>and</strong> noch plastic caps wertvolle for Mate-<br />

parts - a visual inspection of all parts must be carried out sealing the support legs internally<br />

Transportschäden. to check for any transport damage. Die Verpackungsrialien. Sie enthalten aber auch schädli-<br />

n Round stickers to cover the tension lock openings<br />

materialien sind nach umweltverträgche n Operating Stoffe, <strong>instructions</strong> die für ihre Funktion und Si-<br />

n Any damages are to be noted on the delivery papers <strong>and</strong> n Key to lock the CONFI‑COOL<br />

lichen und entsorgungstechnischen cherheit notwendig waren. Im Restmüll<br />

sent to VIESSMANN KÄLTETECHNIK AG immediately.<br />

Gesichtspunkten ausgewählt und deshalb<br />

recycelbar.<br />

Das Rückführen der Verpackung in den<br />

Materialkreislauf spart Rohstoffe und<br />

verringert das Abfallaufkommen. Ihr<br />

Fachhändler nimmt die Verpackung zu-<br />

oder bei falscher Beh<strong>and</strong>lung können<br />

diese 4.3 DISPOSAL der menschlichen OF ThE PACkAGING Gesundheit<br />

MATERIAL<br />

und der Umwelt schaden. Geben Sie<br />

Ihr Altgerät deshalb auf keinen Fall in<br />

den Restmüll.<br />

The packaging protects the device during transport. The<br />

packaging material was selected specifically with environmental<br />

aspects in mind <strong>and</strong> is therefore recyclable.<br />

Nutzen Sie stattdessen die von Ihrer<br />

Kommune eingerichtete Sammelstelle<br />

zur Rückgabe und Verwertung elektrischer<br />

und elektronischer Altgeräte.<br />

Achten Sie darauf, dass die Rohrleitungen<br />

Ihres Kältegerätes bis zum<br />

Abtransport zu einer sachgerechten,<br />

9

5. Assembly<br />

The CONFI‑COOL must me assembled in compliance with<br />

the <strong>instructions</strong> provided. Please note that any damage or<br />

loss of profits due to inappropriate assembly shall not be<br />

compensated under warranty!<br />

5.1. bEFORE STARTING ThE ASSEMbLy<br />

The floor at the <strong>installation</strong> location must be even, stable,<br />

rigid (must not deform under load stresses) <strong>and</strong> level.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

10<br />

Slight irregularities in the flooring can be compensated<br />

using the Allen key provided to adjust the support legs<br />

on the device.<br />

Please verify during set-up that the floor or the <strong>installation</strong><br />

surface has sufficient load bearing capacity to support<br />

the max. overall weight of the CONFI‑COOL incl.<br />

cooled goods.<br />

Ambient temperature of the <strong>installation</strong> location should<br />

be in the range +14 to +35 °C (devices without winter arrangement)<br />

or +8 to +35 °C (devices with winter arrangement).<br />

Relative humidity must not exceed 75 %.<br />

Installation locations in direct sunlight or near heat sources<br />

must be avoided. The same applies for insufficiently<br />

ventilated areas.<br />

When selecting an <strong>installation</strong> location, ensure good ventilation<br />

of the <strong>cooler</strong>; the infeed <strong>and</strong> exhaust air vents of<br />

the <strong>cooler</strong> must be unimpeded <strong>and</strong> free of any covering<br />

at all times.<br />

Exhaust air temperatures may reach +50 °C.<br />

WARNING<br />

The sharp-edged mounting tabs on the <strong>cooler</strong><br />

pose an injury hazard! Wear protective gloves<br />

<strong>and</strong>/or use the attached carry h<strong>and</strong>les to move the device.<br />

WARNING<br />

Reaching into the fan area of the <strong>cooler</strong> poses<br />

an injury hazard! Please take note of the <strong>instructions</strong><br />

attached to the <strong>cooler</strong>.<br />

WARNING<br />

Escaping refrigerant may result in respiratory<br />

distress/ suffocation.<br />

5.2 MOUNTING ThE COOLER CORPUS<br />

Illustration: CONFI-COOL with 2 doors (2 x 240l, 3 x 240l)<br />

When unpacking the carton, the base (A) of the offal <strong>cooler</strong><br />

