RoadNews for new roads – the VÖGELE Magazine - Resansil

RoadNews for new roads – the VÖGELE Magazine - Resansil

RoadNews for new roads – the VÖGELE Magazine - Resansil

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

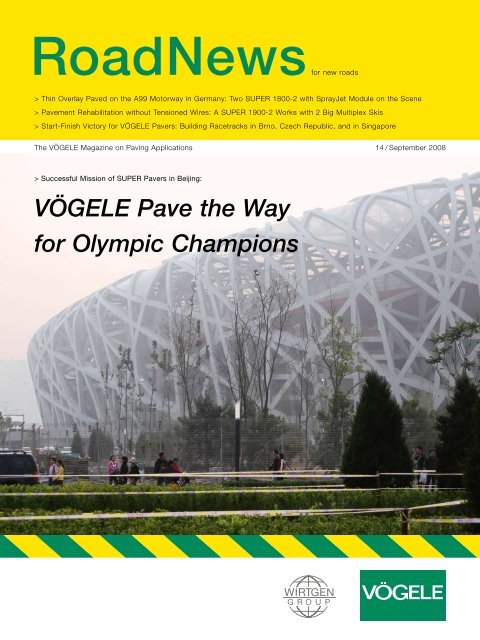

<strong>RoadNews</strong><strong>for</strong> <strong>new</strong> <strong>roads</strong><br />

> Thin Overlay Paved on <strong>the</strong> A99 Motorway in Germany: Two SUPER 1800-2 with SprayJet Module on <strong>the</strong> Scene<br />

> Pavement Rehabilitation without Tensioned Wires: A SUPER 1900-2 Works with 2 Big Multiplex Skis<br />

> Start-Finish Victory <strong>for</strong> <strong>VÖGELE</strong> Pavers: Building Racetracks in Brno, Czech Republic, and in Singapore<br />

The <strong>VÖGELE</strong> <strong>Magazine</strong> on Paving Applications 14 / September 2008<br />

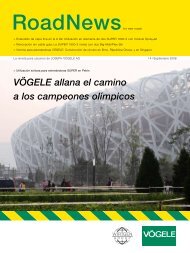

> Successful Mission of SUPER Pavers in Beijing:<br />

<strong>VÖGELE</strong> Pave <strong>the</strong> Way<br />

<strong>for</strong> Olympic Champions

2<br />

04<br />

In front of Beijing’s Olympic Stadium:<br />

SUPER 2100-2 pavers resurface <strong>the</strong><br />

4th Ring Road.<br />

10<br />

On Germany’s A99 motorway:<br />

Two SUPER 1800-2 with SprayJet Module<br />

pave thin overlay.<br />

19<br />

Grade and slope control with two<br />

Big MultiPlex Skis: Road rehabilitation<br />

without tensioned wires.<br />

Accurate paving without tensioned wires:<br />

SUPER 1900-2 works with 2 Big Multiplex Skis <strong>for</strong> grade and slope control.<br />

Centre Pages: Tips & Tricks<br />

from Practical Applications<br />

How to avoid Segregation.<br />

23<br />

Focus on racetracks: SUPER pavers in<br />

pole position on racetracks all over <strong>the</strong><br />

world.<br />

27<br />

Preparations <strong>for</strong> <strong>the</strong> first Formula 1 race<br />

in Singapore: Two SUPER 1600-2 pave<br />

special F1 mix.<br />

36<br />

Automotodrom Brno circuit: <strong>VÖGELE</strong><br />

pavers restore <strong>the</strong> motorcycle circuit‘s<br />

speed and grip.

<strong>VÖGELE</strong> Make <strong>the</strong> Grade<br />

The construction of racetracks is subject to <strong>the</strong> most stringent demands ever made on<br />

asphalt paving, machine technology and paving teams. Be it <strong>the</strong> evenness, skid<br />

resistance or resistance to de<strong>for</strong>mation, maximum precision is called <strong>for</strong> on high-speed<br />

circuits. Consequently, <strong>VÖGELE</strong> are proud to have occupied <strong>the</strong> pole position <strong>for</strong><br />

decades now when it comes to paving <strong>the</strong> way <strong>for</strong> motor sports all over <strong>the</strong> world.<br />

In this edition, <strong>RoadNews</strong> reports on two such projects. One story covers <strong>the</strong><br />

rehabilitation of <strong>the</strong> Automotodrom Brno circuit in <strong>the</strong> Czech Republic, ano<strong>the</strong>r <strong>the</strong> use<br />

of SUPER pavers in Singapore. The latter involves construction of a particularly<br />

spectacular Grand Prix circuit: <strong>the</strong> first ever Formula 1 race to be held in <strong>the</strong> island<br />

nation will take place on 28 September, 2008 on <strong>the</strong> city circuit. What‘s more, it will also<br />

be <strong>the</strong> first race in <strong>the</strong> history of Formula 1 racing to be held at night under floodlights.<br />

The Big MultiPlex Ski <strong>for</strong> grade and slope control is an innovative sensor system<br />

offered by <strong>VÖGELE</strong> <strong>for</strong> <strong>the</strong>ir pavers. The system really shows its strengths when<br />

long irregularities in <strong>the</strong> base have to be levelled out. <strong>RoadNews</strong> reports on <strong>the</strong><br />

use of a paver with two Big Multiplex Skis.<br />

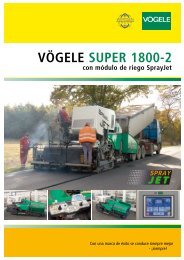

Two SUPER 1800-2 with SprayJet Module played a key role in <strong>the</strong> rehabilitation of a 4.5km<br />

stretch of Munich‘s A99 ring motorway. The two <strong>VÖGELE</strong> pavers placed a thin overlay<br />

on spray seal, hot on hot. The spray job went excellently, despite adverse conditions -<br />

<strong>the</strong> A99 is one of <strong>the</strong> busiest motorways in Germany.<br />

Two SUPER pavers completed a very special mission in Beijing. The volume of construction<br />

work in China is spectacular, and this not only refers to <strong>the</strong> projects associated with <strong>the</strong><br />

Olympic Games. <strong>RoadNews</strong> reports on a job in front of <strong>the</strong> Olympic Stadium,<br />

affectionately referred to by Beijing‘s residents as <strong>the</strong> “Bird‘s Nest”. Two SUPER 1800-2<br />

pavers rehabilitated a stretch of <strong>the</strong> 4th Ring Road, one of <strong>the</strong> Chinese capital‘s main<br />

traffic arteries.<br />

Enjoy reading.<br />

Roland Schug<br />

Marketing Director<br />

Imprint <strong>RoadNews</strong> <strong>for</strong> <strong>new</strong> <strong>roads</strong> <strong>–</strong> <strong>the</strong> <strong>VÖGELE</strong> <strong>Magazine</strong> on Paving Applications | Editorial Address: Neckarauer Straße 168 <strong>–</strong> 228, 68146 Mannheim,<br />

Germany, Telephone +49 (0) 621 8105-202, Fax +49 (0) 621 8105-469, E-Mail road<strong>new</strong>s@voegele.info, Website www.voegele.info | Editors:<br />

Roland Schug, Martin Hilken, Anja Sehr | Translations: Maria Weckesser | Agency: bilekjaeger, Stuttgart | Reproduction of articles<br />

is permitted after written consent. We disclaim liability <strong>for</strong> editorial submissions, which have not been requested. Trademarks and registered<br />

trademarks are <strong>the</strong> property of <strong>the</strong> owners.

India<br />

China<br />

4<br />

Mongolia<br />

Beijing<br />

Hong Kong<br />

CHINA<br />

Two SUPER 1800-2 pavers rehabilitate <strong>the</strong> city motorway in front of <strong>the</strong> “Bird’s Nest”.<br />

2008 Olympic Games:<br />

The 1,000 m Sprint<br />

of <strong>the</strong> <strong>VÖGELE</strong> Pavers<br />

In <strong>the</strong> run up to <strong>the</strong> 29th Olympic Games, <strong>the</strong> capital of China has made massive investments in its infrastructure.<br />

In addition to numerous <strong>new</strong> sports facilities <strong>for</strong> <strong>the</strong> 302 competitions in 28 different sporting disciplines, <strong>the</strong> investments<br />

also financed <strong>the</strong> rehabilitation of public <strong>roads</strong>. Equipment from <strong>the</strong> WIRTGEN Group was on <strong>the</strong> scene, too. A team of<br />

WIRTGEN cold milling machines, <strong>VÖGELE</strong> pavers and HAMM rollers resurfaced a stretch of <strong>the</strong> 4th Ring Road in <strong>the</strong><br />

immediate vicinity of <strong>the</strong> Beijing National Stadium, affectionately referred to by Beijing’s residents as <strong>the</strong> “Bird‘s Nest”.<br />

The special challenge <strong>for</strong> <strong>the</strong> two <strong>VÖGELE</strong> SUPER 1800-2 pavers was that <strong>the</strong>y had a time slot of just two nights to pave<br />

1,000m of wearing course in both directions.

