RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DATA SHEET<br />

Features<br />

• Outstanding resistance to cyclic<br />

oxidation through 2250°F (1232°C)<br />

• Excellent high temperature creeprupture<br />

strength<br />

• Resistant to carburizing environments<br />

• Highly resistant to grain growth in<br />

service<br />

• Superior behavior in oxidizing/<br />

chloridizing environments<br />

• Good resistance to metal dusting<br />

Applications<br />

• Calciners shells<br />

• Muffles and retorts<br />

• Chemical vapor deposition retorts<br />

• Nitric acid catalyst support grids<br />

• Radiant tubes<br />

• Vacuum furnace fixtures<br />

• Molten glass process equipment<br />

• Vitrification of nuclear wastes<br />

• Reheaters & convection tubes in direct<br />

reduction iron ore (DRI) plants<br />

Chemical Composition Range, %<br />

Min Max<br />

Chromium 24.0 26.0<br />

Nickel balance<br />

Carbon 0.15 0.25<br />

Aluminum 1.8 2.4<br />

Titanium 0.1 0.2<br />

Yttrium 0.05 0.12<br />

Zirconium 0.01 0.10<br />

Manganese -- 0.15<br />

Silicon -- 0.5<br />

Copper -- 0.1<br />

Iron 8.0 11.0<br />

Specifications<br />

UNS N0<strong>602</strong>5 W.Nr. 2.4633<br />

ASTM B 168/ASME SB168<br />

Plate, Sheet, Strip<br />

ASTM B 166/ASME SB166<br />

Rod, Bar, Wire<br />

Weld Wire: ERNiCrFe-12<br />

Covered electrodes: ENiCrFe-12<br />

ASME Code Case 2359 to 1800°F (1032°C)<br />

Stress, psi<br />

1<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> ®<br />

ALLOY<br />

Performance Profile<br />

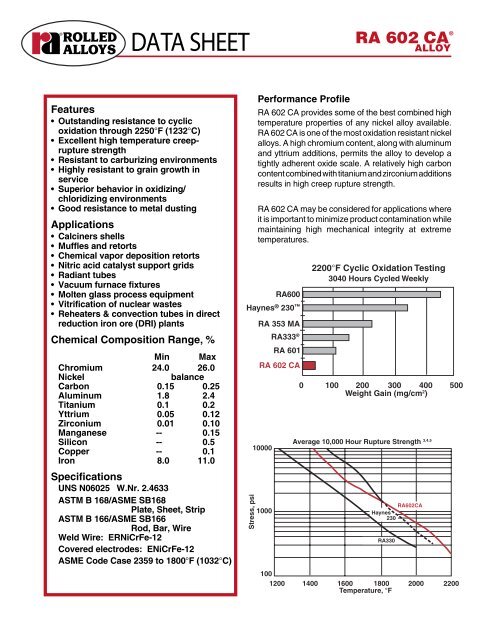

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> provides some of the best combined high<br />

temperature properties of any nickel alloy available.<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> is one of the most oxidation resistant nickel<br />

alloys. A high chromium content, along with aluminum<br />

and yttrium additions, permits the alloy to develop a<br />

tightly adherent oxide scale. A relatively high carbon<br />

content combined with titanium and zirconium additions<br />

results in high creep rupture strength.<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be considered for applications where<br />

it is important to minimize product contamination while<br />

maintaining high mechanical integrity at extreme<br />

temperatures.<br />

10000<br />

1000<br />

<strong>RA</strong>600<br />

Haynes ® 230 <br />

<strong>RA</strong> 353 MA<br />

<strong>RA</strong>333 ®<br />

<strong>RA</strong> 601<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

2200°F Cyclic Oxidation Testing<br />

3040 Hours Cycled Weekly<br />

0 100 200 300 400 500<br />

Weight Gain (mg/cm 2 )<br />

Average 10,000 Hour Rupture Strength 3,4,5<br />

Haynes<br />

230<br />

<strong>RA</strong>330<br />

<strong>RA</strong><strong>602</strong><strong>CA</strong><br />

100<br />

1200 1400 1600 1800 2000 2200<br />

Temperature, °F

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

2100°F (1149°C) Cyclic Oxidation Testing 1,2<br />

3000 Hours Cycled Weekly<br />

<strong>RA</strong>330 ®<br />

<strong>RA</strong> 353 MA ®<br />

<strong>RA</strong>333 ®<br />

Alloy 617<br />

Haynes ® 230 <br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Oxidation Resistance<br />