is on top.<br />

(B)<br />

(A)<br />

(C) Spirit level<br />

(D)<br />

1 The support legs (B) have been pre-mounted ex works.<br />

2 Place the base (A) into the desired position, with legs (B)<br />

underneath.<br />

3 Use a spirit level (C) to level the base at all four corners<br />

(support legs have an adjustment range of approx.<br />

30 mm).<br />

4 Use an Allen key to adjust the leg height from above. The<br />

external access openings for adjusting the support legs<br />

will later be covered by the side walls.<br />

5 For larger <strong>cooler</strong>s, please insert the foam rubber stoppers<br />

<strong>and</strong> plastic covers provided into the middle bore<br />

holes (D) for optimised sealing.<br />

6 Insert the side panel (E), <strong>and</strong> ensure that the adjustment<br />

pins lock into their respective openings.<br />

(E)<br />

Technical modifications reserved! Status 01/2012

IMPORTANT<br />

The wall integrated tension locks must be<br />

locked by means of an Allen key in the direction<br />

of the arrow, when joining together the wall<br />

If turned in the opposite direction, the locking mechanism<br />

will be damaged! Please ensure that all tension<br />

locks are in their home position before use! (Home position<br />

of excentre: metal clip is lose within the fitting.)<br />

7 Use the Allen key provided to lock the two bottom tension<br />

locks in arrow direction.<br />

8 Position the back panel (F).<br />

9 Use the Allen key to lock the tension locks to the side<br />

panel <strong>and</strong> the base from the inside in arrow direction. Do<br />

not tighten the tension locks completely yet!<br />

10 Position the second side panel (G), <strong>and</strong> fix it in place.<br />

Make sure to follow the arrow direction! Do not tighten<br />

the tension locks completely yet!<br />

(H)<br />

(J)<br />

11 Put the top part (H) into position.<br />

12 Now lock all tension locks completely from the inside in<br />

arrow direction.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

(F)<br />

(G)<br />

13 Use the round stickers to cover the tension lock openings.<br />

The adhesive area must be clean <strong>and</strong> grease-free.<br />

14 Position the door with the leaf (J) into its hinges <strong>and</strong> insert<br />

the hinge pins.<br />

15 Attach the second door (K). The lock (L) must fit into its<br />

counterpart on the lid (receiver). The receiver can be adjusted<br />

if necessary by loosening one of its attachment<br />

screws.<br />

(L)<br />

(K)<br />

(M)<br />

16 Attach the external <strong>cooler</strong> (M) as described in the following<br />

steps.<br />

5.3. MOUNTING ThE ExTERNAL COOLER<br />

The mounting of the external <strong>cooler</strong> will require two people,<br />

as an injury hazard exists, should the external <strong>cooler</strong><br />

slide out of the frame.<br />

The opening required for <strong>installation</strong> is 367 x 297mm, <strong>and</strong><br />

must be covered completely by the <strong>cooler</strong>.<br />

The cooling unit requires a 230V/ 50Hz wall plug with 16 A<br />

fuse for mains connection.<br />

IMPORTANT<br />

When selecting an <strong>installation</strong> location, ensure<br />

good ventilation of the <strong>cooler</strong>; the infeed <strong>and</strong><br />

exhaust air vents of the <strong>cooler</strong> must be unimpeded <strong>and</strong><br />

free of any covering at all times.<br />

1 Remove protective film from the <strong>cooler</strong> <strong>and</strong> the <strong>cooler</strong><br />

corpus.<br />

2 Check, whether the guide rail (O) on the side of the<br />

<strong>cooler</strong> corpus has been pre-mounted ex works or attach<br />

same. See drawing "Cut-out frame“ (N).<br />

11

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

12<br />

(N)<br />

(O)<br />

Upper edge cut-out to<br />

upper edge fixed rail<br />

3 Slightly tilt the <strong>cooler</strong> (M), slide upper frame (P) under<br />

the guide rail (O), <strong>and</strong> position the <strong>cooler</strong> vertically in<br />

