TUB 2765 SHS Welded Joints - Tata Steel

TUB 2765 SHS Welded Joints - Tata Steel

TUB 2765 SHS Welded Joints - Tata Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

15 Design of <strong>SHS</strong> welded joints<br />

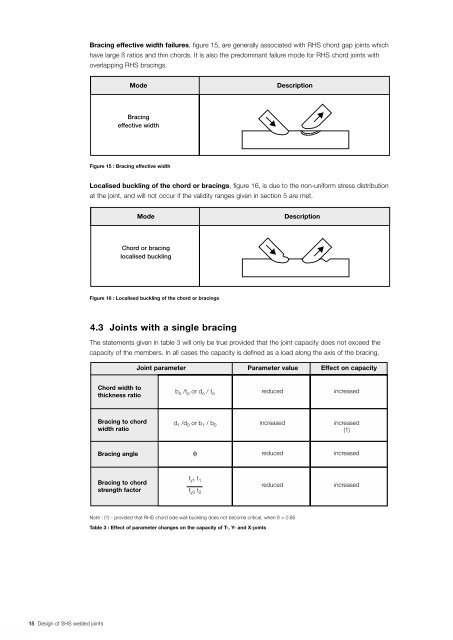

Bracing effective width failures, figure 15, are generally associated with RHS chord gap joints which<br />

have large ß ratios and thin chords. It is also the predominant failure mode for RHS chord joints with<br />

overlapping RHS bracings.<br />

Mode Description<br />

Bracing<br />

effective width<br />

Figure 15 : Bracing effective width<br />

Localised buckling of the chord or bracings, figure 16, is due to the non-uniform stress distribution<br />

at the joint, and will not occur if the validity ranges given in section 5 are met.<br />

Mode Description<br />

Chord or bracing<br />

localised buckling<br />

Figure 16 : Localised buckling of the chord or bracings<br />

4.3 <strong>Joints</strong> with a single bracing<br />

The statements given in table 3 will only be true provided that the joint capacity does not exceed the<br />

capacity of the members. In all cases the capacity is defined as a load along the axis of the bracing.<br />

Chord width to<br />

thickness ratio<br />

Bracing to chord<br />

width ratio<br />

Bracing angle<br />

Bracing to chord<br />

strength factor<br />

Joint parameter Parameter value Effect on capacity<br />

b o /t o or d o / t o<br />

d 1 /d 0 or b 1 / b 0<br />

Note : (1) - provided that RHS chord side wall buckling does not become critical, when ß > 0.85<br />

Table 3 : Effect of parameter changes on the capacity of T-, Y- and X-joints<br />

θ<br />

f y1 t 1<br />

f y0 t 0<br />

reduced increased<br />

increased increased<br />

(1)<br />

reduced increased<br />

reduced increased