Specially formulated for use on metal roof and ... - Triangle Fastener

Specially formulated for use on metal roof and ... - Triangle Fastener

Specially formulated for use on metal roof and ... - Triangle Fastener

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Visit our website <str<strong>on</strong>g>for</str<strong>on</strong>g> the most up-to-date product <strong>and</strong> technical in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>!<br />

TAPE-SEAL<br />

SIZES<br />

Stocked sizes - Others available up<strong>on</strong> request<br />

Size<br />

(T x W x L) TFC P.N.<br />

PACKAGING<br />

Rolls/<br />

Ctns<br />

Ctns/<br />

Pallet<br />

3/32” x 3/8” x 45’ 0937BCT 48 30<br />

3/32” x 1/2” x 50’ 0950BCT 22 50<br />

3/32” x 1” x 45’ 0910BCT 24 30<br />

1/8” x 1/2” x 50’ 1250BCT50 13 48<br />

1/8” x 1” x 50’ 1210BCT50 8 48<br />

3/16” x 1/4” x 40’ 1825BCT 20 48<br />

3/16” x 7/8” x 40’ *DB 1887BCT 10 48<br />

3/16” x 7/8” x 25’ *TB 1887BCT25TRI 8 64<br />

3/16” x 2-1/2” x 20 *TB TC826W 6 60<br />

*DB denotes double bead<br />

*TB denotes triple bead<br />

BUTYL TAPE-SEAL is extruded butyl material<br />

with a silic<strong>on</strong>e backed release paper that is rolled<br />

<strong>and</strong> cut to specifi c lengths.<br />

Our master cart<strong>on</strong>s are c<strong>on</strong>structed of 200<br />

pound test material <strong>and</strong> the rolls are separated<br />

by silic<strong>on</strong>e divider pads <strong>and</strong> protected by upright<br />

stacking cores.<br />

CLEAN UP<br />

Mineral spirits will readily facilitate the cleaning of tools <strong>and</strong> equipment.<br />

C 266<br />

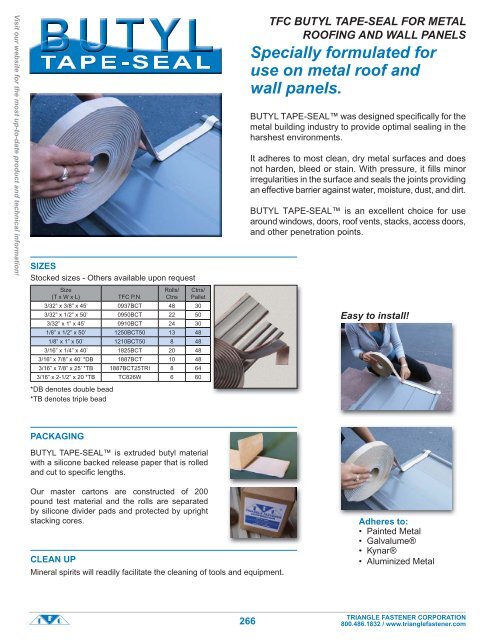

TFC BUTYL TAPE-SEAL FOR METAL<br />

ROOFING AND WALL PANELS<br />

<str<strong>on</strong>g>Specially</str<strong>on</strong>g> <str<strong>on</strong>g><str<strong>on</strong>g>for</str<strong>on</strong>g>mulated</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

<str<strong>on</strong>g>use</str<strong>on</strong>g> <strong>on</strong> <strong>metal</strong> <strong>roof</strong> <strong>and</strong><br />

wall panels.<br />

BUTYL TAPE-SEAL was designed specifi cally <str<strong>on</strong>g>for</str<strong>on</strong>g> the<br />

<strong>metal</strong> building industry to provide optimal sealing in the<br />

harshest envir<strong>on</strong>ments.<br />

It adheres to most clean, dry <strong>metal</strong> surfaces <strong>and</strong> does<br />

not harden, bleed or stain. With pressure, it fi lls minor<br />

irregularities in the surface <strong>and</strong> seals the joints providing<br />

an effective barrier against water, moisture, dust, <strong>and</strong> dirt.<br />

BUTYL TAPE-SEAL is an excellent choice <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>use</str<strong>on</strong>g><br />

around windows, doors, <strong>roof</strong> vents, stacks, access doors,<br />

<strong>and</strong> other penetrati<strong>on</strong> points.<br />

Easy to install!<br />

Adheres to:<br />

• Painted Metal<br />

• Galvalume®<br />

• Kynar®<br />

• Aluminized Metal<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

TAPE-SEAL<br />

MATERIAL SPECIFICATION<br />

TEST DATA<br />

BUTYL TAPE-SEAL has been tested to<br />

ASTM st<strong>and</strong>ards <strong>and</strong> meets Military <strong>and</strong><br />

