GB Chiller room - Viessmann Kältetechnik AG

GB Chiller room - Viessmann Kältetechnik AG

GB Chiller room - Viessmann Kältetechnik AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

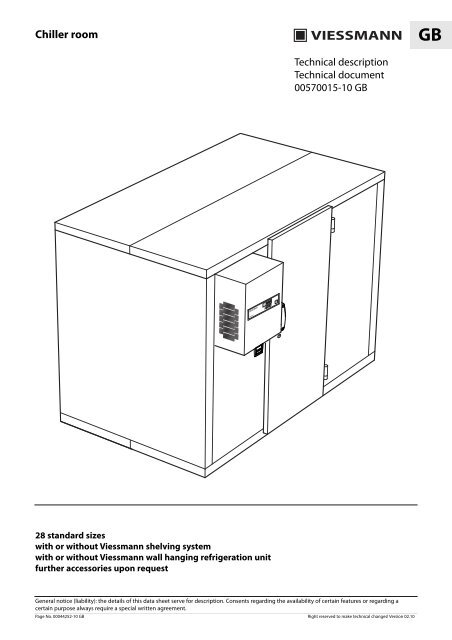

<strong>Chiller</strong> <strong>room</strong><br />

28 standard sizes<br />

with or without <strong>Viessmann</strong> shelving system<br />

with or without <strong>Viessmann</strong> wall hanging refrigeration unit<br />

further accessories upon request<br />

Technical description<br />

Technical document<br />

00570015-10 <strong>GB</strong><br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044252-10 <strong>GB</strong> Right reserved to make technical changes! Version 02.10<br />

<strong>GB</strong>

<strong>GB</strong> Table of contents<br />

1. Heat insulation<br />

2. Special features<br />

3. General remarks<br />

4. <strong>Chiller</strong> <strong>room</strong> surface<br />

5. Rigid polyurethane foam<br />

6. Connection of chiller <strong>room</strong> panels<br />

6.1 Wall panel joints<br />

7. <strong>Chiller</strong> <strong>room</strong> assembly<br />

7.1 Exterior assembly only under a protective roof<br />

8. Floor panels<br />

8.1 <strong>Chiller</strong> <strong>room</strong> with heat-insulated floor panels<br />

8.2 Joint-free stainless steel flooring<br />

8.3 Stainless steel flooring surface<br />

(Non-slip certification)<br />

9. Doors<br />

9.1 Description<br />

9.2 Door position<br />

9.3 Installed externally on door frame<br />

9.4 Installed internally on door frame<br />

9.5 Opening field of traverse of chiller <strong>room</strong> door<br />

10. Ceiling panels<br />

11. Dimensions of chiller <strong>room</strong>s<br />

11.1 Standard chiller <strong>room</strong><br />

11.2 Industrial chiller <strong>room</strong><br />

12. Scope of delivery / delivery term<br />

12.1 Standard chiller <strong>room</strong> - recommended refrigerating<br />

capacity, useful area, cubic capacity<br />

12.2 Industrial chiller <strong>room</strong> - recommended refrigerating<br />

capacity, useful area, cubic capacity<br />

13. Accessories<br />

13.1 Refrigeration units<br />

13.2 Shelving systems<br />

13.3 Meat and sausage hanging rails for wall assembly<br />

13.4 Meat and sausage hanging rails for ceiling assembly<br />

13.5 Hanging basket<br />

14. Tendering text - chiller <strong>room</strong><br />

14.1 Features<br />

14.2 Connecting of the chiller <strong>room</strong> panels<br />

14.3 <strong>Chiller</strong> <strong>room</strong> panels (wall and ceiling panels, floor exterior)<br />

14.4 Floor panels - upper surface<br />

14.5 <strong>Chiller</strong> <strong>room</strong> doors<br />

14.6 Accessories<br />

15. Tendering text - specifications chiller <strong>room</strong><br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044253-06 <strong>GB</strong> Contents Right reserved to make technical changes!

