Full Conference Details Inside

Full Conference Details Inside

Full Conference Details Inside

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

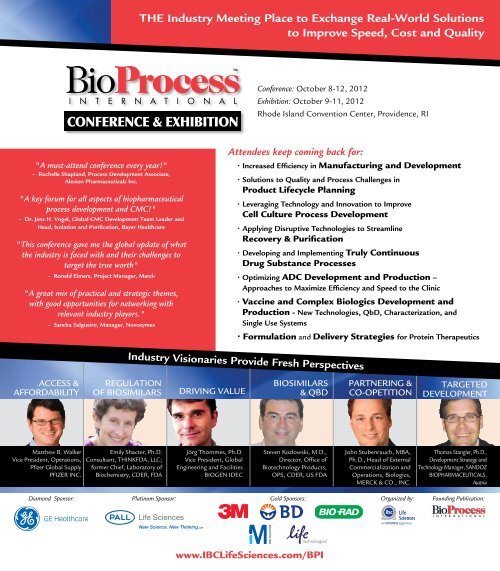

"A must-attend conference every year!"<br />

– Rochelle Shapland, Process Development Associate,<br />

Alexion Pharmaceuticals Inc.<br />

"A key forum for all aspects of biopharmaceutical<br />

process development and CMC!"<br />

– Dr. Jens H. Vogel, Global CMC Development Team Leader and<br />

Head, Isolation and Purification, Bayer Healthcare<br />

"This conference gave me the global update of what<br />

the industry is faced with and their challenges to<br />

target the true worth"<br />

ACCESS &<br />

AFFORDABILITY<br />

Matthew B. Walker<br />

Vice President, Operations,<br />

Pfizer Global Supply<br />

PFIZER INC.<br />

– Ronald Eimers, Project Manager, Merck<br />

"A great mix of practical and strategic themes,<br />

with good opportunities for networking with<br />

relevant industry players."<br />

– Sancha Salgueiro, Manager, Novozymes<br />

REGULATION<br />

OF BIOSIMILARS<br />

Emily Shacter, Ph.D.<br />

Consultant, THINKFDA, LLC;<br />

former Chief, Laboratory of<br />

Biochemistry, CDER, FDA<br />

Diamond Sponsor: Platinum Sponsor:<br />

THE Industry Meeting Place to Exchange Real-World Solutions<br />

to Improve Speed, Cost and Quality<br />

<strong>Conference</strong>: October 8-12, 2012<br />

Exhibition: October 9-11, 2012<br />

Rhode Island Convention Center, Providence, RI<br />

Attendees keep coming back for:<br />

• Increased Efficiency in Manufacturing and Development<br />

• Solutions to Quality and Process Challenges in<br />

Product Lifecycle Planning<br />

• Leveraging Technology and Innovation to Improve<br />

Cell Culture Process Development<br />

• Applying Disruptive Technologies to Streamline<br />

Recovery & Purification<br />

• Developing and Implementing Truly Continuous<br />

Drug Substance Processes<br />

• Optimizing ADC Development and Production –<br />

Approaches to Maximize Efficiency and Speed to the Clinic<br />

• Vaccine and Complex Biologics Development and<br />

Production - New Technologies, QbD, Characterization, and<br />

Single Use Systems<br />

• Formulation and Delivery Strategies for Protein Therapeutics<br />

Industry Visionaries Provide Fresh Perspectives<br />

DRIVING VALUE<br />

Jörg Thömmes, Ph.D.<br />

Vice President, Global<br />

Engineering and Facilities<br />

BIOGEN IDEC<br />

BIOSIMILARS<br />

& QBD<br />

Steven Kozlowski, M.D.,<br />

Director, Office of<br />

Biotechnology Products,<br />

OPS, CDER, US FDA<br />

Gold Sponsors:<br />

www.IBCLifeSciences.com/BPI<br />

PARTNERING &<br />

CO-OPETITION<br />

John Stubenrauch, MBA,<br />

Ph.D., Head of External<br />

Commercialization and<br />

Operations, Biologics,<br />

MERCK & CO., INC.<br />

Organized by:<br />

TARGETED<br />

DEVELOPMENT<br />

Thomas Stangler, Ph.D.,<br />

Development Strategy and<br />

Technology Manager, SANDOZ<br />

BIOPHARMACEUTICALS,<br />

Austria<br />

Founding Publication:

COLLABORATE ... LEARN ... INNOVATE<br />

Experience more perspectives and strategies than any other event of<br />

its kind where every presentation has been carefully selected to offer<br />

new ideas and real-world solutions to improve your processes and<br />

overcome your most pressing challenges.<br />

Expand your knowledge with unparalleled access to new,<br />

unpublished data and exclusive case studies from companies of all<br />

sizes and perspectives at the most comprehensive event for those<br />

directly involved with improving the speed, cost and quality of<br />

developing and manufacturing biotherapeutics.<br />

The <strong>Conference</strong>... Realize innovation and ensure success with proven strategies<br />

for process and manufacturing excellence<br />

> Debottleneck your processes, reduce cycle time and variability, and avoid cross contamination in<br />

multi-product facilities<br />

> Ensure a reliable supply chain and reduce variability caused by raw material changes<br />

> Plan for integrated, fully continuous bioprocessing platforms<br />

> Implement the new process validation guidance with continuous process verification and<br />

QbD strategies<br />

> Create efficient processes and support sustainable pipelines through collaboration with discovery<br />

and development<br />

> Adopt cost-effective approaches to comparability to enable post approval changes and<br />

biosimilar and biobetter development<br />

Unpublished scientific data from exclusive case studies, novel technical<br />

advances and new modalities<br />

> Develop truly continuous drug substance processes and move towards becoming a more integrated<br />

development organization<br />

> Significantly reduce cycle times with fully automated process workflows for both cell line and<br />

cell culture development<br />

> Implement distruptive technologies to replace centrifugation and remove steps in downstream processing<br />

> Effectively streamline two-column purification processes<br />

> Optimize the research-development interface to improve predictability of molecule manufacturability<br />

> Use continuous downstream processing to maximize yield, product quality and equipment utilization for<br />

compact facilities of the future<br />

> Understand assessment, development and production of antibody drug conjugates, bispecifics, cell<br />

therapies and other novel therapies<br />

> Evaluate disposable centrifuge technologies for cell recovery<br />

Specialized Content...<br />

Quality Content for Quality Groups – New This Year!<br />

If you are a quality professional, find expanded content designed just for you in the Track on<br />

Product Lifecycle Planning: Innovative Solutions to Meet Quality and Process Challenges, including<br />

performance by design, regulatory strategies and using comparability to implement process change.<br />

Many of the Pre-<strong>Conference</strong> Symposia and Training Courses can also help you with new tools for<br />

your day –to-day work.<br />

Engineered for Engineers – New This Year!<br />

Process engineers will find practical solutions to current challenges in the Track on Enhancing<br />

Manufacturing and Development Efficiency where sessions focus on procedures and technologies to<br />

enable safe, cost-effective and flexible, multi-product biomanufacturing. Learn tools and strategies<br />

for enabling a secure supply chain, and speeding start of manufacturing through rapid process<br />

development and adaptation of new technologies.<br />

2 To Register, Call: (800) 390-4078 • Fax: (941) 365-0104 • E-mail: reg@ibcusa.com • www.IBCLifeSciences.com/BPI

The world’s largest gathering of industry suppliers & collaborators<br />

As you set foot into the exhibit hall, you will be surrounded by a full array of technologies, services<br />

and systems that you need to move your projects forward. Right now more than ever, suppliers and<br />

biopharmaceutical manufacturers are working together to drive innovation in biopharmaceutical<br />

manufacturing. This is your chance to influence and make your mark on that future! See the new and<br />

exciting opportunities that can improve your process during your visit to BPI on pages 14-15.<br />

Networking cocktail receptions, luncheons and refreshment breaks<br />

During our networking functions, you will have the opportunity to mix and mingle with the industry<br />

experts in the field in a more relaxed setting surrounded by all of the new innovations being displayed by<br />

over 150 suppliers and novel scientific data presented in the poster hall.<br />

Your BioProcess International Passport<br />

When you arrive to the conference, you will receive your BPI passport which will bring a lot of fun and<br />

opportunity to you as you visit the exhibit hall. This interactive venture leads you to many exhibitors<br />

that will be donating several useful and exciting prizes. Throughout your journey the more participating<br />

companies you visit the better chances you have to win one of these great prizes.<br />

The Emerging Marketplace<br />

This area of the exhibit hall gives you the opportunity to visit with companies that are new in the market<br />

and/or start-up companies that offer technologies or services that may be the leaders of the future.<br />

