Drilling for excellence on the North Sea

Drilling for excellence on the North Sea

Drilling for excellence on the North Sea

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INFORMATION FROM DNV TO THE OIL, GAS AND PROCESS INDUSTRIES<br />

NO. 3 – AUGUST 2003<br />

Oil & Gas News<br />

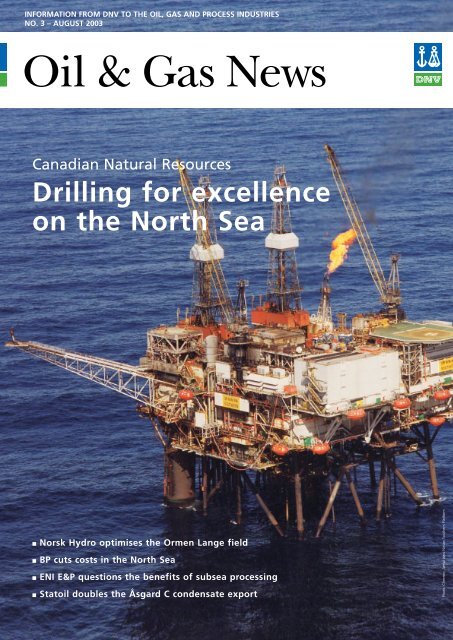

Canadian Natural Resources<br />

<str<strong>on</strong>g>Drilling</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>excellence</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

Plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m<br />

Sou<strong>the</strong>rn<br />

■ Norsk Hydro optimises <strong>the</strong> Ormen Lange field<br />

Ninian<br />

■ BP cuts costs in <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

view Aerial<br />

■ ENI E&P questi<strong>on</strong>s <strong>the</strong> benefits of subsea processing<br />

Chevr<strong>on</strong>:<br />

■ Statoil doubles <strong>the</strong> Åsgard C c<strong>on</strong>densate export Photo:

A new risk reality<br />

in <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

Increased frequency<br />

of gas<br />

releases has lead<br />

to greater risk of<br />

large accidents<br />

<strong>on</strong> <strong>the</strong> Norwegian<br />

Sector,<br />

according to <strong>the</strong><br />

Norwegian Petroleum<br />

Directorate.<br />

The operators<br />

are now faced<br />

with <strong>the</strong> challenge<br />

of turning this trend around.<br />

With mature fields, <strong>the</strong> oil companies in<br />

<strong>the</strong> <strong>North</strong> <strong>Sea</strong> have to balance <strong>the</strong> tasks of<br />

reducing costs while at <strong>the</strong> same time maintaining<br />

or even improving safety. Internati<strong>on</strong>ally<br />

<strong>the</strong> whole industry is in a period<br />

of restructuring with mergers, internal reorganisati<strong>on</strong>s<br />

and o<strong>the</strong>r initiatives to optimise<br />

<strong>the</strong> efficiency.<br />

The process is being watched with eagleeyes<br />

by shareholders, <strong>the</strong> finance market<br />

and society in general. These stakeholders<br />

all demand robust ec<strong>on</strong>omic results toge<strong>the</strong>r<br />

with <strong>the</strong> maintenance of high safety standards.<br />

DNV believes <strong>the</strong> key to handling this<br />

new scenario is to build safety improvement<br />

work into <strong>the</strong> drive <str<strong>on</strong>g>for</str<strong>on</strong>g> higher efficiency. We<br />

assist our customers in making use of a riskbased<br />

approach to management, planning<br />

and executi<strong>on</strong> of projects, operati<strong>on</strong>s and<br />

maintenance. The results of this approach<br />

are encouraging – more streamlined organisati<strong>on</strong>s<br />

can be better at achieving high reliability<br />

and safety levels, when streamlining<br />

leads to more focus <strong>on</strong> <strong>the</strong> critical elements<br />

of <strong>the</strong> facilities and <strong>the</strong>ir operati<strong>on</strong>s.<br />

Successful implementati<strong>on</strong> of a riskbased<br />

approach depends <strong>on</strong> how <strong>the</strong> organisati<strong>on</strong><br />

views this matter and <strong>on</strong> <strong>the</strong> provisi<strong>on</strong><br />

of leadership. There is c<strong>on</strong>siderable<br />

potential <str<strong>on</strong>g>for</str<strong>on</strong>g> operators to succeed if <strong>the</strong>y<br />

are willing to recognise <strong>the</strong> new risk reality<br />

and do something about it.<br />

Magne Tørhaug<br />

Director of DNV C<strong>on</strong>sulting Norway<br />

2 OIL & GAS NEWS 3 2003<br />

Optimising producti<strong>on</strong><br />

New c<strong>on</strong>cept increases<br />

investment returns<br />

The Norwegian state-owned company Petoro is evaluating<br />

how investments in <strong>the</strong> new Smart Operati<strong>on</strong>s c<strong>on</strong>cept can<br />

increase rates of returns from <strong>the</strong>ir offshore assets in <strong>the</strong><br />

<strong>North</strong> <strong>Sea</strong>. Preliminary results indicate a potential revoluti<strong>on</strong><br />

in <strong>the</strong> way future offshore operati<strong>on</strong>s could be per<str<strong>on</strong>g>for</str<strong>on</strong>g>med.<br />

Smart Operati<strong>on</strong>s is a term used to<br />

describe c<strong>on</strong>cepts where real time<br />

data, new in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> and technology<br />

soluti<strong>on</strong>s are used to optimise offshore<br />

field operati<strong>on</strong>s <strong>on</strong> <strong>the</strong> Norwegian<br />

