May 2024

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Roofing Updates<br />

MARLEY LINCOLN UPDATE<br />

For further info on all these updates and more, visit www.total-contractor.co.uk<br />

Marley has re-launched a new range of its<br />

long-standing Lincoln clay pantiles, which<br />

will become one of the only clay pantiles<br />

manufactured in Britain.<br />

The Lincoln Clay Interlocking Pantile with an<br />

s-curve profile and thin leading edge, is now<br />

available and offers roofing contractors and their<br />

customers a series of design enhancements that<br />

underpin the product’s traditional appearance and<br />

robust performance. Production for the new Lincoln<br />

has moved to Keele in Staffordshire from Germany,<br />

with the clay used for its manufacture sourced<br />

from nearby quarries, meaning Marley is now able<br />

to offer the same colourway found on its Red<br />

Smooth Single Camber Clay Plain Tiles.<br />

This makes Marley one of the only providers of a<br />

British-made clay pantile, delivering an additional<br />

confidence boost to the region’s manufacturing<br />

capacity.<br />

Marley says the decision to transition production to<br />

the UK will deliver environmental benefits too,<br />

through a reduction in shipping and transport<br />

requirements, and subsequent reductions in<br />

associated carbon emissions. The manufacturer<br />

says it will also provide additional versatility and<br />

assurance of product supply for the UK roofing<br />

sector.<br />

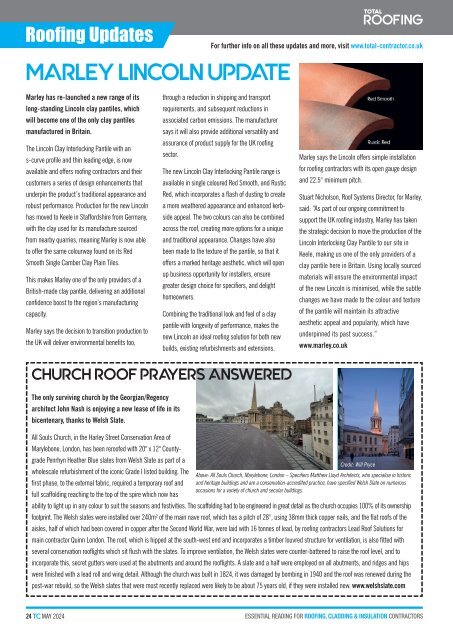

The new Lincoln Clay Interlocking Pantile range is<br />

available in single coloured Red Smooth, and Rustic<br />

Red, which incorporates a flash of dusting to create<br />

a more weathered appearance and enhanced kerbside<br />

appeal. The two colours can also be combined<br />

across the roof, creating more options for a unique<br />

and traditional appearance. Changes have also<br />

been made to the texture of the pantile, so that it<br />

offers a marked heritage aesthetic, which will open<br />

up business opportunity for installers, ensure<br />

greater design choice for specifiers, and delight<br />

homeowners.<br />

Combining the traditional look and feel of a clay<br />

pantile with longevity of performance, makes the<br />

new Lincoln an ideal roofing solution for both new<br />

builds, existing refurbishments and extensions.<br />

Marley says the Lincoln offers simple installation<br />

for roofing contractors with its open gauge design<br />

and 22.5° minimum pitch.<br />

Stuart Nicholson, Roof Systems Director, for Marley,<br />

said: “As part of our ongoing commitment to<br />

support the UK roofing industry, Marley has taken<br />

the strategic decision to move the production of the<br />

Lincoln Interlocking Clay Pantile to our site in<br />

Keele, making us one of the only providers of a<br />

clay pantile here in Britain. Using locally sourced<br />

materials will ensure the environmental impact<br />

of the new Lincoln is minimised, while the subtle<br />

changes we have made to the colour and texture<br />

of the pantile will maintain its attractive<br />

aesthetic appeal and popularity, which have<br />

underpinned its past success.”<br />

www.marley.co.uk<br />

CHURCH ROOF PRAYERS ANSWERED<br />

The only surviving church by the Georgian/Regency<br />

architect John Nash is enjoying a new lease of life in its<br />

bicentenary, thanks to Welsh Slate.<br />

All Souls Church, in the Harley Street Conservation Area of<br />

Marylebone, London, has been reroofed with 20" x 12" Countygrade<br />

Penrhyn Heather Blue slates from Welsh Slate as part of a<br />

Credit: Will Pryce<br />

wholescale refurbishment of the iconic Grade I listed building. The<br />

Above: All Souls Church, Marylebone, London – Specifiers Matthew Lloyd Architects, who specialise in historic<br />

first phase, to the external fabric, required a temporary roof and and heritage buildings and are a conservation-accredited practice, have specified Welsh Slate on numerous<br />

occasions for a variety of church and secular buildings.<br />

full scaffolding reaching to the top of the spire which now has<br />

ability to light up in any colour to suit the seasons and festivities. The scaffolding had to be engineered in great detail as the church occupies 100% of its ownership<br />

footprint. The Welsh slates were installed over 240m 2 of the main nave roof, which has a pitch of 28°, using 38mm thick copper nails, and the flat roofs of the<br />

aisles, half of which had been covered in copper after the Second World War, were laid with 16 tonnes of lead, by roofing contractors Lead Roof Solutions for<br />

main contractor Quinn London. The roof, which is hipped at the south-west end and incorporates a timber louvred structure for ventilation, is also fitted with<br />

several conservation rooflights which sit flush with the slates. To improve ventilation, the Welsh slates were counter-battened to raise the roof level, and to<br />

incorporate this, secret gutters were used at the abutments and around the rooflights. A slate and a half were employed on all abutments, and ridges and hips<br />

were finished with a lead roll and wing detail. Although the church was built in 1824, it was damaged by bombing in 1940 and the roof was renewed during the<br />

post-war rebuild, so the Welsh slates that were most recently replaced were likely to be about 75 years old, if they were installed new. www.welshslate.com<br />

24 TC MAY <strong>2024</strong>