NBA Winter Magazine_2023_

For everyone with an interest in the British Beef Industry

For everyone with an interest in the British Beef Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

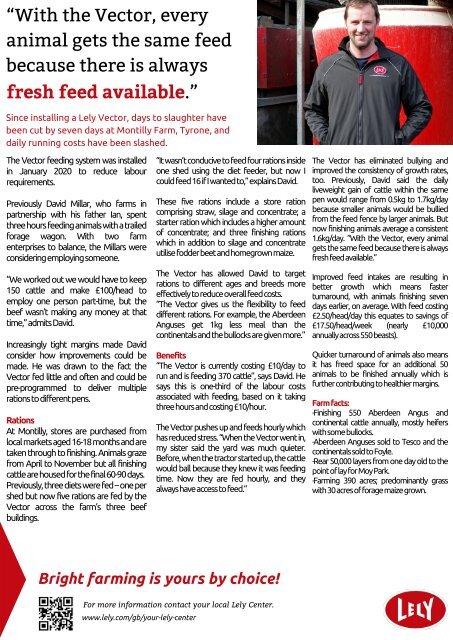

“With the Vector, every<br />

animal gets the same feed<br />

because there is always<br />

fresh feed available.”<br />

Since installing a Lely Vector, days to slaughter have<br />

been cut by seven days at Montilly Farm, Tyrone, and<br />

daily running costs have been slashed.<br />

The Vector feeding system was installed<br />

in January 2020 to reduce labour<br />

requirements.<br />

Previously David Millar, who farms in<br />

partnership with his father Ian, spent<br />

three hours feeding animals with a trailed<br />

forage wagon. With two farm<br />

enterprises to balance, the Millars were<br />

considering employing someone.<br />

“We worked out we would have to keep<br />

150 cattle and make £100/head to<br />

employ one person part-time, but the<br />

beef wasn’t making any money at that<br />

time,” admits David.<br />

Increasingly tight margins made David<br />

consider how improvements could be<br />

made. He was drawn to the fact the<br />

Vector fed little and often and could be<br />

pre-programmed to deliver multiple<br />

rations to different pens.<br />

Rations<br />

At Montilly, stores are purchased from<br />

local markets aged 16-18 months and are<br />

taken through to finishing. Animals graze<br />

from April to November but all finishing<br />

cattle are housed for the final 60-90 days.<br />

Previously, three diets were fed – one per<br />

shed but now five rations are fed by the<br />

Vector across the farm’s three beef<br />

buildings.<br />

“It wasn’t conducive to feed four rations inside<br />

one shed using the diet feeder, but now I<br />

could feed 16 if I wanted to,” explains David.<br />

These five rations include a store ration<br />

comprising straw, silage and concentrate; a<br />

starter ration which includes a higher amount<br />

of concentrate; and three finishing rations<br />

which in addition to silage and concentrate<br />

utilise fodder beet and homegrown maize.<br />

The Vector has allowed David to target<br />

rations to different ages and breeds more<br />

effectively to reduce overall feed costs.<br />

“The Vector gives us the flexibility to feed<br />

different rations. For example, the Aberdeen<br />

Anguses get 1kg less meal than the<br />

continentals and the bullocks are given more.”<br />

Benefits<br />

“The Vector is currently costing £10/day to<br />

run and is feeding 370 cattle”, says David. He<br />

says this is one-third of the labour costs<br />

associated with feeding, based on it taking<br />

three hours and costing £10/hour.<br />

The Vector pushes up and feeds hourly which<br />

has reduced stress. “When the Vector went in,<br />

my sister said the yard was much quieter.<br />

Before, when the tractor started up, the cattle<br />

would ball because they knew it was feeding<br />

time. Now they are fed hourly, and they<br />

always have access to feed.”<br />

The Vector has eliminated bullying and<br />

improved the consistency of growth rates,<br />

too. Previously, David said the daily<br />

liveweight gain of cattle within the same<br />

pen would range from 0.5kg to 1.7kg/day<br />

because smaller animals would be bullied<br />

from the feed fence by larger animals. But<br />

now finishing animals average a consistent<br />

1.6kg/day. “With the Vector, every animal<br />

gets the same feed because there is always<br />

fresh feed available.”<br />

Improved feed intakes are resulting in<br />

better growth which means faster<br />

turnaround, with animals finishing seven<br />

days earlier, on average. With feed costing<br />

£2.50/head/day this equates to savings of<br />

£17.50/head/week (nearly £10,000<br />

annually across 550 beasts).<br />

Quicker turnaround of animals also means<br />

it has freed space for an additional 50<br />

animals to be finished annually which is<br />

further contributing to healthier margins.<br />

Farm facts:<br />

·Finishing 550 Aberdeen Angus and<br />

continental cattle annually, mostly heifers<br />

with some bullocks.<br />

·Aberdeen Anguses sold to Tesco and the<br />

continentals sold to Foyle.<br />

·Rear 50,000 layers from one day old to the<br />

point of lay for Moy Park.<br />

·Farming 390 acres; predominantly grass<br />

with 30 acres of forage maize grown.<br />

Bright farming is yours by choice!<br />

For more information contact your local Lely Center.<br />

www.lely.com/gb/your-lely-center