C<strong>on</strong>tinental Shelf. The methodology is<br />

designed to offer complementary<br />

opportunities to existing improvements<br />

within drilling, producti<strong>on</strong> optimisati<strong>on</strong><br />

and reservoir management,<br />

as well as operati<strong>on</strong>s and maintenance.<br />

Petoro project manager Roy Ruså<br />

says: “We believe that Smart Operati<strong>on</strong>s<br />

has <strong>the</strong> potential to improve drilling<br />

operati<strong>on</strong>s and regularity, increase<br />

hydrocarb<strong>on</strong> recovery, optimise offshore<br />

operati<strong>on</strong>s and maintenance,<br />

and improve <strong>the</strong> health, safety and<br />

envir<strong>on</strong>mental indicators – but we are<br />

not yet sure to what extent.<br />

“The results of <strong>the</strong> project so far<br />

have significantly enhanced our basis<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> decisi<strong>on</strong> support. Smart Operati<strong>on</strong>s<br />

can accelerate and increase <strong>the</strong> recovery<br />

of hydrocarb<strong>on</strong>s throughout <strong>the</strong><br />

life cycle of a field. C<strong>on</strong>sensus has<br />

been reached in Petoro <strong>on</strong> <strong>the</strong> focus<br />

of <strong>the</strong> field prioritisati<strong>on</strong> of our Smart<br />

Operati<strong>on</strong>s investments. The improvements<br />

that this c<strong>on</strong>cept will bring to<br />

certain assets could revoluti<strong>on</strong>ise <strong>the</strong><br />

way our offshore operati<strong>on</strong>s will<br />

be per<str<strong>on</strong>g>for</str<strong>on</strong>g>med in <strong>the</strong> future.”<br />

Ruså c<strong>on</strong>tinues: “There are c<strong>on</strong>siderable<br />

opportunities to enhance <strong>the</strong><br />

existing infrastructure through <strong>the</strong> use<br />

of fibre optic cables, SOIL, modern<br />

instrumentati<strong>on</strong> and c<strong>on</strong>trol systems,<br />

with improved and prol<strong>on</strong>ged hydrocarb<strong>on</strong><br />

producti<strong>on</strong> as a result. New<br />

investments are required to obtain <strong>the</strong><br />

full benefits, but we believe that <strong>the</strong><br />

payback period <str<strong>on</strong>g>for</str<strong>on</strong>g> investments in<br />

Smart Operati<strong>on</strong>s is less than <strong>on</strong>e year<br />

in a large number of cases. We also<br />

expect <strong>the</strong> rewards to be l<strong>on</strong>g-lasting<br />

throughout an extended life cycle.”<br />

DNV has been assisting Petoro in<br />

assessing <strong>the</strong> effect of Smart Operati<strong>on</strong>s<br />

<strong>on</strong> <strong>the</strong>ir portfolio, and preparing specific<br />

business cases. This included<br />

benchmarking and ranking <strong>the</strong><br />

licences relative to various ec<strong>on</strong>omic<br />

and technical key per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance indicators.<br />

DNV project manager Art Kenich<br />

says: “The effects of new in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong><br />

and technology soluti<strong>on</strong>s, such as realtime<br />

m<strong>on</strong>itoring and operati<strong>on</strong> per<str<strong>on</strong>g>for</str<strong>on</strong>g>med<br />

from remote land-based locati<strong>on</strong>s<br />

supported by risk centred maintenance<br />

programmes, have a tremendous<br />

potential. Reduced operating<br />

costs, improvements in producti<strong>on</strong><br />

regularity, hydrocarb<strong>on</strong> recovery, producti<strong>on</strong><br />

life and safety are just some of<br />

<strong>the</strong> benefits that will result in excepti<strong>on</strong>al<br />

levels of return <str<strong>on</strong>g>for</str<strong>on</strong>g> comparatively<br />

small investments.”<br />

Petoro has been successful in presenting<br />

business cases to partners in<br />

strategically selected licences as a support<br />

to <strong>the</strong>ir <strong>on</strong>going work. C<strong>on</strong>sequently,<br />

several operators and partners<br />

have agreed to include investment<br />

provisi<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> Smart Operati<strong>on</strong>s in <strong>the</strong>ir<br />

future plans.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Art.Kenich@dnv.com<br />

FACTS<br />

Petoro is a state-owned limited<br />

company resp<strong>on</strong>sible <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

Norwegian State’s financial interests<br />

<strong>on</strong> <strong>the</strong> Norwegian C<strong>on</strong>tinental Shelf.<br />

One of Petoro’s main objectives is to<br />

be a proactive partner in strategically<br />

important licenses and originate and<br />

develop initiatives like Smart<br />

Operati<strong>on</strong>s that will lead to<br />

maximised rates of return <strong>on</strong> <strong>the</strong><br />

State’s investments.

<str<strong>on</strong>g>Drilling</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>excellence</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

Aerial view of Ninian Sou<strong>the</strong>rn Plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m CNR´s Casey McWhan, left, and Richard Turnbull.<br />

DNV is working with <strong>North</strong><br />

<strong>Sea</strong> newcomer CNR Internati<strong>on</strong>al<br />

(UK), a subsidiary of<br />

Canadian Natural Resources<br />

(CNR) to help <strong>the</strong> company<br />

realise its goal of <str<strong>on</strong>g>excellence</str<strong>on</strong>g><br />

in integrity management.<br />

CNR is <strong>on</strong>e of a number of Canadian<br />

independents helping to maximise<br />

<strong>the</strong> life of, and return from, mature<br />

<strong>North</strong> <strong>Sea</strong> fields. Since entering this<br />

market over two years ago, <strong>the</strong> company<br />

has acquired several assets in <strong>the</strong><br />

East Shetland Basin, including three<br />

plat<str<strong>on</strong>g>for</str<strong>on</strong>g>ms in <strong>the</strong> Ninian field and <strong>the</strong><br />

single plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m in <strong>the</strong> Murchis<strong>on</strong><br />

field.<br />

Casey McWhan, CNR’s offshore<br />

producti<strong>on</strong> operati<strong>on</strong>s manager,<br />

believes <strong>the</strong>re are a lot of opportunities<br />

in <strong>the</strong> <strong>North</strong> <strong>Sea</strong>. “At present this<br />

market is very similar to what Western<br />

Canada was when CNR started out in<br />

<strong>the</strong> early ‘90s. When <strong>the</strong> big oil companies<br />

can no l<strong>on</strong>ger make a profit<br />

due to high operating costs, we are<br />

successful as we are a streamlined,<br />

profit organisati<strong>on</strong> that is focussed <strong>on</strong><br />

efficient delivery,” he says.<br />

Ambitious plans<br />

CNR expects to be in <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

until at least 2020 and has ambitious<br />

plans <str<strong>on</strong>g>for</str<strong>on</strong>g> its acquisiti<strong>on</strong>s. These plans<br />