The 3rd Annual Best Poster Award Contest<br />

We recognize the cutting-edge science, techniques and expertise that can improve existing methods<br />

and processes while reducing time and cost. The awards are sponsored by BioProcess InternationalTM magazine, in partnership with the BioProcess InternationalTM <strong>Conference</strong> and Exhibition.<br />

The BioProcess International Awards: Honoring a Decade of BioProcess<br />

Dinner and Ceremony: Tuesday, October 9th from 7:00 pm – 9:00 pm<br />

Four awards will be granted for each of the three pillars of bioprocessing: Upstream<br />

Processing, Downstream Processing, and Manufacturing which include:<br />

Technology of the Decade, Technical Application of the Decade, Collaboration of<br />

the Decade and Thought Leader of the Decade. To attend, a separate fee is required.<br />

To submit your nomination, visit www.bioprocessintl.com/awards<br />

Case Study of a Viral Contamination at Genzyme<br />

and Steps Taken to Mitigate Future Risk<br />

Understand and plan for the most crucial future industry trends.<br />

Kris DeSmet, Ph.D., Lead Cell Culture<br />

Operational Technical Support,<br />

GENZYME, A SANOFI COMPANY, Belgium<br />

Biologics Manufacturing Facility<br />

of the Future<br />

Berthold Boedeker, Ph.D., Chief Scientist;<br />

Head, Cell Culture and Pilot Plants,<br />

BAYER PHARMA AG, Germany<br />

Special Events...<br />

Speed Networking Sessions: Back by Popular Demand!<br />

The Speed Networking session last year was such a big success that we decided to bring it back with two time<br />

options to choose from to better fit your schedule. Attendees told us they liked the opportunity to discuss current<br />

topics, gather best practices and insights from fellow attendees. Come prepared to talk fast, talk best practices,<br />

and make new business connections. Pre-registration is required and is open to all registered attendees.<br />

Thought Leadership Forums<br />

The series of thought-leadership forums in the program provide a unique educational setting for you to discuss, debate<br />

and listen to the best practices of your peers and industry experts on today’s pressing topics such as: Biotech-CMO<br />

partnerships, the future of Single-Use technology, updates on global advances in the development of Biosimilars and<br />

structuring process knowledge to achieve robust processes, simplified technology transfer and regulatory compliance.<br />

Getting Trastuzumab Emtansine(T-DM1)<br />

from the Lab-Bench to the Pharmacy Shelf<br />

Fred Jacobson, Ph.D.,<br />

Principal Scientist,<br />

GENENTECH, INC.<br />

For full abstracts and to register, visit www.IBCLifeSciences.com/BPI 3

Monday, October 8, 2012<br />

Symposium #1: Biosimilars: Defining<br />

Successful Development Strategies in an<br />

Evolving Regulatory Environment<br />

Symposium #5:<br />

Best Practices in Cleaning<br />

and Cleaning Validation<br />

Agenda-at-a-Glance –With So Much Going On, Take Advantage of Group Discounts<br />

Tuesday, October 9, 2012 Exhibit Hall Hours: 3:15 pm - 7:00 pm<br />

Enhancing<br />

Manufacturing and<br />

Development Efficiency<br />

Optimizing Manufacturing<br />

Operations<br />

Product Lifecycle<br />

Planning: Innovative<br />

Solutions to Meet Quality<br />

and Process Challenges<br />

Performance by Design:<br />

Mapping and Controlling<br />

Critical Quality Attributes<br />

Antibody Drug<br />

Conjugate Development<br />

and Production<br />

Keynote from Genentech and<br />

analytical, regulatory and process<br />

development approaches<br />

Analytical Technologies<br />

for Biopharmaceutical<br />

Development<br />

Ensuring Quality, Demonstrating<br />

Comparability and Implementing<br />

Novel Technologies<br />

Formulation Strategies<br />

for Protein Therapeutics<br />

Formulation Strategies for<br />

Biosimilars and Next-Generation<br />

Biologics<br />

Technology Workshops Sponsored by: BD Biosciences, Fujifilm Diosynth Biotechnologies, GE Healthcare Life Sciences and Life Technologies<br />

Impact of Raw Material<br />

Variability and Reliability on<br />

Supply Chain and Development<br />

Process Innovation and<br />

Regulatory Submission<br />

Strategies<br />

Luncheon Presentation Sponsored by: EMD Millipore<br />

Antibody Drug Conjugate Scale up and Transfer,<br />

Facility Design and Formulation<br />

Grand Opening of Poster and Exhibit Hall Refreshments Sponsored by Pall Life Sciences<br />

Keynote Presentations: Successfully Partnering Pharmaceutical Manufacturing Throughout Product Lifecycle<br />

Targeted Development of a Biosimilar Using QbD Concepts<br />

Panel Discussion: Ten Key<br />

Questions for Subvisible<br />

Particle Characterization,<br />

Monitoring and Control<br />

Rational Selection and Design<br />

for Improved Pharmacokinetics<br />

Opening Night Networking Reception in Poster and Exhibit Hall Sponsored by IBC Life Sciences / BioProcess International Award Dinner and Ceremony<br />

(To attend, a separate fee is required.)<br />

Wednesday, October 10, 2012 Exhibit Hall Hours: 9:45 am - 7:15 pm<br />

Product Lifecycle<br />

Enhancing<br />

Planning: Innovative<br />

Manufacturing and<br />

Solutions to Meet Quality<br />

Development Efficiency<br />

and Process Challenges<br />

Achieving Rapid Process<br />

Development and<br />

Novel Technology<br />

Implementation<br />

Sponsored by: Pall Life Sciences<br />

Symposium #2:<br />

Best Practices for Implementation<br />

Challenges with Single-Use Systems<br />

Symposium #6:<br />

Risk Management in<br />

Fill/Finish Operations<br />

Viral Safety<br />

for Biologics<br />

Mixed Mode<br />

Chromatography<br />

Strategies for<br />

Biomolecule Purification<br />

Hosted by Bio-Rad Laboratories<br />

Technology Workshop with Light Continental Breakfast Sponsored by: Thermo Scientific<br />

Advancing the Science<br />

of Comparability: Cost<br />

Effective Approaches for the<br />

Implementation of Process<br />

Change Through the Lifecycle<br />

Latest Regulatory<br />

Perspectives and Novel<br />

Technologies<br />

Maximizing Downstream<br />

Process Method Development<br />

Technology Workshops Sponsored by: GE Healthcare Life Sciences, Life Technologies, Kerry Inc, and Sartorius Stedim<br />

Plenary Session:<br />

Implementation of Quality by Design for a Monoclonal<br />

Antibody Therapeutic<br />

Case Study of a Viral Contamination at Genzyme and Steps<br />

Taken to Mitigate Future Risk<br />

Biologics Manufacturing Facility of the Future<br />

Symposium #3:<br />

Best Practices in Managing Variability<br />

of Raw Materials<br />

Symposium #7:<br />

CMC Project Management throughput<br />

the Product Development Life Cycle<br />

Networking Luncheon in Exhibit and Poster Hall with Dedicated Poster Viewing<br />

Recovery & Purification<br />

Improving Predictability with Developability Assessments and<br />

Speed with High Throughput Screening Methods<br />

Keynote Presentations: Regulatory Challenges for Biologics: Biosimilars, Characterization & QbD<br />

Driving Value through Biopharmaceutical Manufacturing<br />

Improving Access and Affordability to Biopharmaceuticals in Emerging Markets through Partnerships<br />

Networking Reception in Poster and Exhibit Hall<br />

Symposium #4:<br />

Regulatory Requirements<br />

in Preclinical CMC Development<br />

Symposium #8:<br />

Microbial Protein<br />

Production Systems<br />

Formulation<br />

Strategies for Protein<br />

Therapeutics<br />

Quality by Design for Drug<br />

Product Development<br />

Product Characterization for<br />

Formulation Development<br />

Predictive Methods in<br />

Formulation Development<br />

4 To Register, Call: (800) 390-4078 • Fax: (941) 365-0104 • E-mail: reg@ibcusa.com • www.IBCLifeSciences.com/BPI

Agenda-at-a-Glance –With So Much Going On, Take Advantage of Group Discounts<br />