1. Heat insulation<br />

Wall thickness 60 mm<br />

Exterior height<br />

Interior height<br />

Recommended temperature<br />

difference to VDI 2055<br />

T= (Kelvin)<br />

2. Special features<br />

- Sandwich construction of frost heave preventing chiller<br />

<strong>room</strong> panels, stable, self-supporting and dimensionally<br />

precise.<br />

- Equipped as standard with the antimicrobial<br />

SilverProtec® agent.<br />

- No wood used in wall, ceiling or door panels.<br />

- Stainless steel chiller <strong>room</strong> floors, finished joint-free, even<br />

and firmly underlapped, with multi-directional non-slip<br />

(certificate).<br />

- <strong>Chiller</strong> <strong>room</strong>s with opening door, interior light and<br />

thermometer. Exterior fittings are integrated.<br />

- 28 standard sizes<br />

- Supplied with <strong>Viessmann</strong> stainless steel or with<br />

aluminium upright shelving.<br />

- Supplied with <strong>Viessmann</strong> refrigeration units.<br />

3. General remarks<br />

1950 mm<br />

1830 mm<br />

30 K<br />

Temperature range +2°C to +19°C<br />

Foam density 40 kg/m 3<br />

Heat conductivity<br />

to DIN 4108<br />

025<br />

k - Value according to DIN 52612 0,34 W/m 2 * K<br />

Building material class<br />

to DIN 4102,<br />

Classification B3<br />

Insulation<br />

Rigid polyurethane foamed with<br />

cyclopentane non-CFC<br />

- <strong>Viessmann</strong> chiller <strong>room</strong> panels are produced using<br />

polyurethane foam with cyclopentane (non CFC) and are<br />

dimensionally precise and homogeneous. They have low<br />

heat transmission values, high pressure resistance and<br />

great stability.<br />

- The connecting panels using a groove and tongue system<br />

and corrosion resistant eccentric cam locks allow fast<br />

assembly and disassembly.<br />

- <strong>Viessmann</strong> chiller <strong>room</strong> are suitable for assembly<br />

outdoors, but local construction measures (protective<br />

roof and sidewalls) must be taken to ensure that the<br />

chiller <strong>room</strong> is not exposed to the influence of weather<br />

(snow loading, wind pressure).These precautions must<br />

be completed before assembly.<br />

- The ceiling panels are not designed for additional<br />

forces (i. e. snow or wind). Prior to applying<br />

force to the roof, e. g. during installation of a<br />

ceiling refrigeration unit or installation of meat<br />

hanging equipment, pipes, etc., additional<br />

supports must be installed to ensure sufficient<br />

strength in the structure.<br />

4. <strong>Chiller</strong> <strong>room</strong> surface<br />

The chiller <strong>room</strong> panels can be supplied with the<br />

following surface coating:<br />

STA = <strong>Viessmann</strong> Standard white powder coating,<br />

galvanized steel coating with antimicrobial<br />

<strong>Viessmann</strong> SilverProtec® powder coating (similar<br />

to RAL 9016).<br />

None transfer and spreading of potentially<br />

dangerous bacteria by targeted release of<br />

natural silver ions. The silver ions leads to<br />

bacteria and fungi dying on contact with the<br />

upper surface.<br />

5. Rigid polyurethane foam<br />

<strong>Viessmann</strong> chiller <strong>room</strong>s are effectively insulated with<br />

cyclopentane foamed polyurethane (no CFC) and sealed<br />

using a groove and tongue system. Cyclopentane makes<br />

it possible to foam out the chiller <strong>room</strong>s panels with<br />

dimensional precision, allowing simple assembly.<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044254-08 <strong>GB</strong> 1 - 5 Right reserved to make technical changes!<br />