During <strong>the</strong> Games, <strong>the</strong> “Bird's Nest” in <strong>the</strong> Chinese capital<br />

accommodated 91,000 spectators. After completion of <strong>the</strong><br />

Beijing National Stadium, a number of <strong>roads</strong> in <strong>the</strong> vicinity had<br />

to be rehabilitated <strong>for</strong> <strong>the</strong> Summer Olympic Games. Beijing<br />

Urban Construction Group Co., Ltd. (BUCG) was awarded <strong>the</strong><br />

contract to resurface a 1km long section of <strong>the</strong> 4th Ring Road,<br />

one of Beijing's main traffic arteries. However, what initially<br />

sounded like a relatively small contract presented <strong>the</strong> BUCG<br />

team with a complex challenge in terms of job site logistics.<br />

Work could only be carried out at night time, and even <strong>the</strong>n<br />

one lane in each direction had to be kept open to traffic. This was<br />

a crucial condition as heavy goods traffic can only drive into<br />

<strong>the</strong> inner rings of <strong>the</strong> Chinese capital during <strong>the</strong> night. Job sites<br />

on one of <strong>the</strong> immensely busy ring <strong>roads</strong> would threaten to<br />

cause mile-long traffic jams. The reason <strong>for</strong> this is that more<br />

than 3 million vehicles already use Beijing's <strong>roads</strong> and 1,000<br />

<strong>new</strong> vehicle registrations are made every single day.<br />

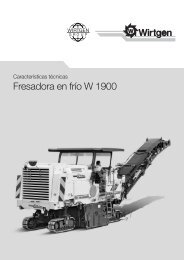

WIRTGEN cold milling machine removes<br />

6cm of asphalt layer<br />

After meticulous planning of <strong>the</strong> job site, <strong>the</strong> resurfacing<br />

work was started as usual with a cold milling machine that<br />

removed 6cm of <strong>the</strong> asphalt wearing course. This task was<br />

handled by a WIRTGEN W 1900 Cold Milling Machine with a<br />

working width of 2m. The W 1900 dumped a total of 4,200 tonnes<br />

of milled asphalt granulate onto a preceding truck. All told,<br />

6 to 7 passes were necessary in each direction in order<br />

to remove all of <strong>the</strong> damaged section of <strong>the</strong> 4th Ring Road.<br />

Night shift <strong>for</strong> <strong>the</strong> <strong>VÖGELE</strong> pavers<br />

Once <strong>the</strong> surface had been milled off, it was <strong>the</strong> turn of <strong>the</strong><br />

<strong>VÖGELE</strong> pavers. Two SUPER 1800-2 proved to be just <strong>the</strong> ticket<br />

<strong>for</strong> this task. Both pavers were equipped with AB 600-2 TV<br />

Extending Screeds featuring a basic pave width of 3m. The sturdy<br />

single-tube telescoping system of <strong>the</strong> screed allows infinite<br />

variation in width up to 6m. By mounting bolt-on extensions, a<br />

maximum width of 9.5m can be paved without joints. On <strong>the</strong><br />

job site in Beijing, two 0.75cm bolt-on extensions were fitted<br />

to each of <strong>the</strong> screeds building <strong>the</strong>m up to 7.5m. On <strong>the</strong> busy<br />

road, <strong>the</strong> pavers placed 6cm wearing course of stone mastic<br />

Job Site Data<br />

4th Ring Road<br />

2nd Ring Road<br />

3rd Ring Road<br />

Resurfacing work on <strong>the</strong> 4th Ring Road<br />

in Beijing, China<br />

Length of section: 1,000m<br />

Olympic Stadium<br />

Paving Details<br />

Pave width: 15m (2 strips of 7.5m each)<br />

Layer thickness: 6cm<br />

Paving Material<br />

Stone Mastic Asphalt (SMA)<br />

Equipment<br />

WIRTGEN W 1900 Cold Milling Machine<br />

2 SUPER 1800-2 with<br />

AB 600-2 TV Extending Screeds<br />

2 HAMM HD O120V Rollers<br />

asphalt (SMA). The paving work had to be completed in just<br />

two night shifts. Every delay, be it caused by bottlenecks in<br />

<strong>the</strong> mix logistics or <strong>the</strong> failure of a machine, would have had<br />

far-reaching consequences. There<strong>for</strong>e, <strong>the</strong> service engineers<br />

of WIRTGEN China were always on site to intervene in <strong>the</strong><br />

event of an emergency.<br />

5

6<br />

Beijing National Stadium:<br />

The “Bird’s Nest”<br />

Be<strong>for</strong>e <strong>the</strong> 29th Olympic Games could take place in<br />

Beijing this summer, <strong>the</strong> People‘s Republic of China<br />

undertook enormous ef<strong>for</strong>ts to modernize its infrastructure<br />

and sports facilities, as well as building <strong>new</strong><br />

ones. The Games were declared open in <strong>the</strong> evening<br />

of August 08, at precisely 8 minutes and 8 seconds<br />

past 8 o‘clock. The number eight is considered a lucky<br />

number in China.<br />

The heart of <strong>the</strong> venue is without doubt <strong>the</strong> “Bird‘s Nest”,<br />

as <strong>the</strong> Olympic stadium is known. The unique structure<br />

was designed by Swiss starchitects Jacques Herzog<br />

and Pierre de Meuron. A total of 45,000 tonnes of steel<br />

was needed to build <strong>the</strong> 330m long, 220m wide and<br />

70m high “Bird‘s Nest”. During <strong>the</strong> Games, <strong>the</strong> stadium<br />

accommodated 91,000 spectators.

The 4th Ring Road, one of Beijing‘s<br />

busiest traffic arteries.<br />

Beijing amazed at low noise emission<br />

8<br />

The SUPER 1800-2's ECO Mode ensures low noise levels<br />

during operation. The 129.6kW engine installed in <strong>the</strong> powerful<br />

paver runs particularly quietly in this mode, saves fuel and<br />

stands out through low exhaust emission. As on many o<strong>the</strong>r<br />

job sites, <strong>the</strong> ECO Mode supplied more than enough power <strong>for</strong><br />

<strong>the</strong> inner-city contract.<br />

SUPER 1800-2 proves a success in China<br />

As one of <strong>the</strong> most compact and powerful tracked pavers<br />

in its class, <strong>the</strong> SUPER 1800-2 handles an impressive variety<br />

of applications. Indeed, <strong>the</strong> all-rounder is a very successful<br />

per<strong>for</strong>mer in China. The machine is particularly popular with<br />

users due to its ease of operation and com<strong>for</strong>t. With ErgoPlus ®,<br />

<strong>the</strong> concept <strong>for</strong> intuitive paver handling, <strong>the</strong> “dash 2” generation<br />

<strong>VÖGELE</strong> pavers have set a <strong>new</strong> standard. ErgoPlus ® includes<br />

a modern workplace with an operator's seat that can be swung<br />

out to <strong>the</strong> sides toge<strong>the</strong>r with <strong>the</strong> operating console, on which<br />

controls are arranged in logical groups. The operator has an<br />

unimpeded view of <strong>the</strong> material hopper, <strong>the</strong> screed and all o<strong>the</strong>r<br />

key points of <strong>the</strong> paver. These are just some of <strong>the</strong> features<br />

rendering paving as convenient and efficient as possible.<br />

HAMM tandem rollers <strong>for</strong> final compaction<br />

Two HAMM HD O120V rollers were used <strong>for</strong> subsequent<br />

final compaction of <strong>the</strong> <strong>new</strong> wearing course on <strong>the</strong> 4th Ring<br />

Road. These machines operate with both vibration and<br />

oscillation. Thanks to <strong>the</strong> combination of <strong>the</strong> two technologies,<br />

<strong>the</strong> stone mastic asphalt requiring a high compactive ef<strong>for</strong>t<br />

was easily trans<strong>for</strong>med into a pavement of lasting, high<br />

load-carrying density.

Close to our customers <strong>the</strong> world over<br />

The reason why machines from three WIRTGEN Group<br />

members were used in Beijing was due not only to <strong>the</strong><br />

innovative machine technology. “The overall package offered<br />

by WIRTGEN China was very impressive,” explains Mr. Luo,<br />

Deputy General Director of BUCG. “With <strong>the</strong> service centre in<br />

Langfang, not far away from Beijing, <strong>the</strong> WIRTGEN Group is<br />

always close at hand.” True to <strong>the</strong>ir motto “Close to our<br />

customers”, <strong>the</strong> WIRTGEN Group provides in China, too, a 24-hour<br />

on-site service. “We don't usually have to call, but knowing<br />

<strong>the</strong>y are around gives us peace of mind. On <strong>the</strong> job site in<br />

Beijing, nothing was to go wrong. There<strong>for</strong>e, WIRTGEN<br />

immediately delegated <strong>the</strong>ir service engineers who provided<br />

us with <strong>the</strong>ir expert advice. It's things like this that make<br />

WIRTGEN China a true partner <strong>for</strong> us.” ,<br />

Photo above:<br />

Perfectly organized job site logistics.<br />

The two SUPER 1800-2 paved “hot to hot”.<br />

SUPER 1800-2: Facts and Figures<br />

n Maximum pave width 10m<br />

n Laydown rate up to 700 tonnes/h<br />

n Maximum layer thickness 30cm<br />

n Transport width 2.55m<br />

n Pave speed up to 24m/min.<br />

n Travel speed up to 4.5km/h<br />

n PERKINS engine rated at 129.6kW<br />

n ErgoPlus ® operating concept<br />

9

France<br />

10<br />

Germany<br />

Munich<br />

Berlin<br />

Austria<br />

Poland<br />

GERMANy<br />

Two SUPER 1800-2 with SprayJet Module rehabilitate one of Germany‘s<br />

busiest motorways.<br />

Clear <strong>the</strong> Ring<br />

on <strong>the</strong> A99<br />

In <strong>the</strong> years to come, <strong>the</strong> focus of roadworks in Western Europe will increasingly shift from construction of <strong>new</strong> <strong>roads</strong><br />

to rehabilitating <strong>the</strong> existing ones. In Germany alone, a network of asphalt <strong>roads</strong> spanning more than 60,000km has to<br />

be maintained or repaired. In this context it is only logical that both contract-letting authorities and contractors are more<br />

and more looking <strong>for</strong> cost-effective alternatives when it comes to pavement rehabilitation. One such example was<br />

Munich‘s A99 ring motorway. German contractor Stratebau was awarded <strong>the</strong> pavement preservation contract <strong>for</strong> a<br />

4.5km stretch of <strong>the</strong> busy motorway. They paved a thin overlay on spray seal, hot on hot.

