RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

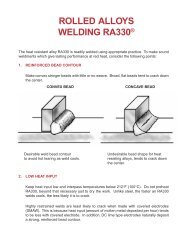

Grain Growth<br />

The brittle fracture of components exposed to<br />

extreme temperatures is a common occurrence.<br />

At temperatures near or exceeding the annealing<br />

temperature of a heat resistant alloy, grain growth is<br />

likely to occur. Extensive grain growth can result in a<br />

loss of ductility. As a result, the component can be<br />

prone to brittle fracture. An alloy 601 corrugated muffle<br />

that suffered brittle fracture due to combination of<br />

extensive grain growth and carburization is shown<br />

above.<br />

The results of testing at 2050°F (1121°C) are detailed<br />

in the table below. The information provides a<br />

comparison of various heat resisting alloys that are<br />

commonly used above 1900°F (1038°C). The data was<br />

compiled from intermittent exposure of sample<br />

coupons to 2050°F (1121°C) for a total of 990 hours.<br />

Each sample was in the mill annealed condition. The<br />

figure at right shows a sample of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> after long<br />

term exposure to 2100°F (1149°C).<br />

3<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

Brittle fracture of an alloy 601 muffle from the combination of extensive grain growth and carburization.<br />

Sample of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> examined after exposure to<br />

2100°F (1149°C) for over 3150 hours. The grain size<br />

was originally ASTM 7. After the 3000 hour test<br />

period the grains had only grown to ASTM 5.5.<br />

Magnification: 90x<br />

Effects of High Temperature Exposure on ASTM Grain Size8 - 2050°F (1121°C)<br />

Time ASTM Average Grain Size<br />

Hours <strong>RA</strong> <strong>602</strong> <strong>CA</strong> <strong>RA</strong>601 601GC <strong>RA</strong>330 <strong>RA</strong> 353 MA <strong>RA</strong>333 <strong>RA</strong>600<br />

0 7 5 5.5 7 6 4 8<br />

2 7 5 5.5 3.5 4 4 4<br />

24 7 1.5 5 3.5 3 3.5 1<br />

72 7 1 5 3 2.5 3 0<br />

184 6.5 1 3.5 3 2.5 2.5 0<br />

344 6.5 0 3.5 2.5 2 2 0<br />

510 6.5 0 3 2 2 2 00<br />

670 6.5 00 3 2 1.5 2 00<br />

830 6.5 00 3 2 1.5 2 00<br />

990 6.5 00 2.5 1.5 1.5 1 00