0 10 20 30 40 50 60<br />

Weight Gain (mg/cm 2 )<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> is one of the most oxidation resistant nickel<br />

alloys available. Outstanding oxidation resistance is<br />

achieved through a high chromium content (25%)<br />

supplemented with aluminum (2.2%) and a<br />

microalloying addition (0.1%) yttrium. High chromium<br />

contents are known to be beneficial for resisting<br />

oxidation. The aluminum addition allows for the<br />

formation of a continuous homogenous self repairing<br />

AI 2 O 3 subscale. The addition of yttrium improves the<br />

adhesion and spalling resistance of the chromium and<br />

aluminum oxide scales. The extremely low scaling rate<br />

of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> makes it an excellent candidate for<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> after 3150 hours exposure to<br />

2100°F (1149°C) Magnification: 200x<br />

<strong>RA</strong> 601<br />

H<br />

Haynes ® 214<br />

2<br />

Alloy 617<br />

<strong>RA</strong> 353 MA<br />

<strong>RA</strong>333 ®<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

2250°F Cyclic Oxidation Testing<br />

3000 Hours Cycled Weekly<br />

0 100 200 300 400 500<br />

Weight Gain (mg/cm 2 )<br />

applications such as calciners, where minimal<br />

contamination from scaling is permissible.<br />

The figures below compare the appearance of<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> versus <strong>RA</strong>601 after more than 3000 hours<br />

at 2100°F (1149°C). <strong>RA</strong>601, as seen, has extensive<br />

internal oxidation attack6 . In contrast, only a thin surface<br />

oxide scale formed on <strong>RA</strong> <strong>602</strong> <strong>CA</strong>2 . This is especially<br />

important in applications that use thin sheet such as<br />

radiant tubes. No internal oxidation means the entire<br />

wall thickness is sound metal and the alloy retains a<br />

greater amount of its original properties.<br />

<strong>RA</strong>601 after 3150 hours exposure to<br />

2100°F (1149°C) Magnification: 200x

Grain Growth<br />

The brittle fracture of components exposed to<br />

extreme temperatures is a common occurrence.<br />

At temperatures near or exceeding the annealing<br />

temperature of a heat resistant alloy, grain growth is<br />

likely to occur. Extensive grain growth can result in a<br />

loss of ductility. As a result, the component can be<br />

prone to brittle fracture. An alloy 601 corrugated muffle<br />

that suffered brittle fracture due to combination of<br />

extensive grain growth and carburization is shown<br />

above.<br />

The results of testing at 2050°F (1121°C) are detailed<br />

in the table below. The information provides a<br />

comparison of various heat resisting alloys that are<br />

commonly used above 1900°F (1038°C). The data was<br />

compiled from intermittent exposure of sample<br />

coupons to 2050°F (1121°C) for a total of 990 hours.<br />

Each sample was in the mill annealed condition. The<br />

figure at right shows a sample of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> after long<br />

term exposure to 2100°F (1149°C).<br />

3<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Brittle fracture of an alloy 601 muffle from the combination of extensive grain growth and carburization.<br />

Sample of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> examined after exposure to<br />

2100°F (1149°C) for over 3150 hours. The grain size<br />

was originally ASTM 7. After the 3000 hour test<br />

period the grains had only grown to ASTM 5.5.<br />

Magnification: 90x<br />

Effects of High Temperature Exposure on ASTM Grain Size8 - 2050°F (1121°C)<br />

Time ASTM Average Grain Size<br />

Hours <strong>RA</strong> <strong>602</strong> <strong>CA</strong> <strong>RA</strong>601 601GC <strong>RA</strong>330 <strong>RA</strong> 353 MA <strong>RA</strong>333 <strong>RA</strong>600<br />

0 7 5 5.5 7 6 4 8<br />

2 7 5 5.5 3.5 4 4 4<br />

24 7 1.5 5 3.5 3 3.5 1<br />

72 7 1 5 3 2.5 3 0<br />

184 6.5 1 3.5 3 2.5 2.5 0<br />

344 6.5 0 3.5 2.5 2 2 0<br />

510 6.5 0 3 2 2 2 00<br />

670 6.5 00 3 2 1.5 2 00<br />

830 6.5 00 3 2 1.5 2 00<br />

990 6.5 00 2.5 1.5 1.5 1 00

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Carburization 8<br />

Extended exposure to methane (CH 4 ), carbon<br />

monoxide (CO), and other carbon rich gases can lead<br />

to carburization. As heat resistant alloys absorb carbon,<br />

their ductility will gradually decrease. <strong>Alloys</strong> that are<br />

high in nickel, such as <strong>RA</strong> <strong>602</strong> <strong>CA</strong> possess excellent<br />

