am magazine shell - Australian Automotive Aftermarket Association

am magazine shell - Australian Automotive Aftermarket Association

am magazine shell - Australian Automotive Aftermarket Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

REGULAR DEPARTMENTS<br />

AAAA Report..............................4<br />

Calendar & New Members ...........5<br />

News.........................................6<br />

HR Matters ..............................15<br />

SPECIAL FEATURE<br />

Products..................................18<br />

PRTC ......................................90<br />

4WD .......................................92<br />

Retail......................................94<br />

Show Review ...................................................................................28<br />

A complete wrap-up from the <strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> Expo<br />

in Sydney, including reports on the AAAA Award winners.<br />

FEATURES<br />

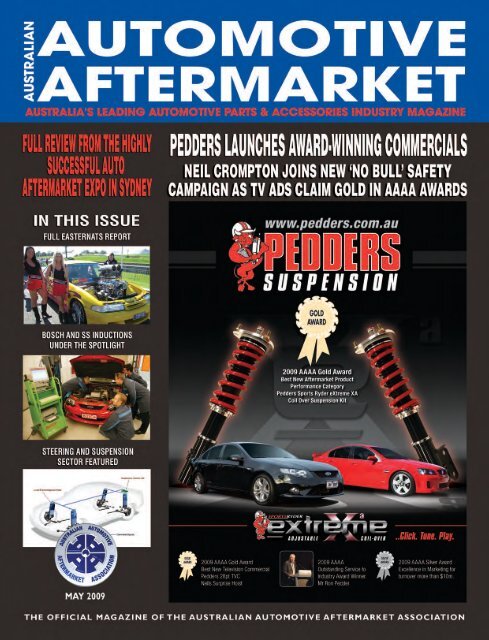

Crompton and no bull.......................................................................16<br />

Pedders’ new award-winning TV commercials<br />

Preparing workshops for the future ....................................................26<br />

Bosch has you covered<br />

Breathe easy ...................................................................................54<br />

From backyard to successful business<br />

Making money from replacement parts...............................................56<br />

Exploring what’s new in a lucrative market<br />

Taking control..................................................................................64<br />

Steering and Suspension sector featured<br />

Raising capital.................................................................................80<br />

Purchasing new equipment for the workshop<br />

Burnout! .........................................................................................88<br />

The full report from the Easternats<br />

ABOUT THE COVER<br />

Pedders Suspension – Australia’s number<br />

one shock absorber, steering and suspension<br />

specialist – dominated the recent <strong>Australian</strong><br />

<strong>Automotive</strong> <strong>Aftermarket</strong> Expo.<br />

More details found on page 36.<br />

16<br />

28<br />

All material appearing in <strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> <strong>magazine</strong> is copyright. Reproduction in whole or in part is strictly forbidden without prior written consent.<br />

Contribution: Freelance contribution and submissions are welcomed by this <strong>magazine</strong>. No responsibility is accepted for unsolicited manuscripts, photographs and<br />

transparencies. The opinions expressed by contributors are not necessarily those of the AAAA. All statements made, although based on information believed to be<br />

reliable and accurate, cannot be guaranteed and no fault or liability can be accepted for error or omission. The publisher reserves the right to omit or alter any<br />

advertisement and the advertiser agrees to indemnify the publisher for all d<strong>am</strong>ages or liabilities arising from the published material.<br />

64<br />

88

AAAA REPORT<br />

MAY 2009<br />

Peter Hein<br />

President<br />

Stuart Charity<br />

Executive Director<br />

AAAA<br />

Suite 5 622 Ferntree Gully Road<br />

Mulgrave Vic 3170<br />

Ph: 03 9561 7044 Fax: 03 9561 7066<br />

email: info@aaaa.com.au<br />

www.aaaa.com.au<br />

NSW Office<br />

Box 693 Penrith BC<br />

Penrith NSW 2751<br />

Ph: 0407 866 671 Fax: 02 4731 5671<br />

Email: grah<strong>am</strong>e@aaaa.com.au<br />

Stuart Charity<br />

Executive Director<br />

execdir@aaaa.com.au<br />

2009 Auto <strong>Aftermarket</strong> and Collision Repair Expo<br />

The Auto <strong>Aftermarket</strong> Expo and Collision Repair<br />

Expo held at the Sydney Exhibition Centre from April<br />

2-4 received a strong endorsement from the<br />

aftermarket, mechanical and crash repair sectors,<br />

with 8144 visitors exploring the 370 exhibitor<br />

displays. The combined Expos covered 20,000<br />

square metres of floor space with high quality<br />

exhibits showcasing <strong>Australian</strong> and international<br />

products and services.<br />

A highlight of the Expo was the significant effort<br />

exhibitors put into their stands with 70 per cent<br />

custom designed. All four full halls of the Sydney<br />

Exhibition Centre looked fantastic and exhibitors<br />

should be congratulated for their determination to<br />

defy the economy and showcase the strength of the<br />

<strong>Australian</strong> auto aftermarket.<br />

The AAAA Awards to Industry and Trade Show<br />

awards presented at a breakfast and gala banquet<br />

were another highlight. Nearly 750 guests attended<br />

At the AAAA Awards to Industry Banquet in<br />

Sydney on April 2, we launched a major AAAA led<br />

consumer advocacy initiative. Titled "Choice of<br />

Repairer", this c<strong>am</strong>paign is the culmination of 12<br />

months planning by a steering committee of AAAA<br />

member companies and will form the cornerstone<br />

of our overall Government relations strategy moving<br />

forward.<br />

The aim of the Choice of Repairer c<strong>am</strong>paign is<br />

to protect choice and competition in the vehicle<br />

repair, servicing, replacement parts and accessories<br />

sector by eliminating any technical or legal barriers<br />

that impact on the <strong>Australian</strong> consumers' right to<br />

have their vehicle serviced, maintained and repaired<br />

at competitive prices in the workshop of their<br />

choice.<br />

The c<strong>am</strong>paign will also address the growing<br />

practice by dealers of signing customers to so-called<br />

'extended' warranties, which have restrictive<br />

PRESIDENT Mr Peter Hein (VIC) – NGK Spark Plug (Australia) Pty Ltd<br />

Ph: 03 9730 4900 Fax: 03 9730 4990<br />

VICE PRESIDENT Mr David Fraser (WA) – Capricorn Society<br />

Ph: 08 6250 9500 Fax: 08 6250 9576<br />

SECRETARY Mr Greg Barker (VIC) – RSP Australia Pty Ltd<br />

Ph: 03 9305 4000 Fax: 03 9305 3520<br />

TREASURER Mr Peter Martin (VIC) – Hella Australia Pty Ltd<br />

Ph: 03 9581 9333 Fax: 03 9584 1741<br />

DIRECTORS<br />

Mr Andrew Schr<strong>am</strong> (VIC) – Burson <strong>Automotive</strong> P/L<br />