front of the cut-out (N) (297 x 367mm) while ensuring<br />

that the white foam rubber seal of the <strong>cooler</strong> completely<br />

seals the edges of the cut-out.<br />

(M)<br />

Exhaust air<br />

(R)<br />

(P)<br />

(S)<br />

(R)<br />

(Q)<br />

Air infeed<br />

4 The support plate (Q) on the frontal frame must lie flush<br />

on the top of the cut-out. Lock the device in place using<br />

four screws (R) threaded through the height adjustable<br />

mounting tabs (S).<br />

WARNING<br />

Make sure that no personnel or animal is present<br />

inside the <strong>cooler</strong> corpus before sealing off<br />

the cooling chamber.<br />

Technical modifications reserved! Status 01/2012

0 L Tonnen<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

52 mm 650 mm<br />

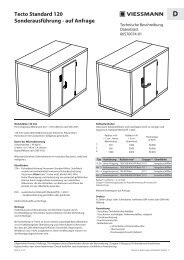

6. Dimensions CONFI‑COOL for 120 l containers<br />

6. Abmessungen<br />

6.1 Abmessungen CONFI-COOL für 120 L Tonnen<br />

3 x 120 L<br />

563 mm<br />

620 mm<br />

828 mm<br />

320 mm<br />

1720 mm<br />

1 x 240l<br />

6.1 Abmessungen CONFI-COOL für 120 L Tonnen<br />

1 x 120 L 2 x 120 L<br />

6. Abmessungen<br />

3 x 120 L<br />

563 mm<br />

620 mm<br />

320 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

117,5 mm 415 mm 117,5 mm<br />

117,5 mm 415 mm 117,5 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

359 mm 595 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

13 mm 1070 mm<br />

79 mm<br />

702 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

1162 mm<br />

1162 mm<br />

6.1 Abmessungen CONFI-COOL für 120 L Tonnen<br />

1 x 120 L 2 x 120 L<br />

6. Abmessungen<br />

6.1 Abmessungen CONFI-COOL für 120 L Tonnen<br />

1 x 120 L 2 x 120 L<br />

3 x 120 L<br />

2 x 120 L<br />

563 mm<br />

620 mm<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

2 x 240l<br />

3 x 240l<br />

Allgemeiner Hinweis (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in Bezug auf Vorh<strong>and</strong>ensein<br />

bestimmter Eigenschaften oder einen bestimmten Zweck bedürfen stets besonderer schriftlicher Vereinbarung.<br />

Allgemeiner Hinweis (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in<br />

Blatt Nr. 09-01 D bestimmter Eigenschaften 6 - 6.1 oder einen bestimmten Zweck bedürfen Technische stets besonderer Änderungen vorbehalten! schriftlicher Vereinbarung.<br />

828 mm<br />

828 mm<br />

1720 mm<br />

320 mm<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

117,5 mm<br />

320 mm<br />

563 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

1190 mm<br />

563 mm<br />

320 mm<br />

828 mm<br />

828 mm<br />

Technical modifications Allgemeiner reserved! Hinweis Status 01/2012 (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in Bezug auf Vorh<strong>and</strong>ensein<br />

bestimmter Eigenschaften 1720 mm oder einen bestimmten 320 Zweck mm bedürfen stets besonderer schriftlicher Vereinbarung.<br />

563 mm<br />

828 mm<br />

6.1 Abmessungen CONFI-COOL für 120 L Tonnen<br />

1 x 120 L 2 x 120 L<br />

3 x 120 L<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

702 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

702 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 117,5 mm mm 595 mm415<br />

mm 117,5 mm 117,5 mm 415 mm 117,5 mm<br />

13 mm 52 mm 1070 mm 650 mm 79 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

359 mm 595 mm<br />

1162 mm<br />

13 mm 1070 mm<br />

79 mm 13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

1162 mm<br />

6. Abmessungen<br />

1 x 120 L 2 x 120 L<br />

3 x 120 L<br />

D<br />

563 mm<br />

620 mm<br />

563 mm<br />

620 mm<br />

563 mm<br />

320 mm 828 mm<br />

320 mm<br />

563 mm<br />

320 mm<br />

1190 mm<br />

563 mm<br />

1190 mm 828 mm 320 mm<br />

1720 mm<br />

1190 mm<br />

563 mm<br />

563 mm<br />

320 mm<br />

828 mm<br />

320 mm<br />

320 mm<br />

Allgemeiner Hinweis (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in<br />

bestimmter Eigenschaften oder einen bestimmten Zweck bedürfen stets besonderer schriftlicher Vereinbarung.<br />

Blatt Nr. 09-01 D 6 - 6.1<br />

1720 mm<br />

828 mm<br />

D<br />

D<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

359 mm 595 mm<br />

13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

117,5 mm 415 mm 117,5 mm<br />

52 mm 650 mm<br />

117,5 mm 415 mm 117,5 mm 117,5 mm 415 mm 117,5 mm<br />

359 mm 595 mm<br />

52 mm 650 mm<br />

52 mm 650 mm<br />

13 mm 1070 mm<br />

79 mm<br />

359 mm 595 mm<br />

359 mm 595 mm<br />

1162 mm<br />

702 mm<br />

13 mm 1070 mm 702 mm 79 mm 13 mm 1070 mm<br />

79 mm<br />

1162 mm<br />

1162 mm<br />

320 mm<br />

Blatt Nr. 09-01 D 6 - 6.1<br />

563 mm<br />

563 mm<br />

13<br />

D<br />

1190 mm<br />

1190 mm<br />

563 m<br />

563 m

D<br />

40 L Tonnen<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

50 mm 820 mm<br />

870 mm<br />

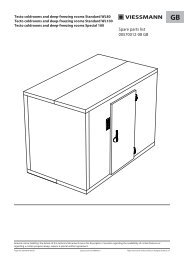

7. Dimensions CONFI‑COOL for 240 l containers<br />

3 x 240 L<br />

General note (liability): The information contained 2020 mm in the Technical Documentation 320 mm serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

14<br />

D<br />

320 mm<br />

2 x 240 L<br />

202,5 mm<br />

D<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

3 x 240 L<br />

680 mm<br />

720 mm<br />

980 mm<br />

320 mm<br />

320 mm<br />

320 mm<br />

2020 mm<br />

202,5 mm 415 mm 202,5 mm<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

202,5 mm 415 mm 202,5 mm<br />

02,5 mm 415 mm 202,5 mm<br />

50 mm 820 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

870 mm<br />

320 mm<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1 x 240 L 2 870 x 240 mm L<br />