Metal Wastage Rate (mg/cm 2 h)<br />

1.00E-01<br />

1.00E-02<br />

1.00E-03<br />

1.00E-04<br />

1.00E-05<br />

1.00E-06<br />

<strong>RA</strong>600<br />

0 2000 4000 6000 8000 10000<br />

Exposure Time (Hours)<br />

4<br />

resistance to carburization attack. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> forms a<br />

tenacious oxide scale, which provides increased<br />

protection from carburization. This protective scale<br />

impedes the carbon fro being absorbed into the base<br />

metal.<br />

Cyclic Carburization in CH /H Environment (A =0.8), Weight Change (mg/m 4 2 c 2h) 850°C (1562°F) 1000°C (1832°F) 1150°C (2102°F)<br />

<strong>RA</strong>310 130 305 —<br />

<strong>RA</strong>800AT 143 339 813<br />

<strong>RA</strong>600 50 190 626<br />

<strong>RA</strong>601 64 170 508<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> 13 70 175<br />

Metal dusting is a form of carburization that can lead<br />

to the rapid corrosion of heat resistant alloys. The<br />

photo at left shows a section of an <strong>RA</strong>330 fan shroud<br />

taken from a carburizing furnace displaying the pitting<br />

typical of metal dusting attack.<br />

The combination of high aluminum and chromium<br />

additions to <strong>RA</strong> <strong>602</strong> <strong>CA</strong> results in a resistance to metal<br />

dusting superior to alloys such as <strong>RA</strong>330, <strong>RA</strong>600,<br />

<strong>RA</strong>601, and 800HT ® alloy.<br />

<strong>RA</strong>601<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Coupon testing<br />

of alloys in<br />

simulated metal<br />

dusting<br />

atmosphere<br />

consisting of<br />

H 2 +CO+H 2 O at<br />

650°C (1202°F).

Hot Corrosion 9<br />

Weight change values for<br />

nickel alloys exposed for 100<br />

hours at 800°C (1472 °F)<br />

Weight Gain (mg/cm2)<br />

Physical Properties Melting Range: 2350-2550°F (1288-1400°C)<br />

Permeability at 20°C/68°F (RT):

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Mechanical Properties<br />

Typical Tensile Properties, Solution Treated 2228°F (1220°C)<br />

Temperature, °F Tensile Strength, psi 0.2% Yield Strength, psi Elongation, % Reduction of Area, %<br />

68 105,000 50,500 38 39<br />

800 95,400 39,200 42 33<br />

900 94,600 38,600 43 35<br />

1000 93,400 38,300 40 36<br />

1200 84,000 37,700 48 45<br />

1400 54,400 36,500 55 52<br />

1500 41,200 34,800 78 72<br />

1600 32,800 28,700 82 72<br />

1700 24,900 21,000 82 74<br />

1800 17,100 15,200 78 75<br />

1900 13,600 12,200 80 72<br />

2000 13,000 11,600 85 74<br />

2100 10,200 9,000 86 78<br />

2200 5,800 5,000 96 76<br />

Note: Above 1155°F (624°C), time dependent properties, ie., creep-rupture are the basis for design.<br />

Typical Tensile Properties (Metric)<br />

Temperature, °C Tensile Strength, MPa 0.2% Yield Strength, MPa Elongation, % Reduction of Area, %<br />

20 721 348 38 39<br />

400 664 272 42 32<br />

600 632 262 36 37<br />

800 311 251 76 74<br />

900 198 180 82 72<br />

1100 789 78 86 75<br />

1200 42 39 92 76<br />

ASME Allowable Stresses (Code Case 2359-1)<br />

For Metal Maximum For Metal Maximum<br />

Temperature Not Allowable Temperature Not Allowable<br />

Exceeding, °F Stress Values Exceeding, °F Stress Values<br />

ksi {Notes (1) ksi {Notes (1)<br />

and (2)} and (2)}<br />

100 26.0 1100 9.2<br />

200 25.5 1150 6.9<br />

300 24.7 1200 4.1<br />

400 23.7 1250 2.8<br />

500 22.7 1300 2.0<br />

600 21.7 1350 1.5<br />

650 21.2 1400 1.2<br />

700 20.8 1450 0.97<br />

750 20.5 1500 0.80<br />

800 20.2 1550 0.68<br />

850 20.0 1600 0.58<br />

900 19.8 1650 0.51<br />

950 19.6 1700 0.44 (Note 3)<br />

1000 16.3 1750 0.37 (Note 3)<br />

1050 12.3 1800 0.32 (Note 3)<br />

General Note: Time Dependent Values are shown in italics<br />

6<br />

Please consult Code Case 2359-1 for all<br />

requirements for designing with <strong>RA</strong> <strong>602</strong><br />

<strong>CA</strong> to Section 1 and Section VIII, Division<br />

1 requirements.<br />

Notes:<br />

(1) This alloy in the solution-annealed<br />

condition is subject to severe loss of<br />

rupture ductility in the temperature range<br />

of 1200-1400°F.<br />

(2) The allowable stress values are based<br />

on the revised criterion for tensile strength<br />

of 3.5, where applicable.<br />

(3) For Section VIII, Division 1 use only.<br />

(4) The criteria used to establish allowable<br />

stresses at design temperatures above<br />

1500°F included consideration of the Favg factor as defined in Appendix 1 of Section<br />

II, Part D.<br />

(5) Creep-fatigue, thermal ratcheting, and<br />

environmental effects are increasingly<br />

significant failure modes at temperatures<br />

in excess of 1500°F and shall be<br />

considered in the design.

