TUB 2765 SHS Welded Joints - Tata Steel

TUB 2765 SHS Welded Joints - Tata Steel

TUB 2765 SHS Welded Joints - Tata Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

29 Design of <strong>SHS</strong> welded joints<br />

5.2.5.2 T- and X-joints with out-of-plane moments<br />

h 1 (1 + ß) 2b 0 b 1 (1 + ß) 0.5<br />

Chord face deformation, Mop,1 = fy0 t 2<br />

0 + f(n)<br />

(ß ≤ 0.85 only) 2 (1 - ß) (1 - ß)<br />

Chord side wall crushing, Mop,1 = fyk t0 (h1 + 5 t0 ) (b0 - t0 )<br />

(0.85 ≤ ß ≤ 1.0 only) with fyk = fy0 for T-joints and 0.8 fy0 for X-joints<br />

Bracing effective width, Mop,1 = fy1 [Wpl,1 - 0.5(1 - beff /b1 ) 2 b 2<br />

1 t1 ]<br />

(0.85 ≤ ß ≤ 1.0 only)<br />

Chord distortional failure (lozenging), Mop,1 = 2fy0 t0 [h1 t0 + ( b0 h0 t (<br />

0 b0 + h0 )) 0.5 ]<br />

(T joints only)<br />

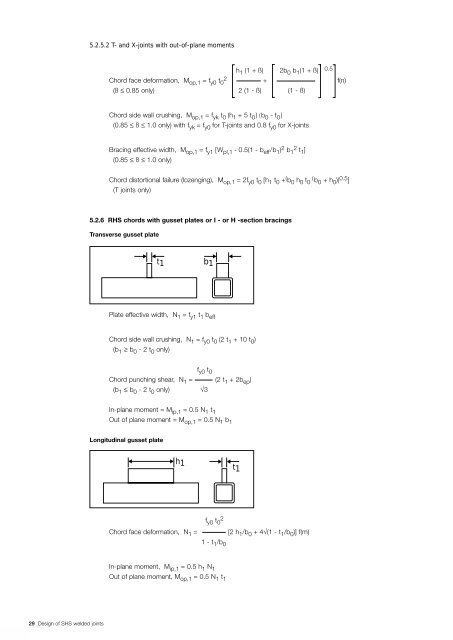

5.2.6 RHS chords with gusset plates or I - or H -section bracings<br />

Transverse gusset plate<br />

t1<br />

Plate effective width, N 1 = f y1 t 1 b eff<br />

Chord side wall crushing, N1 = fy0 t0 (2 t1 + 10 t0 )<br />

(b1 ≥ b0 - 2 t0 only)<br />

fy0 t0 Chord punching shear, N1 = (2 t1 + 2bep )<br />

(b1 ≤ b0 - 2 t0 only) √3<br />

In-plane moment = Mip,1 = 0.5 N1 t1 Out of plane moment = Mop,1 = 0.5 N1 b1 Longitudinal gusset plate<br />

h1<br />

b1<br />

f y0 t 0 2<br />

Chord face deformation, N1 = [2 h1 /b0 + 4√(1 - t1 /b0 )] f(m)<br />

1 - t1 /b0 In-plane moment, Mip,1 = 0.5 h1 N1 Out of plane moment, Mop,1 = 0.5 N1 t1 t1