13 mm 1200 mm<br />

82 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

1295 mm<br />

1295 mm<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

1 x 240 L 2 x 240 L<br />

1 x 240 l<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

1 x 240 L 2 x 240 L<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

1 x 240 L 2 x 240 L<br />

320 mm<br />

680 mm<br />

720 mm<br />

3 x 240 L<br />

680 mm<br />

720 mm 320 mm<br />

680 mm<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

202,5 mm 415 mm 202,5 mm<br />

50 mm 820 mm<br />

524 mm 595 1 mm x 240 L 2 x 240 L<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

6.2 Abmessungen CONFI-COOL für 240 L Tonnen<br />

1420 mm<br />

320 mm<br />

320 mm<br />

680 mm<br />

6.2 Abmessungen CONFI-COOL 202,5 mm für 240 415 L mm Tonnen 202,5 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

1 x 240 L 870 mm<br />

13 mm 2 x 240 L 1200 mm<br />

82 mm<br />

1295 mm<br />

1 x 240 L 2 x 240 L<br />

D<br />

D<br />

320 mm<br />

320 mm<br />

3 x 240 L<br />

2 x 240 l<br />

3 x 240 l<br />

980 mm<br />

202,5 mm 415 mm 202,5 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

320 mm<br />

320 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

202,5 mm 415 mm 202,5 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

320 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm 320 mm<br />

1295 mm<br />

202,5 mm 415 mm 202,5 mm<br />

415 mm 202,5 mm<br />

202,5 mm 415 mm 202,5 680 mm mm<br />

680 mm<br />

680 mm<br />

202,5 mm<br />

50 mm 820 mm<br />

720 mm 50 320 mm 820 mm<br />

1420 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

524 mm 595 mm<br />

524 mm 595 mm<br />

870 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

1295 mm<br />

1295 mm<br />

3 x 240 L<br />

680 mm<br />

720 mm<br />

1420 mm320<br />

mm<br />

980 mm<br />

320 mm 980 mm<br />

680 mm<br />

320 mm<br />

1420 mm<br />

Allgemeiner Hinweis (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in Bezug auf Vorh<strong>and</strong>ensein<br />

bestimmter Eigenschaften oder einen bestimmten Zweck<br />

Allgemeiner<br />

bedürfen stets<br />

Hinweis<br />

besonderer<br />

(Haftung):<br />

schriftlicher<br />

Die Angaben<br />

Vereinbarung.<br />

dieser Technischen Unterlage dienen der Beschreibung. Zusag<br />

Blatt Nr. 10-01 D bestimmter Eigenschaften 6 - 6.2 oder einen bestimmten Zweck bedürfen Technische stets besonderer Änderungen vorbehalten! schriftlicher Vereinbaru<br />

980 mm<br />

980 mm<br />

D<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

D<br />

320 mm<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

3 x 240 L<br />

680 mm<br />

680 mm<br />

720 mm<br />

Technical modifications reserved! Status 01/2012<br />

Allgemeiner 980 mm Hinweis (Haftung): 980 Die mm Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusagen in Bezug auf Vorh<strong>and</strong>ensein<br />

bestimmter Eigenschaften oder einen bestimmten Zweck bedürfen stets besonderer schriftlicher Vereinbarung.<br />

680 mm<br />

680 mm<br />

320 mm<br />

1 x 240 L 2 x 240 L<br />

870 mm<br />

415 mm 202,5 mm<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

50 mm 820 mm<br />

320 mm<br />

320 mm<br />

320 mm<br />

1420 mm<br />

320 mm<br />

202,5 mm<br />

680 mm<br />

2020 mm<br />

320 mm<br />

680 mm<br />

320 mm<br />

980 mm<br />

202,5 mm 415 mm 202,5 mm<br />

680 mm<br />

680 mm<br />

50 320 mm 820 mm<br />

1420 mm<br />

524 mm 595 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

320 mm<br />

320 mm<br />

320 mm<br />

320 mm<br />

320 mm<br />

Blatt Nr. 10-01 D 6 - 6.2<br />

320 mm<br />

3 x 240 L<br />

202,5 mm 415 mm 202,5 mm<br />

202,5 mm 415 mm 202,5 mm 202,5 mm<br />

680 mm<br />

415 mm<br />

680<br />

202,5<br />

mm<br />

mm<br />

50 mm 820 mm<br />

50 320 mm 820 mm<br />

50 mm 820 1420 mm mm<br />

320 524 mm 595 mm<br />

524 mm 595 mm<br />

524 mm mm 595 mm<br />

870 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm<br />

870 mm<br />

13 mm 1200 mm<br />

82 mm 13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

1295 mm<br />

1295 mm<br />

680 mm<br />

1420 mm<br />

Allgemeiner Hinweis (Haftung): Die Angaben dieser Technischen Unterlage dienen der Beschreibung. Zusage<br />

bestimmter Eigenschaften oder einen bestimmten Zweck bedürfen stets besonderer schriftlicher Vereinbaru<br />