Creep-Rupture Properties 3<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> possesses excellent creep rupture<br />

properties. The relatively high carbon level in the alloy<br />

ensures the precipitation of bulky homogeneously<br />

distributed carbides. Alloying with titanium and<br />

zirconium ensures that these carbides and also<br />

carbonitrides are finely distributed. Even solution<br />

annealing at 1200°C (2192°F) does not completely<br />

7<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

dissolve these carbides. As a result, the alloy achieves<br />

its high creep strength through a combination of solid<br />

solution hardening and carbide strengthening.<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> has a strength advantage over <strong>RA</strong>601 at<br />

all temperatures. At temperatures in the 1800-1900°F<br />

(982-1038°C) range and above, <strong>RA</strong> <strong>602</strong> <strong>CA</strong> has<br />

equivalent or greater creep rupture properties than<br />

Haynes 230 alloy.<br />

Creep-Rupture Properties, grain size 70 µm or coarser ( ≅ ASTM 4.5 or coarser)<br />

Temperature Average Stress to Rupture, psi Average Stress for 1% Total Creep, psi<br />

°F 1,000 Hrs 10,000 Hrs 100,000 Hrs 1000 Hrs 10,000 Hrs 100,000 Hrs<br />

1200 37,700 31,200 20,300 31,900 26,800 20,900<br />

1400 17,400 11,300 5800 13,900 9400 5400<br />

1600 4600 3200 1750 3500 2380 1300<br />

1700 3600 2180 1100 2230 1520 910<br />

1800 2300 1490 740 1300 960 580<br />

1900 1700 990 485 810 590 320<br />

2000 1250 670 (310) 540 330 (160)<br />

2100 670 440 (200) 260 140 (60)<br />

Temperature Average Stress to Rupture, MPa Average Stress for 1% Total Creep, MPa<br />

°C 1,000 Hrs 10,000 Hrs 100,000 Hrs 1,000 Hrs 10,000 Hrs 100,000 Hrs<br />

650 260 215 140 220 185 120<br />

700 155 100 132 85<br />

750 90 48 75 46<br />

800 42 20 32 16.5<br />

850 26 14 19 9.7<br />

900 18 9.7 2.2 13 7.5<br />

950 13 6.7 8.8 5.4<br />

1000 14.1 9.0 4.5 7.5 5.8 3.4<br />

1050 6.2 3.1 3.6 1.9<br />

1100 7.2 4.4 (2.1) 3.2 1.9 0.85<br />

1150 3.0 (1.4) 1.0 0.40<br />

1200 3.0 1.9 (0.42) 0.97

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Fatigue Properties10 Fatigue strength of<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> at elevated<br />

temperatures.<br />

Impact Properties 9<br />

Loading ± σ m ,N/mm2<br />

100<br />

80<br />

60<br />

40<br />

20<br />

1100°C<br />

1000°C<br />

Effects of Long Term Exposure at Elevated Temperatures on Ductility 3<br />

0<br />

1.E+02 1.E+03 1.E+04 1.E+05 1.E+06 1.E+07<br />

Number of Cycles<br />

Condition Aging Temperature Time at Aging Impact Strength<br />

°C (°F) Temperature Joules (ft-lb)<br />

Annealed N/A 0 78-84 (58-62)<br />

Annealed 500°C (932°F) 8000 30 (22.1)<br />

Annealed 640°C (1184°F) 8000 30 (22.1)<br />

Annealed 740°C (1364°F) 8000 27 (20)<br />

Annealed 840°C (1544°F) 8000 58 (42.8)<br />

10% Cold Worked 500°C (932°F) 8000 22 (16.2)<br />

10% Cold Worked 640°C (1184°F) 8000 27 (20)<br />

10% Cold Worked 740°C (1364°F) 8000 25 (18.4)<br />

10% Cold Worked 840°C (1544°F) 8000 68 (50.2)<br />

10% C.W. + Aged + Annealed 500°C (932°F) 8000 78 (58)<br />

10% C.W. + Aged + Annealed 640°C (1184°F) 8000 85 (62.7)<br />

10% C.W. + Aged + Annealed 740°C (1364°F) 8000 76 (56.1)<br />

10% C.W. + Aged + Annealed 840°C (1544°F) 8000 80 (59)<br />

8<br />

1150°C

Forming<br />

Hot Working<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be hot-worked in the temperature<br />