Thursday, October 11, 2012 Exhibit Hall Hours: 9:45 am - 1:40 pm<br />

Cell Culture & Upstream<br />

Processing<br />

Case Studies and Lessons Learned in<br />

Cell Culture Process Development<br />

Effect of the Cell Culture Environment<br />

on Product Quality<br />

Friday, October 12, 2012<br />

Cell Culture & Upstream<br />

Processing<br />

Cell Culture Process Development for<br />

Novel Molecules and Next Generation<br />

Protein Therapeutics<br />

__________________<br />

Keynote Presentation:<br />

The Evolution of QbD Implementation<br />

in Cell Culture at Genentech and<br />

Lessons Learned<br />

__________________<br />

Early Process Development<br />

and Cell Line Engineering<br />

Eliminating Bottlenecks – Impact<br />

of New Tools on Cell Culture<br />

Development<br />

__________________<br />

Disposables in Cell Culture<br />

Recovery & Purification<br />

Delivery Strategies<br />

for Biologics<br />

Technology Workshop with Light Continental Breakfast Sponsored by: Repligen<br />

Expanding the Toolbox – Disruptive<br />

Technologies in Harvest and Recovery<br />

Sponsored by: Novasep<br />

Delivery Strategies for High Viscosity<br />

and High Concentration Drug Products<br />

Technology Workshops Sponsored by: 3M, Life Technologies, TAP Biosystems and SAFC<br />

Networking Luncheon & Last Chance to Visit the Exhibit and Poster Hall<br />

Streamlining Downstream Processes to<br />

Improve Cost and Time to Clinic<br />

Plenary Session: Developing Truly Continuous Drug Substance Processes<br />

Recovery & Purification<br />

Technology Workshop Sponsorship Still Available<br />

Understanding Sources of Process<br />

Variability<br />

__________________<br />

Impact of Disposable Technologies<br />

and Flexible Platforms/Manufacturing<br />

on Downstream Processing<br />

__________________<br />

Keynote Presentation:<br />

Implementation of a QbD Approach<br />

for a Monoclonal Antibody BLA - A<br />

Downstream Purification Case Study<br />

Technology Workshop Sponsorship Still Available<br />

Lunch on Your Own<br />

Developing Downstream<br />

Processes for Next Generation and<br />

Novel Molecules<br />

Co-Development Strategies for<br />

Biologic-Device Product Combinations<br />

Delivery Strategies for<br />

Biologics<br />

Localized and Targeted Delivery<br />

of Biologics<br />

Next Generation Routes of<br />

Administration for Biologics<br />

Vaccine and Complex<br />

Biologics Development and<br />

Production<br />

Improving Vaccine Technologies<br />

Quality by Design and Analytical<br />

Technologies for Vaccines<br />

Thought Leadership<br />

Forums<br />

Smart Solutions for Early<br />

Development & Manufacturing of<br />

Biopharmaceuticals: How CMO’s<br />

Can Help Product Companies be<br />

Successful<br />

Tuesday 1:30 pm – 3:15 pm<br />

Co-Sponsored by BioAlta, Boehringer<br />

Ingelheim, DSM Biologics,<br />

Rentschler Biotechnologie<br />

Reducing the Risk of a<br />

Contamination Event Due to Raw<br />

Materials<br />

Wednesday 10:30 am – 12:00 pm<br />

Sponsored by BD Biosciences<br />

Update on Global Advances in the<br />

Development and Regulation of<br />

Biosimilars<br />

Thursday 10:30 am – 12:00 pm<br />

Structuring Process Knowledge<br />

to Achieve Robust Processes,<br />

Simplified Technology Transfer<br />

and Regulatory Compliance<br />

Friday 10:15 am – 11:45 am<br />

Co-Sponsored by BioPharm Services<br />

5 To Register, Call: (800) 390-4078 • Fax: (941) 365-0104 • E-mail: reg@ibcusa.com • www.IBCLifeSciences.com/BPI

Symposium #1: Biosimilars: Defining<br />

Successful Development Strategies in an<br />

Evolving Regulatory Environment<br />

The global biosimilars sector continues to gain<br />

momentum with the emergence of significant new<br />

commercial partnerships and the continued evolution<br />

of the global regulatory environment over the past year.<br />

Recent advances in the global regulatory framework for<br />

biosimilar products include the publication of the first<br />

three draft guidance documents related to biosimilars<br />

by the US FDA in February and an update to the<br />

overarching guideline for biosimilar medicinal products<br />

and new product-specific guidelines by the European<br />

Medicines Agency. Both originator and biosimilar<br />

companies are refining their strategies to enter and<br />

compete in this dynamic new market. This symposium<br />

will discuss overall business trends and biosimilar<br />

development and manufacturing strategies.<br />

Agenda to include:<br />

• What is the emerging competitive landscape and what<br />

will be the keys to success in this space?<br />

• What technical and regulatory challenges are<br />

presented by alternative development and<br />

manufacturing strategies?<br />

• What are the opportunities for innovation in this area?<br />

Co-Chairpersons:<br />

Thomas Stangler, Ph.D., Development Strategy and<br />

Technology Manager, Biopharmaceuticals, Sandoz,<br />

Austria<br />

Thomas J. Vanden Boom, Ph.D., Vice President,<br />

Global Biologics R&D, Hospira, Inc.<br />

1:00 Co-Chairperson’s Remarks<br />

Thomas Stangler, Ph.D., Development Strategy<br />

and Technology Manager, Biopharmaceuticals,<br />

Sandoz Biopharmaceuticals, Austria<br />

Thomas J. Vanden Boom, Ph.D., Vice President,<br />

Global Biologics R&D, Hospira, Inc.<br />

1:15 A Global Update on the State of<br />

Biosimilars in the Highly Regulated<br />

Markets: A Regulatory and Policy<br />

Perspective<br />

Gillian Woollett, D. Phil, Vice President,<br />

Avalere Health<br />

1:45 Update on US Regulation<br />

of Biosimilars<br />

John M. Pakulski, R.Ph., Head US Biopharmaceutical<br />

Regulatory Affairs, Sandoz Inc. a Novartis company<br />

2:15 How to Leverage Resources for<br />

Biosimilar CMC Activities: Hindsight<br />

is 20/20<br />

Nadine M. Ritter, Ph.D., Senior CMC Consultant,<br />

Biologics Consulting Group<br />

2:45 Networking Refreshment Break<br />

3:15 Biosimilar Development –<br />

An Emerging Market Perspective<br />

Cyrus Karkaria, Ph.D., President, Biotech Division,<br />

Lupin Ltd., India<br />

3:45 The Potential Role of Network<br />

Strategies in the Emerging<br />

Biosimilars Space<br />

Thomas J. Nikolai, Senior Director, Global<br />

Biologics R&D, Hospira Corp.<br />

4:15 Audience Interactive Panel<br />

Discussion with all presenters<br />

5:00 Close of Pre-<strong>Conference</strong> Symposium<br />

Pre-<strong>Conference</strong> Symposia • Monday, October 8, 2012 • 1:00 pm - 5:00 pm<br />

Symposium #2:<br />

Best Practices for Implementation<br />

Challenges with Single Use Systems<br />

This session will focus on addressing challenges when<br />

implementing single use systems. Single use systems<br />

have become critical components of many processes,<br />

so an understanding of potential risks and challenges<br />

is critical to developing successful control strategies<br />

when implementing processes which utilize single<br />

use systems. This session will discuss the challenges,<br />

risks and potential control strategies that can be<br />

implemented throughout the supply chain.<br />

1:00 Chairperson’s Remarks<br />

Robert Repetto, M.S., MBA., Research<br />

Fellow, External Affairs, Pfizer BioTherapeutics<br />

Pharmaceutical Sciences; Chair, PDA Single-Use<br />

System Task Force<br />

1:15 Evolution and Sustainability of<br />

Single Use Systems<br />

Robert Repetto, M.S., MBA., Research<br />

Fellow, External Affairs, Pfizer BioTherapeutics<br />

Pharmaceutical Sciences; Chair, PDA Single-Use<br />

System Task Force<br />

1:45 Economics of Single Use Operations<br />

and Loss Risk<br />

Andrew Sinclair, Managing Director, BioPharm<br />

Services Ltd., United Kingdom<br />

2:15 Material Understanding and<br />

Supplier Partnerships<br />

Duncan Low, Ph.D., Scientific Executive Director,<br />

Amgen Inc.<br />

2:45 Networking Refreshment Break<br />

3:15 Using Single-Use Technologies<br />

to Improve Speed to Clinic:<br />

A Case Study Looking at Scalability as<br />

Well as Leachables and Extractables in a<br />

<strong>Full</strong>y Disposable Downstream Process<br />

Joshua Hayes, Field Marketing Manager – Single Use<br />

Processing Systems, Biopharm Process Solutions,<br />

EMD Millipore<br />

3:45 Global Adoption of Single Use<br />

Technologies: Perspectives from an End<br />

User<br />

Jeffrey C. Johnson, New Technology Lead, Sterile<br />

Technology and Commercialization, Merck & Co.,<br />

Inc.<br />

4:15 Audience Interactive Panel<br />

Discussion with all presenters<br />

5:00 Close of Pre-<strong>Conference</strong> Symposium<br />

12:00 pm Registration<br />

Symposium #3:<br />

Best Practices in Managing Variability<br />

of Raw Materials<br />

Managing raw material variability is becoming<br />

an increasingly important topic within the<br />

biopharmaceutical industry. This symposium will discuss<br />

best practices within process development, clinical and<br />

commercial manufacturing, supply chain and quality to<br />

ensure that the impact from raw material variability to<br />

process performance and product quality is minimized.<br />

1:00 Symposium Introduction and<br />

Overview: Current Challenges in<br />

Managing Raw Material Variability –<br />

From Development to Commercial<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