2020 mm<br />

980 mm<br />

320 mm<br />

Blatt Nr. 10-01 D 6 - 6.2<br />

320 mm<br />

870 mm<br />

415 mm 202,5 mm<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

870 mm<br />

415 mm 202,5 mm<br />

524 mm 595 mm<br />

13 mm 1200 mm<br />

82 mm<br />

1295 mm<br />

50 mm 820 mm<br />

50 mm 820 mm<br />

524 mm 595 mm<br />

mm 1200 mm<br />

82 mm<br />

1295 mm<br />

202,5 mm<br />

320 mm<br />

870 mm<br />

415 mm 202,5 mm<br />

202,5 mm<br />

680 mm<br />

720 mm<br />

870 mm<br />

415 mm 202,5 mm<br />

50 mm 820 mm<br />

202,5 mm<br />

50 mm 820 mm<br />

202,5 mm<br />

680 mm<br />

720 mm<br />

82 mm<br />

320 mm<br />

680 mm<br />

3 x 240 L<br />

595 mm<br />

m<br />

m<br />

1420 mm<br />

2 mm

8. Commissioning<br />

NOTE<br />

Units installed outdoors or in unheated areas will<br />

require an oil heating unit for winter months, which<br />

is only available as a factory installed component of the<br />

external cooling system.<br />

Before initial commissioning, clean the <strong>cooler</strong>, the <strong>cooler</strong><br />

corpus inside <strong>and</strong> out, <strong>and</strong> all accessories. Use warm water<br />

<strong>and</strong> dry with a soft cloth.<br />

1 Wipe the interior with a moist cloth <strong>and</strong> rub dry before<br />

(initial) commissioning.<br />

2 Plug the mains plug of the <strong>cooler</strong> into an appropriately<br />

installed <strong>and</strong> grounded wall socket. Mains voltage must<br />

comply with machine specifications.<br />

3 Press the main switch on the device. The digital thermostat<br />

indicates current cooling temperature, the fan operates<br />

constantly. The device will continue to cool until<br />

the temperature of +4 °C (pre-set ex works) has been<br />

reached.<br />

4 Ensure that the infeed air <strong>and</strong> exhaust vents are uncovered<br />

to ensure faultless function of the <strong>cooler</strong>.<br />

5 The internally attached loading ramp can be lowered for<br />

easy access to the waste containers.<br />

6 Disconnect the <strong>cooler</strong> when not in use for an extended<br />

period of time. Leave the doors to the cooling compartments<br />

open to ensure proper air circulation while not in<br />

use.<br />

NOTE<br />

Do not use any other mechanical devices or other<br />

means than those recommended by the manufacturer<br />

for defrosting.<br />

NOTE<br />

Do not operate any electrical appliances inside the<br />

food storage room other than those approved by<br />

the manufacturer.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

9. What if?<br />

. . . ThE DEVICE DOESN'T COOL?<br />

n Check if the device is switched on. The temperature display<br />

must be lit.<br />

n Check the mains plug in the wall socket for correct seating.<br />

n Check the wall socket for voltage.<br />

. . . ThE ACTIVATION FREqUENCy AND OPERATION<br />

DURATION OF ThE COOLING UNIT INCREASES?<br />

n Check whether the air infeed <strong>and</strong> exhaust vents at the<br />

head of the <strong>cooler</strong> are covered or dirty.<br />

n The <strong>cooler</strong> door has been opened frequently, or a large<br />

amount of goods was added.<br />

n Check the device doors for proper locking.<br />

n Check the function <strong>and</strong> adherence of the door seal.<br />

15

10. Operation<br />

10.1 PREREqUISITES FOR OPERATION<br />

n Device is switched on<br />

n Device settings ex works<br />

n No active error messages<br />

WARNING<br />

The storing of explosive or flammable materials,<br />

pressurised containers (spray cans) or other<br />

hazardous materials in the offal <strong>cooler</strong> is not permitted.<br />

10.2. DEFROSTING<br />

The unit automatically switches to defrost mode every<br />

two hours. The refrigeration unit will st<strong>and</strong> still for approx.<br />