Federal Specifi cati<strong>on</strong>s.<br />

BUTYL TAPE-SEAL meets or exceeds<br />

the following specificati<strong>on</strong>s:<br />

MIL-C-18969B, Type II, Class B<br />

TT-C-1996A, Type II, Class B (supersedes<br />

MIL-C-18909B) AAMA 804.3-92 <strong>and</strong><br />

807.3-92USDA Acceptable Freight<br />

Classificati<strong>on</strong>: Caulking Compound,<br />

NOIBN, NFMC #149610, Class 55<br />

C 267<br />

TFC BUTYL TAPE-SEAL FOR METAL<br />

ROOFING AND WALL PANELS<br />

BUTYL TAPE-SEAL is made from a blend of<br />

elastomers, butyl, EPDM rubber, <strong>and</strong> proprietary<br />

co-polymers.<br />

The plasticizers are of the polyisobutylene <strong>and</strong><br />

polybutene type, <strong>and</strong> permit no oxidati<strong>on</strong> or migrati<strong>on</strong>.<br />

The fillers are inert <strong>and</strong> are primarily <str<strong>on</strong>g>use</str<strong>on</strong>g>d as<br />

extenders <strong>and</strong> process aids <strong>and</strong>, to a lesser extent,<br />

as rein<str<strong>on</strong>g>for</str<strong>on</strong>g>cing pigments. The remaining materials are<br />

antioxidents, fungicides <strong>and</strong> organic processing aides.<br />

Property Value<br />

Color Off-White<br />

Specifi c Gravity (ASTM D792)- 1.6 ± 5<br />

Percent Solids (ASTM C771)- 100%<br />

C<strong>on</strong>e Penetrati<strong>on</strong> (ASTM D217)- 80 - 95<br />

Tensile Adhesive Strength (ASTM C907)- 15 – 18 psi<br />

Applicati<strong>on</strong> Temperature Range -5°F to120°F -20°C to 49°C<br />

Service Temperature Range -40°F to 200°F -40°C to 93°C<br />

Sag (AAMA 800)- N<strong>on</strong>e<br />

El<strong>on</strong>gati<strong>on</strong> (ASTM C908) > 1000%<br />

Low Temperature Flexibility (ASTM C734 -40°F/-40°C)- No<br />

cracking or loss of adhesi<strong>on</strong><br />

Peel Adhesi<strong>on</strong> (ASTM D3330) > 8 psi<br />

Staining (ASTM D925)- Will not stain<br />

painted/ unpainted surfaces<br />

Water Penetrati<strong>on</strong> / Static Water<br />

Pressure<br />

(ASTM E2140) - Pass/No leakage<br />

Shelf Life 18 M<strong>on</strong>ths<br />

TFC122012<br />

Applicati<strong>on</strong>: For optimum sealing the surfaces should be free of<br />

oil, dust, dirt <strong>and</strong> moisture. Light fi lms of lubricant <strong>on</strong> unpainted<br />

<strong>metal</strong>s should not adversely affect per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance. Rubex 126 can be<br />

applied in cold temperatures however, at temperatures below 40°F,<br />

any c<strong>on</strong>densati<strong>on</strong> or frost present should fi rst be removed. Positi<strong>on</strong><br />

product in desired locati<strong>on</strong> <strong>and</strong> press in place through the release<br />

paper. When using to seal applicati<strong>on</strong>s involving fasteners, positi<strong>on</strong><br />

<strong>on</strong> the entry side to prevent penetrati<strong>on</strong> of weather elements<br />

through fastener holes. Remove release paper prior to assembly /<br />

fastening of adjoining surface.<br />

TFC PRODUCT DISCLAIMER<br />

DISCLAIMER: ALL TEST RESULTS AND SPECIFICATIONS ARE A RESULT<br />

OF LABORATORY TESTS. THE USER OR SPECIFIER SHOULD USE<br />

APPROPRIATE SAFETY FACTORS. DETERMINING USE OF THIS PRODUCT<br />

IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION<br />

CONDITIONS VARY AND ARE UNCONTROLLABLE BY TFC, WE ASSUME NO<br />

LIABILITY FOR THE USE OF THIS INFORMATION.<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com<br />

Visit our website <str<strong>on</strong>g>for</str<strong>on</strong>g> the most up-to-date product <strong>and</strong> technical in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>!