Paving thin overlay on spray seal, hot on hot:<br />

The two SUPER 1800-2 with SprayJet Module per<strong>for</strong>med excellently.<br />

11

Paving thin overlays on spray seal, hot on hot, is a<br />

cost-effective method <strong>for</strong> rehabilitating wearing courses and<br />

restoring a pavement’s skid resistance. The process is<br />

appropriate <strong>for</strong> all classified <strong>roads</strong>, especially highly trafficked<br />

ones, such as <strong>the</strong> A99. High initial and long-term skid<br />

resistance, less water spray on <strong>the</strong> road when wet with rain<br />

and reduced rolling noise generated by vehicles are just a few<br />

advantages offered by this method.<br />

Ideal <strong>for</strong> paving thin overlays: SUPER 1800-2<br />

with SprayJet Module<br />

Paving thin asphalt surfacings on spray seal hot on hot,<br />

however, requires special machine technology. Here <strong>the</strong><br />

<strong>VÖGELE</strong> SUPER 1800-2 with SprayJet Module is <strong>the</strong> solution,<br />

as this role suits it to a tee. The paver allows <strong>the</strong> old pavement<br />

to be sprayed with bitumen emulsion and <strong>new</strong> wearing course<br />

to be paved in a single pass. As a result, vehicles never pass over<br />

<strong>the</strong> fresh emulsion, as <strong>the</strong> emulsion film is immediately covered<br />

with asphalt. This provides <strong>for</strong> a perfect tack coat and a<br />

perfect bond of layers. The SprayJet concept is based on a<br />

SUPER 1800-2 of standard design which, after just a few<br />

The spray nozzles of double-slotted design provide<br />

<strong>for</strong> uni<strong>for</strong>m spreading of emulsion.<br />

12<br />

modifications and in combination with a <strong>new</strong>ly developed<br />

spray module, can be used as a spray paver. The idea behind<br />

<strong>the</strong> concept is a double use of <strong>the</strong> machine. Within a very short<br />

time, <strong>the</strong> machine can be converted back into a paver of<br />

standard design, so that to contractors it is available <strong>for</strong> spray<br />

jobs and conventional paving jobs alike.<br />

Small rates of spread, no <strong>for</strong>mation of spray mist<br />

But beyond that, <strong>the</strong> <strong>VÖGELE</strong> SprayJet Technology offers<br />

o<strong>the</strong>r benefits. It, <strong>for</strong> instance, allows to select a rate of spread<br />

ranging from a very small quantity of 0.2kg/m² to a large<br />

volume of 1.5kg/m², at pave speeds from 2 to 20m/min. As a<br />

result, bitumen emulsion can be metered very precisely and<br />

sprayed in small quantities at low operating speeds. As in <strong>the</strong><br />

system a constant spraying pressure of no more than 3 bar<br />

prevails, <strong>the</strong> <strong>for</strong>mation of spray mist and pollution are reduced<br />

to an absolute minimum. Similar results are not possible with<br />

previous systems. Thus, <strong>the</strong> SprayJet concept is a trailblazing<br />

innovation in terms of both economy and eco-friendliness.<br />

No doubt, <strong>the</strong>re<strong>for</strong>e, that <strong>the</strong> SUPER 1800-2 with SprayJet Module<br />

was just <strong>the</strong> right candidate <strong>for</strong> <strong>the</strong> A99 rehabilitation scheme.<br />

The spray paver, like all “dash 2” SUPER pavers,<br />

is operated from <strong>the</strong> ErgoPlus ® console.

14<br />

Job Site Details<br />

Pavement rehabilitation on <strong>the</strong> A99 ring<br />

motorway between München-Feldmoching<br />

and Allach junctions, Germany<br />

Method applied: thin overlay placed<br />

Length of section: 4.5km<br />

on spray seal, hot on hot<br />

Paving Details<br />

Pave width: 8m (2 strips of 4m each)<br />

Layer thickness: 1.5cm<br />

Pave speed: 6 - 8m/min.<br />

Quantities Paved<br />

2,500 tonnes of mix (0/5) <strong>for</strong> thin overlay<br />

500 tonnes of mix (0/5), white, <strong>for</strong> thin overlay<br />

Emulsion Spread Rates<br />

0.8kg/m² on binder course<br />

0.45kg/m² on concrete in <strong>the</strong> tunnel<br />

(a total of some 55 tonnes)<br />

Equipment<br />

2 SUPER 1800-2 with SprayJet Module<br />

and AB 500-2 TV Extending Screed<br />

HAMM DV 70 Roller<br />

Full steam ahead <strong>for</strong> <strong>the</strong> ring motorway<br />

In order to keep <strong>the</strong> roadworks as short as possible on <strong>the</strong><br />

very busy section of <strong>the</strong> A99 motorway between München<br />

Feldmoching and Allach junctions, a seven-day working week<br />

was scheduled <strong>for</strong> <strong>the</strong> job. Paving inside <strong>the</strong> 960m long Allach<br />

Tunnel could only be carried out at night between 10 p.m. and<br />

5 a.m., so that <strong>the</strong> tunnel remained open to traffic during <strong>the</strong><br />

daytime. The thin 1.5cm overlay proved especially useful here,<br />

as it cooled much faster than layers of conventional thickness<br />

and could quickly carry traffic.<br />

Two SUPER 1800-2 with SprayJet Module<br />

working in echelon<br />

Stratebau’s paving team organized perfect job site logistics<br />

and left nothing to chance. On account of <strong>the</strong> tight schedule,<br />

two SUPER 1800-2 pavers with SprayJet Module moved<br />

onto <strong>the</strong> site. They worked in echelon and paved <strong>the</strong> two<br />

stips, each 4m wide, hot to hot. On this job, bitumen emulsion<br />

was spread at a rate of 0.8kg/m². The quantity of emulsion<br />

required to be applied depends on <strong>the</strong> nature of <strong>the</strong> base.<br />

On open-textured bases, some 0.7 to 0.9kg/m² need to be<br />

sprayed, whereas on close-textured bases 0.4 to 0.6kg/m² are<br />

sufficient.<br />

Inside <strong>the</strong> Allach Tunnel, where asphalt was laid on concrete<br />

featuring a close-textured surface, 0.45kg of tack coat per<br />

square metre was enough. On <strong>the</strong> whole, some 55 tonnes of<br />

bitumen emulsion were sprayed on <strong>the</strong> 4.5km stretch of <strong>the</strong><br />

ring motorway.<br />

Paving white asphalt in <strong>the</strong> Allach Tunnel<br />

Asphalt paving inside <strong>the</strong> Allach Tunnel was <strong>for</strong> a couple of<br />

reasons different from paving as usual. In order to enhance <strong>the</strong><br />

lighting conditions in <strong>the</strong> tunnel tube, a white coloured asphalt<br />

overlay was paved. This meant that strict attention had to be<br />

paid to absolute cleanliness, as residues from black asphalt<br />

would have immediately soiled <strong>the</strong> thin wearing course.<br />

Ano<strong>the</strong>r circumstance rendering work in <strong>the</strong> tunnel a bit special<br />

was <strong>the</strong> limited height. The low ceiling allowed only short

2-axle feed vehicles to be used <strong>for</strong> material supply. These were<br />

busy working all <strong>the</strong> time to feed <strong>the</strong> pavers with mix and keep<br />

<strong>the</strong> ball rolling. Yet even under <strong>the</strong>se special circumstances,<br />

<strong>the</strong> two SUPER 1800-2 with SprayJet Module worked smoothly<br />

and reliably, so that <strong>the</strong> tunnel could be opened to traffic on<br />

time at 5 a.m. every morning.<br />

“The job went like clockwork”<br />

Contractor Stratebau was very satisfied with <strong>the</strong> job on <strong>the</strong><br />

A99 motorway. The company had taken delivery of <strong>the</strong> two<br />

SUPER 1800-2 with SprayJet Module just a short time be<strong>for</strong>e<br />

<strong>the</strong> job started and no more than three days were left <strong>for</strong> <strong>the</strong><br />

paving team to get to grips with <strong>the</strong> <strong>new</strong> machines.<br />

“Never<strong>the</strong>less, <strong>the</strong> job went like clockwork,” sums up<br />

Operations Manager Hanns Benkert. “The job could be<br />

completed exactly as scheduled after five days and two<br />

nights. And it was easy to adhere to <strong>the</strong> specified surface<br />

accuracy with a maximum admissible tolerance of 4mm over<br />

4m in <strong>the</strong> transverse direction.” ,<br />

The paver operator’s seat swivels out to <strong>the</strong> side toge<strong>the</strong>r with <strong>the</strong> ErgoPlus ® console <strong>for</strong> good visibility.<br />

15

New Options <strong>for</strong> <strong>the</strong> SprayJet Module:<br />

Since its launch into <strong>the</strong> market over a year ago, <strong>the</strong> SUPER 1800-2 with<br />