12 minutes. The thermostat's digital display switches to<br />

"dfr" (eliwell) or "dEF" (LAE).<br />

The display switches back to displaying the current temperature,<br />

once the pre-set temperature has been reached<br />

or 10 minutes have passed.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

16<br />

In defrost mode, interior temperature can increase slightly,<br />

particularly if the doors are opened during that time. The<br />

core temperature of stored goods remains however mostly<br />

unaffected.<br />

10.3. CONDENSATE<br />

The condenser water is fed into the hot gas-heated condensate<br />

evaporation tray for evaporation. Evaporation<br />

output is set to match central European st<strong>and</strong>ard ambient<br />

temperatures <strong>and</strong> humidity.<br />

IMPORTANT<br />

In case of extrene amounts of condensate due<br />

to high humidity or excessive air exchange inside<br />

the cooling chamber, a direct condensate outlet<br />

must be installed!<br />

11. Modifying Cooling Chamber<br />

Temperatures (without heating<br />

unit for winter months)<br />

ThERMOSTAT LAE AT1‑5<br />

All parameter modifications must be carried out by your<br />

refrigeration specialist, as incorrect programming of the<br />

thermostat may result in malfunction of your offal <strong>cooler</strong><br />

CONFI-COOL <strong>and</strong> would void your warranty!<br />

MENU ACCESS AND DATA DISPLAy<br />

1 Press <strong>and</strong> release the button i .<br />

2 Select the data to be displayed via the buttons or .<br />

3 Display the desired value by pressing i .<br />

4 Press the button to exit the menu or wait 10 seconds.<br />

RESETTING ThE STORED VALUES ThI, TLO, CND<br />

1 Press the button or to select the value to reset.<br />

2 Display the desired value by pressing i .<br />

3 Press <strong>and</strong> hold the button i <strong>and</strong><br />

simultaneously press .<br />

DISPLAy AND MODIFICATION OF ThE SETPOINT TEM‑<br />

PERATURE<br />

1 Press <strong>and</strong> hold the button for at least half a second<br />

to display the setpoint value.<br />

2 Press <strong>and</strong> hold the button <strong>and</strong> use<br />

or to set the desired value (a value between the min.<br />

value "SPL“ <strong>and</strong> max. value "SPH“ can be selected).<br />

3 The new value is stored once the button is released.<br />

Technical modifications reserved! Status 01/2012

STAND‑by<br />

Pressing the button for 3 seconds allows the controller<br />

to switch over to various <strong>operating</strong> modes or to St<strong>and</strong>-by<br />

(only if "SB“=YES).<br />

bUTTON LOCk<br />

The button lock prevents unwanted or potentially harmful<br />

actions if the controller is e.g. positioned in a publicly<br />

accessible location.<br />

Set the parameter in the menu INFO to "LOC"=YES to lock<br />

out all button comm<strong>and</strong>s; set the parameter to "LOC"=NO<br />

to reinstate the button functions.<br />

DEFROSTING<br />

ThERMOSTAT ELIWELL ID961<br />

Defrosting with timer: The defrost cycle starts automatically<br />

when the the time set for defrost frequency ("DFR") on All parameter modifications must be carried out by your<br />

7. Änderung der Kühlraumtemperatur<br />

the internal timer has elapsed. Example: "DFR"=4 will initi- refrigeration specialist, as incorrect programming of the<br />

ate 4 defrost cycles in 24 hours, i.e. one defrost cycle every thermostat may result in malfunction of your offal <strong>cooler</strong><br />

Gerät ohne Winterregelung<br />

6 hours.<br />

CONFI-COOL <strong>and</strong> would void your warranty!<br />

The internal timer is set to zero Thermostat when the device LAE AT1-5 is switched<br />

on, <strong>and</strong> is reset with each new defrost cycle; the timer stops<br />

in St<strong>and</strong>-by mode (does not Temperatur count down). einstellen/ändern FRONTAL CONTROLS<br />

1 Taste drücken und gedrückt halten<br />

Manual defrosting: Pressing 2 the mit button Taste for oder 2 seconds Solltemperatur set When ändern pressed, the setpoint value is displayed <strong>and</strong> the<br />

will activate the manual defrost 3 Zum mode. Verlassen des Menüs die Taste LED “DEF/SET” drücken is blinking.<br />

oder 10 sec. warten.<br />

Modifications/ settings can now be effected. The new value<br />

Defrost type: Once defrosting has commenced, the con- will be stored automatically after the frontal controls have<br />

denser <strong>and</strong> defrost outputs Tastensperre are controlled aktivieren/deaktivieren<br />

according to the not been actuated for 15 seconds.<br />

parameters "DTY" <strong>and</strong> "OAU".<br />

1<br />

The AUX<br />

nur<br />

output<br />

kurz<br />

is<br />

drücken<br />

only tied to<br />

the defrost function if "OAU"=DEF.<br />

wird angezeigt<br />

Button for increasing the setpoint value <strong>and</strong>/or param-<br />

2 einmal drücken<br />

eter values. Pressing <strong>and</strong> holding the button will accelerate<br />

Defrost end: The defrost cycle ends once the time "DTO" is<br />

LOC wird angezeigt<br />

the value increase.<br />

reached; if the evaporator is activated ("T2"=YES) <strong>and</strong> tem-<br />