can <strong>on</strong>ly be realised with an assurance<br />

of process integrity delivered through<br />

a fully developed and implemented<br />

strategy focussing <strong>on</strong> <strong>the</strong> specific<br />

needs of mature assets.<br />

However, like o<strong>the</strong>r new investors<br />

in <strong>the</strong> <strong>North</strong> <strong>Sea</strong>, CNR found that<br />

its recently acquired assets were not<br />

in excellent c<strong>on</strong>diti<strong>on</strong> due to cost<br />

cutting measures and reduced maintenance<br />

by <strong>the</strong> previous operators.<br />

Richard Turnbull, facilities manager<br />

at CNR, says: “Ninian South had problems<br />

in areas we didn’t expect when<br />

we took it over. Some of <strong>the</strong> lower risk<br />

systems, such as <strong>the</strong> processed oil system,<br />

gave us some problems.”<br />

CNR has learnt quickly from this.<br />

“We’re safety c<strong>on</strong>scious and are now<br />

refocusing <strong>on</strong> changes to <strong>the</strong> integrity<br />

management system that was in <strong>the</strong><br />

process of being revamped. In recogniti<strong>on</strong><br />

of <strong>the</strong> business-critical nature<br />

of <strong>the</strong> integrity management, we’ve<br />

elected to bring that focus internally,”<br />

says Turnbull.<br />

Integrity management<br />

DNV is able to provide a multi-discipline<br />

integrity management team with<br />

resp<strong>on</strong>sibility <str<strong>on</strong>g>for</str<strong>on</strong>g> offshore facility<br />

integrity. Pers<strong>on</strong>nel from DNV C<strong>on</strong>sulting<br />

and DNV Technology Services<br />

are now working offshore and within<br />

CNR’s Aberdeen headquarters to help<br />

<strong>the</strong> operator develop and implement<br />

a detailed integrity management<br />

system <str<strong>on</strong>g>for</str<strong>on</strong>g> all its <strong>North</strong> <strong>Sea</strong> assets.<br />

Photo Capti<strong>on</strong>: Chevr<strong>on</strong><br />

This follows <strong>on</strong> from an earlier DNV<br />

review of CNR’s integrity management<br />

arrangements <str<strong>on</strong>g>for</str<strong>on</strong>g> pressure systems<br />

and technical support during an<br />

intensive programme of process<br />

rec<strong>on</strong>figurati<strong>on</strong> and inspecti<strong>on</strong> <strong>on</strong> <strong>the</strong><br />

Ninian South plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m. “We had DNV<br />

assist us in <strong>the</strong> early days of <strong>the</strong> Ninian<br />

South problems. We saw a professi<strong>on</strong>alism<br />

<strong>the</strong>re that could help us,” says<br />

Turnbull.<br />

DNV is currently assisting CNR to<br />

identify needs and define best practices<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> integrity management, and<br />

CNR aims to have <strong>the</strong>ir new system<br />

in operati<strong>on</strong> by <strong>the</strong> end of this year.<br />

“I d<strong>on</strong>’t think that appropriate<br />

focus has previously been placed<br />

<strong>on</strong> integrity management by <strong>the</strong><br />

regulatory authorities, but its going to<br />

become more prominent. We want to<br />

make sure we run our plat<str<strong>on</strong>g>for</str<strong>on</strong>g>ms safely<br />

and efficiently,” adds Casey McWhan.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Martin.Munday@dnv.com<br />

Stuart.D.Brewer@dnv.com<br />

OIL & GAS NEWS 3 2003 3

The Ormen Lange field is <strong>the</strong><br />

first deepwater discovery to be<br />

developed offshore Norway.<br />

Located 130 km from <strong>the</strong> west<br />

coast of Norway at a depth of<br />

about 1,000 metres, <strong>the</strong> development<br />

of this field represents<br />

a major challenge <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> operator,<br />

Norsk Hydro.<br />

The challenge lies in <strong>the</strong> combinati<strong>on</strong> of<br />

deep water, extremely rough seabed c<strong>on</strong>diti<strong>on</strong>s,<br />

a l<strong>on</strong>g tie-back distance and<br />

demanding wea<strong>the</strong>r c<strong>on</strong>diti<strong>on</strong>s.<br />

DNV is involved in several aspects of<br />

this project during <strong>the</strong> development<br />

phase, such as looking <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> best subseato-land<br />

soluti<strong>on</strong> and setting reliability targets<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> critical comp<strong>on</strong>ents.<br />

Looking <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> optimal subsea-to-land<br />

soluti<strong>on</strong><br />

During <strong>the</strong> c<strong>on</strong>cept selecti<strong>on</strong> phase a<br />

number of ways of developing <strong>the</strong> field<br />

were c<strong>on</strong>sidered, ranging from innovative<br />

soluti<strong>on</strong>s like a novel subsea-to-land c<strong>on</strong>cept<br />

that included subsea wells tied back<br />

to an <strong>on</strong>shore terminal, to a more traditi<strong>on</strong>al<br />

deepwater c<strong>on</strong>cept c<strong>on</strong>sisting of an<br />

offshore processing facility with wet and<br />

4 OIL & GAS NEWS 3 2003<br />

Offshore operati<strong>on</strong>s<br />

Optimising<br />

soluti<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

Ormen Lange<br />

Setting reliability goals <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

downhole safety valves<br />

The gas producti<strong>on</strong> at Ormen Lange is<br />

scheduled to start in 2007. Due to <strong>the</strong> prolific<br />

reservoir c<strong>on</strong>diti<strong>on</strong>s, it is planned to<br />

use big bore tubing (9 5/8 inch), high<br />

flow rate wells (13 MSm 3 /day), with 7 inch<br />

downhole safety valves <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> first eight<br />

pre-drilled wells, <strong>the</strong>reby limiting <strong>the</strong><br />

number of wells to be drilled later in <strong>the</strong><br />

life of <strong>the</strong> field.<br />

The plans are to install deep set subsurface<br />

safety valves as far down as 1,600m<br />

in <strong>the</strong> wells. This unusual depth is due to<br />

<strong>the</strong> risk of hydrate <str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> after a shutdown.<br />