Ph: 03 9914 5555 Fax: 03 9914 5544<br />

Mr Bob Pattison (VIC) – GUD <strong>Automotive</strong> Pty Ltd<br />

Ph: 03 9243 3333 Fax: 03 9243 3366<br />

these two events, which recognised outstanding<br />

contributions to the industry by individuals and<br />

companies. I would like to take this opportunity to<br />

congratulate all award finalists and winners. We<br />

would also like to acknowledge the outstanding<br />

contribution to our industry by the following<br />

individuals:<br />

• Guy Nicholls – winner of the 2009 Kim Aunger<br />

Young Achiever Award;<br />

• Ron Pedder – winner of the 2009 AAAA<br />

Outstanding Service to Industry Award;<br />

• George Kallinikos and David Wright – inductees<br />

into the AAAA Hall of F<strong>am</strong>e.<br />

Further information on the Expo and all award<br />

winners is included in this edition of the <strong>Australian</strong><br />

<strong>Automotive</strong> <strong>Aftermarket</strong> Magazine.<br />

Planning is already well advanced for the next<br />

Expo, which will be held from 12-14 May 2011 at<br />

the Melbourne Exhibition Centre.<br />

Choice of Repairer C<strong>am</strong>paign Launched<br />

provisions on the choice of repairer and parts used,<br />

and tie customers to long-term service schedules<br />

with the dealer. Our contention is that many of these<br />

contracts provide little benefit additional to the<br />

consumer's basic statutory rights.<br />

Further information on this initiative<br />

can be viewed on the c<strong>am</strong>paign website:<br />

www.choiceofrepairer.com.au<br />

We are now seeking support from the industry<br />

and key consumer groups with an interest in<br />

achieving a fair and competitive regulatory<br />

environment that recognises vehicle owners' right to<br />

their choice of repairer and parts used. Following<br />

this process, we will launch a major awareness<br />

c<strong>am</strong>paign to ensure that these issues are brought to<br />

the attention of the industry, its regulators and<br />

consumers.<br />

We will keep you regularly updated via this<br />

column on the progress of the c<strong>am</strong>paign.<br />

COMMITTEE<br />

Mr Peter Armstrong (NSW) – IBS Auto Solutions Pty Ltd<br />

Ph: 02 9892 4004 Fax: 02 9892 2897<br />

Mr David Duncan (VIC) – Dayco Australia Pty Ltd<br />

Ph: 03 9796 4044 Fax: 03 9796 4731<br />

Mr Roger Lassen (SA) – Tenneco<br />

Ph: 08 8374 5212 Fax: 08 8276 1653<br />

Mr Mark Pedder (VIC) – Pedders Suspension<br />

Ph: 03 9706 3500 Fax: 03 9706 3355<br />

Mr Geoff Rosenbaum (NSW) – Motospecs – Drivetech<br />

Ph: 02 9847 5724 Fax: 02 9847 5757<br />

Mr Grah<strong>am</strong> Scud<strong>am</strong>ore-Smith (QLD) – Fulcrum Suspensions<br />

Ph: 07 3892 9000 Fax: 07 3892 1526<br />

4 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

AAAA<br />

4WD1 Pty Ltd<br />

23/44 Carrington Road<br />

CASTLE HILL NSW 2154<br />

Ph: 02 9899 3989 Fax: 02 9680 3441<br />

All Terrain 4x4<br />

6/192 Chesterville Road<br />

MOORABBIN VIC 3189<br />

Ph: 03 9532 5558 Fax: 03 9532 5446<br />

Can Do <strong>Automotive</strong><br />

145 Main Street<br />

LILYDALE VIC 3140<br />

Ph: 03 9739 5000<br />

Care Marketing<br />

35 Glenvale Crescent<br />

MULGRAVE VIC 3170<br />

Ph: 03 9545 1892 Fax: 03 9545 1897<br />

Carlec<br />

197a Semaphore Road<br />

EXETER SA 5019<br />

Ph: 08 8449 8400 Fax: 08 8449 8439<br />

Carservice.com.au<br />

547 Blackburn Road<br />

MT WAVERLEY VIC 3174<br />

Ph: 03 9535 2222 Fax: 03 9562 8143<br />

Diver Consolidated Industries<br />

45 Trawalla Ave<br />

THOMASTOWN VIC 3074<br />

Ph: 03 9357 2511 Fax: 03 9359 2191<br />

E.F.I Carware Components<br />

PO Box 8566<br />

HEATHERTON VIC 3202<br />

Eagle SMF Distributors<br />

66 Orange Grove Road<br />

LIVERPOOL NSW 2170<br />

Engine & Transmission Parts<br />

72 Killara Road<br />

CAMPBELLFIELD VIC 3061<br />

Ph: 03 9357 0854 Fax: 03 9357 0845<br />

<strong>Australian</strong> <strong>Automotive</strong><br />

<strong>Aftermarket</strong> Magazine<br />

is a member of the<br />

Circulations Audit Board.<br />

PUBLISHER –<br />

Stuart Charity,<br />

Executive Director<br />

<strong>Australian</strong> <strong>Automotive</strong><br />

<strong>Aftermarket</strong> <strong>Association</strong><br />

NEW MEMBERS<br />

Fluid Drive Technologies P/L<br />

50 Nanson Street<br />

WEMBLEY WA 6014<br />

Garware Polyester Ltd<br />

Garware House, Western Express Hwy<br />

VILE PARLE (EAST), MUMBAI 400-057 India<br />

Ph: +91 22 6698 8177<br />

Harrop Engineering<br />

96 Bell Street<br />

PRESTON VIC 3072<br />

Ph: 03 9474 0900 Fax: 03 9474 0999<br />

Master Mobile Mechanics<br />

42 Kernot Crescent<br />

NOBLE PARK VIC 3174<br />

1300 760 818<br />

MoTeC Pty Ltd<br />

MoTeC Research Centre,<br />

121 Merrindale Drive<br />

CROYDON SOUTH VIC 3136<br />

Ph: 03 9761 5050 Fax: 03 9761 5051<br />

N.L. & Z. Import Co<br />

17 Mills Street<br />

CHELTENHAM NORTH VIC 3192<br />

Ph: 03 9583 9777 Fax: 03 9583 9501<br />

National Freight Management<br />

Unit 17, 735-741 Boronia Road<br />

WANTIRNA VIC 3152<br />

Ph: 03 9800 1444 Fax: 03 9800 1199<br />

NAVTEQ<br />

Level 2, 577-579 Church Street<br />

RICHMOND VIC 3121<br />

Ph: 03 9420 5935 Fax: 03 9420 5901<br />

Optibelt Australia Pty Ltd<br />

114-118 Rodeo Drive<br />

DANDENONG VIC 3175<br />

Pedders Suspension South Melbourne<br />

131 Market Street<br />

SOUTH MELBOURNE VIC 3205<br />

Ph: 03 9699 4630<br />

The <strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> <strong>magazine</strong> is the official publication of the<br />

<strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> <strong>Association</strong> (AAAA).<br />

Published by<br />

The <strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> <strong>Association</strong><br />

