AUTOMATIC FILLING VALVES AUTOMATIC ... - Watts Industries

AUTOMATIC FILLING VALVES AUTOMATIC ... - Watts Industries

AUTOMATIC FILLING VALVES AUTOMATIC ... - Watts Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

01C301-GB<br />

<strong>AUTOMATIC</strong> <strong>FILLING</strong> <strong>VALVES</strong><br />

<strong>AUTOMATIC</strong> <strong>FILLING</strong> UNITS<br />

RELIABILITY<br />

AND COMFORT<br />

The <strong>Watts</strong> Cazzaniga ALIMAT automatic<br />

filling valve ensures prompt automatic<br />

make up of water losses from the<br />

heating system by highly accurate<br />

and reliable adjustment of the heating<br />

system pressure until reaching the<br />

required operating parameter.<br />

EASY <strong>FILLING</strong><br />

The use of the <strong>Watts</strong> Cazzaniga ALIMAT filling valve allows fully<br />

automatic filling of water in the system with appreciable time<br />

saving.<br />

PROTECTION<br />

The <strong>Watts</strong> Cazzaniga ALIMAT automatic filling valve includes an<br />

inspectable check valve whose function is to prevent risk of back<br />

flows which could cause contamination of the water main with the<br />

water of the heating system. When an even higher level of safety is<br />

required, <strong>Watts</strong> Intermes offers filling and back flow preventer units<br />

for systems with capacities either higher or lower than 70 kW.

APPLICATION<br />

A closed circuit heating system should be connected to<br />

the water main via a valve ensuring the following conditions:<br />

- a filling pressure suitable for system requirements;<br />

- protection against risk of back flow which could cause<br />

pollution of the water main;<br />

- stop of water filling upon reaching a preset pressure.<br />

Such conditions are guaranteed by the ALIMAT automatic<br />

filling valve which combines the following functions:<br />

- pressure control;<br />

- non-return;<br />

- checking for correct check valve operation;<br />

- shut-off ;<br />

- filtration;<br />

- check of heating system pressure via pressure gauge.<br />

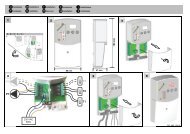

1<br />

2<br />

3<br />

E U<br />

10<br />

4<br />

Overall dimensions (mm)<br />

AL - ALM - ALO - ALOM<br />

Key:<br />

1. Inlet connection<br />

2. Setting pin<br />

3. Spring<br />

4. Plug<br />

5. Diaphragm<br />

6. Check valve<br />

7. Vent<br />

8. Knob<br />

9. Filter cartridge<br />

10. Chamber<br />

TECHNICAL CHARACTERISTICS<br />

Max. inlet pressure 10 bar<br />

Set pressure 0,3 to 4 bar<br />

Max. flow rate 1,8 m3/h<br />

Operating sensitivity 0,2 bar<br />

Max. fluid temperature 40°C<br />

5<br />

6<br />

7<br />

9<br />

8<br />

6<br />

AL<br />

ALIMAT.<br />

Automatic filling valve<br />

complete with check valve,<br />

manual shut-off, stainless<br />

steel filter, vent screw.<br />

ALM<br />

Like AL but with pressure<br />

gauge MR50 (dial 50 mm,<br />

radial connection, 0-4 bar).<br />

Flow rate - pressure drop chart<br />

PRESSURE DROPS<br />

[bar]<br />

4<br />

3,5<br />

3<br />

2,5<br />

2<br />

1,5<br />

1<br />

0,5<br />

0<br />

Part No. Size<br />

0240100 1/2”MF<br />

Part No. Size<br />

0240200 1/2”MF<br />

ALO<br />

Part No. Size<br />

Like AL but with cap made of<br />

brass CW617N. 0240110 1/2”MF<br />

ALOM<br />

Like ALO but with pressure<br />

gauge MR50 (dial 50 mm,<br />

radial connection, 0-4 bar).<br />

FLOW RATES<br />

Part No. Size<br />

0240210 1/2”MF<br />

DESIGN FEATURES<br />

Body and head end Nickel-plated brass<br />

Body Shot-blasted stamped brass<br />

Diaphragm NBR rubber reinforced with nylon fabric<br />

Inlet connection 1/2" M tailpiece (UNI-ISO228/1)<br />

Outlet connection 1/2" F (UNI-ISO228/1)<br />

Gauge connection 1/4" F (UNI-ISO228/1)<br />

O-rings NBR rubber<br />

Cap (AL-ALM) High impact plastic<br />

Cap (ALO-ALOM) Die-cast brass<br />

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 [ m 3 /h]