The impact of lot-to-lot variability of raw materials on<br />

process performance and product quality has gained<br />

increased attention. This talk will provide an overview<br />

of the strategies one can incorporate to effectively<br />

manage the impact of raw material variability.<br />

Examples will include development approaches to<br />

minimize variability, as well as data analysis and<br />

supply chain tools to manage variability.<br />

Niall Carolan, Ph.D., Director of Manufacturing<br />

Sciences, Human Genome Sciences, Inc.<br />

1:30 Amgen’s Supplier Excellence Program<br />

Ran Zheng, Ph.D., Executive Director, Plant Manager,<br />

Amgen Inc.<br />

2:00 Development of a Novel Chemically-<br />

Defined Growth Media for CHO Cell<br />

Applications: Coupling Raw Material<br />

Quality and a Design of Experiments<br />

Approach to Optimize Cell Culture<br />

Media Performance<br />

Michael A. Cunningham, Ph.D., Senior Research<br />

Scientist, EMD Millipore<br />

2:30 Networking Refreshment Break<br />

3:00 Single Use Systems and the<br />

Challenges They Present Regarding Raw<br />

Material Quality and Management<br />

Melissa Morandi, Vice President Quality,<br />

Acceleron Pharma Inc.<br />

3:30 Joint Presentation: How Can<br />

Industry and Suppliers Work Together<br />

to Identify Critical Raw Material<br />

Attributes to Ensure More Consistent<br />

and Reliable Performance?<br />

David Radspinner, Ph.D., Director of Global Marketing<br />

and Customer Applications, Thermo Fisher Scientific<br />

and end-user to be announced<br />

4:00 Audience Interactive Panel Discussion<br />

sponsored by<br />

How Can Industry and Suppliers Work<br />

Together to Identify Critical Raw<br />

Material Attributes to Ensure More<br />

Consistent and Reliable Performance?<br />

Panelists will discuss the potential for integration of<br />

suppliers’ and end-users’ quality systems including<br />

product safety data, change control and change<br />

control notification and related topics.<br />

Moderator:<br />

Niall Carolan, Ph.D., Director of Manufacturing<br />

Sciences, Human Genome Sciences, Inc.<br />

Panelists:<br />

Industry End-User to be named<br />

Melissa Morandi, Vice President Quality,<br />

Acceleron Pharma Inc.<br />

David Radspinner, Ph.D., Director of Global Marketing<br />

and Customer Applications, Thermo Fisher Scientific<br />

Ran Zheng, Ph.D., Executive Director, Plant Manager,<br />

Amgen Inc.<br />

Additional End-users and providers to be identified<br />

5:00 Close of Symposium<br />

Symposium #4:<br />

Regulatory Requirements in<br />

Preclinical CMC Development<br />

This symposium provides a comprehensive overview<br />

of the FDA regulatory requirements applicable to<br />

pharmaceutical research organizations during the<br />

preclinical stages of drug development and the<br />

preparation of an IND (Investigational New Drug)<br />

application. The CMC (Chemistry, Manufacturing<br />

and Controls) section of the IND application will be<br />

reviewed in detail, and a short preview will be provided<br />

of the regulatory process during clinical development.<br />

The course is intended to provide participants from<br />

all facets of the pharmaceutical and biotech industry<br />

with a broad understanding of what is required from a<br />

regulatory standpoint in early drug development.<br />

Agenda to include:<br />

• FDA structure and function<br />

• The product development timeline from R&D to IND<br />

• Good Laboratory Practice (GLP)<br />

• Preclinical studies required throughout drug<br />

development<br />

• Good Manufacturing Practice<br />

• GMP compliance throughout drug development<br />

• The CMC section of the initial IND<br />

• Regulatory compliance in CMO relationships<br />

Instructor:<br />

Bruce K. Burnett, Ph.D., RAC, Director of<br />

Regulatory Affairs, Duke Translational Medicine<br />

Institute, Duke University School of Medicine<br />

Early Registration and Group Discounts are Available (see page 27) 6

Symposium #5: Best Practices in<br />

Cleaning and Cleaning Validation<br />

A Science-based and Integrated Approach<br />

for Biopharmaceuticals<br />

Room ???<br />

In this symposium we will identify the elements of a<br />

robust cleaning program for biopharmaceuticals. we will<br />

then see how each element is systematically developed<br />

and integrated to ensure successful implementation.<br />

The symposium will cover current regulatory<br />

expectations, science-based methodologies for cleaning<br />

characterization, and the lifecycle approach to cleaning<br />

validation and monitoring.<br />

In addition to the fundamentals of cleaning,<br />

this symposium will also cover the following<br />

advanced topics:<br />

Agenda to include:<br />

• Unique cleaning challenges for multiproduct<br />

bioprocesses equipment.<br />

• Effective strategies for addressing these challenges<br />

through planned small-scale studies.<br />

• Degradation/inactivation studies and how they can<br />

be used to eliminate product-specific assays and the<br />

traditional MAC approach.<br />

• Acceptance limits for degraded/inactivated product.<br />

• Cleaning tenacious residues in bioreactors and media<br />

tanks.<br />

• The use of master soils to streamline and<br />

provide flexibility for scheduling cleaning validation<br />

activities.<br />

Instructor:<br />

Rizwan Sharnez Ph.D., Principal Engineer, Process<br />

Engineering,<br />

Amgen Inc.<br />

Pre-<strong>Conference</strong> Symposia • Monday, October 8, 2012 • 1:00 pm - 5:00 pm<br />