ABN 23 002 271 454<br />

Suite 5 622 Ferntree Gully Road Mulgrave Vic 3170<br />

Ph: 03 9561 7044 Fax 03 9561 7066 email: info@aaaa.com.au<br />

NSW Office<br />

Box 693 Penrith BC Penrith NSW 2751<br />

Ph: 0407 866 671 Fax: 02 4731 5671 Email: info@aaaa.com.au<br />

EDITORIAL –<br />

Allan Edwards,<br />

Pole Position Productions<br />

Tel 61 3 9331 2608<br />

ADVERTISING MANAGER –<br />

Janene Ch<strong>am</strong>pion,<br />

Ch<strong>am</strong>pion Ads<br />

Tel 61 3 5862 3090<br />

PJL Diesel Electric<br />

1 Granite Place<br />

WELSHPOOL WA 6106<br />

Ph: 08 9258 7555 Fax: 08 9258 7577<br />

Precision International Pty Ltd<br />

591 Blackburn Road<br />

NOTTING HILL VIC 3168<br />

Ph: 03 9545 0788 Fax: 03 9561 9500<br />

Renniks Publications<br />

Unit 3, 37-39 Green Street<br />

BANKSMEADOW NSW 2019<br />

Sodablast<br />

17/8 Hopper Ave<br />

ORMEAU QLD 4208<br />

Ph: 07 5540 7289 Fax: 07 5540 7905<br />

Superstop Brake & Clutch<br />

727-729 Whitehorse Road<br />

MONT ALBERT VIC 3127<br />

Ph: 03 9890 1924 Fax: 03 9890 5502<br />

SXD Performance Parts<br />

18-20 George Street<br />

GRANVILLE NSW 2142<br />

Ph: 02 9897 1966 Fax: 02 9897 3473<br />

Sydney Wide Europeon Autos<br />

150 Elderidge Rd (Cnr Edgar St)<br />

CONDELL PARK NSW 2200<br />

Ph: 02 9708 4848 Fax: 02 9708 4088<br />

Total Auto Parts<br />

5-7, Unit 1 Ween Road<br />

POORAKA SA 5095<br />

Ph: 08 8359 6777 Fax: 08 9359 5055<br />

Ultra Tune Unley<br />

110A Unley Road<br />

UNLEY SA 5061<br />

Ph: 08 8271 5155 Fax: 08 8271 5778<br />

Universal Auto Accessory<br />

7/109-111 President Ave<br />

CARINGBAH NSW 2229<br />

PRODUCTION & DESIGN –<br />

Brigid Fraser,<br />

Possprint<br />

Tel 61 3 9505 0121<br />

CALENDAR<br />

2009<br />

Automechanika Middle East 2009<br />

Dubai International Convention<br />

& Exhibition Centre<br />

Dubai, UAE<br />

May 31st – June 2nd 2009<br />

www.automechanika.messefrankfurt.com<br />

SEMA Show<br />

Las Vegas Convention Center<br />

Nevada, USA<br />

3-6 November, 2009<br />

www.semashow.com<br />

AAPEX Show<br />

<strong>Automotive</strong> <strong>Aftermarket</strong> Products Expo<br />

Sands Expo Center<br />

Las Vegas, Nevada<br />

3-5 November, 2009<br />

www.aapexshow.com<br />

APRA BIG R show<br />

Riviera Hotel and Casino,<br />

Las Vegas, Nevada<br />

October 31 - November 2, 2009<br />

www.bigrshow.com<br />

Automechanika Shanghai<br />

Shanghai New International Expo<br />

Center, Pudong, Shanghai, China<br />

9-11 December 2009<br />

www.automechanika.messefrankfurt.com<br />

Performance Racing<br />

Industry Trade Show<br />

Orange County Convention Center<br />

Orlando, Florida, USA<br />

10-12 December 2009<br />

www.performanceracing.com<br />

2010<br />

Automechanika Frankfurt 2010<br />

Frankfurt, Germany<br />

14-19 September 2010<br />

www.automechanika.messefrankfurt.com<br />

2011<br />

<strong>Australian</strong> Auto <strong>Aftermarket</strong> Expo<br />

Melbourne Exhibition Centre<br />

Melbourne, Australia<br />

12-14 May 2011<br />

www.aftermartketexpo.com.au<br />

Collision Repair Expo<br />

Melbourne Exhibition Centre<br />

Melbourne, Australia<br />

12-14 May 2011<br />

www.collisionrepair.com.au<br />

AUTOMO TIVE AFTERMARKET MAG A ZINE MAY 2009 5

NEWS<br />

YOUR CAR, YOUR CHOICE<br />

On behalf of Australia's independent aftermarket, the <strong>Australian</strong> <strong>Automotive</strong><br />

<strong>Aftermarket</strong> <strong>Association</strong> (AAAA) is launching a c<strong>am</strong>paign to promote<br />

consumer choice and fair competition in the automotive parts,<br />

accessories, repair and service industry.<br />

Vehicles are becoming increasingly<br />

complex, due to the growing use of hi-tech<br />

materials and electronics to control more<br />

systems, including drivetrain, safety<br />

equipment, and comfort and convenience<br />

functions. The challenge for independent<br />

aftermarket workshops is to keep up to date<br />

with the information, technology and tools<br />

required to repair modern vehicles.<br />

In the meantime, Australia's car company<br />

dealer service centres have automatic access<br />

to data and equipment. There is no clear<br />

requirement for vehicle manufacturers and<br />

importers operating in Australia to make<br />

technical repair and diagnostic information<br />

available to independent aftermarket<br />

repairers.<br />

AAAA Executive Director Stuart Charity<br />

said that most independent aftermarket<br />

businesses find that technical information is<br />

difficult to access.<br />

"In Australia, we have no regulated process<br />

to ensure this vital information is<br />

disseminated. This means independent parts<br />

and accessories suppliers, service,<br />

mechanical and collision repair workshops in<br />

Australia must rely on the goodwill of vehicle<br />

manufacturers to get the information or<br />

equipment," he said.<br />

"At present, some vehicle manufacturers<br />

make it easy for independent aftermarket<br />

businesses to access vital technical manuals,<br />

update bulletins, software patches and<br />

equipment. Many do not make it easy. So the<br />

technology 'playing field' is not level and in<br />

the future customers will have less choice<br />

about who can do their repairs and what parts<br />

are used. This issue is especially relevant in<br />

regional centres and when vehicles age past<br />

their statutory warranty period.<br />

"The aim of the Choice of Repairer<br />

c<strong>am</strong>paign is to protect choice and<br />

competition in vehicle repair, servicing and<br />

replacement parts sectors by eliminating any<br />

technical or legal barriers that impact on the<br />

<strong>Australian</strong> consumers' rights to have their<br />

vehicle serviced, maintained and repaired in<br />

a timely manner, at competitive prices in the<br />

workshop of their choice," Mr Charity said.<br />

International experience<br />

In 2002, the European Commission<br />

introduced the <strong>Automotive</strong> Block Exemption<br />

Regulation covering distribution and servicing<br />

agreements for motor vehicles. This regulation<br />

preserves the motorists' rights to have their<br />

vehicle serviced or repaired at the workshop of<br />

their choice and at prices determined by open<br />

competition. The European Union aftermarket<br />

association is currently lobbying the European<br />

Commission to strengthen this protection.<br />

In North America, the <strong>Automotive</strong><br />

<strong>Aftermarket</strong> Industry <strong>Association</strong> is<br />

c<strong>am</strong>paigning to win Congressional support for<br />

a 'motor vehicle owners' right to repair act' to<br />

prevent manufacturers from unfairly<br />

restricting access to the information and tools<br />

required to diagnose, repair, re-progr<strong>am</strong> or<br />

install automotive replacement parts. The act<br />

would not affect dealers' rights to service and<br />

does not force breaches of intellectual<br />

property.<br />

At present, some vehicle<br />

manufacturers make it easy<br />

for independent aftermarket<br />

businesses to access vital<br />

technical manuals, update<br />

bulletins, software patches<br />

and equipment. Many do not<br />

make it easy.<br />

Vehicle safety<br />

Australia's independent aftermarket<br />

presently has no promise of such open access<br />

to the vital information required to continue<br />

providing customers with safe,<br />

environmentally sound, cost effective repair<br />

services for today's vehicles.<br />

"The AAAA Choice of Repairer initiative<br />

will ensure that the independent aftermarket<br />

can continue to supply the parts and<br />

accessories, follow all procedures and use all<br />

systems required to return vehicles to<br />

customers in a safe, environmentally correct<br />

condition," Mr Charity said.<br />

"The c<strong>am</strong>paign will also address the<br />

growing practice by dealers of signing<br />

customers to so-called 'extended' warranties,<br />

which have restrictive provisions on the<br />

choice of repairer and parts used, and tie<br />

customers to long term service schedules with<br />

the dealer. Our contention is that many of<br />

these contracts provide little benefit<br />

additional to the consumer's basic statutory<br />

rights.<br />

"The mission of the <strong>Australian</strong> automotive<br />

industry is not just to provide customers with<br />

new vehicles. It is estimated that over a 10<br />

year period, a vehicle will require service and<br />

repairs estimated to equal one and a half<br />

times the original purchase price. Each year,<br />

Australia's 15 million vehicle owners spend<br />

about $8 billion on parts and services.<br />

Ensuring that owners can access a<br />

competitive price for their vehicle parts and<br />

services can make the difference between<br />

affordable and unaffordable motoring.<br />

"Australia now has 52 vehicle brands<br />

offering 320 models in its market. That<br />

generates a lot of information and equipment<br />

to be kept up to date by the nation's<br />

independent aftermarket repairers and the<br />

replacement parts sector. And if it is difficult<br />

for the aftermarket now, it will be even more<br />

difficult in future as the high technology<br />

content of every vehicle increases to promote<br />

safety, fuel economy, performance and<br />

comfort. The aftermarket has a huge<br />

responsibility in maintaining the national<br />

vehicle fleet.<br />

"This AAAA Choice of Repairer initiative<br />

will fight for fair competition in the<br />

accessories and replacement parts sector, and<br />

for the independent repairers' right to gain<br />

access to the technical and diagnostic<br />

information and the equipment required, to<br />

correctly service all vehicles sold in<br />

Australia,” Mr Charity said.<br />

"We are now seeking support from industry<br />

and consumer groups with an interest in<br />

achieving a fair and competitive regulatory<br />

environment that recognises vehicle owners<br />

right to their choice of repairer. Following this<br />

process, we will launch a major awareness<br />

c<strong>am</strong>paign to ensure that these issues are<br />

brought to the attention of the industry, its<br />

regulators and consumers.”<br />

Mr Charity encouraged interested industry<br />

members to visit www.choiceofrepairer.com.au<br />

to learn about the initiative, to register for<br />

c<strong>am</strong>paign updates, and to download<br />

educational material for customers.<br />

6 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

NEWS<br />

LED WINS HISTORIC TEST CASE<br />

Australia's automotive industry has won an historic court ruling banning the sale in Australia of<br />

imported copies of their <strong>Australian</strong>-designed parts and products.<br />