SprayJet Module in its standard version <strong>for</strong> pave widths up to 5m and equipped<br />

with an emulsion tank holding 2,000 litres has per<strong>for</strong>med excellently in many<br />

countries. Now an extra emulsion tank is available as an option <strong>for</strong> contracts<br />

requiring very large rates of spread. The extra tank holds 5,000 litres, so that a total<br />

of 7,000 litres of bitumen emulsion can be carried on board <strong>the</strong> paver. The extra<br />

tank is accommodated in <strong>the</strong> paver’s material hopper.<br />

On such applications, supply of <strong>the</strong> paver with mix is by <strong>the</strong> MT 1000-1 Mobile<br />

Feeder transferring <strong>the</strong> material, via a receiving bin in <strong>the</strong> extra tank, right onto <strong>the</strong><br />

paver’s conveyors. A stand-alone heating unit operated by diesel fuel and featuring<br />

a heating capacity of 30kW is installed in <strong>the</strong> extra tank, thus keeping <strong>the</strong> emulsion<br />

at <strong>the</strong> desired temperature. Fur<strong>the</strong>rmore, <strong>the</strong> extra tank comes with its own pump<br />

circulating <strong>the</strong> emulsion and maintaining it in a highly homogeneous state. If <strong>the</strong><br />

emulsion level in <strong>the</strong> standard tank drops below 1,000 litres, emulsion is<br />

automatically delivered from <strong>the</strong> extra tank into <strong>the</strong> standard tank.<br />

Also <strong>new</strong> <strong>for</strong> <strong>the</strong> SUPER 1800-2 with SprayJet Module are spray bars <strong>for</strong> pave<br />

widths up to 6m as ano<strong>the</strong>r option. For 6-metre applications, <strong>the</strong> lateral spray bars<br />

are longer and fitted with two additional spray nozzles, so that a total of 24 nozzles<br />

is equipped <strong>for</strong> spraying. Combined with a <strong>VÖGELE</strong> AB 600-2 Extending Screed or<br />

an AB 500-2 with bolt-on extensions, <strong>the</strong> spray paver is capable of easily<br />

handling pave widths up to 6m.<br />

These two options open up to contractors an even wider field of applications. Now<br />

<strong>the</strong> SUPER 1800-2 with SprayJet Module, combined with <strong>the</strong> 2,000-litre emulsion<br />

tank, can be used <strong>for</strong> pave widths up to 5m or 6m. If larger rates need to be spread,<br />

<strong>the</strong> extra emulsion tank allows a total of 7,000 litres to be stored. This configuration,<br />

too, is available <strong>for</strong> pave widths up to 5m or 6m.<br />

The SUPER 1800-2 with SprayJet Module covers a wide spectrum of paving tasks.<br />

It com<strong>for</strong>tably handles minor contracts <strong>for</strong> thin overlays in residential areas where<br />

spaces often are confined. Beyond that, also major jobs requiring larger rates of<br />

tack coat to be spread can be carried out with <strong>the</strong> innovative <strong>VÖGELE</strong> SprayJet<br />

system in an efficient, clean and highly economical way.<br />

16<br />

1<br />

Level indicator <strong>for</strong> <strong>the</strong> extra emulsion<br />

tank holding 5,000 litres.<br />

3

Greater Volume, Larger Pave Width<br />

2<br />

Receiving bin in <strong>the</strong> emulsion tank <strong>for</strong> supply<br />

of <strong>the</strong> paver with mix from a Mobile Feeder.<br />

Large spray bar <strong>for</strong> pave widths<br />

up to 6m.<br />

1<br />

2<br />

4<br />

3 4<br />

Pump to deliver emulsion into<br />

<strong>the</strong> standard tank.<br />

17

France<br />

18<br />

Germany<br />

Berlin<br />

Böttingen<br />

Dürbheim<br />

Austria<br />

Poland<br />

GERMANy<br />

SUPER 1900-2 with two Big MultiPlex Skis:<br />

User-friendly handling, high surface accuracy.

SUPER 1900-2 builds rural road without tensioned wires.<br />

Easy and Accurate: Grade and Slope Control<br />

with 2 Big MultiPlex Skis<br />

How to build a road true to line and level without an existing reference ? The Big MultiPlex Ski, <strong>VÖGELE</strong>’s sensor system<br />

<strong>for</strong> grade and slope control, was fitted to a SUPER 1900-2 and helped German contractor Leonhard Weiss achieve a<br />

perfect paving result when rehabilitating a rural road in <strong>the</strong> Swabian Alb region in Germany.<br />

On account of road damage and an increase in traffic<br />

volume, a 2km stretch of <strong>the</strong> L438 rural road between<br />

Böttingen and Dürbheim in Baden-Wurttemberg needed<br />

rehabilitating and widening.<br />

Placing <strong>the</strong> base course had already begun last year.<br />

The roadworks, however, could not be brought to a close<br />

due to bad wea<strong>the</strong>r and <strong>the</strong> pavement, though not<br />

completed, was opened to traffic <strong>for</strong> <strong>the</strong> winter. In <strong>the</strong><br />

spring of <strong>the</strong> following year, <strong>the</strong> base was in a poor<br />

condition as expected, spread with cracks, rutting and<br />

potholes. The Regional Authorities of Freiburg, letting <strong>the</strong><br />

road rehabilitation contract, saw no o<strong>the</strong>r choice than to<br />

mill off parts of <strong>the</strong> base course and start from scratch.<br />

The Regional Authority preferred working with tensioned<br />

wires, as no reference such as kerbstones or <strong>the</strong> like<br />

existed along <strong>the</strong> roadway.<br />

SUPER 1900-2: Facts and Figures<br />

n Maximum pave width 11m<br />

n Laydown rate up to 900 tonnes/h<br />

n Maximum layer thickness 30cm<br />

n Transport width 2.55m<br />

n Pave speed up to 25m/min.<br />

n Travel speed up to 4.5km/h<br />

n PERKINS engine rated at 142kW<br />

n ErgoPlus ® operating concept<br />

But thanks to an alternative, <strong>the</strong>re was no need to carry<br />

out time-consuming surveying and preparation of <strong>the</strong><br />

job site as would have been necessary <strong>for</strong> grade and<br />

slope control with tensioned wires. The paving team of<br />

contractor Leonhard Weiss moved onto <strong>the</strong> job site with<br />

<strong>the</strong>ir SUPER 1900-2 fitted with two Big Multiplex Skis.<br />

They carried out grade and slope control without a<br />

reference. During paving, <strong>the</strong> result was constantly<br />

monitored and checked by <strong>the</strong> Regional Authorities of<br />

Freiburg. According to <strong>the</strong> specification, <strong>the</strong> tolerance<br />

admitted <strong>for</strong> evenness in <strong>the</strong> longitudinal direction<br />

was 4mm over a distance of 4 metres. Thanks to<br />

NIVELTRONIC Plus ®, <strong>the</strong> System <strong>for</strong> Automated Grade<br />

and Slope Control installed in SUPER pavers, <strong>the</strong> finished<br />

pavement fully complied with <strong>the</strong> specified requirements.<br />

Paving without tensioned wires saves costs<br />

The successful outcome of <strong>the</strong> project proved that<br />

contractor Leonhard Weiss’ decision was right: working with<br />

two Big MultiPlex Skis instead of tensioned wires was <strong>the</strong><br />

clue. All so more so with regard to pave width. For working with<br />

a tensioned wire installed on one side only, <strong>the</strong> recommended<br />

pave width is confined to 6.5m. O<strong>the</strong>rwise, <strong>the</strong> specified<br />

evenness on <strong>the</strong> side controlled with <strong>the</strong> slope sensor cannot<br />

be guaranteed. On this contract, however, <strong>the</strong> width of <strong>the</strong><br />

carriageway varied between 6.5m and 8m.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> L438 is a winding road featuring a varying<br />

crossfall. On jobs like this it is almost impossible to achieve<br />

a perfect surface accuracy with just one reference wire.<br />

19

Job Site Details<br />

Rehabilitation of <strong>the</strong> L438 rural road between Böttingen<br />

and Dürbheim in Baden-Wurttemberg, Germany<br />

Length of section: 2km<br />

Paving Details<br />

Pave width: 6.5m <strong>–</strong> 8m<br />

Layer thickness: Base course: 12cm<br />

Binder course: 6cm<br />

Wearing course: 4cm<br />

Paving Material<br />

Base course: Asphalt base (0/32 CS)<br />

Binder course: Asphalt binder (0/16)<br />

Wearing course: Asphaltic concrete (0/11)<br />

Quantities Paved<br />

Crushed-stone base: 16,000t<br />

Asphalt base course: 4,100t<br />

Asphalt binder course: 2,050t<br />

Asphalt wearing course: 1,400t<br />

Equipment<br />

SUPER 1900-2 with AB 500-2 TV Extending Screed<br />

and 2 Big MultiPlex Skis<br />

When considering <strong>the</strong> material and time required <strong>for</strong> surveying<br />

and installing two wires, considerable costs incur. Based on an<br />

estimated expense of some 1,750 Euros per linear metre of<br />

tensioned wire, an extra charge of some 7,000 Euros would<br />

have accrued <strong>for</strong> this job site.<br />

Mounts and operates very easily<br />

20<br />

Mounting <strong>the</strong> Big MultiPlex Skis is simplicity itself. With<br />

