RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

RA 602 CA - Rolled Alloys

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GMAW - Gas Metal Arc Welding<br />

11<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong><br />

GMAW welding of <strong>RA</strong> <strong>602</strong> <strong>CA</strong> should be performed using the matching composition weld wire designated as<br />

S <strong>602</strong>5. <strong>RA</strong> <strong>602</strong> <strong>CA</strong> should be joined using the pulse arc process. For welding material thicknesses less than<br />

3/16” thick use of 100% Argon shielding has been satisfactory. For welding thicknesses above 3/16”, it is recommended<br />

to utilize the welding gas AR Ni5He5CD300. (Available from Airgas 419-666-7155) to reduce the<br />

likelihood of centerline cracking.<br />

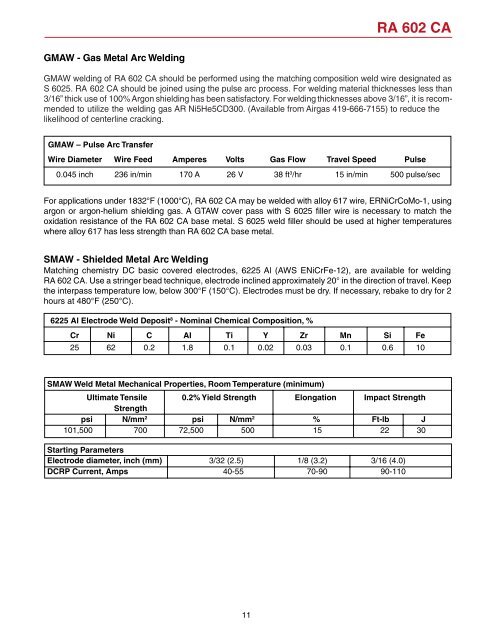

GMAW – Pulse Arc Transfer<br />

Wire Diameter Wire Feed Amperes Volts Gas Flow Travel Speed Pulse<br />

0.045 inch 236 in/min 170 A 26 V 38 ft 3 /hr 15 in/min 500 pulse/sec<br />

For applications under 1832°F (1000°C), <strong>RA</strong> <strong>602</strong> <strong>CA</strong> may be welded with alloy 617 wire, ERNiCrCoMo-1, using<br />

argon or argon-helium shielding gas. A GTAW cover pass with S <strong>602</strong>5 filler wire is necessary to match the<br />

oxidation resistance of the <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal. S <strong>602</strong>5 weld filler should be used at higher temperatures<br />

where alloy 617 has less strength than <strong>RA</strong> <strong>602</strong> <strong>CA</strong> base metal.<br />

SMAW - Shielded Metal Arc Welding<br />

Matching chemistry DC basic covered electrodes, 6225 Al (AWS ENiCrFe-12), are available for welding<br />

<strong>RA</strong> <strong>602</strong> <strong>CA</strong>. Use a stringer bead technique, electrode inclined approximately 20° in the direction of travel. Keep<br />

the interpass temperature low, below 300°F (150°C). Electrodes must be dry. If necessary, rebake to dry for 2<br />

hours at 480°F (250°C).<br />

6225 Al Electrode Weld Deposit 8 - Nominal Chemical Composition, %<br />

Cr Ni C AI Ti Y Zr Mn Si Fe<br />

25 62 0.2 1.8 0.1 0.02 0.03 0.1 0.6 10<br />

SMAW Weld Metal Mechanical Properties, Room Temperature (minimum)<br />

Ultimate Tensile 0.2% Yield Strength Elongation Impact Strength<br />

Strength<br />

psi N/mm 2 psi N/mm 2 % Ft-lb J<br />

101,500 700 72,500 500 15 22 30<br />

Starting Parameters<br />

Electrode diameter, inch (mm) 3/32 (2.5) 1/8 (3.2) 3/16 (4.0)<br />

DCRP Current, Amps 40-55 70-90 90-110