PDi 2-2007 (Bauma) - PDWorld

PDi 2-2007 (Bauma) - PDWorld

PDi 2-2007 (Bauma) - PDWorld

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hall: A6<br />

Booth no. 405<br />

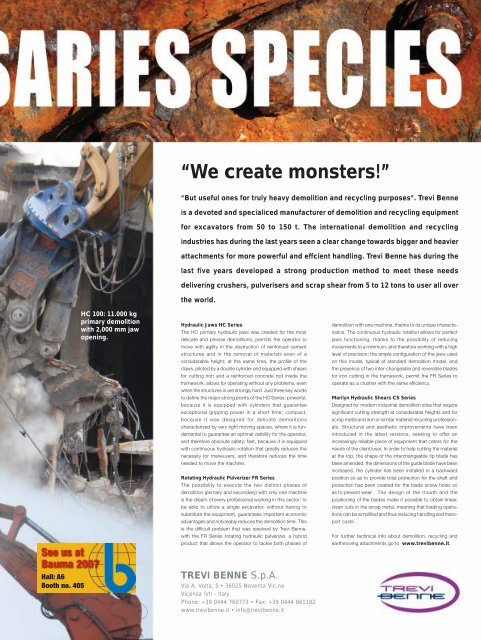

HC 100: 11.000 kg<br />

primary demolition<br />

with 2,000 mm jaw<br />

opening.<br />

“We create monsters!”<br />

“But useful ones for truly heavy demolition and recycling purposes”. Trevi Benne<br />

is a devoted and specialiced manufacturer of demolition and recycling equipment<br />

for excavators from 50 to 150 t. The international demolition and recycling<br />

industries has during the last years seen a clear change towards bigger and heavier<br />

attachments for more powerful and effcient handling. Trevi Benne has during the<br />

last five years developed a strong production method to meet these needs<br />

delivering crushers, pulverisers and scrap shear from 5 to 12 tons to user all over<br />

the world.<br />

Hydraulic Jaws HC Series<br />

The HC primary hydraulic jaws was created for the most<br />

delicate and precise demolitions, permits the operator to<br />

move with agility in the destruction of reinforced cement<br />

structures and in the removal of materials even of a<br />

considerable height; at the same time, the profile of the<br />

claws, piloted by a double cylinder and equipped with shears<br />

for cutting iron and a reinforced concrete rod inside the<br />

framework, allows for operating without any problems, even<br />

when the structures in are strongly hard. Just three key words<br />

to define the major strong points of the HC Series: powerful,<br />

because it is equipped with cylinders that guarantee<br />

exceptional gripping power in a short time; compact,<br />

because it was designed for delicate demolitions<br />

characterized by very tight moving spaces, where it is fundamental<br />

to guarantee an optimal visibility for the operator,<br />

and therefore absolute safety; fast, because it is equipped<br />

with continuous hydraulic rotation that greatly reduces the<br />

necessity for maneuvers, and therefore reduces the time<br />

needed to move the machine.<br />

Rotating Hydraulic Pulverizer FR Series<br />

The possibility to execute the two distinct phases of<br />

demolition (primary and secondary) with only one machine<br />

is the dream of every professional working in this sector: to<br />

be able to utilize a single excavator, without having to<br />

substitute the equipment, guarantees important economic<br />

advantages and noticeably reduces the demolition time. This<br />

is the difficult problem that was resolved by Trevi Benne,<br />

with the FR Series rotating hydraulic pulverizer, a hybrid<br />

product that allows the operator to tackle both phases of<br />

TREVI BENNE S.p.A.<br />

Via A. Volta, 5 • 36025 Noventa Vic.na<br />

Vicenza (VI) - Italy<br />

Phone: +39 0444 760773 • Fax: +39 0444 861182<br />

www.trevibenne.it • info@trevibenne.it<br />

demolition with one machine, thanks to its unique characteristics.<br />

The continuous hydraulic rotation allows for perfect<br />

jaws functioning, thanks to the possibility of reducing<br />

movements to a minimum, and therefore working with a high<br />

level of precision; the ample configuration of the jaws used<br />

on this model, typical of standard demolition model, and<br />

the presence of two inter-changeable and reversible blades<br />

for iron cutting in the framework, permit the FR Series to<br />

operate as a crusher with the same efficiency.<br />

Marilyn Hydraulic Shears CS Series<br />

Designed for modern industrial demolition sites that require<br />

significant cutting strength at considerable heights and for<br />

scrap metal and iron or similar material recycling professionals.<br />

Structural and aesthetic improvements have been<br />

introduced in the latest versions, seeking to offer an<br />

increasingly reliable piece of equipment that caters for the<br />

needs of the client/user. In order to help cutting the material<br />

at the top, the shape of the interchangeable tip blade has<br />

been amended, the dimensions of the guide blade have been<br />

increased, the cylinder has been installed in a backward<br />

position so as to provide total protection for the shaft and<br />

protection has been created for the blade screw holes so<br />

as to prevent wear. The design of the mouth and the<br />

positioning of the blades make it possible to obtain linear,<br />

clean cuts in the scrap metal, meaning that loading operations<br />

can be simplified and thus reducing handling and transport<br />

costs.<br />

For further technical info about demolition, recycling and<br />

earthmoving attachments go to www.trevibenne.it.