<strong>the</strong> beam made up of several 2-metre elements, <strong>the</strong> system<br />

can be fitted quickly by just one person. Attaching <strong>the</strong><br />

Big MultiPlex Ski to <strong>the</strong> screed arm offered a great advantage<br />

over attachment to <strong>the</strong> screed’s end plate. In this position, <strong>the</strong><br />

sensors scanned <strong>the</strong> base and level-regulating layer within<br />

<strong>the</strong> screed’s pave width and not <strong>the</strong> strip of crushed stone<br />

at <strong>the</strong> <strong>roads</strong>ide. This gradually improved <strong>the</strong> evenness from<br />

layer to layer. On <strong>the</strong> job site in Baden-Wurttemberg, <strong>the</strong><br />

Big MultiPlex Skis covered a distance of 11 metres each.<br />

Thanks to <strong>the</strong> pivoted brackets, <strong>the</strong> Big MultiPlex Ski can be<br />

swung outwards within <strong>the</strong> range of one metre. The individual<br />

sensors are displaceable on <strong>the</strong> beam <strong>for</strong> optimal adjustment<br />

to job site conditions.<br />

<strong>VÖGELE</strong> developed <strong>the</strong> Big MultiPlex Ski also with its<br />

practical handling in mind. The Big MultiPlex Ski comes with<br />

a simple design and its operation is easy. Control of <strong>the</strong><br />

Ski is from <strong>the</strong> ErgoPlus ® screed console into which<br />

NIVELTRONIC ® Plus, <strong>the</strong> <strong>VÖGELE</strong> System <strong>for</strong> Automated<br />

Grade and Slope Control, is fully integrated. The team from<br />

Leonhard Weiss was enthusiastic about <strong>the</strong> combination of<br />

<strong>the</strong>ir SUPER 1900-2 and <strong>the</strong> Big MultiPlex Skis. “Paving is<br />

child’s play thanks to <strong>the</strong> user-friendly ErgoPlus ® operating<br />

concept,” said <strong>for</strong>eman Reinhold Schopf, and he adds: “We<br />

were much impressed not only by <strong>the</strong> machine’s com<strong>for</strong>table<br />

operation, but also by <strong>the</strong> outstanding paving results.“<br />

The Big MultiPlex Ski levels out irregularities<br />

The Big MultiPlex Ski is suited <strong>for</strong> <strong>the</strong> most varied<br />

applications. The system is ideal <strong>for</strong> jobs on which long<br />

irregularities in <strong>the</strong> base need to be levelled out. This is achieved<br />

by 3 sonic grade sensors and a mean value calculated from<br />

<strong>the</strong>ir measurements. A single sensor would not be capable of<br />

detecting a long irregularity as a fault. And this was exactly <strong>the</strong><br />

feature required on <strong>the</strong> job site in Baden-Wurttemberg.<br />

Especially when paving binder course it was necessary to level<br />

out any remaining irregularities in <strong>the</strong> previously placed base<br />

and level-regulating layers, in order to achieve a surface course<br />

of absolute evenness, true to line and level.<br />

Feel <strong>the</strong> evenness<br />

The SUPER 1900-2 was combined with an AB 500-2 TV<br />

Extending Screed equipped with tamper and vibrators that<br />

provided <strong>for</strong> excellent pre-compaction. The achieved evenness<br />

was superb. “I could even feel it from my seat,” said Sahim<br />

Yldirim, a roller operator from Leonhard Weiss’ team. ,

Foreman Reinhold Schopf calibrates <strong>the</strong> sonic sensors<br />

of <strong>the</strong> Big MultiPlex Ski on <strong>the</strong> control panel.<br />

Like all sonic sensors, <strong>the</strong> Big MultiPlex Ski is suited <strong>for</strong> <strong>the</strong><br />

most varied applications. The operating height of <strong>the</strong> sensor<br />

is variable between 200 and 650mm.<br />

21

The Big MultiPlex Ski translates <strong>the</strong> advantages of <strong>the</strong><br />

proven <strong>VÖGELE</strong> sonic grade sensor onto a greater length.<br />

A range up to 13 metres can be covered. Thus, even<br />

long irregularities in <strong>the</strong> base can easily be levelled out.<br />

22<br />

Highlights of <strong>the</strong> Big MultiPlex Ski,<br />

<strong>the</strong> sensor system <strong>for</strong> grade and slope control<br />

n Comprises 3 sonic grade sensors provided<br />

with 5 sensing cells each. Sensors are<br />

attached to a telescopic beam.<br />

n Out of <strong>the</strong> sensing cells’ 5 measurements,<br />

an average is calculated from <strong>the</strong> 3 best<br />

ones. This serves to filter out large<br />

obstacles and minor irregularities.<br />

n Non-contacting operation. Sensors<br />

can be set to a variable height between<br />

200 and 650mm.<br />

n Ideally suited <strong>for</strong> levelling out long<br />

irregularities in <strong>the</strong> base.<br />

n Ski length variable between 6.5 and 13.5m.<br />

n Suited <strong>for</strong> <strong>the</strong> most varied applications,<br />

also on curved sections.<br />

n Easy operation.<br />

n Mounts easily and quickly to ei<strong>the</strong>r <strong>the</strong><br />

screed arm or <strong>the</strong> screed’s end plate.

08<br />

Tips and Tricks from pracTical applicaTions<br />

How to Avoid Segregation<br />

The target pursued by all road building contractors<br />

is to construct high-quality pavements. A crucial<br />

requirement <strong>for</strong> high paving quality is a homogeneous<br />

mix. In this issue of Tips and Tricks, we want to explain<br />

how to effectively avoid mix segregation and what<br />

to do if, <strong>for</strong> some reason or o<strong>the</strong>r, segregation should<br />

once occur.<br />

andré felchner, Head of applications Technology at VÖGElE, Germany, provides “Tips & Tricks from practical<br />

applications”. He is an expert in both practical applications and paver technology and conveys his knowledge<br />

also in VÖGElE training courses and workshops to paving teams from all over <strong>the</strong> world.<br />

When paving asphalt, segregation is an often encountered<br />

problem. The reasons <strong>the</strong>re<strong>for</strong> are manifold. Mixes<br />

featuring large differences in aggregate size and, at<br />

<strong>the</strong> same time, a low binder content are particularly<br />

susceptible to segregation. The binder can be easily<br />

stripped off <strong>the</strong> stone. In order to be able to pave<br />

<strong>the</strong>se delicate mixes, too, to a high standard of<br />

quality, a number of design features have been<br />

installed in <strong>VÖGELE</strong> pavers to minimize <strong>the</strong> risk of<br />

segregation.<br />

But what can we do if segregation already occurs<br />

in an early stage, when loading <strong>the</strong> mix at <strong>the</strong> mixing<br />

plant into <strong>the</strong> feed vehicle or when dumping <strong>the</strong> mix<br />

into <strong>the</strong> paver’s material hopper? What to do when<br />

signs of segregated mix suddenly appear while<br />

paving? In <strong>the</strong> following, we show four examples<br />

and describe how segregation can be effectively<br />

counteracted.

08<br />

Tips and Tricks from pracTical applicaTions<br />

What to do if segregation occurs while paving ?<br />

Example 1 Example 2<br />

<strong>for</strong>mation of Transverse strips strips in <strong>the</strong> middle of <strong>the</strong> pavement<br />

Strips of segregated mix appear in <strong>the</strong> pavement<br />

at right angles to <strong>the</strong> direction of travel when feed<br />

lorries change.<br />

cause<br />

Use of a mix with large differences in aggregate<br />

size and, at <strong>the</strong> same time, a low binder content.<br />

These mixes are usually susceptible to segregation.<br />

Segregation is fur<strong>the</strong>r promoted by frequently<br />

folding <strong>the</strong> hopper sides in or out when <strong>the</strong><br />

material hopper is almost empty.<br />

remedy<br />

n See to it that <strong>the</strong> material hopper is always<br />

well filled. Watch <strong>the</strong> mix level indicated on<br />

<strong>the</strong> display of <strong>the</strong> ErgoPlus ® operating console.<br />

n See to a sufficient supply with mix at all<br />

times, so that <strong>the</strong> need to fold hopper<br />

sides in or out is reduced to a minimum.<br />

A porous or rough strip of segregated material<br />

appears in <strong>the</strong> middle of <strong>the</strong> pavement.<br />

cause<br />

The head of mix in front of <strong>the</strong> screed is too low.<br />

remedy<br />

n Increase <strong>the</strong> clearance between <strong>the</strong> centre<br />

auger box and <strong>the</strong> tamper shield.<br />

Change position of screed Larger auger tunnel<br />

n Adjust <strong>the</strong> augers in height. As a general rule<br />

applies: <strong>the</strong> auger blades should be set some<br />

4cm higher than <strong>the</strong> lower edge of <strong>the</strong> screed.<br />

n Turn one or two auger blades in <strong>the</strong> area of <strong>the</strong><br />

centre auger box round to convey mix inwards.