range 1200 to 900°C (2190 to 1650°F), followed by<br />

water quenching or rapid air cool. As with other<br />

austenitic alloys, do not attempt to form in the 600-<br />

800°C (1100-1500°F) temperature range.<br />

Heating must be performed in a furnace with accurate<br />

temperature control, and a neutral to slightly oxidizing<br />

atmosphere. The atmosphere should not fluctuate<br />

between oxidizing and reducing. Natural gas used to<br />

fire the furnace should contain no more than 0.1<br />

weight % sulfur, and fuel oil no more than 0.5% sulfur.<br />

Spin formed radiant tube return bend. 6 inch<br />

diameter on 6 inch centers formed out of 11ga<br />

(0.120”) <strong>RA</strong> <strong>602</strong> <strong>CA</strong> sheet.<br />

Heat Treatment<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> is solution annealed at 2160-2230°F<br />

(1180-1220°C) followed by water quenching. For<br />

sheet 16 gage (1.5mm) and lighter, rapid air cooling<br />

is acceptable.<br />

9<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

The flame must not impinge directly on the workpiece.<br />

Do not heat <strong>RA</strong> <strong>602</strong> <strong>CA</strong>, or any other nickel alloy,<br />

with a torch to bend it. The lack of temperature control<br />

will often result in cracking.<br />

Cold Forming<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> has a high carbon content, and work<br />

hardens rapidly. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be bent 120° around<br />

a diameter equal to three times the material thickness<br />

(3T bend) for material up to 0.4” (10 mm) thick. This<br />

grade cannot be bent to as tight a radius as the lower<br />

carbon alloys, e.g, <strong>RA</strong>600 or <strong>RA</strong>330.<br />

As with other nickel alloys, the shear drag (burr)<br />

should be removed, or placed on the inside of the<br />

bend. During bending this heavily cold-worked burr<br />

may initiate cracking. Sawed plate may be preferred<br />

for severe forming operations.<br />

3/8” thick retort head press formed from 3/8” thick<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> plate. 3-1/2 inch deep and 17 inches in<br />

diameter.

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Welding<br />

GTAW - Gas Tungsten Arc Welding<br />

10,000 Hour Creep Rupture<br />

Strength, N/mm2<br />

30<br />

25<br />

20<br />

15<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> Base Metal<br />

10<br />

-18%<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> GTAW<br />

5<br />

W/Matching Filler<br />

-16%<br />

0<br />

800 900 1000<br />

-16%<br />

1100<br />

-18%<br />

1200<br />

Temperature, °C<br />

10.000 hour stress to rupture values of <strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

GTAW weld as compared to <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal. 10<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be joined by Gas Tungsten Arc<br />

Welding and by Plasma Arc Welding. In both cases<br />

the back side of the weld root must be shielded with<br />

100% welding grade argon (not nitrogen). Good root<br />

shielding is required because of the high aluminum<br />

content of this alloy. The torch gas must be 97.5%<br />

argon, 2.5% nitrogen, for both processes. The<br />

2.5% N 2 addition to the argon is necessary for<br />

improved weldability and reduced hot cracking<br />

susceptiblity in <strong>RA</strong> <strong>602</strong> <strong>CA</strong>.<br />

Manual GTAW Parameters<br />

Shielding gas: 98% Argon - 2% Nitrogen<br />

Plate Filler Metal Root Pass Filler Pass Travel Arc Energy Shielding<br />

Thickness Diameter Speed Gas Flow<br />

inches inches Amps Volts Amps Volts in/min KJ/in, max cfh<br />

11 ga 0.063 90-100 11 -- -- 4-6 20 17-21<br />

1/4 0.063-0.094 110 11 130-150 15 4-6 20 17-21<br />

1/2 0.094 110 11 130-150 15 4-6 20 17-21<br />

Automatic GTAW Parameters<br />

Shielding gas: 98% Argon - 2% Nitrogen<br />

Plate Filler Metal Root Pass Filler Pass Travel Arc Energy Shielding<br />

Thickness Diameter Speed Gas Flow<br />

inches inches Amps Volts Amps Volts in/min KJ/in, max cfh<br />

11 ga 0.035-0.045 manual 150-250 10-15 8-12 20 30-40<br />

5/16 0.035-0.045 manual 150-250 10-15 8-12 20 30-40<br />

10<br />

Stress, psi<br />

45,000<br />

40,000<br />

35,000<br />

UTS Base Metal<br />

YS Base Metal<br />

UTS Weld<br />

30,000<br />

25,000<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

0<br />

YS Weld<br />

1500 1600 1700 1800 1900 2000 2100 2200<br />

Temperature, °F<br />

Comparison of mechanical properties of <strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