The Federal Court of Australia decision is<br />

set to have a major impact on the multibillion<br />

dollar automotive sector as news of the<br />

result filters through the industry and<br />

manufacturing generally.<br />

After two years' research, Melbourne<br />

businessman Tony Ottobre developed a new<br />

way of making LED rear lights for trucks and<br />

trailers that improved quality and halved the<br />

cost. In June 2004 he registered his designs<br />

under the Federal Parli<strong>am</strong>ent's Designs Act<br />

2003. His lights were an instant hit with<br />

truck and trailer manufacturers and his sales<br />

jumped from $100,000 in 2003 to more<br />

than $12 million last year. His total sales for<br />

the five-year period topped $34 million.<br />

His breakthrough design profoundly<br />

influenced the automotive LED (light<br />

emitting diode) industry in Australia. His<br />

Thomastown firm, LED Technologies, was the<br />

first in Australia to introduce a five-year<br />

warranty, and more recently a lifetime<br />

warranty, and derive its income solely from<br />

LED products.<br />

In November 2006 a China-made copy of<br />

Mr Ottobre's design appeared on the<br />

<strong>Australian</strong> market, selling for about 20<br />

percent less than Mr Ottobre's products. The<br />

copy had the potential to cost Mr Ottobre<br />

millions of dollars in lost sales and<br />

significantly d<strong>am</strong>age the excellent reputation<br />

of his business and its products. In what was<br />

a test case, Mr Ottobre was the first<br />

businessman in Australia's multi-billion<br />

dollar automotive industry to use the Designs<br />

Act 2003 to sue an importer and distributors<br />

for copying his product and selling it in<br />

Australia.<br />

After a two-year battle in the Federal<br />

Court of Australia and $900,000 in legal<br />

Leading Lean Manufacturing Consultant, TXM has significant experience in working with<br />

manufacturers of <strong>Automotive</strong> <strong>Aftermarket</strong> products.<br />

TXM ran the AAAA Introduction to Lean Enterprise workshop last<br />

year. According to TXM Principal, Tim Mclean, "automotive aftermarket<br />

manufacturing is a vibrant industry sector with a high degree of<br />

innovation and some unique challenges due to the complexity of the<br />

supply chain. TXM is focused on helping companies address these<br />

challenges.”<br />

TXM was an exhibitor at the recent Austech 2009 in May at the<br />

Melbourne Exhibition Centre.<br />

fees, Mr Ottobre recently won a<br />

landmark decision for his business<br />

and all makers and sellers of<br />

<strong>Australian</strong>-designed goods. His win<br />

sets a precedent and - for the first<br />

time in <strong>Australian</strong> manufacturing<br />

history - protects <strong>Australian</strong>designed<br />

automotive parts and<br />

products from predatory copycat<br />

practices.<br />

"This has been going on for years,<br />

copies undermining the manufacture<br />

and sale of <strong>Australian</strong>-designed parts<br />

and products, costing Aussie firms hundreds<br />

of millions of dollars and thousands of jobs,"<br />

Mr Ottobre said.<br />

This is a huge win not just<br />

for my business but for<br />

all makers and sellers of<br />

Aussie-designed goods.<br />

"Someone had to take a stand. I was<br />

determined to fight for my business. It's<br />

taken two years and nearly a million dollars<br />

but we're now protected. This is a huge win<br />

not just for my business but for all makers<br />

and sellers of Aussie-designed goods."<br />

The Designs Act 2003 includes the<br />

important new benchmark substantially<br />

similar. "Many people in the automotive<br />

industry are under the impression you can<br />

copy someone else's product so long as at<br />

least 10 per cent of it is different. This is not<br />

the case and has now been confirmed by this<br />

ruling."<br />

Justice Michelle Gordon said Ren<br />

International and distributors Olsen<br />

Industries, Advanced <strong>Automotive</strong> Australia<br />

and Elecspess infringed Mr Ottobre's<br />

registered <strong>Australian</strong> designs and<br />

contravened sections of the Trade Practices<br />

Act 1974 by manufacturing, importing and<br />

selling in Australia its copy, known as the<br />

Condor model.<br />

On February 24, 2009, Justice Gordon<br />

barred Ren International and the distributors<br />

from "directly or indirectly making, importing,<br />

selling or offering for sale" any automotive<br />

l<strong>am</strong>ps that are "identical to or substantially<br />

similar in overall impression" to Mr Ottobre's<br />

registered <strong>Australian</strong> designs. She ordered<br />

Ren International and its distributors to pay<br />

LED Technologies $200,000 in d<strong>am</strong>ages by<br />

March 25, 2009, and awarded Mr Ottobre<br />

legal costs.<br />

Ren International's copy is being pulled<br />

from distributors' shelves across Australia.<br />

Many more imported copies of <strong>Australian</strong>designed<br />

parts and products are expected to<br />

come under scrutiny as news of the decision<br />

filters through Australia's automotive industry<br />

and manufacturing generally.<br />

AFTERMARKET INDUSTRY LEAN<br />

EXPERTS AT AUSTECH<br />

Visitors experienced case studies of TXM projects and a hands-on<br />

exhibit of some of the simple techniques used to improve operational<br />

performance.<br />

Visitors also had the chance to win one of five lean assessments and<br />

action plans valued at over $3000.<br />

For more information email info@txm.com.au or visit www.txm.com.au<br />

AUTOMO TIVE AFTERMARKET MAG AZINE MAY 2009 7

NEWS<br />

INTERNATIONAL<br />

NEWS<br />

AUTOMECHANIKA MALAYSIA A GREAT SUCCESS<br />

Buoyed by the success of the last show in 2007, the sixth<br />

edition of Automechanika Malaysia was held at the Kuala<br />

Lumpur Convention Centre from March 25–28, 2009.<br />

The event maintained the momentum and attracted 133<br />

exhibitors from 14 countries and regions; and 4521 visitors<br />

passed through the doors.<br />

The top five visitor countries and regions outside Malaysia<br />

were Singapore, China, Thailand, Korea and Egypt.<br />

The Malaysian Government understands the needs of<br />

having an automotive parts and aftermarket trade fair to boost<br />

the industry.<br />

Malaysia’s Deputy Minister of International Trade &<br />

Industry, YB Dato' Jacob Dungau Sagan officially opened<br />

Automechanika Malaysia.<br />

“I <strong>am</strong> happy to note that Messe Frankfurt Hong Kong<br />

proceeded with this event although the automobile industry is<br />

experiencing a bumpy ride,” he said.<br />

Running alongside the fair was a series of comprehensive<br />

progr<strong>am</strong>s for industry players to exchange information and<br />

update their market intelligence, including the Cater<br />

Workshop on Mass Customisation of Vehicles, which was<br />

aimed at sharing state-of-the-art knowledge.<br />

The three-day workshop welcomed many industry players.<br />

Speaker Dr Halimahtun M. Khalid, Executive Director of<br />

D<strong>am</strong>ai Sciences Sdn Bhd, commented: “Automechanika<br />

Malaysia is the right kind of event for us to share the results<br />

and innovations from the project. In light of the current<br />

automotive industry environment, it is even more important<br />

for automotive enterprises to be more customer-centric and<br />

therefore to improve their business.”<br />

Co-located with the fair for the third time was the<br />

Federation of Automobile Workshop Owners’ <strong>Association</strong> of<br />

Malaysia (FAWOAM) Annual Convention which attracted over<br />

300 participants.<br />

President Mr Cho Chee Seng said: “Through participating<br />

in the convention and trade fair, we aim to educate and<br />

update our members with the latest technical developments<br />

and market and product knowledge. I <strong>am</strong> glad that our<br />

members are very satisfied and have shown great support to<br />

the event.”<br />

The Automechanika Academy featured many esteemed<br />

industry speakers, including: Ms Marsitah Wariss, Consultant<br />

of Frost & Sullivan <strong>Automotive</strong> & Transportation Practice, Asia<br />