<strong>GB</strong>

<strong>GB</strong><br />

6. Connection of chiller <strong>room</strong> panels<br />

The sandwich panels of the chiller <strong>room</strong> (flooring, walls,<br />

ceilings) are connected using a self-centering groove and<br />

tongue system. Eccentric cam locks are installed in the<br />

panels and foamed in with plastic housing and corrosionresistant<br />

clamping hooks. The cam locks are activated from<br />

the interior. The chiller <strong>room</strong> does not have to be accessible<br />

from the outside during assembly.<br />

6.1 Wall panel joints<br />

The chiller <strong>room</strong> wall panel joints are made using a groove<br />

and tongue system and a PE gasket seal.<br />

The plates have no overlap.<br />

7. <strong>Chiller</strong> <strong>room</strong> assembly<br />

The chiller <strong>room</strong> must be assembled in a well ventilated<br />

<strong>room</strong>, so that the heat produced by the refrigeration unit can<br />

be properly eliminated, thus preventing overheating of the<br />

<strong>room</strong> where the chiller <strong>room</strong> is installed. This reduces the<br />

running time of the refrigeration unit, reducing energy<br />

consumption and cost, and reducing wear and tear on the<br />

refrigeration unit. The distance between the chiller <strong>room</strong> and<br />

the wall of the building and the free space over the chiller<br />

<strong>room</strong> must be at least 50 mm for above zero operation. Prior<br />

to assembly the <strong>room</strong> should be carefully measured.<br />

Attention must be paid to installing the floor panels only on<br />

a perfectly horizontal and smooth floor (VOB regulations). lf<br />

the floor is uneven or angled, the difference must be<br />

compensated for.<br />

7.1 Exterior assembly only under a protective roof<br />

The <strong>Viessmann</strong> chiller <strong>room</strong> is suitable for assembly outdoors<br />

but this must be done under a protective roof<br />

(local construction measure)<br />

<strong>Chiller</strong> <strong>room</strong>s installed outdoors can show colour fading due<br />

to UV exposure.<br />

<strong>Chiller</strong> <strong>room</strong> walls with foamed in cam lock<br />

connectors<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044255-05 <strong>GB</strong> 6 - 7.1 Right reserved to make technical changes!

8. Floor panels<br />

T0 = Standard flooring<br />

8.1 <strong>Chiller</strong> <strong>room</strong>s with heat-insulated floor panels<br />

Flooring construction:<br />

- Austenitic stainless steel, material no. 1.4301<br />

- Pressure compensation plate (water resistant presswood)<br />

- Rigid PU foam with groove and tongue<br />

- Metal bottom plate<br />

Features:<br />

- Floor panel joints are joint-free, even, and firmly<br />

underlapped, and are riveted during assembly.<br />

- Stainless steel surface multidirectional, non-slip embossed<br />

(R 11), using the special <strong>Viessmann</strong> pressing process.<br />

(excluding complete floor panels)<br />

- Permissible loads on the chiller <strong>room</strong> floor:<br />

250 N / hard bakery wheel<br />

1000 N / rubber wheel<br />

30000 N/m 2 area load<br />

8.2 Joint-free stainless steel flooring<br />

With stainless steel flooring, the joint between the floor<br />

panels is seamless, even and firmly underlapped, with a<br />

glued on high-quality gasket seal glued. During assembly,<br />

the underlap is riveted, preventing dampness from<br />

penetrating the chiller <strong>room</strong> flooring and thus preventing<br />

bacteria formation. <strong>Viessmann</strong> stainless steel chiller <strong>room</strong><br />

flooring can be cleaned using a water hose or steam cleaner.<br />

8.3 Stainless steel flooring surface<br />

(non-slip certification)<br />

More safety using non-slip stainless steel flooring surface.<br />

Our stainless steel flooring is multidirectional, non-slip<br />

embossed (R11), using the special <strong>Viessmann</strong> pressing<br />

process (excluding complete floor panels).<br />

Lower or higher non-slip classes can be supplied<br />

(R10, R12 etc.).<br />

Stainless steel floor underlapping<br />

Connection of T0-floor - wall<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044256-05 <strong>GB</strong> 8 - 8.3 Right reserved to make technical changes!<br />