Tips and Tricks from pracTical applicaTions<br />

Example 3 Example 4<br />

08<br />

strips in <strong>the</strong> lateral areas patches of mix in <strong>the</strong> surface Texture<br />

When paving large widths, strips of segregated mix<br />

appear in <strong>the</strong> lateral areas of <strong>the</strong> pavement.<br />

cause<br />

No uni<strong>for</strong>m head of mix in front of <strong>the</strong> screed<br />

across <strong>the</strong> pave width.<br />

remedy<br />

n Fit limiting plates <strong>for</strong> <strong>the</strong> auger tunnel and<br />

deflector plates across <strong>the</strong> full pave width.<br />

n Fit mix level sensors <strong>for</strong> <strong>the</strong> augers to <strong>the</strong><br />

end plates of <strong>the</strong> screed.<br />

n Check <strong>the</strong> mix level sensors <strong>for</strong> correct<br />

set-up and optimize settings, if necessary.<br />

Paddle-type<br />

Sensor<br />

Conveying Direction<br />

Sonic<br />

Sensor<br />

Patches sporadically appear in <strong>the</strong> surface texture<br />

while paving. The surface is smoo<strong>the</strong>r or smeared<br />

with bitumen.<br />

cause<br />

Mainly fine grains with a high bitumen content,<br />

such as residues from <strong>the</strong> mixing plant, are<br />

delivered to <strong>the</strong> job site with <strong>the</strong> mix. Or <strong>the</strong><br />

screed is not sufficiently heated.<br />

remedy<br />

n Check screed heating <strong>for</strong> proper function.<br />

n Clean tractor and screed and check <strong>the</strong> tamper<br />

shield <strong>for</strong> correct set-up.<br />

n In<strong>for</strong>m <strong>the</strong> mixing plant operator of <strong>the</strong> residues.<br />

n Reduce <strong>the</strong> tamper speed.

Tips and Tricks from pracTical applicaTions<br />

An Optimal Material Flow Prevents Segregation<br />

As already mentioned, a number of features are installed<br />

in <strong>VÖGELE</strong> pavers which help keep <strong>the</strong> paving material<br />

No Residues of Mix<br />

in <strong>the</strong> Material Hopper<br />

Due to <strong>the</strong> material hopper’s sloped inner design, no<br />

residues of mix accumulate in <strong>the</strong> lateral areas. A hydraulic<br />

hopper front, available as an option, provides that <strong>the</strong><br />

mix, once dumped into <strong>the</strong> material hopper by <strong>the</strong> feed<br />

vehicle, is directed right onto <strong>the</strong> conveyors. Toge<strong>the</strong>r<br />

with <strong>the</strong> sloped inner design of <strong>the</strong> hopper, <strong>the</strong> hydraulic<br />

hopper front creates optimal conditions <strong>for</strong> a consistent<br />

flow of mix and a constant mix quality.<br />

08<br />

in a highly homogeneous state on its way through <strong>the</strong><br />

paver, from <strong>the</strong> material hopper to <strong>the</strong> screed.<br />

Conveying Direction Paddle-type Sensor<br />

Smooth Transfer of Mix<br />

to <strong>the</strong> Augers<br />

To ensure that <strong>the</strong> paving material is transferred from <strong>the</strong><br />

conveyors to <strong>the</strong> augers as smoothly as possible, <strong>the</strong><br />

conveyors rise towards <strong>the</strong> rear. As a result, <strong>the</strong> mix is<br />

dumped onto <strong>the</strong> augers instead of being pressed into<br />

<strong>the</strong>m. In addition, an extremely narrow centre auger<br />

box along with large auger blades provide <strong>for</strong> smooth<br />

transverse spreading of <strong>the</strong> paving material in front of<br />

<strong>the</strong> screed.

<strong>VÖGELE</strong> pavers fulfil strictest requirements when constructing race tracks.<br />

At Home in <strong>the</strong> Fastest Bends<br />

of <strong>the</strong> World<br />

Perfect surface evenness, top-notch paving quality and a good grip on every square centimetre <strong>–</strong> <strong>the</strong> requirements on<br />

race track construction are extremely strict. yet however stringent <strong>the</strong>se requirements may be, <strong>the</strong> machine technology<br />

of <strong>VÖGELE</strong> is more than capable of fulfilling <strong>the</strong> specified criteria. Race tracks of highest evenness and featuring<br />

outstanding ride qualities are a natural domain of <strong>the</strong> SUPER pavers.<br />

<strong>VÖGELE</strong> pavers have already completed <strong>the</strong>ir laps on many race tracks all over <strong>the</strong> world. Now, two more projects can<br />

be added to <strong>the</strong> reference list: <strong>the</strong> Automotodrom Brno circuit in <strong>the</strong> Czech Republic, particularly famous amongst<br />

motorcycle racing enthusiasts, was rehabilitated, while in Singapore, <strong>the</strong> “Monaco of <strong>the</strong> East” is being completed, a <strong>new</strong><br />

city circuit on which <strong>the</strong> first ever night-time race in Formula 1 history will be held. <strong>RoadNews</strong> reports on both job sites.<br />

23

24<br />

<strong>VÖGELE</strong> <strong>–</strong> Synonymous with <strong>the</strong> Construction of Race Tracks<br />

For decades, construction firms and race track operators<br />

have relied on SUPER pavers <strong>for</strong> building <strong>new</strong> circuits or<br />

rehabilitating existing ones.<br />

Formula 1 Circuits<br />

Autodromo Enzo e Dino Ferrari, Imola, Italy<br />

Length of circuit: 4.933km, Lap record: 1:19.753<br />

(Jenson Button, BAR Honda, 2004)<br />

Autodromo José Carlos Pace,<br />

Interlagos / São Paulo, Brazil<br />

Length of circuit: 4.309km, Lap record: 1:10.646<br />

(Rubens Barrichello, Ferrari, 2004)<br />

Bahrain International Circuit<br />

Length of circuit: 5.412km, Lap record: 1:29.848<br />

(Fernando Alonso, Renault, 2005)<br />

Circuit de Catalunya, Barcelona, Spain<br />

Length of circuit: 4.655km, Lap record: 1:14.648<br />

(Fernando Alonso, Renault, 2006)<br />

Circuit de Monaco, Monte Carlo<br />

Length of circuit: 3.340km, Lap record: 1:13.644<br />

(Kimi Räikkönen, McLaren-Mercedes, 2005)<br />

O<strong>the</strong>r Racing Circuits<br />

Misano World Circuit, Misano Adriatico, Italy<br />

Length of circuit: 4.060km<br />

Rockingham Motor Speedway, UK<br />

Length of circuit: 2.365km<br />

Sachsenring, Germany<br />

Length of circuit: 3.671km<br />

Pavers from <strong>VÖGELE</strong> have been involved in <strong>the</strong> asphalt<br />

paving work on many circuits <strong>for</strong> Formula 1 events and<br />

o<strong>the</strong>r races. A survey of <strong>the</strong>se locations is given below:<br />

Circuit de Spa-Francorchamps, Belgium<br />

Length of circuit: 7.004km, Lap record: 1:40.365<br />

(Ayrton Senna, McLaren-Mercedes, 1990)<br />

Hockenheimring, Germany<br />

Length of circuit: 4.574km, Lap record: 1:13.306<br />

(Michael Schumacher, Ferrari, 2004)<br />

Indianapolis Motor Speedway, USA<br />

Length of circuit: 4.192km, Lap record: 1:10.223<br />

(Rubens Barrichello, Ferrari, 2004)<br />

Istanbul Otodrom Circuit, Turkey<br />

Length of circuit: 5.338km, Lap record: 1:26.797<br />

(Kimi Räikkönen, McLaren-Mercedes, 2005)<br />

Nürburgring, Germany<br />

Length of circuit: 5.148km, Lap record: 1:14.960<br />

(Michael Schumacher, Ferrari, 2001)<br />

General Motors Proving Ground Cupuan<br />

del Rio, Mexico<br />

Length of circuit: 5.600km<br />

Circuit de Val de Vienne, Le Vigeant, France<br />

Length of circuit: 3.757km

Andaman Sea<br />

26<br />

Gulf of Thailand<br />

Malaysia<br />

Sumatra<br />

Singapore<br />

Kuala Lumpur<br />

Singapore<br />

SINGAPORE<br />

Singapore‘s skyline, a breathtaking set <strong>for</strong> <strong>the</strong> first<br />

night-time Formula 1 race.

<strong>VÖGELE</strong> pavers resurface <strong>the</strong> <strong>new</strong> Formula 1 circuit in Singapore.<br />

The SUPER Pavers’ Fastest Lap<br />

in South-East Asia<br />

Preparations <strong>for</strong> <strong>the</strong> Formula 1 Grand Prix in Singapore are running at full steam. When <strong>the</strong> 900 HP racing cars speed<br />

around <strong>the</strong> city circuit on 28 September, 2008, <strong>the</strong>y will find perfect road conditions thanks to <strong>the</strong> ef<strong>for</strong>ts of an<br />

experienced paving team. On this job site, <strong>the</strong> pole position is held by two SUPER 1600-2 pavers from <strong>VÖGELE</strong>. Several<br />

sections of <strong>the</strong> circuit have been resurfaced with a special asphalt mix that complies with <strong>the</strong> stringent requirements of<br />

<strong>the</strong> Fédération Internationale de l‘Automobile (FIA).<br />

The two main contracts <strong>for</strong> carrying out <strong>the</strong> asphalt paving<br />

work were awarded to construction firm OKP Holdings Limited<br />

in Singapore. The work included resurfacing <strong>the</strong> road in <strong>the</strong><br />