Pacific; Mr Peter Lim, President of Malaysian <strong>Automotive</strong><br />

Component Parts Manufacturers (MACPMA); and Mr Richard<br />

Pratt, CEO of I-CAR Australia.<br />

Automechanika Malaysia is one of 13 global Automechanika<br />

fairs.<br />

The next show will be held in March 2011.<br />

For more information, please visit<br />

www.automechanika.messefrankfurt.com or<br />

email autoasia@hongkong.messefrankfurt.com.<br />

20 GOOD YEARS IN<br />

SHEPPARTON<br />

Barry Cryer and David Morton-John have got good<br />

reason to look pleased – they have just celebrated<br />

their 20th anniversary working in Shepparton.<br />

Barry Cryer and David Morton-John.<br />

It was two decades ago the pair got together and opened the ABS<br />

workshop following them both having worked for over 10 years each in the<br />

auto trade.<br />

When they opened their ABS franchise they were the first to do so in<br />

Australia, and the ABS group now has nearly 50 sites.<br />

But they have come a long way from the first humble tin shed on the<br />

outskirts of town and a decade ago invested in an impressive central site and<br />

a top custom-designed workshop.<br />

“It’s been 20 very good years,” Mr Cryer said.<br />

“We have a great business, a great town and a great country lifestyle which<br />

is terrific for the kids, and only a couple of traffic lights. I wouldn’t swap it<br />

for the world.<br />

“Two decades after starting we now have the very latest in equipment to<br />

ensure our brake & clutch work is matched with a full range of servicing and<br />

repairs,” Mr Cryer said.<br />

ACS AWARDED ISO<br />

ACCREDITATION<br />

<strong>Australian</strong> Clutch Services claims that it has always been<br />

committed to building close partnerships with customers<br />

by helping them develop their market.<br />

“The ACS mission is to excel<br />

in quality and service, be<br />

innovative, efficient and globally<br />

competitive,” Tim Possingh<strong>am</strong>,<br />

Marketing Manager for <strong>Australian</strong><br />

Clutch Services, said.<br />

“As part of <strong>Australian</strong> Clutch<br />

Services’ never-ending drive to<br />

exceed customer expectations,<br />

ACS has recently been awarded<br />

ISO 9001: 2008 quality<br />

accreditation.<br />

"This quality system<br />

encompasses all aspects of our<br />

business, from warehouse<br />

operations to accounts and<br />

administration as well as<br />

product. We continue to pride<br />

ourselves as the market leaders<br />

in Australasia.”<br />

For more information call<br />

1800 CLUTCH or visit<br />

www.australianclutch.com.au<br />

8 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

NEWS<br />

EXIDE’S LOCAL INVESTMENT LEADS<br />

RECYCLING TECHNOLOGY<br />

Exide batteries made at the company’s Adelaide factory boast a recycling rate of over 90 percent –<br />

which is higher than most other industries throughout Australia.<br />

The Exide Technologies company has been<br />

proactively involved in the recycling of batteries<br />

long before it ever become branded with the<br />

current terms of eco-friendly, green washing or<br />

enviro-friendly. It has been done to maintain the<br />

value locked into the many materials built into<br />

batteries, which remain long after their use.<br />

The Exide manufacturing facility in<br />

Elizabeth, South Australia, has been using<br />

recycled polypropylene for battery cases and<br />

recycled lead for many years. This has become<br />

known and trademarked with the slogan “Black<br />

is Green” which describes the recycling of all<br />

colours of polypropylene battery cases into new<br />

black battery boxes.<br />

The process is part of the commitment to<br />

capture spent batteries from the market and<br />

subsequently crush and smelt the products to<br />

regain the polypropylene and lead. This<br />

happens at its company-owned smelter in<br />

Wellington, NZ to service Australia and NZ.<br />

Exide is the only battery company in Australia<br />

and NZ to own and operate such a smelter for<br />

the purposes of recycling lead acid batteries.<br />

There are two other smelters in Australia<br />

that accept old batteries and recycle the<br />

polypropylene and lead. So, along with the<br />

Exide facility, lead acid starting batteries<br />

(including those used in marine applications)<br />

are <strong>am</strong>ong the highest percentage of recycled<br />

goods to reach nearly all markets.<br />

This gives the industry-wide figure of over<br />

90 percent. Other goods of note include: glass<br />

bottles (26 percent), paper (45 percent),<br />

aluminium cans (55 percent) and tyres (26<br />

percent).<br />

The impressive figure of over 90 percent of<br />

batteries sold each year in Australia<br />

being captured for recycling is the<br />

statistic compiled by the battery<br />

industry body, the <strong>Australian</strong><br />

Battery Industry <strong>Association</strong> (ABIA).<br />

The volume is over 60 tonnes of<br />

lead annually – which is prevented<br />

from being mined below the<br />

ground.<br />

But Exide is the only <strong>Australian</strong><br />

battery manufacturer using recycled<br />

polypropylene to produce new cases<br />

with the current surplus of the<br />

recycled material reused in the<br />

plastics industry for other uses.<br />

All this is in addition to the<br />

emerging second tier of battery<br />

recycling as this industry can also be included<br />

in the current push of replacing internal<br />

combustion engines with battery powered<br />

electric to gain a smaller carbon footprint. While<br />

this overall move may be currently slow to gain<br />

pace in automotive applications, electric motors<br />

are increasingly used for steerage and the<br />

popular bass fishing.<br />

However, the current industry focus is all<br />

about electric vehicles (EV) where such<br />

technology is not new to the battery industry<br />

which has been supplying recyclable battery<br />

power for years in a variety of applications<br />

including forklifts, thereby creating a lower<br />

carbon emission for each user.<br />

During recent years, consumers have moved<br />

to the acceptance that batteries can be recycled<br />

and are therefore greener than other products<br />

they purchase for their car or boat. This has<br />

been the result of the public awareness<br />

Exide batteries are being produced at the company’s <strong>Australian</strong><br />

factory with one of the highest recycling rates in any industry.<br />

c<strong>am</strong>paigns by motoring organizations including<br />

the RACV, NRMA and RAA as well as the auto<br />

trade with the ABIA.<br />

While Exide Technologies has a<br />

demonstrated history of commitment to<br />

recycling in Australia, the s<strong>am</strong>e cannot be said<br />

for other battery suppliers who do not invest in<br />

the s<strong>am</strong>e infrastructure to capture and recycle<br />

spent batteries at the end of their life cycle.<br />

However, Exide will continue to work with the<br />

ABIA, government bodies and the battery<br />

reseller market to continually improve the<br />

reclaim rate to ensure batteries remain a<br />

recycling imperative and a green choice for<br />

consumers.<br />

As part of this, Exide batteries carry the<br />

recycle logo as do glass bottles, aluminium cans,<br />

plastic containers and many other products and<br />

more recently the "Don’t Bin It" logo to direct<br />

consumers to not place spent batteries in<br />

domestic garbage for responsible recycling.<br />

GET YOUR FREIGHT MOVING<br />

National Freight Management is keen to expand its services into the automotive aftermarket.<br />

National Freight Management is a freight<br />

broker covering a wide range of services by<br />

air, road and sea.<br />

It provides its customers with access to<br />

over 25 transport companies – taking away<br />

the hassle of sourcing transport companies,<br />

which is often time consuming.<br />

It can give clients a quote on the spot, or<br />

they can do it themselves with its easy to use<br />

online quoting system.<br />

It can organise pick-ups at a set daily<br />

time or as required.<br />

National Freight Management<br />

immediately follows up on any freight or<br />

billing enquiries.<br />

It provides clients with one descriptive<br />

freight invoice, even though the company<br />

provides a wide range of freight services<br />

using many freight companies.<br />

Its also ensures extremely competitive<br />

rates for clients. This is achieved because of<br />

its own growing freight volume, as well as the<br />

many contacts it has in the transport<br />

industry.<br />

For more information contact National<br />

Freight Management on ph 03 9800 1444,<br />

fax 03 9800 1199, Toll free: 1800 990 017<br />

(outside Melbourne Metro)<br />

or email: info@natfreightmgt.com.au<br />

AUTOMO TIVE AFTERMARKET MAG AZINE MAY 2009 9

NEWS<br />

BURSON TOTALLY RETHINKS<br />

ITS LOGISTICS OPERATIONS<br />

When leading <strong>Australian</strong> auto parts distributor, Burson <strong>Automotive</strong>, moved to a new greenfield distribution centre in the<br />

Melbourne suburb of Preston in June 2005, the principal motivation was the need to cater for significant business growth.<br />