3 drücken und gedrückt halten<br />

perature "DLI" is reached within that time, then the defrost<br />

Button for reducing the setpoint value <strong>and</strong>/or param-<br />

cycle will terminate prematurely.<br />

zum Aktivieren: gleichzeitig oder drücken<br />

eter values. Pressing <strong>and</strong> holding the button will accelerate<br />

Attention: With "C-H“=HEA all defrost bis der functions Regler are YES locked anzeigt out; the value reduction.<br />

with "DFT“=0 only the timed defrost Tastensperre function is locked ist eingestellt out. The<br />

overtemperature alarm is locked out zum during Deaktivieren: defrosting. gleichzeitig oder<br />

= DEFROST: Button for the manual activation of the de-<br />

drücken bis der Regler no anzeigt<br />

frost cycle. The button is active outside the programming<br />

Tastensperre ist entfernt phase <strong>and</strong> is actuated by pressing <strong>and</strong> holding for more<br />

than 5 seconds. The LED "DEF/SET" is switched on during<br />

Regler ein/ausschalten<br />

defrosting <strong>and</strong> the condenser is switched off.<br />

1 Die Taste mind. 3 sec. drücken<br />

Regler schaltet auf ON (Normalbetrieb)<br />

LED “COMP”: The LED assigned to the condenser relay.<br />

2 Das Ausschalten erfolgt über die -Taste (3 sek. drücken).<br />

LED “DEF/SET”: This LED blinks while the setpoint value is<br />

Das Ändern der <strong>and</strong>eren Parameter displayed lassen Sie <strong>and</strong> bitte modified, bei Bedarf <strong>and</strong> also during the programming<br />

von Ihrer Kältefach�rma durchführen. of the parameters. It is constantly lit during defrosting.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

12. Modifying Cooling Chamber<br />

Temperatures (with heating unit<br />

for winter months)<br />

17

DISPLAy AND MODIFICATION OF ThE SETPOINT TEM‑<br />

PERATURE<br />

1 Press set to display "SET“.<br />

2 Press the button set again to display the<br />

pre-set setpoint temperature value.<br />

3 Set the desired value via the buttons or .<br />

4 The value is automatically stored after<br />

30 seconds inactivity.<br />

DEFROSTING<br />

The defrost cycle commences automatically every two<br />

hours. The refrigeration unit will st<strong>and</strong> still for approx.<br />

12 minutes. The process is indicated by the blinking defrost<br />

symbol.<br />

The defrost cycle can also be started manually. Defrosting<br />

commences if the button is pressed <strong>and</strong> held for 5 seconds<br />

<strong>and</strong> ends automatically.<br />

During defrost, a slight temperature increase may occur,<br />

particularly if the cooling compartments are opened during<br />

that time. The core temperature of stored goods remains<br />

mostly unaffected.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

18<br />

13. Maintenance <strong>and</strong> Cleaning<br />

The following contains information on the cleaning <strong>and</strong><br />

troubleshooting of the device. Periodic maintenance in<br />

accordance with the maintenance schedule is a critical<br />

requirement for the efficient use of the device.<br />

We recommend entering into a maintenance agreement<br />

with your refrigeration specialist. They will be able to<br />

optimally adjust your cooling system to local conditions<br />

(e.g. reprogramming of sub-routines of the thermostat).<br />

You should similarly contact your refrigeration specialist<br />

for wear <strong>and</strong> spare parts.<br />

13.1 bEFORE CLEANING<br />

1 Remove all refrigerated goods from the cooling corpus<br />

<strong>and</strong> store it in an appropriate location.<br />

2 Extract all removable parts for cleaning.<br />

13.2 CLEANING ThE DEVICE<br />

Clean the <strong>cooler</strong> <strong>and</strong> the cooling corpus at least once every<br />

4 weeks. Your <strong>operating</strong> personnel will be able to carry out<br />