Marina Bay area, widening Raffles Boulevard and paving <strong>new</strong><br />

wearing course on numerous public <strong>roads</strong> and <strong>the</strong> circuit<br />

itself. This involved parts of Raffles Avenue, St. Andrews Road,<br />

Fullerton Road, Nicholl Highway, Temasek Avenue and Temasek<br />

Boulevard. On <strong>the</strong>se stretches, 5 to 5.5cm of <strong>the</strong> surface was<br />

milled off be<strong>for</strong>e <strong>the</strong> <strong>VÖGELE</strong> pavers placed 5 to 10cm of <strong>the</strong><br />

special Formula 1 mix.<br />

Special mix <strong>for</strong> Formula 1 circuits provides better grip<br />

The Formula 1 mix is designated as F1 SBS (Styrene<br />

Butadiene Styrene) PMB (Polymer Modified Binder) and was<br />

developed <strong>for</strong> <strong>the</strong> extreme conditions of high-speed motor<br />

racing. The material is 80 percent more expensive than<br />

conventional wearing course mix, but provides greater resistance<br />

to shear <strong>for</strong>ces and de<strong>for</strong>mation. The Formula 1 asphalt mix<br />

was developed by Hanson Buildings Materials and contains a<br />

special polymer-modified binder with a significantly higher<br />

viscosity. It can withstand high temperatures without softening<br />

and displays a low level of rolling resistance. Its rough surface<br />

texture also provides extra grip <strong>for</strong> <strong>the</strong> Formula 1 racing cars.<br />

“You can‘t compare this material with mixes <strong>for</strong> conventional<br />

road construction. Placing it with <strong>the</strong> pavers was a major challenge<br />

<strong>for</strong> our paving team on account of its high degree of viscosity,”<br />

says General Manager of OKP Holdings, Mr. Or Toh Wat.<br />

Strict tolerance of 3mm<br />

According to <strong>the</strong> strict rules of <strong>the</strong> FIA, <strong>the</strong> surface<br />

evenness may not deviate by more than 3mm over 4 metres in<br />

<strong>the</strong> transverse direction measured at any random point on <strong>the</strong><br />

circuit. What‘s more, special regulations apply to road markings<br />

on city circuits. These have to be removed at <strong>the</strong> braking<br />

points to prevent <strong>the</strong> race cars from skidding. The same<br />

applies in bends and at blind points of corners so that <strong>the</strong><br />

drivers are not confused. Paving work has to be completed<br />

90 days be<strong>for</strong>e <strong>the</strong> start of <strong>the</strong> race in order to allow time <strong>for</strong><br />

<strong>the</strong> circuit to be inspected and approved.<br />

Paving team quickly got to grips with <strong>the</strong> SUPER 1600-2<br />

OKP invested in two <strong>new</strong>, modern <strong>VÖGELE</strong> pavers to<br />

ensure that all requirements of <strong>the</strong> demanding task in Singapore<br />

could be fulfilled and <strong>the</strong> paving work could be carried out as<br />

smoothly as possible. The SUPER 1600-2 pavers of <strong>the</strong> latest<br />

“dash 2” generation are capable of handling maximum pave<br />

widths of 8m. The paving team became quickly familiar with<br />

<strong>the</strong> pavers and NIVELTRONIC Plus ®, <strong>the</strong> System <strong>for</strong> Automated<br />

Grade and Slope Control. “This was an important point. After<br />

all, <strong>the</strong> work on <strong>the</strong> 5.1km circuit had to be perfect from <strong>the</strong><br />

very first metre,” explains Mr. Or Toh Wat.<br />

27

On this project, nothing was left to chance. The paving team<br />

focused all <strong>the</strong>ir attention on every detail of <strong>the</strong> city circuit.<br />

28

SUPER 1600-2: Facts and Figures<br />

n Maximum pave width 8m<br />

n Laydown rate up to 600 tonnes/h<br />

n Maximum layer thickness 30cm<br />

n Transport width 2.55m<br />

n Pave speed up to 24m/min.<br />

n Travel speed up to 4.5km/h<br />

n PERKINS engine rated at 100kW<br />

n ErgoPlus ® operating concept<br />

29

Job Site Details<br />

Resurfacing <strong>the</strong> city circuit <strong>for</strong> <strong>the</strong><br />

Formula 1 Singapore Grand Prix<br />

Length of circuit: 5.067km<br />

Paving Details<br />

Pave width: up to 7.5m<br />

Layer thickness: 5 to 10cm<br />

Paving Material<br />

Special asphalt mix: F1 SBS (Styrene Butadiene Styrene)<br />

PMB (Polymer Modified Bitumen)<br />

Equipment<br />

2 SUPER 1600-2 with AB 500-2 TV Extending Screeds<br />

Grade and slope control with <strong>the</strong> <strong>VÖGELE</strong> Big MultiPlex Ski<br />

30<br />

In order to comply with <strong>the</strong> strict demands made on<br />

evenness <strong>for</strong> <strong>the</strong> Grand Prix circuit, <strong>the</strong> paving team mounted<br />

a <strong>VÖGELE</strong> Big MultiPlex Ski on each of <strong>the</strong> tracked pavers.<br />

This modern sensor system <strong>for</strong> grade and slope control is<br />

based on <strong>the</strong> well-proven technology of <strong>VÖGELE</strong>‘s sonic grade<br />

sensor. The Big MultiPlex Ski offers numerous advantages over<br />

a single sensor: <strong>the</strong> arrangement of three sensors in a row<br />

allows a base to be scanned simultaneously at multiple points<br />

that are relatively distant from one ano<strong>the</strong>r. NIVELTRONIC ® Plus,<br />

<strong>the</strong> System <strong>for</strong> Automated Grade and Slope Control, derives<br />

a virtual reference from <strong>the</strong>se measurements. The 3 sonic<br />

sensors mounted on <strong>the</strong> Big Multiplex Ski can cover a maximum<br />

range of 13 metres. This offers <strong>the</strong> advantage that <strong>the</strong> system is<br />

capable of identifying and levelling out long irregularities in <strong>the</strong><br />

base. The system controls very easily from <strong>the</strong> ErgoPlus ®<br />

screed consoles.<br />

The SUPER 1600-2 paved <strong>the</strong> special mix<br />

<strong>for</strong> a perfect asphalt surfacing.<br />

Expert know-how <strong>for</strong> <strong>the</strong> paving team<br />

OKP Holdings delegated a paving team to <strong>the</strong> job site in<br />

Singapore that has already completed successfully a diverse<br />

array of jobs over many years and has a lot of experience<br />

working toge<strong>the</strong>r. Never<strong>the</strong>less, <strong>the</strong> Grand Prix paving job<br />

presented <strong>the</strong> team with a real challenge. In order to prepare<br />

<strong>for</strong> all eventualities, proven experts in <strong>the</strong> field were also called<br />

in. On <strong>the</strong> one hand it was Dr. Low Boon Hwee, a materials<br />

expert from Hanson Building Materials, <strong>the</strong> company which<br />

had developed <strong>the</strong> Formula 1 mix, and two applications<br />

technology experts from <strong>VÖGELE</strong> on <strong>the</strong> o<strong>the</strong>r. They have a<br />

wealth of experience in all aspects of paving and already<br />

provided <strong>the</strong>ir expert advice at numerous Grand Prix circuits,<br />

including Hockenheim, <strong>the</strong> Nürburgring and <strong>the</strong> circuit in<br />

Barcelona.

Paving team impressed with <strong>the</strong> SUPER pavers<br />

Once <strong>the</strong> test paving had been successfully completed, <strong>the</strong><br />

actual resurfacing of <strong>the</strong> race circuit went smoothly. The OKP<br />

paving team was full of praise <strong>for</strong> <strong>the</strong>ir <strong>new</strong> <strong>VÖGELE</strong> pavers.<br />

Just like <strong>the</strong> actual race itself, resurfacing of <strong>the</strong> circuit was<br />

done counter clockwise. This means that <strong>the</strong> Formula 1 racing<br />

cars will always drive in <strong>the</strong> same direction as <strong>the</strong> special<br />

asphalt mix was placed. This minimizes rolling resistance and<br />

makes <strong>the</strong> circuit perfectly prepared <strong>for</strong> <strong>the</strong> race.<br />

Paving “hot to hot”<br />

The total width of <strong>the</strong> circuit is 15m, so that <strong>the</strong> two<br />

SUPER 1600-2 pavers were set up to pave widths of 7.5m<br />

each. A condition specified <strong>for</strong> <strong>the</strong> circuit was a perfect bond<br />

between adjacent strips. In order to flawlessly meet this<br />

re quirement, <strong>the</strong> SUPER pavers placed <strong>the</strong> two strips hot<br />

to hot.<br />

Quiet <strong>VÖGELE</strong> pavers easy on residents‘ nerves<br />

As most of <strong>the</strong> paving in <strong>the</strong> city with a population of 4.6 million<br />

people was carried out at night, it was important to work as<br />

quietly as possible. This applied in particular to <strong>the</strong> construction<br />

machinery, which had been selected also according to noise<br />

emission aspects. In this respect, <strong>the</strong> modern SUPER pavers<br />

were <strong>the</strong> perfect choice. Their powerful PERKINS engines<br />

already run quietly in standard operating mode. And when<br />

selecting ECO Mode, which is more than adequate <strong>for</strong> a great<br />

number of jobs, noise emissions are reduced even fur<strong>the</strong>r.<br />

31

Assessment according to<br />

<strong>the</strong> International Roughness Index (IRI)<br />

32<br />

Once paving was completed, <strong>the</strong> circuit underwent a<br />

pavement condition survey in two phases in order to assess its<br />

ride qualities according to <strong>the</strong> International Roughness Index<br />