<strong>GB</strong>

<strong>GB</strong><br />

9. Doors<br />

9.1 Description<br />

- One piece cold<strong>room</strong> door, opening to the outside, with<br />

magnetic seals and vertical, adjustable door hinges.<br />

- Cylinder lock, and emergency release to open the closed<br />

door from the inside.<br />

- Door stop can be changed on-site from DIN<br />

turing to DIN turning.<br />

- Door panel polyurethane foamed with cyclopentane,<br />

non CFC.<br />

- Threshold covering plate of stainless steel.<br />

- Inside of door leaf prepared for assembly of 4 hanging<br />

basket.<br />

9.2 Door position<br />

Clear width in the chiller <strong>room</strong> door side, starting 540 mm<br />

from the left can be moved to the right (dimension “X” -<br />

see table).<br />

When ordered in combination with <strong>Viessmann</strong> refrigeration<br />

unit, the left doorframe side part (480 mm) can be prepared<br />

for integration of the refrigeration unit.<br />

<strong>Chiller</strong> <strong>room</strong><br />

width<br />

Doorframe<br />

width “T”<br />

Dimension “X”<br />

1200 1140 540<br />

1500<br />

540<br />

1800<br />

2100<br />

1380<br />

540<br />

540, 1140<br />

2400 540, 1140, 1440<br />

Please indicate dimension “X” when ordering.<br />

(dimension in mm)<br />

9.3 Installed externally on door frame<br />

- Control panel with thermometer and light switch<br />

9.4 Installed internally on door frame<br />

- Oval lamp for humid <strong>room</strong>s (60 W, IP 44) with<br />

bulb and socket (IP 66).<br />

All cables are installed in the door and wired.<br />

9.5 Opening field of traverse of chiller <strong>room</strong> door<br />

<strong>Chiller</strong> <strong>room</strong> cold<strong>room</strong> door<br />

Door dimensions<br />

Rotation of door<br />

LW + 145 mm<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044257-05 <strong>GB</strong> 9 - 9.5 Right reserved to make technical changes!<br />

90°

10. Ceiling panels<br />

The ceiling panels are not designed for additional<br />

force (e. g. weight of snow or wind pressure). The<br />

ceiling structure must be provided with extra supports<br />

during assembly prior to inspection of the ceiling,<br />

installation of a ceiling refrigeration unit or installation<br />

of meat hooks, pipes, etc.<br />

The maximum width of ceiling panels without any<br />

extra support is 3 m. (special version).<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044262-05 <strong>GB</strong> 10 Right reserved to make technical changes!<br />