That said, Burson elected to use this<br />

relocation as an opportunity to totally rethink<br />

and stre<strong>am</strong>line its total logistics operations.<br />

Thus discussions were begun with suppliers<br />

to ensure all inbound stock was properly<br />

identified and barcoded.<br />

A comprehensive new warehouse design<br />

and layout was proposed, based on a full<br />

analysis of the organisation’s business flows.<br />

Receiving, Put Away, Picking,<br />

Replenishment, and Despatch processes<br />

were substantially re-engineered. And finally,<br />

the decision was taken to implement an<br />

advanced warehouse management system<br />

using the Warehouse Management System<br />

(WMS) supplied and installed by Pulse<br />

Logistics Systems.<br />

Now, nearly two years later, Burson reports<br />

the successful completion of this major<br />

logistics project. The final step completed<br />

last year being the picking of more than 1200<br />

daily ‘vehicle off road’ or emergency orders<br />

now being routinely handled by only four staff<br />

using the Pulse WMS.<br />

Established in 1971, by Managing<br />

Director, Garry Johnson, the genesis of the<br />

Burson business was the distribution of a<br />

range of automotive chemical products that<br />

were sold to workshops and service stations<br />

from a single ‘Cash Van’.<br />

Today the company employs over 700<br />

te<strong>am</strong> members in 66 Auto Parts stores<br />

located throughout Victoria, Tasmania, New<br />

South Wales, and Queensland.<br />

With a major focus on serving the auto<br />

trade for all of their aptly n<strong>am</strong>ed<br />

‘aftermarket’ requirements, the new 12,000<br />

From March 30 until the June 30 2009<br />

every Century branded battery purchased from<br />

participating resellers and stockists will receive<br />

an entry form to go into the draw for a chance<br />

to win a mind blowing $100,000 cash<br />

(conditions apply).<br />

Supported with a national print advertising<br />

c<strong>am</strong>paign in leading consumer lifestyle and<br />

motoring <strong>magazine</strong>s and an extensive range of<br />

in-store merchandise and POS materials,<br />

square metres Burson Distribution Centre<br />

(DC) typically ships 15,000 line items per<br />

day, and receives a comparable number of<br />

new stock receipts.<br />

Prior to relocating to the new DC at<br />

Preston, Burson was based in the Melbourne<br />

suburb of Heidelberg. Continued business<br />

expansion forced the company to add to its<br />

then existing single warehouse, by acquiring<br />

a similarly sized warehouse on an adjacent<br />

site. This scenario presented an inherent<br />

range of efficiency challenges. Of principal<br />

concern; however, was that this second<br />

warehouse had also quickly reached its<br />

capacity. And hence the decision was taken<br />

in 2004 to move to a brand new purpose<br />

designed and substantially larger facility. As<br />

an indication of Burson’s growth, the<br />

company had 17 stores when it moved into<br />

the first warehouse at Heidelberg, and had<br />

58 stores when the decision to relocate to<br />

Preston was taken.<br />

As Mr Johnson noted: “We started with<br />

an empty block of land and a blank sheet of<br />

paper. Our aim was to create the most<br />

efficient distribution centre possible. And so<br />

as well as taking a huge <strong>am</strong>ount of care with<br />

the new building’s design, we also elected to<br />

put each and every aspect of our logistics<br />

operations under the microscope. Our view<br />

was quite simply that if we could do<br />

something better we would.<br />

“In doing all of this, we were motivated<br />

by the need to maximise customer service<br />

levels and accommodate future growth as<br />

opposed to only thinking about productivity<br />

gains as many companies no doubt would.<br />

Century is helping resellers grow their battery<br />

business by generating increased customer<br />

‘pull through’ leading to increased sales of<br />

batteries and battery related products. Entries<br />

close July 13 2009.<br />

For more information contact a Century<br />

Batteries representative on 1300 362 287 or<br />

visit www.centurybatteries.com.au<br />

“For instance, many of our customers<br />

need to order a specific part while they are<br />

actually working on an out-of-service vehicle.<br />

And if our stores don’t have that part they<br />

must be able to immediately check the stock<br />

in the DC to see if the part is there. In doing<br />

that, they must also have total confidence<br />

that the information they see is absolutely<br />

correct.<br />

“Next they must be able to order and<br />

receive that product as quickly as possible.<br />

While finally, whatever we pick and despatch<br />

to the stores must be 100 percent accurate.<br />

So if we say we have an item in stock and<br />

we don’t, then we let the customer down.<br />

And if we can’t deliver to them quickly we<br />

let them down. And so too if what we ship is<br />

not correct.<br />

“When we began our logistics review we<br />

felt we were not getting the job done as well<br />

as we could. Some of our systems and<br />

procedures had simply evolved over time.<br />

And so our <strong>am</strong>bition was to do things a little<br />

bit smarter,” Mr Johnson concluded.<br />

For more information call 1800 785 730<br />

or visit www.pulse.com.au<br />

WIN A HUNDRED GRAND IN THE HAND<br />

Century Batteries is supporting its reseller network, with the largest and most exciting<br />

national consumer promotion ever seen in the <strong>Australian</strong> automotive battery industry.<br />

10 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

NEWS<br />

The $12 million 'Kaizen' line will produce<br />

<strong>Australian</strong>-made lights for Toyota’s C<strong>am</strong>ry,<br />

hybrid C<strong>am</strong>ry and Aurion models.<br />

The partnership between Toyota Motor<br />

Corporation Australia and Hella is a fine<br />

ex<strong>am</strong>ple of innovation, collaboration and<br />

investment in the future.<br />

Hella's forward-looking investment shows<br />

just the kind of resilience and confidence<br />

that will help <strong>Australian</strong> manufacturing ride<br />

out the global economic storm.<br />

The Government is providing $35 million<br />

through the Green Car Innovation Fund as<br />

part of a co-investment deal with Toyota to<br />

manufacture the hybrid C<strong>am</strong>ry at the<br />

company’s Altona plant in Victoria from<br />

2010.<br />

Toyota expects production of the hybrid<br />

C<strong>am</strong>ry to result in more than $80 million<br />

NEW AUSTRALIAN PARTS FOR<br />

AUSTRALIAN-MADE CARS<br />

Hella opens new $12M production line in Victoria<br />

Senator Kim Carr, Minister for Innovation, Industry, Science and Research, has welcomed the<br />

opening of Hella Australia's state-of-the-art production line in Mentone, Victoria.<br />

worth of purchases throughout the Victorian<br />

and South <strong>Australian</strong> automotive components<br />

industry.<br />

Mr Carr said the announcement was<br />

extremely pleasing in the current tough<br />

economic environment.<br />

“It is a pleasure to congratulate Hella and<br />

Toyota on this magnificent announcement,”<br />

he said.<br />

“This is exactly the kind of project we<br />

want to encourage.<br />

“It is about building world-class capacity<br />

and making Australia a base for global<br />

manufacturing in the automotive industry.<br />

“It proves the point that this country can<br />

do it as well – if not better – than anyone.<br />

“We’ve had far too much bad news lately<br />

– especially in the automotive industry.<br />

“We are subjected to a steady stre<strong>am</strong> of<br />

announcements about struggling companies,<br />

bleak economic conditions, and – most<br />

tragically of all – job losses for working<br />

<strong>Australian</strong>s.<br />

“In times like this – even more than in<br />

happier times – it is a genuine pleasure to be<br />

involved in opening new projects.”<br />

Hella's new Kaizen line is an ex<strong>am</strong>ple of<br />

the way the Government's $6.2 billion New<br />

Car Plan for a Greener Future is giving the<br />

industry the certainty it needs to invest in<br />

developing the cars of the future.<br />

A New Car Plan for a Greener Future aims<br />

to make the industry cleaner, greener and<br />

more innovative.<br />

More information on A New Car Plan<br />

for a Greener Future is available at<br />

www.innovation.gov.au<br />

AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 11

NEWS<br />

TOYOTA LEADS GREEN CHARGE<br />

AT MOTOR SHOW<br />

The theme of the last Melbourne Motor Show to be held for two years was definitely eco-friendly cars.<br />

Japanese manufacturers lead the (electric)<br />

charge with three new petrol-electric hybrids<br />

and two battery electric cars, which are soon<br />

to enter production in Japan.<br />

The third-generation Toyota Prius, the latest<br />

Lexus high-performance hybrid, the new model<br />

RX-450h, and Honda’s Insight all took centre<br />

stage.<br />

The Motor Show's pure plug-in electric<br />

contingent included production-ready small<br />

cars from Mitsubishi and Subaru.<br />

Mitsubishi's i MiEV is scheduled for<br />

production this year, and began a roadshow<br />

around Australia immediately after the Motor Show.<br />

Completing the electric offerings from major manufacturers was the<br />

Subaru Stella, which is intended for limited production for the Japanese<br />

market later this year to showcase Subaru's<br />

advanced battery technology.<br />

<strong>Australian</strong> motorists were given a glimpse<br />

of the future of motoring with the unveiling<br />

of three hybrid vehicles by Toyota.<br />

The vehicles - the first of which will go<br />

on sale in Australia as early as July -<br />

emphatically confirmed Toyota's long-term<br />

commitment to producing hybrid vehicles<br />

that deliver superior fuel economy and ultralow<br />

emissions.<br />

Toyota showcased the all-new thirdgeneration<br />

Prius (to be launched in<br />

Australia in less than five months), a dr<strong>am</strong>atic locally styled Hybrid<br />