base metal vs. GTAW welds made with matching<br />

filler.<br />

Interpass temperature should not exceed 250°F<br />

(120°C) with lower temperatures preferred. Heat the<br />

metal before welding only if necessary to dry the<br />

workpiece, and then just hot to the touch. Neither<br />

preheat nor postheat is required.<br />

The matching weld filler wire is S <strong>602</strong>5, W.Nr. 2.4649,<br />

AWS ERNiCrFe-12.

GMAW - Gas Metal Arc Welding<br />

11<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

GMAW welding of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> should be performed using the matching composition weld wire designated as<br />

S <strong>602</strong>5. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> should be joined using the pulse arc process. For welding material thicknesses less than<br />

3/16” thick use of 100% Argon shielding has been satisfactory. For welding thicknesses above 3/16”, it is recommended<br />

to utilize the welding gas AR Ni5He5CD300. (Available from Airgas 419-666-7155) to reduce the<br />

likelihood of centerline cracking.<br />

GMAW – Pulse Arc Transfer<br />

Wire Diameter Wire Feed Amperes Volts Gas Flow Travel Speed Pulse<br />

0.045 inch 236 in/min 170 A 26 V 38 ft 3 /hr 15 in/min 500 pulse/sec<br />

For applications under 1832°F (1000°C), <strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be welded with alloy 617 wire, ERNiCrCoMo-1, using<br />

argon or argon-helium shielding gas. A GTAW cover pass with S <strong>602</strong>5 filler wire is necessary to match the<br />

oxidation resistance of the <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal. S <strong>602</strong>5 weld filler should be used at higher temperatures<br />

where alloy 617 has less strength than <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal.<br />

SMAW - Shielded Metal Arc Welding<br />

Matching chemistry DC basic covered electrodes, 6225 Al (AWS ENiCrFe-12), are available for welding<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong>. Use a stringer bead technique, electrode inclined approximately 20° in the direction of travel. Keep<br />

the interpass temperature low, below 300°F (150°C). Electrodes must be dry. If necessary, rebake to dry for 2<br />

hours at 480°F (250°C).<br />

6225 Al Electrode Weld Deposit 8 - Nominal Chemical Composition, %<br />

Cr Ni C AI Ti Y Zr Mn Si Fe<br />

25 62 0.2 1.8 0.1 0.02 0.03 0.1 0.6 10<br />

SMAW Weld Metal Mechanical Properties, Room Temperature (minimum)<br />

Ultimate Tensile 0.2% Yield Strength Elongation Impact Strength<br />

Strength<br />

psi N/mm 2 psi N/mm 2 % Ft-lb J<br />

101,500 700 72,500 500 15 22 30<br />

Starting Parameters<br />

Electrode diameter, inch (mm) 3/32 (2.5) 1/8 (3.2) 3/16 (4.0)<br />

DCRP Current, Amps 40-55 70-90 90-110

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

PAW - Plasma Arc Welding<br />

As with automatic GTAW, shielding gas must be Argon with 2-3% Nitrogen<br />

Plate Filler Metal Root Pass Filler Pass Travel Arc Energy Shielding<br />

Thickness Diameter Speed Gas Flow<br />

inches inches Amps Volts Amps Volts in/min KJ/in, max cfh<br />

3/16 0.045 180 25 -- -- 10-12 28 65<br />

1/2 0.045 180 25 GMAW 10-12 28 65<br />

Dissimilar Welding<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be welded to carbon steel, 304 stainless steel, or <strong>RA</strong>600 using ERNiCr-3 (Alloy 82) bare wire or<br />

ENiCrFe-3 (Alloy 182) covered electrodes.<br />

Joints between <strong>RA</strong> <strong>602</strong> <strong>CA</strong> and <strong>RA</strong>601 may be made using the matching <strong>RA</strong> <strong>602</strong> <strong>CA</strong> weld filler, Nicrofer S <strong>602</strong>5.<br />

Weldments to other heat resistant or nickel alloys should be qualified before production. Choice of weld filler<br />

should be based on high temperature service properties, in addition to weldability considerations.<br />