12:00 pm Registration<br />

Symposium #7:<br />

CMC Project Management<br />

throughout the Product<br />

Development Life Cycle<br />

Room ???<br />

The session will provide a comprehensive overview of<br />

phase-dependent CMC activities and the role of CMC<br />

teams in integrating development plans and facilitating<br />

progress. Talks will cover different models for managing<br />

CMC projects that are tied to company’s resources,<br />

number of products, and phase of development.<br />

Best practices in CMC PM be discussed in detail. The<br />

symposium is intended to provide participants with a<br />

broad understanding of the drug development process<br />

from discovery to commercialization and how CMC-<br />

PM can help integrate the strategic vision with tactical<br />

implementation.<br />

• Overview of Integrated Phase Dependent CMC<br />

Development<br />

• Best Practices in CMC Project Management<br />

• CMC structure: One Size Does Not Fit All<br />

• Bridging Discovery to Human Proof of Concept and<br />

Commercialization<br />

• CMC PM as a Career Path<br />

Talks will be followed by a panel discussion which will<br />

cover topics of interest to the audience and the speakers.<br />

Agenda to include:<br />

• Understand Product Development Life Cycle from a<br />

CMC perspective<br />

• Models for managing CMC activities throughout<br />

development life cycle<br />

• CMC PM organizational structures and functional<br />

roles<br />

• Risk Management processes to maneuver through<br />

development hurdles<br />

• CMC PM business processes, tools and templates<br />

• Managing in-licensed products, partnerships, and<br />

CROs<br />

• Interactive discussions with peers and experts in<br />

managing CMC development<br />

Co-Chairpersons:<br />

Seshu Tyagarajan, Ph.D., Associate Director, CMC<br />

Project Management, ImClone Systems, a whollyowned<br />

subsidiary of Eli Lilly and Company<br />

Zahra Shahrokh, Ph.D., Biotech Product Development<br />

Consultant, ZDev Consulting<br />

Symposium #8:<br />

Microbial Protein<br />

Production Systems<br />

Room ???<br />

Microbial systems are being used to express a growing<br />

number of early stage protein products, circumventing<br />

issues such as viral clearance associated with CHO and<br />

other mammalian platforms, offering lower media costs<br />

and much shorter bioreactor run times. Virtually every new<br />

“antibody-like” scaffold is selected for efficient microbial<br />

expression, thereby facilitating discovery and manufacture.<br />

While almost all approved antibodies and most of those<br />

in clinical development rely on mammalian cell culture for<br />

production, a rapidly growing number of smaller antibody<br />

fragments, scaffold-based therapeutics and other proteins<br />

are produced in microbial systems. These production<br />

platforms include various bacterial hosts, several species of<br />

yeasts, and other small eukaryotes. This session focuses on<br />

recent advances and improvements to microbial systems<br />

and case studies of protein production and manufacture.<br />

Agenda to include:<br />

• Gain an overview of microbial production systems.<br />

• Understand key advantages and challenges of<br />

bacterial and eukaryotic microbial hosts.<br />

• Insights into the latest improvements to established<br />

and novel microbial expression platforms.<br />

• Learn from case studies of current protein products<br />

manufactured by microbial process.<br />

• Be prepared for increasing applications of microbial<br />

systems for new products.<br />

Chairperson:<br />

David Bramhill, Ph.D.,<br />

Research Corporation Technologies and<br />

Bramhill Biological Consulting, LLC.<br />

7 To Register, Call: (800) 390-4078 • Fax: (941) 365-0104 • E-mail: reg@ibcusa.com • www.IBCLifeSciences.com/BPI

8:00<br />

8:15<br />

8:45<br />

Optimizing Manufacturing<br />

Operations<br />

Chairperson’s Opening Remarks<br />

Greg Liposky, Vice President and General<br />

Manager, Site Operations, MedImmune<br />

Operational Excellence - A Transformational<br />

Culture Focused on Performance<br />

OPEX activities focused on team performance and<br />

process cycle time enabled debottlenecking of the<br />

production critical path permitting the facility to<br />

meet supply plan needs for multiple commercial<br />

and clinical products. Approaching improvements<br />

with a focus on learning from others coupled<br />

with the speed of sharing to accelerate learning<br />

is driving a positive transformational shift in the<br />

manufacturing facility’s culture.<br />

Chris N. Pacheco, Director Manufacturing,<br />

Amgen Inc.<br />

Flexible Manufacturing Solutions in<br />

Multi-Product Facilities<br />

Manufacturing facilities have to deal with a wide range<br />

of processes (low-titer legacy and high-titer state of<br />

the art) and tech transfer projects where each project<br />

has its own set of priorities regarding speed, project<br />

cost, COGs and risk. The situation in multi-product<br />

drug substance plants producing multiple approved<br />

products and handling multiple tech transfers per year<br />

will be analyzed and examples of typical challenges<br />

and the corresponding solutions will be given.<br />

Markus Wollenberg, Ph.D., Director,<br />

Manufacturing Sciences and Technology,<br />

Biopharma Operations, Boehringer Ingelheim<br />

Pharma GmbH & Co. KG, Germany<br />

Risk-Based Approaches to Cross<br />

Contamination Prevention in<br />

Multi-Product Facilities<br />

Contemporary biopharmaceutical multiproduct<br />

facilities are continuing to advance new flexibilities<br />

in layouts and in the combinations of products,<br />

product classes, host-cell types, and product<br />

hazards within those facilities. The presenters<br />

will share their proven practices for selecting<br />

different quality risk management tools in order<br />

to successfully identify and control crosscontamination<br />

hazards across a variety of facility<br />

designs and multiproduct operating schemes.<br />

Stephen Reich, Director, Quality Systems, and<br />

Kristin Murray, Associate Director, Global CMC<br />

Regulatory Affairs, Pfizer Inc.<br />

Tuesday, October 9, 2012<br />

7:00 Registration and Coffee<br />

9:15<br />

Enhancing Manufacturing<br />

and Development Efficiency<br />

Product Lifecycle Planning:<br />

Innovative Solutions to Meet<br />

Quality and Process Challenges<br />

Performance by Design:<br />

Mapping and Controlling Critical<br />

Quality Attributes<br />

Chairperson’s Opening Remarks<br />

Sarah Thomas, MBA, Vice President, Quality,<br />

Human Genome Sciences, Inc.<br />

Roadblocks in CMC: Improving your<br />

Quality Submissions throughout the<br />

Product Lifecycle<br />

While the outcome of a clinical trial is never<br />

certain, the quality of the therapeutic protein in<br />

that clinical trial should be under the complete<br />

control of the sponsor. Too often the quality<br />

submission is lacking data or clarity resulting in<br />

an IND hold, a delay in approval of a BLA or a<br />

post-marketing change. This presentation will<br />

highlight roadblocks and speed bumps that occur<br />

throughout the product lifecycle<br />

Marjorie A. Shapiro, Ph.D., Chief, Laboratory<br />

of Molecular and Developmental Immunology,<br />

Division of Monoclonal Antibodies, US FDA<br />

From QbD to Control Strategy<br />

The development of a product control strategy is<br />

not a new concept but should be the culmination<br />

CASE<br />

of the product development lifecycle. The ICH<br />

quartet (Q8, Q9, Q10 and Q11) along with<br />

STUDY<br />

the recently issued FDA guidance on process<br />

validation stress the importance of linking the<br />

product development life cycle with control strategy.<br />

The linkage of product development to ultimate<br />

commercial control strategy is achieved through a<br />

series of structured risk assessments. This talk will<br />

focus on risk management approaches including<br />

examples used in Pfizer and how the output of this<br />

leads to definition of a product control strategy.<br />

Paul B. McCormac, Ph.D., Senior Manager,<br />

Bio-manufacturing Sciences Group,<br />

Pfizer Global Supply, Pfizer Inc.<br />

Advanced Process Modelling<br />

Tools for Innovative Technology<br />

Assessment at Merck & Co, Inc<br />

CASE STUDY<br />

This presentation will examine the use of<br />

advanced process modelling tools to support<br />

critical decision making in the evaluation of<br />

innovative technologies. This will be illustrated<br />

through a case study based on functionalized porous<br />

media chromatography platforms (membrane and<br />

structured hydrogels). Presentation will conclude<br />

with forward looking process modelling techniques<br />

to describe novel unit operations such as continuous<br />

porous media chromatography.<br />

James Velez, Senior Process Engineer, Global<br />

Engineering Services, Merck & Co., Inc.<br />

Miriam Monge, Vice President,<br />

Biopharm Services Ltd, United Kingdom<br />

Chairperson’s Opening Remarks<br />

Nadine M. Ritter, Ph.D., Senior CMC<br />

Consultant, Biologics Consulting Group<br />

Paradigms for Biotech/Biosimilar<br />

Product Characterization and<br />

Comparability<br />

Comprehensive characterization has long been a<br />

key feature of biotechnology product development.<br />

Advances in process design coupled with orthogonal<br />

analytical technologies enhance understanding<br />

of process consistency and product quality.<br />