The drive <str<strong>on</strong>g>for</str<strong>on</strong>g> reducti<strong>on</strong> in well<br />

count and <strong>the</strong> introducti<strong>on</strong> of some ele-<br />

The development of <strong>the</strong> Ormen Lange field represents a major challenge <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

operator Norsk Hydro.<br />

dry wells. In December 2002, Norsk Hydro<br />

announced <strong>the</strong> decisi<strong>on</strong> to use <strong>the</strong> subseato-land<br />

c<strong>on</strong>cept.<br />

The project has now moved into <strong>the</strong><br />

fr<strong>on</strong>t-end engineering and design (FEED)<br />

phase. DNV is assisting Norsk Hydro and<br />

its partners to find <strong>the</strong> optimal subsea-toland<br />

soluti<strong>on</strong> from <strong>the</strong> reservoir to <strong>the</strong><br />

market. This involves a holistic reliability<br />

and maintainability assessment of <strong>the</strong> well<br />

and downhole completi<strong>on</strong> system, subsea<br />

producti<strong>on</strong> and c<strong>on</strong>trol system, <strong>on</strong>shore<br />

plant processing system with utilities and<br />

<strong>the</strong> transportati<strong>on</strong> system to <strong>the</strong> c<strong>on</strong>sumers.<br />

Several soluti<strong>on</strong>s will be assessed<br />

based <strong>on</strong> a cost-benefit approach.<br />

Deepwater explorati<strong>on</strong> and develop-<br />

ments of uncertain technology will make<br />

<strong>the</strong> field very sensitive ec<strong>on</strong>omically to<br />

downhole valve failures. The qualificati<strong>on</strong>,<br />

<strong>the</strong>re<str<strong>on</strong>g>for</str<strong>on</strong>g>e, of <strong>the</strong>se valves is particularly<br />

important.<br />

The valves are subject to <strong>the</strong> qualificati<strong>on</strong><br />

scheme in DNV’s Recommended<br />

Practice RP-A203 Qualificati<strong>on</strong> Procedures<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> New Technology. DNV is managing <strong>the</strong><br />

qualificati<strong>on</strong>, planning and executi<strong>on</strong> of<br />

three types of deep-set 7 inch downhole<br />

safety valves in co-operati<strong>on</strong> with <strong>the</strong><br />

industry. Identificati<strong>on</strong> of possible failure<br />

modes and documentati<strong>on</strong> of <strong>the</strong> margins<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> safe operati<strong>on</strong> based <strong>on</strong> experience,<br />

numeric analysis and/or in-house tests are<br />

being worked <strong>on</strong>, which combined with<br />

ment is characterised by a high level of<br />

investment, a l<strong>on</strong>g payback time and<br />

potentially severe business disrupti<strong>on</strong><br />

costs. Engineers and managers are often<br />

required to make milli<strong>on</strong>-dollar decisi<strong>on</strong>s<br />

in situati<strong>on</strong>s where <strong>the</strong>re is no time to<br />

explore <strong>the</strong> upsides and downsides of<br />

those decisi<strong>on</strong>s. Quantitative reliability<br />

and maintainability assessments allow <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

cost-benefit analyses. Through quantificati<strong>on</strong><br />

and factual understanding of <strong>the</strong><br />

costs and benefits of a design change,<br />

sound ec<strong>on</strong>omic decisi<strong>on</strong>s can be made.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Fredrik.Gustavss<strong>on</strong>@dnv.com<br />

Remi.Eriksen@dnv.com<br />

third-party tests comprise a systematic<br />

qualificati<strong>on</strong> approach that goes bey<strong>on</strong>d<br />

traditi<strong>on</strong>al and current practice.<br />

The main source of documented experience<br />

is based <strong>on</strong> <strong>the</strong> database ‘WellMaster’,<br />

which is a worldwide experience database<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> downhole completi<strong>on</strong> equipment.<br />

It includes in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> about downhole<br />

safety valves from all manufacturers over<br />

<strong>the</strong> past two decades. This experience is<br />

used to set <strong>the</strong> reliability goals <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

Ormen Lange downhole safety valves and<br />

to justify <strong>the</strong>ir selected c<strong>on</strong>figurati<strong>on</strong> from<br />

a range of opti<strong>on</strong>s.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Ole.Rengard@dnv.com<br />

Illustrati<strong>on</strong>: Hydro Media

BP cuts costs in <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

As mature fields in <strong>the</strong> <strong>North</strong> <strong>Sea</strong> struggle to sustain profitability in a declining oil and<br />

gas market, BP is finding success with help from DNV, using a risk-based approach.<br />

Declining oil and gas reserves in <strong>the</strong><br />

<strong>North</strong> <strong>Sea</strong> have driven operators to evaluate<br />

alternative scenarios, including sales,<br />

outsourcing, changing or re-engineering<br />

installati<strong>on</strong>s, as well as enhancing <strong>the</strong><br />

effectiveness of <strong>the</strong>ir organisati<strong>on</strong>.<br />

To meet <strong>the</strong> requirement of reducing<br />

operating expenditures by 30% to reach<br />

top quartile, BP decided to start a wide<br />

range of improvements in <strong>the</strong> organisati<strong>on</strong>.<br />

As part of this process, BP is selling<br />

<strong>the</strong> Gyda field to Talisman Energy and is<br />

re-engineering <strong>the</strong> operati<strong>on</strong> of <strong>the</strong> Ula<br />

and Valhall fields.<br />

DNV has assisted BP by per<str<strong>on</strong>g>for</str<strong>on</strong>g>ming<br />

risk-based screening and analysis of activities<br />

related to producti<strong>on</strong> support, both<br />

<strong>on</strong> land and offshore. Measures to<br />

increase operati<strong>on</strong>al safety and producti<strong>on</strong><br />

have also been identified. The project<br />

identified opti<strong>on</strong>s to streamline work<br />

processes and technical modificati<strong>on</strong>s to<br />

reduce annual operating costs by as much<br />

as 10–15%.<br />

Questi<strong>on</strong>ing <strong>the</strong> cost and<br />

benefit of subsea processing<br />

Compared to traditi<strong>on</strong>al<br />

methods of handling well fluids<br />

to <strong>on</strong>shore terminals, subsea<br />

processing has <strong>the</strong> potential<br />

benefit of increasing reservoir<br />

recovery rate and reducing capital<br />

expenditures.<br />

However, this method can expose companies<br />

to uncertainties in future cash flow.<br />

DNV has been assigned by ENI E&P to<br />

evaluate <strong>the</strong> pros and c<strong>on</strong>s of subsea processing.<br />