(IRI). The first inspection took place right after completion of<br />

The Formula 1 Mix <strong>for</strong> Singapore<br />

In Singapore, <strong>the</strong> high standards specified <strong>for</strong> racetracks<br />

were met by <strong>the</strong> special asphalt mix Type F1 SBS (Styrene<br />

Butadiene Styrene) PMB (Polymer Modified Binder). The mix<br />

was developed especially <strong>for</strong> this application after<br />

extensive tests.<br />

This F1 mix contains a polymer-modified binder designed <strong>for</strong><br />

<strong>the</strong> extreme conditions of high-speed motor racing and test<br />

circuits. The binder features higher viscosity and stiffness, a<br />

Aggregate:<br />

Granite/Stone<br />

Bitumen<br />

Properties<br />

<strong>the</strong> circuit and <strong>the</strong> second 6 weeks prior to <strong>the</strong> race. The IRI<br />

was carried out by an independent and accredited laboratory<br />

using drill cores. Now <strong>the</strong> race can start. Not only <strong>the</strong> paving<br />

team involved in <strong>the</strong> roadworks are waiting impatiently <strong>for</strong> <strong>the</strong><br />

moment on September 28, when <strong>the</strong> red lights of <strong>the</strong> signal<br />

system extinguish and <strong>the</strong> first Formula 1 race in history starts<br />

under floodlights.<br />

Formula 1 Mix<br />

with PMB<br />

Paving Materials<br />

Conventional<br />

Road Construction<br />

Difference<br />

Crushing Value (%) 25 (max) 30 (max) 16% higher<br />

Impact Value (%) 25 (max) 30 (max) 16% higher<br />

Los Angeles Abrasion, LAA (%) 25 (max) 35 (max) 29% higher<br />

Polished Stone Value, PSV 54 (min) not specified<br />

Elongation Index (%) 35 (max) 35 (max) same<br />

Flakiness Index (%) 25 (max) 35 (max) 29% higher<br />

Additive<br />

higher softening point and a lower penetration point compared<br />

to mixes used <strong>for</strong> conventional <strong>roads</strong>.<br />

As shown in <strong>the</strong> wheel tracking test, <strong>the</strong> F1 mix has a higher<br />

resistance to de<strong>for</strong>mation than asphalt mixes used in ordinary<br />

pavement construction. The dynamic creep test revealed that<br />

<strong>the</strong> road’s permanent resistance to rutting is higher, too.<br />

And due to <strong>the</strong> rough surface texture, <strong>the</strong> pavement features<br />

a considerably better grip.<br />

Styrene, Butadiene,<br />

Styrene<br />

Penetration Point (0.1mm) 40.7 66.3 39% stronger<br />

Softening Point (°C) 88.5 48.5 83% higher<br />

Viscosity at 60% (cP) 3,280,000 268,333 1,122% higher<br />

Viscosity at 135% (cP) 2,879 604 376% higher<br />

Reference: SOUTHEAST ASIA CONSTRUCTION, Issue March/April 2008<br />

none

Asphalt Mixes <strong>for</strong> Racing Tracks<br />

Over <strong>the</strong> years, asphaltic concrete has established itself as<br />

<strong>the</strong> optimal paving material <strong>for</strong> all racing tracks hosting Formula 1<br />

events. In <strong>the</strong> focus of <strong>the</strong>se applications primarily are asphalt<br />

characteristics referring to <strong>the</strong> road’s surface properties and ride<br />

quality, such as skid resistance and evenness.<br />

Skidding resistance is achieved, among o<strong>the</strong>rs, by selecting<br />

aggregate with a high resistance to polishing. Used as a measure<br />

in this context is <strong>the</strong> Polished Stone Value (PSV). Aggregate with<br />

a PSV > 58 contributes substantially to excellent anti-skid<br />

properties. Asphaltic concrete is <strong>the</strong> preferred material <strong>for</strong> racing<br />

tracks as it generally displays a well balanced ratio of mega,<br />

macro and micro-roughness due to its aggregate composition<br />

with a high content of sand and no omitted-size grain, thus<br />

possessing good permanent non-skid properties. The<br />

International Roughness Index (IRI) is a standard <strong>for</strong> measuring<br />

pavement roughness. As a general rule applies: <strong>the</strong> higher <strong>the</strong><br />

index, <strong>the</strong> better <strong>the</strong> pavement’s grip.<br />

As far as perfect evenness is concerned, also a key characteristic<br />

of Formula 1 circuits, <strong>the</strong>se projects call <strong>for</strong> sophisticated<br />

machine technology. The machinery, in conjunction with <strong>the</strong><br />

appropriate asphalt mix, must be able to meet <strong>the</strong> requirements<br />

made on <strong>the</strong>se specific contracts.<br />

Shear strength and resistance to de<strong>for</strong>mation are fur<strong>the</strong>r<br />

properties of <strong>the</strong> pavement, which <strong>for</strong> racetracks need to meet far<br />

higher standards compared to conventional road construction.<br />

On high-speed circuits, <strong>the</strong> strain on <strong>the</strong> pavement are not high<br />

static or dynamic loads caused by heavy weights, but ra<strong>the</strong>r <strong>the</strong><br />

horizontal shear <strong>for</strong>ces introduced into <strong>the</strong> pavement by <strong>the</strong><br />

braking and accelerating action of <strong>the</strong> 900 HP racing cars.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> asphalt must feature high stability in order to<br />

prevent de<strong>for</strong>mation in <strong>the</strong> heat of <strong>the</strong> high-speed races.<br />

As a binder, bitumen blended with Trinidad Lake Asphalt or<br />

bitumen enriched with plastic additives (polymers) proved to be<br />

an excellent choice <strong>for</strong> racetracks. The special polymer-modified<br />

binders are perfectly suited to absorbing <strong>the</strong> extreme tangential<br />

<strong>for</strong>ces exerted by <strong>the</strong> racing cars when braking, accelerating or<br />

taking tight bends at high speeds. The binders also feature high<br />

elasticity and have strong adhesion properties. Due to <strong>the</strong>ir high<br />

content of polymers, <strong>the</strong>y are perfectly suited to meeting <strong>the</strong><br />

stringent requirements made on racetracks in terms of resistance<br />

to de<strong>for</strong>mation, aggregate/binder adhesion and flexibility.<br />

33

Singapore Grand Prix: The <strong>new</strong> star in <strong>the</strong> Formula 1 calendar<br />

34<br />

On 28 September 2008, a Formula 1 race will take place <strong>for</strong><br />

<strong>the</strong> first time in <strong>the</strong> South-East Asian city state of Singapore.<br />

In addition to Monaco and Valencia, Singapore is one of just three<br />

city circuits. The grandstands in <strong>the</strong> centre of <strong>the</strong> metropolis can<br />

accommodate 80,000 to 90,000 spectators.<br />

Seventy percent of <strong>the</strong> <strong>new</strong> race circuit comprise public <strong>roads</strong>.<br />

The special sections <strong>for</strong> <strong>the</strong> Formula 1 course were designed by<br />

civil engineer and race track specialist Hermann Tilke, Germany.<br />

The Singapore F1 Circuit<br />

Race: Singapore Grand Prix<br />

Length: 5.067km<br />

Laps: 61<br />

Distance: 309.087km<br />

First Start: September 28, 2008<br />

8:00 p.m. local time<br />

Ano<strong>the</strong>r special feature of <strong>the</strong> Singapore Grand Prix is that it is<br />

currently one of just three races that are driven counter<br />

clockwise.<br />

The start time will make <strong>the</strong> Singapore Grand Prix unique in<br />

Formula 1 history. The race will start at 8 p.m., making it <strong>the</strong> first<br />

night-time Grand Prix race ever. In order to ensure safety, some<br />

1,500 floodlights will light <strong>the</strong> circuit as bright as daylight. ,<br />

St Andrews Road<br />

Esplanade Drive<br />

D<br />

The Esplanade<br />

Arts Centre

A<br />

D<br />

Raffles Avenue<br />

Marina Bay<br />

A<br />

Marina Square Shopping Malls<br />

E<br />

Grandstands<br />

B<br />

Raffles Boulevard<br />

E<br />

Republic Boulevard<br />

C<br />

C<br />

Pit Area<br />

Singapore Flyer<br />

B<br />

Start/Finish<br />

35

Germany<br />

Prague<br />

Czech Republic<br />

<strong>VÖGELE</strong> pavers rehabilitate race track in Brno, Czech Republic.<br />

Paving at Top Speed<br />

Speed is essential on every race track. And that was also true <strong>for</strong> <strong>the</strong> extensive rehabilitation work on <strong>the</strong> Automotodrom<br />

Brno circuit carried out by German contractor Kirchhoff, Leipzig. Bad wea<strong>the</strong>r prevented work being started on schedule,<br />

meaning that <strong>the</strong> 5.4km circuit had to be rehabilitated in a record-breaking six weeks. The contract included stabilization of<br />

<strong>the</strong> base course by cold in situ recycling. Then three <strong>VÖGELE</strong> pavers <strong>–</strong> a SUPER 1800-2, SUPER 1900 and SUPER 2100 <strong>–</strong> had<br />

to place binder and wearing courses in just a few days. It goes without saying that a perfect evenness was to be presented.<br />

36<br />

Austria<br />

Czech Republic<br />

Poland<br />

Brno<br />

Slovak Republic<br />

CzECH REPUBLIC<br />

On <strong>the</strong> steepest section, <strong>the</strong> circuit has a gradient of 7.5%.<br />

Here <strong>the</strong> powerful engines and traction drives installed in <strong>the</strong><br />

<strong>VÖGELE</strong> pavers demonstrated <strong>the</strong>ir abilities.