<strong>GB</strong>

<strong>GB</strong><br />

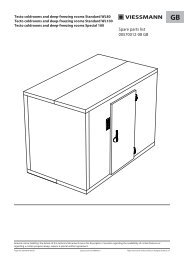

11. Dimensions of chiller <strong>room</strong>s<br />

- Height 1950 mm<br />

- The door stop can be changed on-site from DIN right<br />

turning to DIN left turning<br />

11.1 Standard chiller <strong>room</strong>s<br />

- with 900 mm depth<br />

(picture with <strong>Viessmann</strong> refrigeration unit and<br />

<strong>Viessmann</strong> shelving)<br />

Dimension “f”- see refrigeration units brochures.<br />

1) - continuous gap between chiller <strong>room</strong> wall and<br />

shelves<br />

2) - Clamps between the shelves<br />

1200 x 900 mm<br />

11.2 Industrial chiller <strong>room</strong>s<br />

1200 x 1200 mm to 2400 x 2400 mm<br />

(Picture with <strong>Viessmann</strong> refrigeration unit on the left<br />

side of the door)<br />

Dimensions in mm.<br />

4 Shelving elements<br />

410 x 1040 mm<br />

Refrigeration<br />

unit<br />

15 mm 1)<br />

2 Shelving elements<br />

330 x 293 mm<br />

540 mm 600 mm<br />

Width 1200 mm<br />

60 mm<br />

Dimension “f” - see refrigeration units brochures.<br />

Dimension “X” - see chapter 9 (Doors).<br />

Dimension “X” please specify when ordering.<br />

Refrigeration<br />

unit<br />

1500 x 900 mm<br />

1800 x 900 mm<br />

2 Shelving elements<br />

330 x 293 mm<br />

1200 x 1200 mm to 2400 x 2400 mm<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044258-05 <strong>GB</strong> 11 - 11.2 Right reserved to make technical changes!<br />

Depth 900 mm<br />

f<br />

4 Shelving elements<br />

410 x 1070 mm<br />

540 mm<br />

600 mm<br />

Width 1500 mm<br />

4 Shelving elements<br />

410 x 1070 mm<br />

Refrigeration<br />

unit<br />

15 mm 2)<br />

2 Shelving elements<br />

330 x 293 mm<br />

540 mm 600 mm<br />

Depth 2400<br />

Width 1800 mm<br />

Refrigeration<br />

unit<br />

4 Shelving elements<br />

250 x 740 mm<br />

15 mm 1)<br />

60 mm<br />

15 mm 2) 15 mm 1)<br />

Width 2400<br />

60 mm

12. Scope of delivery / delivery term 13. Accessories see refrigeration brochures<br />

- Delivery with or without <strong>Viessmann</strong> wall hanging<br />

refrigeration units 13.1 Refrigeration Unit<br />

- Delivery with or without <strong>Viessmann</strong> shelving systems<br />

- Delivery from stock<br />

- other sizes upon request 13.2 Shelving systems<br />

Note<br />

13.3 Meat and sausage hanging rails for wall assembly<br />

The right refrigeration unit configuration for the relevant<br />

chiller <strong>room</strong> size must be determined by calculating the<br />

refrigeration requirement. The following tables only serve 13.4 Meat and sausage hanging rails for ceiling assembly<br />

to provide reference values.<br />

12.1 Standard chiller <strong>room</strong> - recommended refrigerating<br />

capacity, useful area, cubic capacity<br />

width x depth<br />

(mm)<br />

1200 x 900<br />

1500 x 900<br />

1800 x 900<br />

useful area (m 2 )<br />

0,842<br />

-<br />

-<br />

12.2 Industrial chiller <strong>room</strong> - recommended refrigerating<br />

capacity, useful area, cubic capacity<br />

cubic capacity (m 3 )<br />

1,5<br />

-<br />

-<br />

13.5 Hanging basket<br />

refrigeration unit<br />

recommended refrigerating capacity 255 W recommended refrigerating capacity ca. 500 W<br />

useful area (m 2 )<br />

0,842<br />

1,076<br />

1,310<br />

cubic capacity (m 3 )<br />

1,5<br />

2,0<br />

2,4<br />

width x depth recommended refrigeration<br />

refrigeration unit<br />

recommended refrigeration recommended refrigeration<br />

(mm)<br />

capacity approx. 500 W<br />

capacity approx. 925 W<br />

capacity approx. 1300 W<br />

useful area (m2 ) cubic capacity (m3 ) useful area (m2 ) cubic capacity (m3 ) useful area (m2 ) cubic capacity (m3 )<br />