Corrosion Rate, mm/a<br />

0.2<br />

0<br />

-0.2<br />

-0.4<br />

-0.6<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> GTAW SMAW<br />

Base Metal<br />

1100°C 1200°C<br />

Comparison of the oxidation of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal to GTAW and SMAW welds<br />

made with matching ERNiCrFe-12 and ENiCrFe-12 filler metal respectively.<br />

12

25” O.D. calciner processing metal oxide pigments<br />

in the 1800-2100°F range. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> selected after<br />

coupon testing of <strong>RA</strong>601, HR-120, Haynes 556, and<br />

HR-160 alloys. Reference <strong>RA</strong> Case History #2027.<br />

60 inch diameter x 30 ft. long calciner processing<br />

high purity alumina at 2050-2100°F. Unit in operation<br />

for 5 years until first repairs. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> selected<br />

over alloy 601 based on higher strength and scaling<br />

resistance.<br />

Serpentine grid formed from 3/16" <strong>RA</strong> <strong>602</strong> <strong>CA</strong> plate.<br />

Material used in vacuum heat treatment of tool<br />

steels at 2175°F-2275°F followed by 6 bar nitrogen<br />

quench. Still in service after 1200 cycles. See Case<br />

History 2063.<br />

13<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Furnace rolls in a specialty steel mill. <strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

replaced water cooled asbestos lined carbon steel.<br />

The <strong>RA</strong> <strong>602</strong> <strong>CA</strong> is not water cooled and was rolled<br />

and welded to form the rolls. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> rolls have<br />

reduced energy consumption by eliminating watercooling<br />

and have reduced marking of sheet product<br />

due to their smooth surface.<br />

30” diameter chemical vapor deposition (CVD)<br />

retort for the aluminide coating of gas turbine<br />

blades. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> replaced Haynes 230 in this<br />

application. Temperatures are 1975°F.

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Radiant tube formed out of 11 ga <strong>RA</strong> <strong>602</strong> <strong>CA</strong> sheet.<br />

Replaced type HT cast tubes. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> tubes<br />

preferred due to their lighter weight, which translates<br />

into easier installation and greater furnace efficiency.<br />

Tube still in service after 18 months no distortion<br />

reported. Reference <strong>RA</strong> Case History 2026.<br />

Test of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> vs. alloy 600 belly bands on an<br />

aluminide coating retort. 69 cycles of operation at<br />

2000°F. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> is now specified for this application<br />

over alloy 600. See Bulletin 2032 for more details.<br />

14<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> liner being formed prior to welding.<br />

Liner is replacing alloy 800HT ® in a hydrogen<br />

reformer bypass duct. Metal dusting has historically<br />

been a problem with the alloy 800HT liners.<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> coating cans fabricated from 11ga<br />

sheet. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> replaced Haynes 214 ® alloy. Due<br />

to the light gage and temperatures in the 1900-<br />

2000°F range oxidation resistance is critical in this<br />

application.

15<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong>

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

References<br />

1. J.C. Kelly & J. D. Wilson, “Oxidation Rates of Some Heat Resistant<br />

<strong>Alloys</strong>”, ASM Proceedings of the 2nd International Conference on<br />

Heat-Resistant Materials, Gatlinburg, TN, USA. September 11-14,<br />

1995.<br />

2. <strong>Rolled</strong> <strong>Alloys</strong> Laboratory Testing, Investigation File #99-55.<br />

3. Personal Correspondence with Krupp VDM 9/28/00.<br />

4. <strong>Rolled</strong> <strong>Alloys</strong>, Inc. <strong>RA</strong> Data Sheet, <strong>RA</strong>330 Alloy, Bulletin 107, 9/98.<br />

5. Haynes International, Haynes 230 Alloy Data Sheet, H-3000F, pgs<br />

5, 6.<br />

6. <strong>Rolled</strong> <strong>Alloys</strong> Laboratory Testing, Investigation File #92-99.<br />

7. <strong>Rolled</strong> <strong>Alloys</strong> Laboratory Testing, Investigation File #00-05.<br />

8. D.C. Agarwal & U. Brill, & J. Kloewer, “Recent Results on Metal<br />

Dusting of Nickel Based <strong>Alloys</strong> and Some Applications,” Corrosion<br />

2001, Paper 1382, NACE International, Houston TX 2001.<br />

9. R. Bender & M. Schultze, “Oxidation Beharior of Several<br />

Commercial <strong>Alloys</strong> in Chlorine Containing High Temperature<br />

Environments.<br />

MIDWEST REGION:<br />

125 West Sterns Road<br />

Temperance, Michigan 48182-9546<br />

800-521-0332<br />

1-734-847-0561<br />

Fax: 1-734-847-6917<br />

email:sales@rolledalloys.com<br />

CENT<strong>RA</strong>L REGION:<br />

9944 Princeton-Glendale Road<br />

Cincinnati, Ohio 45246<br />

800-521-0332<br />

email:sales@rolledalloys.com<br />

EASTERN REGION:<br />

30 Baker Hollow<br />

Windsor, Connecticut 06095<br />

800-521-0332<br />

email:sales@rolledalloys.com<br />

SOUTHERN REGION:<br />

9818 E. Hardy Road<br />

Houston, Texas 77093<br />

800-521-0332<br />

email:sales@rolledalloys.com<br />

WESTERN REGION:<br />

Harvey Titanium Ltd., Division of <strong>Rolled</strong> <strong>Alloys</strong><br />