Subsea processing can significantly<br />

reduce initial investments by removing <strong>the</strong><br />

need <str<strong>on</strong>g>for</str<strong>on</strong>g> expensive, manned floaters. A<br />

c<strong>on</strong>cept based <strong>on</strong> subsea processing offers<br />

companies <strong>the</strong> opti<strong>on</strong> to provide additi<strong>on</strong>-<br />

The use of risk-based methodology has<br />

proven to be a very effective means of:<br />

• Ensuring that high health, safety and<br />

envir<strong>on</strong>mental standards are sustained<br />

and leveraged throughout <strong>the</strong> change<br />

process<br />

• Identifying substantial ec<strong>on</strong>omic opportunities<br />

• Involving <strong>the</strong> organisati<strong>on</strong> in <strong>the</strong><br />

change process<br />

Toge<strong>the</strong>r, BP and DNV are now preparing<br />

to implement <strong>the</strong> identified opportunities<br />

by developing new and more effec-<br />

al energy to <strong>the</strong> well stream to reach treatment<br />

facilities both offshore and <strong>on</strong>shore.<br />

This is particularly important <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

exploitati<strong>on</strong> of hydrocarb<strong>on</strong> reservoirs in<br />

deepwater, where <strong>the</strong> need to provide<br />

energy to <strong>the</strong> well stream is higher. The<br />

potential benefit is realised by increasing<br />

<strong>the</strong> ultimate recovery and accelerati<strong>on</strong> of<br />

<strong>the</strong> producti<strong>on</strong>.<br />

In subsea processing, <strong>the</strong> anticipated<br />

equipment per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance and associated<br />

operating costs are subject to uncertainty.<br />

This is <str<strong>on</strong>g>for</str<strong>on</strong>g>tified in deepwater where subsea<br />

interventi<strong>on</strong>s become more expensive and<br />

are associated with l<strong>on</strong>ger waiting times<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> required interventi<strong>on</strong> vessels. The<br />

fundamental questi<strong>on</strong> about <strong>the</strong> process is<br />

whe<strong>the</strong>r <strong>the</strong> reduced capital expenditure<br />

of a subsea processing system is justified<br />

Photo: BP<br />

BP is reengineering <strong>the</strong> operati<strong>on</strong> of <strong>the</strong> Ula (left) and Valhall (right) fields in <strong>the</strong> <strong>North</strong> <strong>Sea</strong>.<br />

tive processes <str<strong>on</strong>g>for</str<strong>on</strong>g> BP’s new <strong>on</strong>shore organisati<strong>on</strong><br />

in Norway.<br />

DNV is also using its competence to<br />

provide assistance <strong>on</strong> similar projects <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

o<strong>the</strong>r major oil and gas companies<br />

operating in <strong>the</strong> <strong>North</strong> <strong>Sea</strong>. These reengineering<br />

projects are utilising DNV’s<br />

risk-based methodology and broad range<br />

of safety, asset operati<strong>on</strong> and process<br />

mapping services.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Hans.Petter.Ellingsen@dnv.com<br />

by higher operati<strong>on</strong>al expenditures compared<br />

to traditi<strong>on</strong>al systems.<br />

ENI E&P, through its Norwegian affiliate<br />

Norsk Agip, has asked DNV to develop<br />

and dem<strong>on</strong>strate a methodology to assess<br />

alternative subsea processing systems during<br />

feasibility and c<strong>on</strong>cept screening phases.<br />

The results of <strong>the</strong> studies will enable<br />

ENI E&P to predict lifecycle cost elements<br />

and associated uncertainties. It will identify<br />

<strong>the</strong> main c<strong>on</strong>tributors to lifecycle costs,<br />

and evaluate <strong>the</strong> costs and benefits of<br />

different subsea processing systems and<br />

maintenance strategies to find <strong>the</strong> most<br />

optimal soluti<strong>on</strong>.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please c<strong>on</strong>tact:<br />

Ole.Rengard@dnv.com<br />

Remi.Eriksen@dnv.com<br />

Photo: BP<br />

OIL & GAS NEWS 3 2003 5

6 OIL & GAS NEWS 3 2003<br />

Onshore operati<strong>on</strong>s<br />

First European gas export facility<br />

<strong>on</strong> its way Statoil has <strong>on</strong> behalf of <strong>the</strong> Snøhvit licensee group commenced preparati<strong>on</strong>s<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> first export facility <str<strong>on</strong>g>for</str<strong>on</strong>g> liquefied natural gas (LNG) from <strong>the</strong> Snøhvit<br />

field in <strong>the</strong> Barents <strong>Sea</strong>. The marine operati<strong>on</strong>s are expected to pose various<br />

risks, and DNV has been assigned to verify all <strong>the</strong>se operati<strong>on</strong>s during installati<strong>on</strong><br />

in cooperati<strong>on</strong> with L<strong>on</strong>d<strong>on</strong> Offshore C<strong>on</strong>sultants.<br />

FACTS<br />

INSTALLATION SCHEDULE<br />

The Snøhvit gas field is located<br />

70˚41’ north and 23˚30’ east in <strong>the</strong><br />

Barents <strong>Sea</strong>, approximately 140 km<br />

north-west of Hammerfest in<br />

Norway.<br />

All verificati<strong>on</strong> work will be completed<br />

in accordance with <strong>the</strong> DNV<br />

Rules <str<strong>on</strong>g>for</str<strong>on</strong>g> Planning and Executi<strong>on</strong> of<br />