Characterization methods are also used to show<br />

‘developmental continuity’ through appropriate<br />

comparability studies from early development through<br />

commercialization. Post-market comparability studies<br />

also utilize analytical characterization tools to support<br />

implementation of further process improvements.<br />

And now, the emergence of biosimilars requires<br />

challenging analytical characterization strategies as<br />

one part of assessing similarity between products.<br />

This presentation will illustrate the biotechnology<br />

product characterization and comparability paradigm<br />

for each of these applications. It will highlight<br />

emerging analytical tools for characterization, and<br />

share common mistakes made in process and product<br />

comparability studies.<br />

Nadine M. Ritter, Ph.D., Senior CMC<br />

Consultant, Biologics Consulting Group<br />

Applying Quality by Design<br />

Principles to Analytical Development<br />

Quality by design principles are often used in<br />

vaccine manufacturing to understand process<br />

steps that influence final product quality. Similar<br />

principles can also be applied to analytical<br />

development with the goal of minimizing method<br />

variation and increasing method robustness.<br />

Examples of an assay target profile, risk analysis,<br />

selection of assay design space and design of<br />

experiments will be presented.<br />

Marc Thorsteinsson, Ph.D., Research Fellow,<br />

Merck and Co., Inc.<br />

Process Validation by NMR –<br />

Detection and Qualification<br />

of Process Impurities in<br />

Complex Solutions<br />

9:45 Networking Refreshment Break<br />

Analytical Technologies<br />

for Biopharmaceutical<br />

Development<br />

UNPUBLISHED<br />

DATA<br />

Detection of a broad range of process<br />

impurities in protein containing process pools<br />

is challenging due to interference from protein,<br />

buffer components, and water. Using a CPMG<br />

sequence to attenuate protein signals, we are able<br />

use NMR as a general method to quantify organic<br />

impurities in protein based biopharmaceutical<br />

products. This approach works for both expected<br />

and unexpected impurities.<br />

Ken Skidmore, M.S., Associate Scientist,<br />

Genentech, Inc.<br />

Antibody Drug Conjugate<br />

Development & Production<br />

Chairperson’s Opening Remarks<br />

Deborah Meshulam, M.S., Director, Contract<br />

Manufacturing, ImmunoGen, Inc.<br />

Keynote Address<br />

Getting Trastuzumab Emtansine<br />

(T-DM1) from the Lab-Bench to the<br />

Pharmacy Shelf<br />

Fred Jacobson, Ph.D., Principal Scientist,<br />

Genentech, Inc.<br />

Bioassays for ADCs with<br />

Antibodies having Inherent<br />

In Vitro and In Vivo Cell<br />

Killing Activity<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

All antibody-maytansinoid conjugates<br />

have antibody binding activity<br />

and cytotoxic activity from the conjugated<br />

maytansinoid. Some conjugates have additional<br />

activities such as ADCC, CDC, and inherent<br />

apoptosis-inducing activity from the antibody.<br />

Examples of antibody-maytansinoid conjugates<br />

having various activities will be presented<br />

with proposals for release, stability and<br />

characterization testing.<br />

Xiangyang Xu, Ph.D., Principle RA, Translational<br />

Research, ImmunoGen, Inc.<br />

Analytical Approaches to<br />

Support Development of Antibody<br />

Drug Conjugates<br />

Samadhi Vitharana, Senior Scientist, Takeda<br />

(invited)<br />

Early Registration and Group Discounts are Available (see page 27) 8

10:15<br />

10:45<br />

11:15<br />

Enhancing Manufacturing<br />

and Development Efficiency<br />

Single Use and Simplicity – Three Years<br />

in at Shire HGT<br />

Paul Slaman, Associate Director, Manufacturing<br />

Technical Services, Shire Human Genetic Therapies<br />

Cleaning Validation Challenges<br />

for Bioprocesses: Leveraging<br />

Cleaning Characterization to<br />

Streamline New Product Launches<br />

Tuesday, October 9, 2012<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

Strategies for addressing cleaning validation<br />

challenges for bioprocesses will be presented. The<br />

strategies are rooted in systematic and proactive<br />

approaches to cleaning. Several approaches, including<br />

performing small-scale cleanability studies to minimize<br />

at-scale cleaning validation studies, the use of master<br />

soils to streamline and provide flexibility for scheduling<br />

cleaning validation activities, and leveraging inactivation<br />

studies to obviate the need for product-specific assays<br />

and MAC assessments, will be discussed.<br />

Rizwan Sharnez Ph.D., Principal Engineer,<br />

Process Engineering, Amgen Inc.<br />

Co-authors: Michelle Monk, Laura Klewer,<br />

Chris Flint, Arun Tholudur Ph.D., Amgen Inc.<br />

Optimizing Changeover in a Large<br />

Scale Multi Product Bioprocess Plant<br />

MedImmune’s Manufacturing Center in Frederick,<br />

Maryland recently transitioned from a steady,<br />

single product facility to a fast-paced, clinical/<br />

commercial multiproduct facility. Senior<br />

leadership challenged the site to optimize change<br />

over from its early cycle time of 28 days to 14 days<br />

or less. Join us to review the cross-functional work<br />

and operational excellence tools that successfully<br />

drove change over optimization.<br />

Chad Briggs, Senior Manufacturing Manager,<br />

MedImmune<br />

Product Lifecycle Planning:<br />

Innovative Solutions to Meet<br />

Quality and Process Challenges<br />

Life Cycle Management - A Case<br />

Study Using a Novel Protein<br />

Eli Lilly has built, qualified and validated a new<br />

state of the art facility in Kinsale, Ireland. The<br />

subject of this presentation is a novel protein that<br />

was the first molecule validated in this facility. The<br />

talk will highlight the approach taken to incorporate<br />

the new FDA guidance document and current<br />

European perspectives and the business drivers of<br />

global supply chain on process validation, the quality<br />

systems for lifecycle management and discuss the<br />

approach being taken for continuous verification.<br />

Graham McCartney, Ph.D., Technical Services Lead<br />

Biotechnology, Eli Lilly S.A., Ireland<br />

Considerations and Challenges<br />

when Evaluating Vials and<br />

Stoppers as Part of Parenteral<br />

Product Container Closure System<br />

Selecting vial and stopper combinations<br />

with optimal fit can be challenging. Issues during<br />

manufacturing can negatively impact process<br />

productivity and timelines, and proper closure<br />

integrity is of utmost importance. Data will be<br />

shown which demonstrates such challenges and<br />

recommendations will be made on how to evaluate<br />

material attributes and dimensions in order to<br />

implement proper control strategies.<br />

Melissa D. Perkins, Ph.D., Senior Director,<br />

Drug Product Sciences, Human Genome Sciences, Inc.<br />

Strategies for Continued Process<br />

Verification – A Lifecycle Approach<br />

to Quality by Design (QbD) and<br />

Process Validation<br />

CASE STUDY<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

As per the new FDA process validation guidance, the<br />

third validation stage describes a lifecycle approach to<br />

continually assure that the process remains in a state<br />

of control (the validated state) during commercial<br />

manufacture. This presentation will describe strategies<br />

and approaches to implementing a continuous<br />

monitoring and continuous improvement program<br />

consistent with QbD principles applied to earlier stages<br />

such as process design.<br />

Kumar Dhanasekharan, Ph.D., Associate<br />

Director, Process Sciences and Technology,<br />

Genzyme, a Sanofi company<br />

Analytical Technologies<br />

for Biopharmaceutical<br />

Development<br />

Developing an Extractable/<br />

Leachable Program<br />

E&L studies are a required part of license<br />

pplications, but can be challenging for biotech<br />

companies due to lack of infrastructure and<br />

experience. In addition to testing of container<br />

closure materials, the evaluation process at HGS<br />

included a risk assessment for contact materials of<br />

the manufacturing and filling processes to determine<br />

which additional components required testing.<br />

Studies were performed utilizing a combination of<br />

external services and a buildup of internal capabilities.<br />

Helmut Schneider, Ph.D., Principal Scientist,<br />

Analytical Sciences, Human Genome Sciences, Inc.<br />

CASE STUDY<br />

Automated Analytics, Data<br />

Reduction, and Data Management<br />

In order to meet the demands of high sample<br />

numbers and large amounts of data in short<br />

periods of time produced in the Automated<br />

Analytical laboratories, we have developed, and<br />

are evolving, a work stream for sample submission<br />

and tracking, analytical quality, and data<br />

management that requires less "hand-on" time to<br />

allow analysts to focus more time in the labs.<br />

Kristine M. Kearns, Senior Research Biochemist,<br />

Vaccine Analytical Development,<br />

Merck and Co., Inc.<br />

Preliminary Characterization<br />

of a Novel Class of Multi-Specific,<br />

Multi-Valent Therapeutic<br />

Zybodies are a novel class of multi-specific<br />

antibodies that consist of short molecular<br />

recognition domains fused to the termini<br />

of mAbs. The presentation will discuss the<br />

expected attributes and behavior of Zybodies,<br />