291 Coral Circle Drive<br />

El Segundo, California 90245<br />

800-321-0909<br />

1-310-343-6000 fax 1-310-606-9322<br />

email:harveytisales@rolledalloys.com<br />

<strong>CA</strong>NADA:<br />

<strong>Rolled</strong> <strong>Alloys</strong>-Canada, Inc.<br />

151 Brunel Road - Unit 23<br />

Mississauga Ontario Canada L4Z 2H6<br />

800-521-0332<br />

1-905-501-7552 fax 1-905-501-7553<br />

email:racsales@rolledalloys.com<br />

Form<br />

# 1<strong>602</strong><br />

6/<br />

04<br />

500<br />

10. ThyssenKrupp VDM, VDM Report No. 25, High-Temperature <strong>Alloys</strong><br />

from Krupp VDM for Industrial Engineering.<br />

11. D.C. Agarwal & U. Brill “Performance of Alloy <strong>602</strong><strong>CA</strong> (UNS N0<strong>602</strong>5)<br />

in High Temperature Environments up to 1200�C”, Corrosion/2000,<br />

Paper 521, NACE International, Orlando, FL 2000.<br />

General Disclaimer<br />

The data and information in this data sheet are believed to be<br />

reliable, however, this data is not intended as a substitute for competent<br />

professional engineering assistance which is a requisite to any<br />

specific application.<br />

Trade Marks:<br />

<strong>602</strong> <strong>CA</strong> is a registered trademark of ThyssenKrupp VDM.<br />

<strong>RA</strong>330 and <strong>RA</strong>333 are registered trademarks of <strong>Rolled</strong> <strong>Alloys</strong>, Inc.<br />

Haynes 230 and Haynes 214 are registerd trademarks of Haynes<br />

International.<br />

<strong>RA</strong> 353 MA is a registered trademark of Outokumpu Stainless.<br />

800HT is a registered trademark of Special Metals.<br />

ENGLAND:<br />

Walker Industrial Park<br />

Guide, Blackburn<br />

BB1 2QE, United Kingdom<br />

+44-(0)1254 582 999 fax +44- (0)1254 582 666<br />

email:blackburn@rolledalloys.co.uk<br />

Unit 5, Priory Industrial Park<br />

Airspeed Rd., Christchurch, Dorset<br />

BH23 4HD, United Kingdom<br />

+44-(0)1425 280 000 fax +44-(0)1425 280 028<br />

email:christchurch@rolledalloys.co.uk<br />

THE NETHERLANDS:<br />

<strong>Rolled</strong> <strong>Alloys</strong><br />

Voorerf 16<br />

4824 GN Breda, The Netherlands<br />

+31-(0)76-548 44 44 fax +31-(0)76-542 98 88<br />

email:sales@rolledalloys.nl<br />

INTERNATIONAL:<br />

<strong>Rolled</strong> <strong>Alloys</strong> International, Ltd.<br />

14, The Oaks<br />

Clews Road, Redditch, Worcestershire<br />

B98 7ST, United Kingdom<br />

+44-(0)1527-401101 fax +44-(0)1527-401013<br />

email:hbuijnsters@rolledalloys.co.uk<br />

SINGAPORE:<br />

<strong>Rolled</strong> <strong>Alloys</strong> International, Ltd. Singapore<br />

10 Anson Road #24-06<br />

International Plaza, Singapore 079903<br />

+65-62272725 fax +65-62272735<br />

email:railtd@pacific.net.sg<br />

CHINA:<br />

<strong>Rolled</strong> <strong>Alloys</strong>, Ltd.<br />

Room 12B03, 12B Floor<br />

Suncome Liauw's Plaza<br />

738 Shangcheng Road, Pudong New Area<br />

Shanghai, China 200120<br />

+86-(0)21-5835-5329 fax +86-(0)21-5835-5339<br />

E-mail: sales@rolledalloys.com<br />

http://www.<strong>Rolled</strong><strong>Alloys</strong>.com<br />

© 2016<br />

04<br />

<strong>Rolled</strong><br />

<strong>Alloys</strong>,<br />

Inc.<br />

Litho<br />

in<br />

U.<br />

S.<br />

A.