Marine Operati<strong>on</strong>s.<br />

Preassembled units and racks<br />

fabricated at Farbcom in Belgium<br />

and two large slug catchers<br />

fabricated at Heerema in Holland<br />

will be transported to Hammerfest<br />

during summer 2004.<br />

The barge is being built by <strong>the</strong> Izar<br />

Fene yard in Spain, and is expected<br />

to be launched in August 2003.<br />

It will <strong>the</strong>n be towed to Dragados in<br />

Cadiz, Spain to be grounded and<br />

outfitted with most of <strong>the</strong> main<br />

equipment (26,000 t<strong>on</strong>s) <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong><br />

LNG plant and <strong>the</strong>n transported to<br />

Hammerfest within August 2005.<br />

The LNG plant is scheduled to be<br />

completed by <strong>the</strong> end of 2005.<br />

Shipment of gas from <strong>the</strong> Snøhvit<br />

field starts in 2006, and will<br />

c<strong>on</strong>tinue <str<strong>on</strong>g>for</str<strong>on</strong>g> more than 20 years.<br />

The Melkoya Island near Hammerfest where <strong>the</strong> first European gas export facility will be located.<br />

The Snøhvit gas field c<strong>on</strong>sists of a subsea development<br />

c<strong>on</strong>nected to an LNG plant located<br />

<strong>on</strong>shore near Hammerfest in Norway. Huge<br />

volumes of gas deep beneath <strong>the</strong> Barents <strong>Sea</strong><br />

will be piped ashore, cooled down and shipped<br />

by special gas carriers to Spain and <strong>the</strong> US.<br />

Complicated transport<br />

Approximately 60,000 t<strong>on</strong>nes of steel (prefabricated<br />

units/modules) will be transported to<br />

Hammerfest from various fabricati<strong>on</strong> sites in<br />

Europe. The transportati<strong>on</strong> distances from <strong>the</strong><br />

fabricati<strong>on</strong> sites are l<strong>on</strong>g and <strong>the</strong> transport is<br />

complicated with short operati<strong>on</strong>al windows.<br />

Statoil has <strong>the</strong>re<str<strong>on</strong>g>for</str<strong>on</strong>g>e decided to make use of<br />

third-party expertise to verify <strong>the</strong> various<br />

marine operati<strong>on</strong>s. They have assigned this<br />

work to DNV and L<strong>on</strong>d<strong>on</strong> Offshore C<strong>on</strong>sultants.<br />

The risk picture<br />

The marine operati<strong>on</strong>s are expected to pose<br />

various risks during c<strong>on</strong>structi<strong>on</strong> and installati<strong>on</strong>.<br />

Changing envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s such as<br />

wind, snow, temperature and light may be a<br />

challenge during <strong>the</strong> shipment of 60,000 t<strong>on</strong>nes<br />

of steel from Sou<strong>the</strong>rn Europe to <strong>the</strong> nor<strong>the</strong>rn<br />

part of Norway, a distance of approximately<br />

2,600 nautical miles.<br />

Various risks are being c<strong>on</strong>sidered related to<br />

load-out, transportati<strong>on</strong> and lifting. Possible<br />

damage to equipment, vessel and pers<strong>on</strong>nel<br />

safety issues are being c<strong>on</strong>sidered. In additi<strong>on</strong>,<br />

<strong>the</strong> potential <str<strong>on</strong>g>for</str<strong>on</strong>g> delays and financial loss in<br />

completing <strong>the</strong> plant are being analysed.<br />

The verificati<strong>on</strong> task covers approval of engineering<br />

documentati<strong>on</strong>, procedures and survey<br />

of load-out/float-out of all major structures,<br />

tows and sea transportati<strong>on</strong>s, all heavy lift operati<strong>on</strong>s<br />

and installati<strong>on</strong> of permanent and temporary<br />

anchor systems, bollards and winches.<br />

There is an opti<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> installati<strong>on</strong> of subsea<br />

structures, all rig moves <strong>on</strong> <strong>the</strong> field and installati<strong>on</strong><br />

of pipelines and additi<strong>on</strong>al equipment<br />

<strong>on</strong>shore.<br />

Bror.Berge@dnv.com<br />

Photo: Statoil, June 2003

Floating units in operati<strong>on</strong><br />

Doubling Åsgard C<br />

c<strong>on</strong>densate export<br />

The daily export rate of Statoil’s Åsgard C in<br />

<strong>the</strong> <strong>North</strong> <strong>Sea</strong> is due to double from 2005.<br />

DNV has helped to quickly identify <strong>the</strong> optimal<br />

upgrade soluti<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> increased availability.<br />

In 2005, Statoil plans to store <strong>the</strong> c<strong>on</strong>densate<br />

producti<strong>on</strong> from <strong>the</strong> Kristin field<br />

<strong>on</strong>board <strong>the</strong> floating storage unit (FSU)<br />

Åsgard C, which is currently receiving <strong>the</strong><br />

c<strong>on</strong>densate producti<strong>on</strong> from <strong>the</strong> Åsgard<br />

field. This will lead to a doubling of <strong>the</strong><br />

received producti<strong>on</strong>. Due to more frequent<br />

shuttle tanker visits, <strong>the</strong> availability<br />

of <strong>the</strong> FSU’s tandem discharge operati<strong>on</strong><br />

will become vulnerable.<br />

The selecti<strong>on</strong> of <strong>the</strong> optimal soluti<strong>on</strong> to<br />

improve <strong>the</strong> availability of <strong>the</strong> unit<br />

requires c<strong>on</strong>siderati<strong>on</strong> of a complex set of<br />

parameters, including:<br />

• Technical feasibility<br />

• Time window <str<strong>on</strong>g>for</str<strong>on</strong>g> c<strong>on</strong>versi<strong>on</strong><br />

• Pers<strong>on</strong>nel and envir<strong>on</strong>mental risk<br />

• Producti<strong>on</strong> availability<br />

• Regulatory issues<br />

• Political issues<br />

Statoil wanted an early<br />

decisi<strong>on</strong> <strong>on</strong> <strong>the</strong> best course of<br />

acti<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> <strong>the</strong> upgrade, and<br />

assigned DNV to assess <strong>the</strong><br />

c<strong>on</strong>versi<strong>on</strong> alternatives.<br />

A major challenge of this<br />

project was <strong>the</strong> limited timeframe<br />

available to provide<br />

documentati<strong>on</strong> to evaluate <strong>the</strong> numerous<br />

decisi<strong>on</strong> parameters and <strong>the</strong>ir interacti<strong>on</strong>.<br />