the analytical approaches and challenges used<br />

to monitor them, along with a comparison to<br />

mAbs and other bispecific molecules.<br />

Rajesh Krishnamurthy, Ph.D., Director,<br />

Pharmaceutical Development, Zyngenia, Inc.<br />

Antibody Drug Conjugate<br />

Development & Production<br />

Antibody Drug Conjugate Process<br />

Development Considerations<br />

Mark Itterman, Senior Manager, Process<br />

Development, Millennium Pharmaceuticals, Inc.<br />

Approaches to Improve Efficiency<br />

and Speed to the Clinic for Antibody<br />

Drug Conjugates<br />

John Moscariello, Ph.D., Principal Scientist,<br />

Purification Process Development, Amgen Inc.<br />

Regulatory Considerations for the<br />

Manufacture, Characterization and<br />

Quality Assurance of Antibody-Drug<br />

Conjugates<br />

Since the first IND for an antibody-drug conjugate<br />

(ADC) was submitted almost 20 years ago,<br />

only two ADCs have been approved; Mylotarg<br />

in 2000 and Adcetris 2011. During that time,<br />

improvements in the conjugation chemistry result<br />

in ADCs with improved serum stability. New and<br />

improved analytical methods allow a more precise<br />

characterization of the ADC. This presentation<br />

will focus the regulatory approach to ADCs from<br />

the drug and biologics review perspectives.<br />

Marjorie A. Shapiro, Ph.D., Chief, Laboratory<br />

of Molecular and Developmental Immunology,<br />

Division of Monoclonal Antibodies, US FDA<br />

11:45 Concurrent Technology Workshops<br />

What’s Next in<br />

Meeting Marketplace<br />

Single-Use Vs.<br />

Early Process Development<br />

Fed-Batch Cell Culture?<br />

Needs - Rapid<br />

Multi-Use Equipment:<br />

Integrating Chemically<br />

The history of fed-batch as a method of producing Development of Robust<br />

An Environmental Life Cycle Assessment Defined Supplements and Feeds<br />

proteins in CHO cells is remarkable with respect to<br />

the progress made in a relatively short period of time.<br />

Within the past decade we have progressed from<br />

IgG titers in the milligram per liter range to current<br />

routine yields of multiple grams per liter. The latter<br />

have been achieved by both sophisticated feeding<br />

strategies and cell line engineering. This workshop<br />

will provide data related to recent improvements in<br />

the various elements that impact fed-batch culture<br />

and how one can maintain flexibility in scale-up<br />

Peggy Lio, Senior Process Science Fellow, Gibco®<br />

PD-Direct Bioprocess Services, Life Technologies<br />

Manufacturing Processes<br />

As the biopharmaceutical industry matures,<br />

outsourcing has become an integral part of production<br />

strategies including a shift towards the outsourcing<br />

of research and process development activities. For<br />

contract manufacturing organizations, innovation and<br />

providing custom solutions has become ever more<br />

important. We will outline aspects of our current<br />

process and analytical development activities to meet<br />

the needs of the biomanufacturing market.<br />

Greg Adams, Ph.D., Section Leader, Analytical<br />

Development, Fujifilm Diosynth Biotechnologies<br />

of an Entire mAb Production Process<br />

This cradle-to-grave environmental study compares<br />

single-use vs. traditional process equipment for<br />

the production of monoclonal antibodies at 100L,<br />

500L and 2000L scales. The study results show<br />

that, for the conditions explored in this study,<br />

the single-use process technology exhibits lower<br />

environmental impact by reducing or eliminating<br />

the need for large quantities of steam, process<br />

water, and water for injection.<br />

Jeffrey Carter, Ph.D., Director of Research &<br />

Development, GE Healthcare Life Sciences<br />

Elizabeth C. Dodson, Ph.D., Advanced<br />

Bioprocessing, BD Biosciences<br />

12:15 Luncheon Presentation<br />

“Open Sourcing” – Increasing Options to Meet the Challenges of Drug Development and Manufacturing<br />

Developing and implementing a manufacturing process for clinical scale material involves many steps, requiring knowledge, expertise and resources. In this presentation we introduce the concept<br />

of “Open-Sourcing,” an alternative view of how such knowledge, expertise and resources can be accessed and delivered to speed the journey to the clinic. This presentation will highlight through a<br />

case study how a solutions-based approach enabled the development of a clinical manufacturing process for a new drug in parallel with the construction of a new clinical manufacturing facility.<br />

Richard Pearce, Director of Strategy Development, BioPharm Process Solutions, EMD Millipore<br />

Sponsored by:<br />

9 To Register, Call: (800) 390-4078 • Fax: (941) 365-0104 • E-mail: reg@ibcusa.com • www.IBCLifeSciences.com/BPI

Tuesday, October 9, 2012 (continued)<br />

1:30 Thought Leadership Forum Co-Sponsored by:<br />

1:30<br />

1:45<br />

2:15<br />

2:45<br />

Smart Solutions for Early Development & Manufacturing of Biopharmaceuticals: How CMO’s Can Help Product Companies be Successful (See more details on p.21)<br />

Enhancing Manufacturing and<br />

Development Efficiency<br />

Impact of Raw Material Variability and<br />

Reliability on Supply Chain and Development<br />

Chairperson’s Remarks<br />

Ran Zheng, Ph.D., Executive Director, Plant Manager, Amgen Inc.<br />

Mitigating Risk in the Raw Material<br />

Supply Chain<br />

A raw material supply issue can take down your supply<br />

chain resulting in lost production days, increased COGS,<br />

scrapped inventory, product recall, and in extreme<br />

situations result in your product not being available for sale to<br />

the market. How well do you understand your supply base and<br />

relative risks from one part and one supplier to the next and<br />

what are you doing to mitigate this risk? A holistic approach to<br />

assessing risk, developing appropriate and feasible mitigations,<br />

and dynamic monitoring of emerging risks is essential.<br />

Craig Malzahn, Director, Supply Chain, Human Genome Sciences, Inc.<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

Applying Process Analytics towards Controlling Raw<br />

Material Variation: Strategic Directions at Suppliers<br />

and in the Biologics Manufacturing Industry<br />

Challenges in identifying, monitoring and control of raw<br />

material variability exist in biopharmaceutical industry. Insightful<br />

strategies focusing on process analytics applied to raw materials<br />

variation monitoring and control will be provided. Approaches at<br />

the supplier’s end and at the manufacturing end are summarized.<br />

Cenk Undey, Ph.D., Director of Process Development, Amgen Inc.<br />

Understanding Supply Chain Complexities for Raw<br />

Materials and Single Use Systems<br />

Bob Repetto, M.S., MBA, Research Fellow, External Affairs,<br />

Pfizer BioTherapeutics Pharmaceutical Sciences and Chair,<br />

PDA Single-Use Systems Task Force<br />

Product Lifecycle Planning:<br />

Innovative Solutions to Meet Quality<br />

and Process Challenges<br />

Process Innovation and Regulatory<br />

Submission Strategies<br />

Chairperson’s Remarks<br />

Joanne T. Beck, Ph.D., Vice President, Process Development,<br />

Shire Human Genetic Therapies<br />

Process Innovation and Regulatory<br />

Submission Strategies<br />

Even though we work in a very regulated industry it doesn’t<br />

mean we can’t be innovative in our manufacturing environment,<br />

supply chain and regulatory filings. During my talk I will discuss<br />

tools and techniques which can be used to foster an innovative<br />

environment as well as examples where innovation has been<br />

demonstrated in our industry in manufacturing, supply chain and<br />

regulatory dossiers.<br />

Robert O'Hagan, Director Quality Operations,<br />

Abbott Bioresearch Center<br />

Regulatory Considerations for<br />

Implementing Innovation<br />

Biotech innovation, unlike incremental improvements, is<br />

the implementation of a better alternative and represents<br />

change from the norm. In regulated biotech environment,<br />

such advancements are incremental and deliberate that requires<br />

development time and supportive technical data. Whereas<br />

comparability is cornerstone of implementing lifecycle changes, a<br />

sound foundation of process and product knowledge facilitates<br />

regulatory agency approvals. Examples will be discussed.<br />

Andrew Papas, Ph.D., MBA, Director of Regulatory Affairs,<br />

Pharmaceutical and Biologics Practice, Becker & Associates<br />

Consulting, Inc.<br />

A Rapid QBD Based Response to Annual Seasonal<br />

Influenza Vaccine Changes<br />

Protein Sciences Corporation’s platform technology utilizes a<br />

recombinant protein approach for generating vaccines. PSC<br />

leverages a QBD based process for large scale production of<br />

vaccines in less than 50 days from identification of the target virus.<br />

During the presentation, the speaker will discuss a case study<br />

focusing on the rapid modification of the seasonal influenza vaccine<br />

(FluBlok) to accommodate the 2012-2013 virus strain change.<br />

Robert R. Boulanger, Ph.D., Manager, USP Development,<br />

Product Realization, Protein Sciences Corporation<br />

3:15 Grand Opening of Poster and Exhibit Hall with Refreshments Sponsored by:<br />

Keynote Presentations<br />

5:45 Networking Reception in Poster & Exhibit Hall<br />

7:00 BioProcess InternationalTM Award Dinner and Ceremony (see page 14)<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