the task following relevant induction training.<br />

Use warm water <strong>and</strong> some mild detergent for cleaning.<br />

NOTE<br />

Never use abrasive or scouring agents, sodium-rich<br />

detergents or detergents containing acid; avoid<br />

chemical solvents.<br />

1 Switch off the <strong>cooler</strong> on the main power switch. The<br />

mains plug does not have to be disconnected.<br />

2 Only clean the exterior of the <strong>cooler</strong>, <strong>and</strong> the interior <strong>and</strong><br />

exterior of the cooling corpus with warm water (small<br />

amounts of a mild detergent may be added); rinse with<br />

clear water <strong>and</strong> rub dry with a soft cloth.<br />

3 Clean the infeed <strong>and</strong> exhaust air vents on the <strong>cooler</strong> with<br />

a h<strong>and</strong>-held brush or vacuum cleaner.<br />

4 Regularly clean the door seal of the cooling corpus with<br />

clear water <strong>and</strong> dry with a soft cloth. Do not treat the<br />

door seals with oils or greases. The seal could otherwise<br />

become porous over time.<br />

Technical modifications reserved! Status 01/2012

4 The condenser must be thoroughly cleaned <strong>and</strong> checked<br />

by a specialist once a year.<br />

A new door seal can be ordered via customer service (see<br />

spare parts list on p. 21). Recommendation: A periodic treatment<br />

of the door seal with TALCUM will prolong its lifespan.<br />

NOTE<br />

Some of the above mentioned tasks depend significantly<br />

on use <strong>and</strong> ambient conditions.<br />

The above mentioned cycles are minimum values. In<br />

some cases, deviating maintenance cycles may be necessary.<br />

Provide the <strong>operating</strong> personnel with relevant<br />

information as needed.<br />

14. Removal, final Decommis‑<br />

sioning<br />

1 Switch off device.<br />

2 Pull the mains plug, roll up mains cable<br />

<strong>and</strong> secure on the device.<br />

3 Reverse the assembly sequence (see section<br />

4) for removal <strong>and</strong> <strong>disposal</strong> transport.<br />

4 Secure the doors against opening.<br />

14.1 DISPOSAL OF ThE USED APPLIANCE<br />

Used electrical <strong>and</strong> electronic appliance in most cases contain<br />

valuable materials. They also contain hazardous substances,<br />

which were needed for their function <strong>and</strong> safety.<br />

If disposed of with residual waste or if h<strong>and</strong>led incorrectly,<br />

these may be hazardous to human health <strong>and</strong> the environment.<br />

Used devices should therefore never be disposed of<br />

as residual waste.<br />

Utilise instead the collection point provided by your municipality<br />

for the return <strong>and</strong> recycling of used electrical <strong>and</strong><br />

electronic devices. Ensure that the pipework for your <strong>cooler</strong><br />

is not damaged until it can be removed for environmentally<br />

friendly recycling. The coolants contained in the cooling cycle<br />

<strong>and</strong> the oil in the compressor with thus be prevented<br />

from leaking into the environment.<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

Technical modifications reserved! Status 01/2012<br />

Ensure that the used device will be stored safely <strong>and</strong> out of<br />

reach of children until its final removal. For more information<br />

please read the chapter "Safety notices <strong>and</strong> warnings"<br />

in these <strong>operating</strong> <strong>instructions</strong>.<br />

NOTE<br />

Please contact the manufacturer with any remaining<br />

questions regarding <strong>disposal</strong>/ recycling.<br />

15. Liability<br />

The warranty will be voided in case of damage due to incorrect<br />

operation.<br />

All maintenance <strong>and</strong> repair work must only be carried out<br />

by authorised <strong>and</strong> certified personnel in compliance with<br />

local accident prevention regulations <strong>and</strong> applicable safety<br />

requirements.<br />

Accident prevention regulations with regards to the h<strong>and</strong>ling<br />

of coolants must be strictly adhered to.<br />

Electrical or mechanical modifications of any kind on the<br />

device are strictly prohibited <strong>and</strong> will result in the voiding<br />

of the warranty.<br />

The storing of explosive or flammable materials, pressurised<br />

containers (spray cans) or other hazardous materials in<br />

the offal <strong>cooler</strong> is not permitted.<br />

19

16. Fault Detection & Elimination<br />

In case of any functional disruption, please use the table<br />

below to check if all notes <strong>and</strong> <strong>instructions</strong> contained in<br />

these <strong>operating</strong> <strong>instructions</strong> have been complied with. The<br />

fault might just be an easily rectified minor issue.<br />

The following overview offers information about faults,<br />

their causes <strong>and</strong> remedies.<br />

IN CASE OF FAULT:<br />

n Notify trained service personnel<br />

n Notify your refrigeration specialist if needed<br />

n The mains connection must be disconnected <strong>and</strong> secured<br />

before any work is carried out on the <strong>cooler</strong>!<br />

Fault/ Display Possible cause Remedy<br />

Temperature display is off No power at the source Connect mains plug. Check fuse.<br />

Device switch<br />

not lit<br />

Temperature display shows<br />

"dfr“ (eliwell) or "DEF“ (LAE)<br />

General note (liability): The information contained in the Technical Documentation serve as a description only. Assurances with regards to specific attributes<br />

or a specific purpose always require separate written agreement.<br />

20<br />

Mains switch is off<br />

Device is in defrost mode<br />

Have pin contacts at the thermostat<br />

checked (requires certified electrician!)<br />

Wait for the defrost cycle to complete (max. 15 mins.).<br />

Have duration <strong>and</strong> frequency of the defrost cycle<br />

adjusted on the thermostat by an installer.<br />

"REC“ (only LAE) Setpoint value recovery after defrost Wait for end of recovery interval<br />

Temperature in cooling<br />

chamber<br />

too high<br />

Temperature in cooling<br />

chamber<br />

too low<br />

Wrong thermostat setting Adjust setpoint value at thermostat<br />

Condenser insufficiently ventilated Check/ clean condenser (disconnect mains plug first!)<br />

Door seal not tight Replace door seals<br />