To meet this tight deadline, DNV made<br />

use of resources from its various business<br />

areas to implement a multidiscipline project,<br />

including legislative studies, risk<br />

assessment, and a cost/benefit study<br />

assessing cost and time <str<strong>on</strong>g>for</str<strong>on</strong>g> opti<strong>on</strong>al c<strong>on</strong>versi<strong>on</strong><br />

alternatives. In additi<strong>on</strong>, DNV<br />

per<str<strong>on</strong>g>for</str<strong>on</strong>g>med stability, strength and fatigue<br />

calculati<strong>on</strong>s. Through this approach, <strong>the</strong><br />

project was executed and c<strong>on</strong>cluded<br />

Life cycle management<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> FPSOs improved<br />

DNV enhances its services <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

deepwater producti<strong>on</strong> systems<br />

to ensure operators benefit<br />

from cost-efficient maintenance<br />

and integrity management.<br />

By combining current structural re-analysis<br />

systems and risk-based inspecti<strong>on</strong> services<br />

with software soluti<strong>on</strong>s developed by<br />

DNV Software, DNV is now in a unique<br />

positi<strong>on</strong> to work with <strong>the</strong> operators of<br />

deepwater floating, producti<strong>on</strong>, storage<br />

and offloading units (FPSOs) and tensi<strong>on</strong><br />

leg plat<str<strong>on</strong>g>for</str<strong>on</strong>g>ms (TLPs) to ensure cost-efficient<br />

maintenance and integrity management.<br />

The enhanced services will c<strong>on</strong>centrate<br />

<strong>on</strong> <strong>the</strong> following:<br />

• Development of services related to<br />

structural re-analysis systems to ensure<br />

that unified services can be provided<br />

locally in <strong>the</strong> operator’s home markets.<br />

• Development of risk-based inspecti<strong>on</strong> to<br />

include corrosi<strong>on</strong> degradati<strong>on</strong> models<br />

that can be used in numerical predicti<strong>on</strong><br />

of inspecti<strong>on</strong> intervals <str<strong>on</strong>g>for</str<strong>on</strong>g> FPSOs in<br />

hot envir<strong>on</strong>ments. This tool allows <str<strong>on</strong>g>for</str<strong>on</strong>g> a<br />

proactive approach that will <str<strong>on</strong>g>for</str<strong>on</strong>g>ecast<br />

future problems and allow different<br />

repair strategies to be investigated to<br />

obtain minimum maintenance costs <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

steel replacement, coating repair and<br />

anode replacement.<br />

Photo: Arvid Steen<br />

From 2005 <strong>the</strong> c<strong>on</strong>densate producti<strong>on</strong> from <strong>the</strong> Kristin field<br />

will be stored <strong>on</strong>board <strong>the</strong> floating storage unit Åsgard C<br />

(Jorunn Knutsen) in <strong>the</strong> <strong>North</strong> <strong>Sea</strong>.<br />

within 20 days, providing Statoil and<br />

its partners with a complete and independent<br />

basis <str<strong>on</strong>g>for</str<strong>on</strong>g> a high-level business<br />

decisi<strong>on</strong>.<br />

Speaking to Oil&Gas News, Statoil<br />

project manager Arve Lerstad says:<br />

“DNV’s expedite deliverance of this comprehensive<br />

study has made it possible to<br />

c<strong>on</strong>tinue <strong>the</strong> project <strong>on</strong> schedule. They<br />

have d<strong>on</strong>e a very good job.”<br />

Hans.Kristian.Danielsen@dnv.com<br />

• Enhancement of inspecti<strong>on</strong> philosophy<br />

based <strong>on</strong> present practice <str<strong>on</strong>g>for</str<strong>on</strong>g> inspecti<strong>on</strong><br />

and survey used by class.<br />

• Fur<strong>the</strong>r development of maintenance<br />

strategy based <strong>on</strong> corrosi<strong>on</strong> and coating<br />

status determined by inspecti<strong>on</strong>.<br />

Henning.Carlsen@dnv.com<br />

OIL & GAS NEWS 3 2003 7

Health, Safety and Envir<strong>on</strong>ment<br />

DONG E&P expands<br />

in <strong>the</strong> <strong>North</strong> <strong>Sea</strong><br />

As DONG Explorati<strong>on</strong> & Producti<strong>on</strong><br />

(E&P) expands into <strong>the</strong><br />

<strong>North</strong> <strong>Sea</strong>, <strong>the</strong>y are updating<br />

<strong>the</strong>ir management system to<br />

meet Norwegian regulatory<br />

requirements and reflect<br />

changes in DONG’s organisati<strong>on</strong>.<br />

DONG E&P has a l<strong>on</strong>g-term strategy of<br />

enhancing <strong>the</strong>ir oil and gas activities in<br />

<strong>the</strong> <strong>North</strong> <strong>Sea</strong>. Their growth strategy<br />

involves partnerships in major fields,<br />

operatorship of licences and smaller producing<br />

fields. DNV is now assisting DONG<br />

E&P in updating <strong>the</strong>ir management<br />

system to fulfil <strong>the</strong> regulatory requirements<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> offshore operati<strong>on</strong> in Norway,<br />

as well as to reflect changes in DONG’s<br />

organisati<strong>on</strong>.<br />

Norway boosts HSE competency<br />

Norway is <strong>the</strong> first country in<br />

<strong>the</strong> world to offer a comprehensive<br />

regulati<strong>on</strong>s awareness programme<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> operators <strong>on</strong> <strong>the</strong><br />

Norwegian c<strong>on</strong>tinental shelf.<br />

The rising number of serious incidents<br />

and accidents <strong>on</strong> <strong>the</strong> Norwegian shelf during<br />

<strong>the</strong> past years has sparked this project,<br />

which aims to increase <strong>the</strong> understanding<br />

of Norwegian regulati<strong>on</strong>s and promote<br />

greater awareness of health, safety and<br />

envir<strong>on</strong>ment (HSE).<br />

Called Regulati<strong>on</strong>s Competency (RVK),<br />

<strong>the</strong> project provides thorough in<str<strong>on</strong>g>for</str<strong>on</strong>g>ma-<br />