1200 x 1200 1,166 2,1 - - - -<br />

1200 x 1500 1,490 2,7 - - - -<br />

1200 x 1800 1,814 3,3 1,814 3,3 - -<br />

1200 x 2100 2,138 3,9 2,138 3,9 - -<br />

1200 x 2400 - - 2,462 4,5 - -<br />

1500 x 1200 1,490 2,7 - - - -<br />

1500 x 1500 1,904 3,4 1,904 3,4 - -<br />

1500 x 1800 2,318 4,2 2,318 4,2 - -<br />

1500 x 2100 - - 2,732 5,0 - -<br />

1500 x 2400 - - 3,146 5,7 - -<br />

1800 x 1200 1,814 3,3 1,814 3,3 - -<br />

1800 x 1500 2,318 4,2 2,318 4,2 - -<br />

1800 x 1800 - - 2,822 5,1 - -<br />

1800 x 2100 - - 3,326 6,0 - -<br />

1800 x 2400 - - 3,830 7,0 3,830 7,0<br />

2100 x 1200 2,138 3,9 2,138 3,9 - -<br />

2100 x1500 - - 2,732 5,0 - -<br />

2100 x 1800 - - 3,326 6,0 - -<br />

2100 x 2100 - - 3,920 7,1 3,920 7,1<br />

2100 x 2400 - - 4,514 8,2 4,514 8,2<br />

2400 x 1200 - - 2,462 4,5 - -<br />

2400 x 1500 - - 3,146 5,7 - -<br />

2400 x 1800 - - 3,830 7,0 3,830 7,0<br />

2400 x 2100 - - 4,514 8,2 4,514 8,2<br />

2400 x 2400 - - - - 5,198 9,5<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044259-05 <strong>GB</strong> 12 - 13.5 Right reserved to make technical changes!<br />

<strong>GB</strong>

<strong>GB</strong> 14. Tendering text - chiller <strong>room</strong><br />

14.1 Features<br />

- Heat insulation through rigid cyclopentane foamed<br />

polyurethane, non-CFC (closed cell).<br />

- Foam density 40 kg/m 3<br />

- Heat conductivity 025 to DIN 4108<br />

- Building materials to DIN 4102, classification to B3<br />

Wall thickness (mm)<br />

Recommended temperature difference<br />

to VDI 2055 T= (Kelvin)<br />

k-value to DIN 52612 (W/m 2 *K)<br />

- Frost heave preventer sandwich construction of<br />

chiller <strong>room</strong> panels, stable, self-supporting and<br />

dimensionally precise.<br />

- Maximum self-supporting width of the ceiling panels<br />

3000 mm (special version).<br />

- No wood used in wall and ceiling panels and doors<br />

14.2 Connection of the sandwich panels<br />

Connection of sandwich panels of the chiller <strong>room</strong><br />

(flooring, walls, ceilings) takes place using a selfcentering<br />

groove and tongue system. Eccentric cam<br />

locks are foamed into the panels with plastic housing<br />

and corrosion-resistant clamping hooks.<br />

14.3 <strong>Chiller</strong> <strong>room</strong> panels (wall and ceiling panels,<br />

floor exterior)<br />

- Surfaces<br />

STA: <strong>Viessmann</strong> Standard white powder coating,<br />

galvanized steel coating with antimicrobial<br />

<strong>Viessmann</strong> SilverProtec® powder coating (similar<br />

to RAL 9016). None transfer and spreading of<br />

potentially dangerous bacteria by targeted release<br />

of natural silver ions. The silver ions leads to<br />

bacteria and fungi dying on contact with the<br />

upper surface.<br />

- Notes on use:<br />

STA: Cold<strong>room</strong>s with antimicrobial <strong>Viessmann</strong><br />

