RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Welding<br />

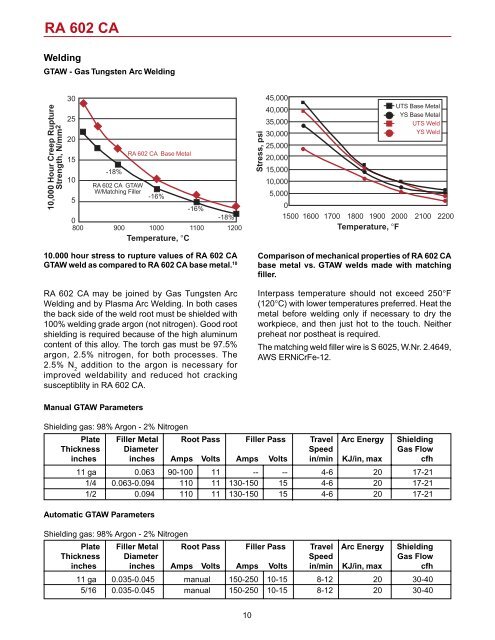

GTAW - Gas Tungsten Arc Welding<br />

10,000 Hour Creep Rupture<br />

Strength, N/mm2<br />

30<br />

25<br />

20<br />

15<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> Base Metal<br />

10<br />

-18%<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> GTAW<br />

5<br />

W/Matching Filler<br />

-16%<br />

0<br />

800 900 1000<br />

-16%<br />

1100<br />

-18%<br />

1200<br />

Temperature, °C<br />

10.000 hour stress to rupture values of <strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

GTAW weld as compared to <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal. 10<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be joined by Gas Tungsten Arc<br />

Welding and by Plasma Arc Welding. In both cases<br />

the back side of the weld root must be shielded with<br />

100% welding grade argon (not nitrogen). Good root<br />

shielding is required because of the high aluminum<br />

content of this alloy. The torch gas must be 97.5%<br />

argon, 2.5% nitrogen, for both processes. The<br />

2.5% N 2 addition to the argon is necessary for<br />

improved weldability and reduced hot cracking<br />

susceptiblity in <strong>RA</strong> <strong>602</strong> <strong>CA</strong>.<br />

Manual GTAW Parameters<br />

Shielding gas: 98% Argon - 2% Nitrogen<br />

Plate Filler Metal Root Pass Filler Pass Travel Arc Energy Shielding<br />

Thickness Diameter Speed Gas Flow<br />

inches inches Amps Volts Amps Volts in/min KJ/in, max cfh<br />

11 ga 0.063 90-100 11 -- -- 4-6 20 17-21<br />

1/4 0.063-0.094 110 11 130-150 15 4-6 20 17-21<br />

1/2 0.094 110 11 130-150 15 4-6 20 17-21<br />

Automatic GTAW Parameters<br />

Shielding gas: 98% Argon - 2% Nitrogen<br />

Plate Filler Metal Root Pass Filler Pass Travel Arc Energy Shielding<br />

Thickness Diameter Speed Gas Flow<br />

inches inches Amps Volts Amps Volts in/min KJ/in, max cfh<br />

11 ga 0.035-0.045 manual 150-250 10-15 8-12 20 30-40<br />

5/16 0.035-0.045 manual 150-250 10-15 8-12 20 30-40<br />

10<br />

Stress, psi<br />

45,000<br />

40,000<br />

35,000<br />

UTS Base Metal<br />

YS Base Metal<br />

UTS Weld<br />

30,000<br />

25,000<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

0<br />

YS Weld<br />

1500 1600 1700 1800 1900 2000 2100 2200<br />

Temperature, °F<br />

Comparison of mechanical properties of <strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

base metal vs. GTAW welds made with matching<br />

filler.<br />

Interpass temperature should not exceed 250°F<br />

(120°C) with lower temperatures preferred. Heat the<br />

metal before welding only if necessary to dry the<br />

workpiece, and then just hot to the touch. Neither<br />

preheat nor postheat is required.<br />

The matching weld filler wire is S <strong>602</strong>5, W.Nr. 2.4649,<br />

AWS ERNiCrFe-12.