Manufacturing Machinery World April 2024

Machinery World was launched in 1982 to serve the machinery & production engineering market. Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and as hard copy.

Machinery World was launched in 1982 to serve the machinery & production engineering market.

Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and as hard copy.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CASE STUDY<br />

FABRICATOR REBALANCES BUSINESS TOWARDS<br />

SUBCONTRACT MACHINING<br />

Twenty years ago, Gareth Davies started<br />

Burton-on-Trent company TAS Engineering<br />

as a steel, stainless steel and aluminium<br />

fabrication shop serving food and beverage<br />

customers, the pharmaceutical and<br />

automotive sectors, and industry in general<br />

with fire escapes, factory staircases and<br />

secondary steelwork.<br />

In 2014, he established a machine shop to<br />

add extra value to the products the company<br />

was shaping and welding. Today, there is a<br />

pair of 3-axis, vertical-spindle machining<br />

centres on-site and three CNC lathes, the<br />

latest of which is a second-hand Cincom L20<br />

sliding-head turning centre from Citizen<br />

<strong>Machinery</strong> UK.<br />

What prompted the purchase in October<br />

2023 of this 20-year-old lathe, the company's<br />

first sliding-head model, was a desire to turn<br />

more efficiently components in a range of<br />

materials from bar up to 20 mm in diameter.<br />

A case in point is the ongoing production<br />

since 2020 of a 16 mm diameter, 316 stainless<br />

steel magnet holder, which is welded to a<br />

small, laser-cut and bent plate to form part of<br />

a safety unit for industrial switchgear. The<br />

turned component, of which 200 are required<br />

per month, was previously produced<br />

complete on one of two fixed-head, twinspindle<br />

lathes (that have since been sold) in a<br />

2.5-minute cycle.<br />

Mr Davies had previous experience of<br />

programming and setting sliding-head<br />

lathes, albeit from 40 years ago working for a<br />

subcontracting firm in London that<br />

happened to be the first ever customer of the<br />

The 20-year-old control system looks surprisingly modern.<br />

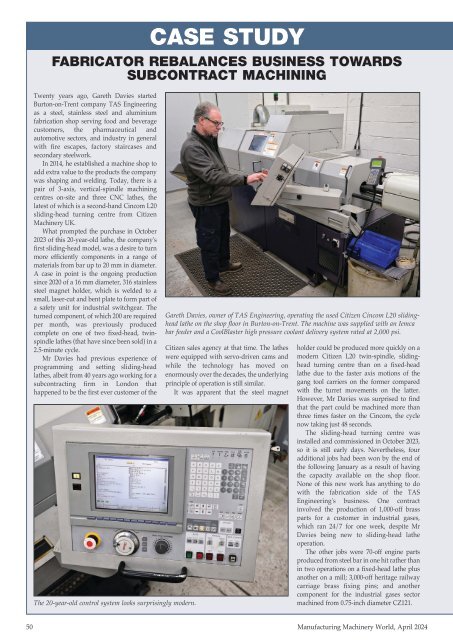

Gareth Davies, owner of TAS Engineering, operating the used Citizen Cincom L20 slidinghead<br />

lathe on the shop floor in Burton-on-Trent. The machine was supplied with an Iemca<br />

bar feeder and a CoolBlaster high pressure coolant delivery system rated at 2,000 psi.<br />

Citizen sales agency at that time. The lathes<br />

were equipped with servo-driven cams and<br />

while the technology has moved on<br />

enormously over the decades, the underlying<br />

principle of operation is still similar.<br />

It was apparent that the steel magnet<br />

holder could be produced more quickly on a<br />

modern Citizen L20 twin-spindle, slidinghead<br />

turning centre than on a fixed-head<br />

lathe due to the faster axis motions of the<br />

gang tool carriers on the former compared<br />

with the turret movements on the latter.<br />

However, Mr Davies was surprised to find<br />

that the part could be machined more than<br />

three times faster on the Cincom, the cycle<br />

now taking just 48 seconds.<br />

The sliding-head turning centre was<br />

installed and commissioned in October 2023,<br />

so it is still early days. Nevertheless, four<br />

additional jobs had been won by the end of<br />

the following January as a result of having<br />

the capacity available on the shop floor.<br />

None of this new work has anything to do<br />

with the fabrication side of the TAS<br />

Engineering's business. One contract<br />

involved the production of 1,000-off brass<br />

parts for a customer in industrial gases,<br />

which ran 24/7 for one week, despite Mr<br />

Davies being new to sliding-head lathe<br />

operation.<br />

The other jobs were 70-off engine parts<br />

produced from steel bar in one hit rather than<br />

in two operations on a fixed-head lathe plus<br />

another on a mill; 3,000-off heritage railway<br />

carriage brass fixing pins; and another<br />

component for the industrial gases sector<br />

machined from 0.75-inch diameter CZ121.<br />

50 <strong>Manufacturing</strong> <strong>Machinery</strong> <strong>World</strong>, <strong>April</strong> <strong>2024</strong>