C<strong>am</strong>ry Concept Vehicle, and the futuristic 1/X (pronounced one-Xth)<br />

show car.<br />

The company's senior executive director sales and<br />

marketing David Buttner said the vehicles reveal<br />

Toyota's determination to make sustainable mobility<br />

a reality.<br />

"The three Toyota hybrid cars unveiled today<br />

contain ground-breaking technologies and highlight<br />

innovative possibilities for the future of motoring," Mr<br />

Buttner said.<br />

The Hybrid C<strong>am</strong>ry Concept Vehicle<br />

was conceived and produced in-house<br />

by Toyota Style Australia.<br />

"The Hybrid C<strong>am</strong>ry Concept Vehicle was conceived<br />

and produced in-house by Toyota Style Australia.<br />

"It is a strong pointer to the hybrid C<strong>am</strong>ry we will<br />

manufacture right here in Australia from early next<br />

year.<br />

"Its startling paintwork, dr<strong>am</strong>atic lines and sporty<br />

appearance definitely convey the passion in our<br />

company to produce Australia's first hybrid car."<br />

Mr Buttner said all-new third-generation Prius is<br />

the culmination of experience gained by Toyota from<br />

selling more than 1.2 million Prius globally over more<br />

than a decade.<br />

"The third-generation Prius is a quantum leap in<br />

technology that includes a remarkable double:<br />

improved performance while using less fuel," he said.<br />

The distinctive 1/X represents a vision for hybrid<br />

motoring in the future.<br />

"The 1/X concept is a vehicle that completely<br />

redefines what it means to be environmentally<br />

considerate.<br />

"The n<strong>am</strong>e says it all: a car that weighs a fraction<br />

of others in its class today - and uses a fraction of the<br />

fuel," he said.<br />

12 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

NEWS<br />

PRO QUIP EXPANDS TO NEW ZEALAND<br />

The range of Pro Quip products is now available throughout New Zealand<br />

following the company’s expansion over the Tasman.<br />

Based in Wellington, the Managing<br />

Director is Grant Marris who is assisted by his<br />

National Sales Manager Jason Hobbs.<br />

Both are very experienced in the local auto<br />

and transport industries.<br />

“This is a very significant move for us,”<br />

Pro Quip’s Martin Haines said.<br />

“The full range of Pro Quip products will<br />

now be given top service in New Zealand. And<br />

CTEK DEFIES DOWNTURN<br />

CTEK has defied the economic downturn by opening a head office<br />

for Australia and New Zealand in Melbourne.<br />

The company, which lays claim to<br />

manufacturing the smartest battery<br />

chargers in the world, opened the office a<br />

week after it exhibited at the <strong>Australian</strong><br />

Auto <strong>Aftermarket</strong> Expo.<br />

CTEK’s Sales and Marketing Manager<br />

for the South Pacific, Stina Wahlqvist, is<br />

running the operation.<br />

The company’s Chairman, Bengt<br />

Wahlqvist, said the products had been<br />

available in Australia for four years and<br />

demand for them had taken off in the last<br />

two.<br />

He said demand for CTEK’s range of<br />

charges will become greater as consumers<br />

look towards maintaining the vehicles they<br />

already own rather than buying new ones.<br />

“It is even more important in tough<br />

economic climate for people to maintain<br />

their cars,” he said.<br />

“When new cars sales are going down,<br />

as it is all over the world, people keep their<br />

old cars so battery manufacturing has not<br />

really gone down so much because<br />

consumers have to replace their batteries.<br />

“The first quarter for us in 2009 was<br />

actually the best quarter we’ve ever had.”<br />

CTEK first began in 2002 and makes<br />

chargers for luxury vehicles including<br />

Porsche, Mercedes, Bentley, Maybach,<br />

Aston Martin, Ferrari, L<strong>am</strong>borghini and<br />

Maserati.<br />

A small panel fitted inside the car’s<br />

cabin informs the driver of the condition<br />

of the car’s battery and whether it needs<br />

charging.<br />

The systems have a surge protector<br />

fitted so that an influx of electricity from<br />

the mains cannot d<strong>am</strong>age the car’s<br />

electrics while it is being charged.<br />

that includes: jerry cans, funnels, battery<br />

boosters, auto electric products, towing<br />

equipment, l<strong>am</strong>ps and accessories.<br />

“Additionally, as we add more exciting<br />

products so those ranges will be quickly<br />

matched out of Wellington,” Mr Haines said.<br />

Pro Quip New Zealand is located at<br />

3/29 Dragon Street, Granada North,<br />

telephone 0800 PRO QUIP (0800 776 7847).<br />

“So you can safely hook up the battery<br />

for an extended period of time without any<br />

risk for overcharging or undercharging,” Mr<br />

Wahlqvist said.<br />

“The latest companies to come on<br />

board are Lexus and BMW, and all of the<br />

companies we build for are very careful<br />

with what you can attach to the car<br />

electronics.<br />

“With it running and attached to the<br />

mains power, you never know what kind of<br />

bad voltage you receive so our chargers<br />

have to protect the car.”<br />

Mr Wahlqvist described CTEK’s<br />

products as high-end professional charging<br />

systems, of which the company has sold<br />

2 million in Europe.<br />

CTEK’s range of battery chargers are<br />

not only aimed at consumers, but also<br />

workshops and garages.<br />

“Batteries are normally undercharged<br />

and when they come in for a service the<br />

mechanics use all of the lights and fans<br />

and things and they are using the battery<br />

to power that up,” Mr Wahlqvist explained.<br />

“So when the cars leave the garage the<br />

battery is in even worse condition so we<br />

recommend mechanics use these bigger<br />

units which they attach to the car during<br />

the service so in the s<strong>am</strong>e time that you<br />

power up the car you are actually also<br />

conditioning the battery.”<br />

The chargers also allow mechanics to<br />

disconnect the battery but retain the<br />

vehicle’s settings so that things like the<br />

audio system do not have to be<br />

reconfigured.<br />

The contact detail’s for CTEK’s Melbourne<br />

office is 03 9863 9390.<br />

Jason Hobbs (left) and Grant Marris.<br />

BOCAR PLACED<br />

IN VOLUNTARY<br />

ADMINISTRATION<br />

<strong>Automotive</strong> aluminium accessory<br />

company Bocar has been placed in<br />

voluntary administration.<br />

Bocar, which is based on the Gold Coast,<br />

makes aluminium bullbars for new cars and<br />

trucks along with trays for one tonners.<br />

The company also supplies a variety of<br />

automotive accessories including sports bars<br />

and nudge bars.<br />

Bocar’s 200 employees have been advised<br />

that the business is for sale.<br />

A number of factors culminated in the<br />

business being placed in voluntary<br />

administration.<br />

Despite growing significantly in the last<br />

few years, the company had recorded a<br />

number of losses.<br />

The company was also being pressured to<br />

move out of its Burleigh Heads premises<br />

because it did not have the number of car<br />

parks required under its council permit.<br />

Moving the company or splitting its<br />

operations between different premises was<br />

not financially affordable.<br />

Bocar lost 30 per cent of its work in<br />

October last year due to the credit crunch,<br />

and could not undertake capital raising as<br />

people shied away from the automotive<br />

industry.<br />

CORRECTION<br />

In our catalogue feature in the March issue of<br />

<strong>Australian</strong> <strong>Automotive</strong> <strong>Aftermarket</strong> Magazine we<br />

inadvertently ran a picture of the latest BOC<br />

Gases catalogue alongside the text for the Bosch<br />

catalogue. AAAM apologises for any problems<br />

this may have caused the affected parties.<br />

AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 13

NEWS<br />

ATKO’S SPONSORSHIP SEARCH<br />

<strong>Australian</strong> World Rally Ch<strong>am</strong>pionship (WRC) driver Chris Atkinson is on the hunt for sponsorship as<br />