DNV (Det Norske Veritas) is an independent,<br />

aut<strong>on</strong>omous Foundati<strong>on</strong> working to safeguard life,<br />

property and <strong>the</strong> envir<strong>on</strong>ment. DNV comprises<br />

300 offices in 100 countries, with 5,500 employees.<br />

DNV services to <strong>the</strong> oil, gas and process industries<br />

We help clients within <strong>the</strong> following service areas:<br />

• Safety, health and envir<strong>on</strong>ment<br />

• Qualificati<strong>on</strong> and innovati<strong>on</strong><br />

• Verificati<strong>on</strong> and classificati<strong>on</strong><br />

• Asset operati<strong>on</strong>s<br />

• Enterprise risk management<br />

8 OIL & GAS NEWS 3 2003<br />

The Norwegian regulatory requirements<br />

in health, envir<strong>on</strong>ment and safety<br />

are mainly functi<strong>on</strong>al, demanding operators<br />

to take a proactive role in establishing<br />

a structured approach <str<strong>on</strong>g>for</str<strong>on</strong>g> policies, objectives,<br />

plans, executi<strong>on</strong> and follow-up.<br />

The regulati<strong>on</strong>s have a str<strong>on</strong>g focus <strong>on</strong>:<br />

• Safety culture and <strong>the</strong> emergency preparedness<br />

organisati<strong>on</strong><br />

• Barrier philosophy<br />

• Employee participati<strong>on</strong> and safety-delegate<br />

functi<strong>on</strong><br />

• Acceptance criteria to be set in <strong>the</strong> management<br />

system<br />

• Envir<strong>on</strong>mental issues<br />

• The duty of ensuring that sub-c<strong>on</strong>tractors<br />

are complying with <strong>the</strong> requirements<br />

• Documentati<strong>on</strong> of c<strong>on</strong>tinuous improvements.<br />

DONG E&P has made a frame agreement<br />

with DNV to provide quality, health,<br />

ti<strong>on</strong> to key players in <strong>the</strong> Norwegian<br />

petroleum industry. It is backed by<br />

nati<strong>on</strong>al authorities and labour organisati<strong>on</strong>s.<br />

RVK meets <strong>the</strong> requirements set <str<strong>on</strong>g>for</str<strong>on</strong>g>th<br />

by <strong>the</strong> Norwegian government in 2001,<br />

when it called <str<strong>on</strong>g>for</str<strong>on</strong>g> a comprehensive safety<br />

and envir<strong>on</strong>ment report every fourth year<br />

and <strong>the</strong> implementati<strong>on</strong> of specific safety<br />

measures by <strong>the</strong> petroleum industry during<br />

this interval period.<br />

RVK partners include <strong>the</strong> Norwegian<br />

Polluti<strong>on</strong> C<strong>on</strong>trol Authority, Petroleum<br />

Directorate, Health Inspectorate and<br />

labour organisati<strong>on</strong>s such as <strong>the</strong> Federati<strong>on</strong><br />

of Trade Uni<strong>on</strong>s (LO) and Federati<strong>on</strong><br />

of Oil Workers.<br />

Oil & Gas News<br />

is a newsletter published by<br />

Det Norske Veritas, Business Areas<br />

Technology Services and C<strong>on</strong>sulting<br />

to <strong>the</strong> Oil, Gas and Process<br />

Industries.<br />

It is distributed to DNV customers<br />

and stati<strong>on</strong>s worldwide. It is also<br />

available at DNV’s web site.<br />

Please direct any enquiries to your<br />

nearest DNV stati<strong>on</strong>, or Oil & Gas<br />

News e-mail: Oil&GasNews@dnv.com<br />

Photo: Niels Åge Skovbo<br />

The DONG operated Siri plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m is being<br />

rec<strong>on</strong>structed to start producing from <strong>the</strong> two<br />

new satellite fields Nini and Cecilie.<br />

safety and envir<strong>on</strong>mental-related services.<br />

The work is undertaken through an integrated<br />

joint team ef<str<strong>on</strong>g>for</str<strong>on</strong>g>t involving key<br />

pers<strong>on</strong>nel from DONG E&P and DNV.<br />

It covers <strong>the</strong> explorati<strong>on</strong>, appraisal, development,<br />

operati<strong>on</strong> and decommissi<strong>on</strong>ing<br />

activities related to <strong>the</strong> life-cycle of a field.<br />

DNV is making use of a cross-functi<strong>on</strong>al<br />

team from c<strong>on</strong>sulting and technology<br />

services.<br />

Espen.Cramer@dnv.com<br />

RVK provides in-depth knowledge and<br />

a comm<strong>on</strong> understanding of <strong>the</strong> health,<br />

safety and envir<strong>on</strong>ment regulati<strong>on</strong>s relating<br />

to <strong>the</strong> petroleum industry. Built <strong>on</strong><br />

<strong>the</strong> active use of <strong>the</strong> regulati<strong>on</strong>s, RVK is a<br />

plat<str<strong>on</strong>g>for</str<strong>on</strong>g>m granting c<strong>on</strong>tinuous improvement<br />

of HSE, ec<strong>on</strong>omy and o<strong>the</strong>r values.<br />

DNV is a key provider of lecturers to<br />

<strong>the</strong> project and maintains that <strong>the</strong> success<br />

of <strong>the</strong> initiative is largely dependent <strong>on</strong><br />

<strong>the</strong> “at work” applicati<strong>on</strong> of knowledge<br />

gained through a RVK course.<br />

For more in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> about <strong>the</strong> RVK project:<br />

www.rvk.no<br />

Espen.Cramer@dnv.com<br />

Published by Corporate<br />

Communicati<strong>on</strong>s.<br />

Editor: Beate V. Ørbeck<br />

DNV<br />

Head Office Norway<br />

NO-1322 Høvik, Norway<br />

Tel: +47 67 57 99 00<br />

Fax: +47 67 57 99 11<br />

Updated list of all regi<strong>on</strong>al offices at<br />

DNV’s web site: www.dnv.com<br />

7,000/08-2003 Design: DNVE Graphic Communicati<strong>on</strong>s 0307-001 Print: GAN Grafisk