standard white powder coating SilverProtec®<br />

are not suitable for use under wet conditions, or for<br />

damp or aggressive refrigerated materials<br />

(e. g. smoked fish operations, bakeries, open meat<br />

stocking etc).<br />

- The wall panel have groove and tongue system,<br />

using a PE gasket seal between panels.<br />

60<br />

30 K<br />

0,34<br />

14.4 Floor panels - upper surface<br />

Stainless steel flooring (Material No 1.4301<br />

austenitic stainless steel)<br />

- The floor panels are joined seamlessly, evenly and<br />

firmly underlapping and are riveted during assembly.<br />

- Stainless steel surface with multi-directional<br />

non slip (R 11) special embossing.<br />

(excluding complete floor panels.)<br />

- Permissible loads on the chiller <strong>room</strong> floor:<br />

Wheel load in N Wheel load in N Area load<br />

> 1 cm 2 , hard >4 cm 2 in N/m 2<br />

bakery wheel rubber wheel<br />

250 1000 30.000<br />

14.5 <strong>Chiller</strong> <strong>room</strong> doors<br />

- One piece cold<strong>room</strong> door, opening to the outside,<br />

with magnetic sealing gasket as well as vertical,<br />

adjustable door hinges.<br />

- Cylinder lock and emergency release to open the<br />

closed door frame the inside.<br />

- The door stop can be changed on-site from DIN<br />

turning to DIN turning.<br />

- Door panel polyurethane foamed with cyclopentane,<br />

non CFC.<br />

- Threshold covering plate of stainless steel.<br />

- Installed on outside of door frame: control panel with<br />

thermometer and light switch.<br />

- Installed on the inside of the door: oval lamp for humid<br />

<strong>room</strong>s (60 W) with bulb and socket (IP 66). It may be<br />

necessary to provide sufficient lighting on site in<br />

accordance with local workshop regulations.<br />

- All cables are installed in the door and wired.<br />

- Inside of door leaf prepared for assembly of 4 hanging<br />

baskets.<br />

14.6 Accessories see refrigeration brochures<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044260-08 <strong>GB</strong> 14 - 14.6 Right reserved to make technical changes!

15. Tendering text - specifications<br />

chiller <strong>room</strong><br />

Item Qty Description Unit Price Total Price<br />

<strong>Chiller</strong> <strong>room</strong> - outside dimensions<br />

Width (door side) mm<br />

Depth mm<br />

Height 1950 mm<br />

Dimension “X” mm<br />

Net cubic capacity of <strong>room</strong> m 3<br />

Cooling capacity Watt<br />

Surfaces Exterior Interior<br />

STA: <strong>Viessmann</strong> Standard white powder coating,<br />

galvanized steel coating with antimicrobial<br />

<strong>Viessmann</strong> SilverProtec® powder coating (similar<br />

to RAL 9016).<br />

Accessories (see refrigeration brochures) Additional Price:<br />

Refrigeration unit with without<br />

Type____________ Order No. _________<br />

Shelving systems with without<br />

Order No. _________<br />

Meat and sausage hanging rails<br />

- for wall assembly Order No. 7117980<br />

in 900 mm depth chiller <strong>room</strong><br />

with width 1500 mm and 1800 mm<br />

for ceiling assembly Order No. 7012488<br />

in chiller <strong>room</strong>s<br />

Set hanging basket Order No. 7155045<br />

4 baskets on door leaf<br />

<strong>Chiller</strong> <strong>room</strong> ....................................................: EUR<br />

(excluding other refrigeration equipment, excluding emergency call unit,<br />

excluding interior equipment, excluding assembly).<br />

Assembly .........................................................: EUR<br />

Delivery and assembly<br />

Delivery and assembly in accordance with our “Special conditions for the delivery<br />

and assembly of cold<strong>room</strong>s”.<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044261-07 <strong>GB</strong> 15 Right reserved to make technical changes!<br />

<strong>GB</strong>

<strong>GB</strong><br />

<strong>Viessmann</strong> <strong>Kältetechnik</strong> <strong>AG</strong><br />

Schleizer Straße 100<br />

95030 Hof/Saale<br />

Germany<br />

Phone +49 (0) 92 81/ 81 4 - 0<br />

Fax +49 (0) 92 81/ 81 4 - 2 69<br />

info@vkag.com<br />

www.vkag.com<br />

Your responsible refrigeration service:<br />

General notice (liability): the details of this data sheet serve for description. Consents regarding the availability of certain features or regarding a<br />

certain purpose always require a special written agreement.<br />

Page No. 00044224-08 <strong>GB</strong>