In order to avoid uncontrollable feeding of water in the<br />

system, which would prevent leak detection, it is recommended,<br />

once filling has finished, to close the shut-off<br />

valve. The pressure gauge will show any leaks which,<br />

whenever of continuous nature, should be promptly<br />

identified and eliminated.<br />

OPERATION<br />

When the pressure exerted by the fluid inside the system<br />

drops below the pressure exerted by spring (3) on diaphragm<br />

(5), the spring pushes plug (4) down. The mains<br />

water flows via inlet (E) through filter cartridge (9), then<br />

rises into chamber (10), opens check valve (6) and thus<br />

flows towards the system (U). When filling of the system<br />

is complete, the pressure in it increases, and therefore in<br />

chamber (10). After exceeding the value balanced by the<br />

force exerted by the opposing spring the pressure pushes<br />

diaphragm (5) upwards while plug (4) closes. Check<br />

valve (6) prevents back flow. Hence the pressure settles<br />

according to the set pressure given by the spring.<br />

SETTING<br />

The ALIMAT automatic filling valve is set by turning screw (2):<br />

- towards + (clockwise) = to increase the pressure;<br />

- towards - (counter-clockwise) = to decrease the pressure.<br />

Pressure of the system can be checked on the pressure<br />

gauge.<br />

APPLICATION<br />

Risk of pollution of drinking water pipes is a factor not be<br />

underestimated.<br />

There are regulations prescribing preventive measurements<br />

against contamination of drinking water: among<br />

these, UNI 9157 - "Three-way back flow preventers" lists<br />

the circuits and/or appliances whose direct connection to<br />

the public water main is recognized as possible source of<br />

pollution; hence the use of a back flow preventing unit is<br />

prescribed:<br />

- independent and central heating systems;<br />

- air conditioning and air treatment systems.<br />

In order to protect public drinking water mains, a filling<br />

and back flow preventing is a useful device for connection<br />

to the heating system.<br />

This unit combines both functions of protection and<br />

automatic feeding of the system.<br />

APPROVALS<br />

The following approvals refer to the back flow preventers<br />

only:<br />

- DIW009:<br />

UNI certification according to UNI 9157<br />

standardCertifications<br />

NF/ANSEAU/KIWA/DVGW/ASSE/AWWA/IAPMO<br />

- DNW9D:<br />

Certifications ANSEAU/KIWA/ASSE/CSA<br />

CONTROL OF CHECK VALVE FOR PRESSURE<br />

TIGHTNESS<br />

The ALIMAT automatic filling valve is able to control the pressure tightness of<br />

the check valve. For such purpose, after closing knob (8), slightly loosen (2 or 3<br />

turns) vent screw (7): if there is faulty sealing of the check valve, there would be<br />

a continuous loss of water. After controlling, fully tighten the vent screw and<br />

again open the knob.<br />

MAINTENANCE<br />

La manutenzione dell’alimentatore automatico ALIMAT si limita alla pulizia periodica<br />

del filtro, in particolare dopo il primo riempimento dell’impianto.<br />

Per estrarre il filtro procedere come segue:<br />

1. Close the gate valve upstream to ALIMAT (if there is no gate valve, shut off the<br />

supply pipe from the water main).<br />

2. Unscrew the bottom nut and remove the knob assembly (8) where filter (9)<br />

is seated.<br />

3. Flush the filter with water (do not use aggressive chemicals).<br />

4. Grease the O-rings mounted on plug (4).<br />

5. Refit the filter and spring in the seat in the bottom nut, then fully tighten the<br />

nut to the body.<br />

6. Re-open the gate valve upstream to ALIMAT or the one before the system.<br />

ALOMDIW<br />

Filling and back flow preventing<br />

unit, complete with<br />

discharge tundish, assembled<br />

for air conditioning and heating<br />

systems with capacity<br />

> 79 kW.<br />

ALOMDNW<br />

Filling and back flow preventing<br />

unit, complete with<br />

discharge tundish, assembled<br />

for air conditioning and heating<br />

systems with capacity<br />

< 70 kW.<br />

Part No. Size<br />

1505199 1/2”<br />

Part No. Size<br />

1505299 1/2”<br />

DESIGN FEATURES<br />

Ball valve body Nickel-plated stamped brass<br />

Ball valve seats PTFE<br />

Inlet connection 1/2" F (UNI-ISO228/1)<br />

Outlet connection 1/2" F (UNI-ISO228/1)<br />

Gauge connection 1/4" F (UNI-ISO228/1)<br />

TECHNICAL CHARACTERISTICS<br />

Max. inlet pressure 10 bar<br />

Set pressure 0.3 to 4 bar<br />

Max. flow rate 1.8 m3/h with set pressure 4 bar<br />

Operating sensitivity 0.2 bar<br />

Max. fluid temperature 40°C

Flow rate - pressure drop chart<br />

PRESSURE DROPS<br />

[bar]<br />

Overall dimensions (mm)<br />

4<br />

3,5<br />

3<br />

2,5<br />

2<br />

1,5<br />

1<br />

0,5<br />

0<br />

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 [ m 3 /h]<br />

FLOW RATES<br />

ALOMDIW ALOMDNW<br />

The descriptions and photographs contained in this product specification sheet are supplied by way of information only and are not binding.<br />

WATTS CAZZANIGA reserves the right to carry out any technical and design improvements to its products without prior notice.<br />

WATTS Cazzaniga S.p.A.<br />

Via Parco, snc - 20046 Biassono (MI) - Italy<br />

Phone ++39 039 49.86.1 - Fax ++ 39 039 49.86.285<br />

www.wattseurope.com e-mail: info@wattscazzaniga.it<br />

ALOM DIW<br />

ALOM DNW<br />

G1- AL- DIW - DNW - GB - 01/’02