he prepares for Australia’s WRC round, the Repco Rally.<br />

The 29-year-old from Bega, New South<br />

Wales, was driving for the factory Subaru Rally<br />

Te<strong>am</strong> until it withdrew from the WRC at the end<br />

of 2008 due to the economic downturn.<br />

Atkinson has since picked up a drive with<br />

the newly formed Citroen Junior Rally Te<strong>am</strong>, but<br />

is seeking for more sponsorship to get to his<br />

goal of the becoming the WRC Ch<strong>am</strong>pion.<br />

“We obviously want to be at the <strong>Australian</strong><br />

round competing for Australia in the top level<br />

and that’s our target,” he said.<br />

Atkinson prides himself on being one of the<br />

fittest drivers in the WRC and attributes his<br />

health to Biosource health and wellbeing<br />

products.<br />

Biosource sponsors Atkinson, who believes<br />

fitness is extremely important for WRC drivers.<br />

He referred to former Subaru te<strong>am</strong>mate,<br />

Petter Solberg, who he said was more<br />

susceptible to colds.<br />

“That was one thing that kept happening<br />

when we were in the world ch<strong>am</strong>pionship, he<br />

was continually getting sick and always running<br />

himself down pushing himself to the limit<br />

training and I was always a little bit fitter than<br />

him, always healthier than him and he couldn’t<br />

understand why,” Atko explained.<br />

“I wasn’t going to let him in on my little<br />

secret and I was going to keep it under wraps.<br />

“In the end, last year we beat him in the<br />

Ch<strong>am</strong>pionship and got five podiums to his one<br />

and I think it paid off.<br />

“Being a little bit smarter and using<br />

preventative techniques helps me a lot and I<br />

think a lot of people haven’t taken that<br />

approach.”<br />

Atkinson was <strong>am</strong>azed at the number of WRC<br />

drivers who got sick.<br />

“In rallying there’s a crew limit like Formula<br />

One and there’s 150 kilos for the two guys.<br />

“Everyone’s trying to stay as lean and light<br />

as possible and you’ve seen people do it the<br />

wrong way by almost starving themselves and<br />

that’s no way to lead up to an event.<br />

“A lot of the leading drivers are sick going<br />

into an event because of the stress; the pressure<br />

on them is unbelievable.”<br />

Atkinson hopes to promote that everyone,<br />

not just elite athletes, should take preventative<br />

measures to stay in shape and that products like<br />

Biosource can help.<br />

Atkinson, who also cycles to keep fit, is no<br />

stranger to injuries sustained in the WRC.<br />

“I knocked myself out pretty well in Wales at<br />

the end of last year,” he explained.<br />

“We rolled eight times and the car crushed<br />

into my head and smashed my helmet.<br />

“I had a bit of brain swelling but there<br />

wasn’t much there to swell,” Atko laughed.<br />

Atkinson revealed that it was sometimes a<br />

struggle to convince crew members that being<br />

in tip top shape was the key to good results.<br />

“You’ve got the sports scientists trying to<br />

look after our health and you have got the<br />

engineer looking after the performance of the<br />

car,” he explained.<br />

“I’ve even had stages where engineers have<br />

said ‘we’re not going to put a water bottle or a<br />

c<strong>am</strong>el back in the car’.<br />

“You go out and do a four hour race and<br />

you’ve got no water with you; it’s absolutely<br />

mindless to think that you’re not going to<br />

hydrate yourself or look after your body.<br />

“Most times the sports scientist win, but<br />

people forget that it is a human driving the car.”<br />

To inquire about sponsoring Atkinson,<br />

email chris@chrisatkinson.com.au<br />

RARE SPARES LEGEND ANNOUNCED<br />

In just its second successful year, the Rare Spares ‘Legend’ Award has already established itself as an industry favourite<br />

for both recipients and those involved in the motoring enthusiasts market.<br />

Created by leading automotive company<br />

Rare Spares, the national ‘Legend’ award<br />

recognises the lifetime achievements of those<br />

that have given great levels of dedication to the<br />

motor industry. Each year an inductee earns<br />

their place in the Legend Hall of F<strong>am</strong>e and<br />

receives a number of personal benefits.<br />

In addition, Rare Spares uses one of the<br />

industry's major events, Summernats, to make<br />

the annual presentation to the inductee each<br />

year in the form of a dedicated timeslot in the<br />

popular Saturday night schedule with the<br />

inductee paraded via a lap of honour of the<br />

main Summernats arena.<br />

The 2009 inductee into the Rare Spares<br />

Legend Hall of F<strong>am</strong>e is serial car builder and<br />

one of the most <strong>am</strong>icable people in the<br />

industry, Howard Astill.<br />

Mr Astill joins the inaugural "Legend", hot<br />

rod icon, Rod Hadfield in the Legend Hall of<br />

F<strong>am</strong>e.<br />

"Since building his first modified Ford in the<br />

1970s, Howard has inspired thousands of<br />

<strong>Australian</strong> car enthusiasts at shows and through<br />

<strong>magazine</strong> articles. Howard has won Street<br />

Machine Magazine's Street Machine of the<br />

Year, three Summernats Grand Ch<strong>am</strong>pions and<br />

has spent most of his life committed to<br />

excellence in the art of car craftsmanship," said<br />

Rare Spares General Manager, David Rayner.<br />

"He is a very worthy inductee into the Rare<br />

Spares Legend Hall of F<strong>am</strong>e and on behalf of<br />

the Directors of Rare Spares and the entire<br />

motoring industry, we congratulate Howard on<br />

his achievement," Mr Rayner added.<br />

2009 Inductee, Mr Astill said: "It is with<br />

great honour that I accept this prestigious<br />

award and <strong>am</strong> privileged to join Rod Hadfield,<br />

the inaugural member. I would like to thank all<br />

those people that have worked with me over the<br />

years and supported my obsession with cars. I<br />

must say Rare Spares are to be congratulated<br />

on their foresight to create the Legend Award<br />

and I look forward in anticipation to the coming<br />

years as others join the Hall of F<strong>am</strong>e.<br />

‘Legends’ receive its own exclusive gold<br />

helmet with the year of the induction and their<br />

n<strong>am</strong>e sign written on to it. The helmet is<br />

designed and painted by well-known artist John<br />

Kral in a scheme exclusive to the Legend<br />

award”.<br />

To ensure that recipients receive<br />

mainstre<strong>am</strong> recognition, they are also provided<br />

with a dedicated full page advertisement in<br />

leading publication Street Machine Magazine,<br />

along with a professional photo shoot.<br />

Rare Spares has also set up a Legend<br />

website at www.rarespareslegend.com.au<br />

14 AUTOMO TIVE AFTERMARKET MAGAZINE MAY 2009 www.aaaa.com.au

HR MATTERS<br />

REMUNERATION PACKAGES<br />

Tips for Effective Negotiation.<br />

Money is one of the most sensitive<br />

issues in the whole hiring process.<br />

Discussing a remuneration package often<br />

causes anxiety for both the employer and<br />

future employee. The following tips aim to<br />

help you negotiate your package in the<br />

most effective manner.<br />

Do your research.<br />

The more information you can gather in<br />

regards to your market value and your<br />

employer the better. For ex<strong>am</strong>ple, by<br />

researching the remuneration packages for<br />

comparable positions prior to entering into<br />

negotiations you will be better equipped to<br />

establish realistic expectations about the<br />

process.<br />

There is a wealth of information<br />

available on the internet, at the public<br />

library, networking groups and universities.<br />

Time spent learning negotiation skills and<br />

preparing for negotiations may be the best<br />

and most worthwhile investment you ever<br />

make.<br />

Be fair<br />

Having consideration for the constraints<br />

of the business and structure, most<br />

employers will agree to any reasonable<br />

salary request. This means that you should<br />

be able to provide a justification for any<br />

request you make (i.e. as accepting the<br />

position will require me to move interstate<br />

is it possible to arrange some paid time off<br />

during the first month so as I can seek new<br />

accommodation? Or, if it is industry<br />

standard that all on call employees receive<br />

monthly remuneration for mobile calls<br />

made then it is reasonable for you to also<br />

expect this) When the negotiations are<br />

finalised your new employer will want you<br />

to feel as if you have accepted an offer<br />

which is fair and reasonable.<br />

Understanding this basic principal often<br />

means the difference between<br />

accomplishment and disappointment.<br />

Pushing further when a deal<br />

has been set could give a<br />

negative first impression.<br />

Use the truth to your benefit<br />

You should never lie in employment<br />

negotiations. If you choose to lie during the<br />

salary negotiations sooner or later you will<br />

be caught. Even if you do not lose the offer<br />

of employment you will be at a tremendous<br />

disadvantage and your credibility will be<br />

called into question. Conversely, total<br />

candour may not be appropriate either, you<br />

are under no obligation to reveal everything<br />

and often it is wise to choose what to<br />

disclose and when to disclose it. It is also<br />

advisable to put a positive spin on<br />

everything. As part of the preparation<br />

process it is a good idea to consider the<br />

possible negative points your new employer<br />

may bring up in the negotiations and work<br />

out in advance how to best deal with these<br />

points in the most upbeat and positive<br />

manner.<br />

Look at the bigger picture<br />

When you are negotiating your salary<br />

package understand that it is not always<br />

DO YOU HAVE A QUESTION YOU REALLY WANT TO ASK?<br />

For more information and assistance phone: AAAA HR Hotline on 1300 735 306 or e-mail hr@aaaa.com.au<br />

The material contained in this publication is general comment and is not intended as advice on any particular matter. No reader should act or fail to act on the basis of any<br />