Specialty Focus Track<br />

Antibody Drug Conjugate<br />

Development & Production<br />

Chairperson’s Remarks<br />

Deborah Meshulam, M.S., Director, Contract Manufacturing,<br />

ImmunoGen, Inc.<br />

Characterization of Stress-Related<br />

Degradants in Antibody-Drug Conjugate<br />

Formulation Development<br />

UNPUBLISHED<br />

DATA<br />

Characterization of impurities and degradants for biologics<br />

is an ICH recommendation for New Drug Application.<br />

Characterization of ADC provides a unique analytical challenge<br />

as impurities/degradants can be derived from the protein, the<br />

linker or the drug-linker. Here we present our strategies on the<br />

generation and characterization of these stress-related degradants<br />

for both mAb and ADC during formulation development.<br />

Stanley Kwok, Ph.D., Senior Scientist, Formulations,<br />

Fill/Finish, Seattle Genetics<br />

Complexities Associated with Scale Up and<br />

Transfer of a Conjugated Process<br />

ImmunoGen develops conjugates consisting of one of its<br />

proprietary derivatives of the cytotoxic agent maytansine attached<br />

to tumor-targeting antibodies. The conjugation process is complex<br />

which involves development and transfer of both small and large<br />

molecules. Key process parameters can be identified and controlled<br />

thus minimizing uncertainty in the transfer and scale-up effort.<br />

Deborah Meshulam, M.S., Director, Contract Manufacturing,<br />

ImmunoGen, Inc.<br />

ADC Manufacturing Facility Design – Current<br />

Requirements and Flexibility for the Future<br />

Given that ADC technology is still evolving, collaboration with<br />

customers early and often in the facility design phase is essential<br />

to define requirements. A robust facility design addresses current/<br />

potential customer needs, cGMP facility quality requirements<br />

and safety aspects for high potent compound handling. New<br />

technologies in equipment and instrumentation enable flexibility<br />

for the future.<br />

Bill Seaton, MBA, Vice President, Operations, SAFC<br />

4:00 Chairperson’s Remarks Joanne T. Beck, Ph.D., Vice President, Process Development, Shire Human Genetic Therapies<br />

4:15 Successfully Partnering Pharmaceutical Manufacturing<br />

5:00 Targeted Development of a Biosimilar Using Quality<br />

throughout Product Lifecycle<br />

by Design Concepts<br />

In a unique business development deal, MedImmune and Merck have entered into a<br />

The primary goal in biosimilar development is to deliver products which<br />

15-year manufacturing capacity-sharing agreement that initially utilizes MedImmune’s<br />

are highly similar to the originator product. Comparable safety and efficacy<br />

Frederick, Md., facility for Merck Biotech bulk product manufacturing. The agreement<br />

need to be demonstrated in an extensive comparability exercise. This talk<br />

serves to grow MedImmune’s manufacturing capabilities, while providing Merck with world class<br />

will discuss how QbD concepts can serve as key enablers for successful development of a<br />

manufacturing capability and capacity for its novels and biosimilars pipeline. In this presentation we will<br />

biosimilar product. In a systematic approach, development targets are defined based on<br />

highlight both the deal structure and execution as an industry best practice. The platform of the agreement, originator product data with the comparability exercise in mind. A science- and risk-based<br />

which allows for joint capacity planning, represents a strategic long-range solution that addresses capacity approach combined with product and process understanding enable to set the right priorities<br />

issues within the industry. While it is not unusual for bio-pharmaceutical companies to share manufacturing throughout product development in order to finally achieve a highly similar product.<br />

capacity, it is less common for two companies to jointly plan for capacity utilization in a facility built and<br />

owned by one of the parties. The companies are also exploring the suitability of Merck’s facilities in the<br />

production of microbial-based compounds in MedImmune’s pipeline, and other potential manufacturing<br />

opportunities where business strategies intersect.<br />

John Stubenrauch, MBA, Ph.D., Head of External Commercialization and Operations, Biologics,<br />

Merck & Co., Inc.<br />

Thomas Stangler, Ph.D., Development Strategy and Technology Manager,<br />

Sandoz Biopharmaceuticals, Austria<br />

Early Registration and Group Discounts are Available (see page 27) 10

Achieving Rapid Process<br />

Development and Novel<br />

Technology Implementation<br />

Session Sponsored by:<br />

Chairperson’s Opening Remarks<br />

Jon Petrone, Vice President, Technical Services,<br />

Pall Life Sciences<br />

Challenges of Concurrent Multi-<br />

Product Manufacturing of Bulk Drug<br />

Substances in a Ballroom Environment<br />

This presentation will discuss the challenges and<br />

benefits of reduced levels of environmental controls<br />

for concurrent multi-product manufacturing within<br />

a ballroom facility concept. Design, operational,<br />

organizational and testing challenges will be<br />

addressed with solutions to mitigate identified risks.<br />

Mitigation will include quality risk management<br />

approaches and assurance of closed processing via<br />

the integrity of equipment design, procedural and<br />

operational controls. Benefits extend to realizing<br />

facility capacity and reducing operational costs whilst<br />

maintaining product quality and operator safety.<br />

Kenneth D. Green, Ph.D., Director,<br />

Operational Excellence, Pfizer<br />

Simon Chalk, Director, BioPhorum<br />

Operations Group<br />

Electronic Visual Factory: Enhance<br />

Operational Excellence through<br />

Visualization and Mobility<br />

Wednesday, October 10, 2012<br />

7:00 Networking Coffee<br />

7:30 Technology Workshop with Light Continental Breakfast Sponsored by:<br />

8:00<br />

8:15<br />

8:45<br />

Enhancing Manufacturing<br />

and Development Efficiency<br />

CASE STUDY<br />

Electronic Visual Factory is a means<br />

of finding innovative ways of making<br />

information available and useful. Today’s<br />

biopharmaceutical factory produces a vast<br />

amount of data that can be used to make better<br />

process and business decisions. Discover ways to<br />

improve process monitoring, achieve paperless<br />

manufacturing, enhance “purposeful presence<br />

on-the-floor”, improve business communications<br />

and increase efficiency through mobile solutions.<br />

Fernando Nuno Fialho, Senior Manager,<br />

Manufacturing, Amgen Inc.<br />

Product Lifecycle Planning:<br />

Innovative Solutions to<br />

Meet Quality and Process<br />

Challenges<br />

Advancing the Science<br />

of Comparability: Cost-<br />

Effective Approaches for the<br />

Implementation of Process<br />

Change through the Lifecycle<br />

Chairperson’s Opening Remarks<br />

Victor A. Vinci, Ph.D., Chief Scientific Officer<br />

and Vice President, Cook Pharmica<br />

TBA<br />

Comparability Strategies<br />

for Bioproducts<br />

Changes to pharmaceutical processes<br />

or products may be implemented at any<br />

stage of development or post-licensure,<br />

and have the potential to impact product<br />

quality. Regardless of the nature of the change,<br />

quality assessments are always conducted to<br />

demonstrate the comparability of pre- and postchange<br />

material. The purpose of this talk is to<br />

discuss the approaches to establishing analytical<br />

comparability of bioproduct drug substance<br />

and drug product solutions, including risk<br />

assessments, establishing acceptance criteria and<br />

designing the appropriate stability studies for pre<br />

and post change material.<br />

Sarah Demmon, Senior Research Scientist,<br />

Bioproduct R&D, Eli Lilly and Company<br />

UNPUBLISHED<br />

DATA<br />

Specialty Focus Track<br />

Viral Safety for Biologics<br />

Chairperson’s Opening Remarks<br />

Hannelore Willkommen, Ph.D., Regulatory<br />

Affairs and Biological Safety Consulting, Germany<br />

Demonstration of Consistent<br />

and Robust Retrovirus Removal<br />

by Parvovirus Filter...A Co-spiking<br />

Approach to Support Modular<br />

Clearance for IND/CTA Filing<br />

Dayue Chen, Ph.D., Research Advisor,<br />

Process Development, Eli Lilly and Company<br />

UVC Based Viral Inactivation<br />

of Cell Culture Media –<br />

Prototype Design and<br />

Experimental Verification<br />

CASE STUDY<br />

UNPUBLISHED<br />

DATA<br />

UNPUBLISHED<br />

DATA<br />

A novel high-throughput UVC treatment<br />

device for cell culture media was designed using<br />

computational modeling techniques. With<br />

high UV absorbances of cell culture media,<br />

the primary challenge was to accomplish a<br />

sufficiently narrow UVC dose distribution at<br />

high flow rates to allow for media preparation<br />

in a reasonable time for a perfusion culture. A<br />

prototype was built and experimentally verified<br />

using chemical actinometry techniques with<br />

fluorescent microspheres in media that undergo<br />

photobleaching corresponding to UVC dose. The<br />

results indicate a viable device and technology for<br />

successful treating of cell culture media with high<br />

throughput requirements for perfusion culture.<br />

Kumar Dhanasekharan, Ph.D., Associate<br />

Director, Process Sciences and Technology,<br />

Genzyme, a Sanofi company<br />

Mixed Mode<br />

Chromatography<br />

Strategies for<br />

Biomolecule Purification<br />

8:00 am - 12:00 pm<br />

Maximizing Downstream<br />

Process Method<br />

Development<br />

A majority of monoclonal antibodies<br />

are purified using affinity on protein A.<br />

For each non-antibody therapeutic in<br />

today’s pipeline, the lack of an affinity<br />

capture increases the burden on every<br />

step of the downstream process to<br />

achieve final product purity. Mixed mode<br />

media have a significant role in polishing<br />

for monoclonal applications, and are<br />

now being leveraged into capture,<br />

intermediate and polishing steps for new<br />