p/Cover Story/Sep - Roof & Facade

p/Cover Story/Sep - Roof & Facade

p/Cover Story/Sep - Roof & Facade

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Roof</strong>&<strong>Facade</strong> Asia Feature: Translucent & Transparent Materials<br />

ETFE in Membrane Constructions<br />

– Important aspects of ETFE<br />

cushion structures<br />

Mr Dieter Linke, covertex GmbH / Engineering + Design GbR, Germany, highlighted the<br />

potential for the use of ETFE (ethyl tetra fluoro ethylene) cladding in the building industry, in<br />

his presentation at FLUOROPLAST 2004 World Congress which addressed the theme<br />

‘Fluoropolymers in Architecture - Construction – Design – Engineering’. The event, held on 28<br />

and 29 April 2004 in Zurich, Switzerland, was organised by Maack Business Services of Zurich.<br />

(The next FLUOROPLAST World Congress will be held in Zurich from 14 to 15 March 2006).<br />

Introduction<br />

Traditional architectural membranes are coated fabrics.<br />

Wind and snow loads are carried by the fabric.<br />

The coating protects the fabric against environmental<br />

impacts and it allows for the weld assembly of<br />

the panels.<br />

These membranes with PE-fabric and PVC<br />

coating or glass fibres with PVC coating are light<br />

and very strong – but never transparent.<br />

Typical characteristics of ETFE are its<br />

transparency (also combined with printing), natural<br />

light transmittance for visible light and UV-rays, its<br />

low weight and the possibility to build extended and<br />

variable curved surfaces in one piece. These<br />

characteristics make it very interesting for<br />

architectural purposes.<br />

But as ETFE membranes in roofing and cladding<br />

are not reinforced, they have to carry the loads<br />

without fabric. Thus, ETFE membranes have only a<br />

fractional amount of tensile strength, compared to<br />

coated fabric materials.<br />

It is obvious that the supporting structure and<br />

the detailing for the ETFE attachment must take this<br />

fact into account. A good way to do so, is to use ETFE<br />

in claddings as air supported cushions.<br />

It is a great challenge to merge the architect’s<br />

intentions with the special needs of ETFE<br />

structures, in order to achieve a good, durable and<br />

economic building.<br />

But to do so, knowledge about the less obvious,<br />

4 <strong>Roof</strong> & <strong>Facade</strong> Asia • <strong>Sep</strong>tember 2004<br />

though very important technical aspects relating to<br />

the use of ETFE as a structural element in buildings,<br />

is required, too. As building with ETFE has very<br />

little history, principals, architects, and engineers<br />

usually are not aware of the sometimes very rigid,<br />

boundary conditions.<br />

Depending on the type of supporting structure<br />

and the physical needs of the cladding, like thermal<br />

insulation, shading, and internal humidity, two<br />

main design groups can be identified - ETFE<br />

cushions and mechanically prestressed ETFE in a<br />

single layer.<br />

First, important aspects about ETFE cushions will<br />

be highlighted. Against this background, the special<br />

design features of the world’s largest ETFE cushion<br />

project, Allianz Arena Soccer Stadium, Munich, will<br />

be explained, and towards the end, the prospects<br />

with single layer ETFE constructions, will be<br />

discussed.<br />

Typical configuration of ETFE cushions<br />

ETFE cushions basically consist of one inner and one<br />

outer foil. Both are stabilised by automatically<br />

controlled, moderate, overpressure of the air<br />

trapped between them. This pressure is retained by<br />

fans. The layers are usually welded together along<br />

the edges and attached to the support structure with<br />

special aluminium extrusions.<br />

Static mode of operation<br />

Inward-aimed external loads (wind pressure, snow),<br />

are led to the inner foil by the internal overpressure.<br />

It carries the load, hammock-like.<br />

Outward-aimed external loads (wind suction) are<br />

carried by the outer layer in similar manner. Internal<br />

pressure and external wind suction add up to a<br />

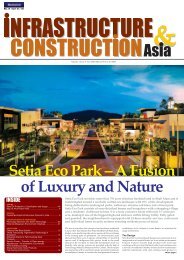

Allianz Arena Soccer Stadium, Munich, Germany: The world’s<br />

largest ETFE cushion project.<br />

certain extent and need to be calculated carefully.<br />

The overpressure usually amounts to 250 Pa and<br />

can be changed up to the equivalent snow load, if<br />

necessary.<br />

Owing to the instability in windy conditions, a<br />

lack of air pressure should be avoided. If water<br />

ponding is excluded by well designed slopes on the<br />

roof, a lack of air pressure is usually not a static<br />

danger. The foils are designed for the expected loads<br />

and it is not important, whether, for example, snow<br />

load effects are applied to the inner layer via air<br />

cushion or applied directly.<br />

EXTERNAL LOAD E.G. SNOW<br />

HORIZONTAL<br />

SUPPORT<br />

REACTION<br />

INTERNAL OVER PRESSURE<br />

VERTICAL<br />

SUPPORT<br />

REACTION<br />

RADIUS OF OUTER FOIL<br />

OUTER<br />

INNER<br />

RISE<br />

OF<br />

ARCH<br />

Limited strength of ETFE foil<br />

The performance of a cushion-carrying load is<br />

dependent on the deployed thickness of the foil<br />

which is usually between 150 and 250 microns and<br />

on its radius of curvature. With typical building<br />

code design loads, the free span of a long,<br />

rectangular ETFE cushion, can reach up to<br />

approximately 4 m. Its length is limited only by<br />

practical considerations.<br />

High tension forces at the attachment structure<br />

and/or the space for the dip, must be taken into<br />

account. A radius of 3.5 m to 4 m for the curvature<br />

of a cushion layer between the attachment lines, is<br />

a good value to start with, for the design. A small<br />

radius reduces stress but increases the rise of the<br />

arch of the cushion foils.<br />

Supported with cable nets, to reduce the static<br />

free span of the foil, ETFE cushions have been built<br />

with up to 50 m in diameter.<br />

Safe air supply<br />

The normal excess pressure of 250 Pa equals 0.0025<br />

bar or 0.25 kN/sqm. The surplus amount of air<br />

required to provide this pressure in the cushion, is<br />

only a few litres. The air to fill the cushions and to<br />

replace losses, is led into the cushions via pipes and<br />

hoses, and is usually taken from outside of the<br />

building.<br />

Except under extremely windy conditions or<br />

when there is a danger of water ponding, the air<br />

overpressure in the cushion is not a vital element in<br />

the static performance of the cushions. But lack of<br />

air pressure could have negative effects on inner<br />

foils, internals, thermal insulation and durability of<br />

the entire construction.<br />

Usually, two electric engines with two fans (not<br />

Continued on page 5 >>>