InFORM 02.2008 (PDF-File) - Duktus

InFORM 02.2008 (PDF-File) - Duktus

InFORM 02.2008 (PDF-File) - Duktus

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.<br />

Volume<br />

Jahrgang<br />

4 Issue<br />

Ausgabe<br />

2 July<br />

2<br />

2008<br />

Juli 2007<br />

The magazine for employees<br />

and business partners of the<br />

company<br />

Berlin-Brandenburg International<br />

Airport: Clear decision<br />

in favour of ductile cast iron<br />

Winnebach: Turbine pipe<br />

including special structures<br />

Bad Mitterndorf: Deep foundations<br />

using TRM piles

Contents<br />

3 Editorial<br />

Contents<br />

The company<br />

4 IFAT 2008 – The industry‘s big event<br />

6 Cast iron veins to carry some of the lifeblood of Berlin-<br />

Brandenburg International Airport<br />

8 Small hydroelectric generator station at Winnebach in<br />

South Tyrol – Turbine pipe including a large number of<br />

special structures<br />

10 Grimming-Therme thermal spa in Bad Mitterndorf – on deep<br />

foundations driven with TRM piles<br />

11 The Lebrija solar energy park – TRM piles safeguard the<br />

foundation soil<br />

Places and people<br />

12 The cultural attractions of Vienna are overwhelming<br />

13 The international water industry is meeting in Vienna –<br />

World Water Congress and Exhibition, 7th to 12th of<br />

September 2008<br />

14 HamBaker – a partner who can be relied on in Britain<br />

News<br />

15 Blue impressions in the Erzgebirge mountains – DN 600<br />

Buderus pipe with BLS ® joints maintain the water supply<br />

in the Zwickau region<br />

16 SMAGuA in Zaragoza<br />

WETEX 2008<br />

17 SAM ALpEXpo in Grenoble and ALpITEC in Bozen<br />

WoD-KAN 2008<br />

VoDoWoDY-KANALIZACE 2008<br />

18 BLS ® and puR Top – the tailor-made solution to problems<br />

Culverting of a canal between the Neuwieser and partwitzer<br />

Lakes in the Lausitz<br />

About us<br />

19 The important thing was always water – An excursion during<br />

the sale force conference in April at Blankenburg am Harz<br />

20 The Wipptal region played host to Vienna – the Tyrolean Ball<br />

at Vienna Town Hall<br />

21 New colleagues: More people who are now working to<br />

make ductile cast iron pipe and piles a success<br />

22 THE „STop SIGN“ scheme for employees‘ suggestions –<br />

Sometimes it‘s the little things ...<br />

23 A nice, but heavy, present – a ton of molten iron for<br />

Special Castings<br />

Day of Action on the 30th of August 2008<br />

Invitation to the Family Day on the 13th of September 2008<br />

Anniversaries<br />

Imprint

Dear readers,<br />

We are delighted to be able to present you with a new issue of<br />

our corporate magazine inFORM – published specially and exclusively<br />

for customers, employees and friends of our business<br />

in cast iron pipe and piles.<br />

Work on the aspects of our restructuring covered by company<br />

law have now been completed. Together with their sales and<br />

marketing companies Buderus Litinové Systémy s.r.o. (Czech<br />

Republic) and Buderus Pipe Systems FZCO (United Arab Emirates),<br />

Buderus Giesserei Wetzlar GmbH (BGW) and Tiroler<br />

Röhren- und Metallwerke AG (TRM) now form an independent<br />

group of companies. We are glad to see the business developing<br />

in this way, because we can now concentrate our forces on<br />

the cast iron pipe business and devote all our efforts to our core<br />

business and its customers.<br />

In this issue, we report as usual on current projects, events and<br />

people in our group of companies.<br />

This time we have made a special feature of our activities in the<br />

field of piled foundations using ductile piles. In the first half of the<br />

year we have already worked with our customers to carry out a<br />

number of very interesting projects, such as the new Grimming-<br />

Therme thermal spa in Bad Mitterndorf in Austria and the Solar<br />

Energy Park at Lebrija in Andalusia. You will find reports on these<br />

projects on pages ten and eleven.<br />

Other high spots of the first half of the year were the many international<br />

fairs and exhibitions. The Alpitec exhibition in Bozen<br />

and the SAM in Grenoble were this year‘s most significant exhibitions<br />

in the market for Alpine snow-making facilities. They<br />

were followed by national exhibitions in Saragossa (Spain), Brno<br />

(Czech Republic), Bydgoszcz (Poland) and in the Russian capital<br />

Moscow. The industry‘s main event was of course the IFAT,<br />

which took place in early May in Munich, and you will find a detailed<br />

report on this on the pages below. The high point of the<br />

year‘s conferences and exhibitions in 008 will be the World Water<br />

Congress of the International Water Association, which will<br />

be held from the 7th to the 1 th of September in Vienna. For<br />

the first time for years, this congress is going to be returning to<br />

the German-speaking part of the world. May we take this opportunity<br />

of extending to all of you a cordial invitation to attend<br />

this event, which is highly esteemed in the industry.<br />

We regret to say that we are increasingly concerned about worldwide<br />

developments on the raw materials and procurement markets.<br />

The effects of the international boom in demand in the construction<br />

and steel industries are now making themselves felt in<br />

our business too. For example, just in the months from March<br />

to June this year, the purchase price of our main raw material,<br />

scrap iron, went up by more than 00 Euros per ton – a rise, the<br />

like of which has never before been seen on the raw materials<br />

market. Regrettably, the price of coke too is moving upwards at<br />

the moment in a similar headlong fashion. With products such as<br />

cast iron pipes and ductile piles which use large amounts of mate-<br />

rial, developments like these have a major impact on the cost of<br />

the product. It is virtually impossible to compensate for them by<br />

making savings elsewhere. This is why we are finding ourselves<br />

compelled to pass on the major part of these price rises to our<br />

customers. As from 1 June 008, we have had to introduce surcharges<br />

for the price of scrap in almost all areas of the business<br />

to enable the situation to be dealt with in a reasonable way. It is<br />

clear to us that this will make it considerably more difficult for<br />

fairly long-term projects to be costed. However, the action we<br />

have taken here is simply a reflection of the general trends in<br />

the prices of raw materials and we therefore trust that our customers,<br />

and the clients for whom they are working, will understand<br />

why we have had to do this. At the same time, we hope<br />

that the situation will soon settle down, because this will be in<br />

the interests of everybody in the industry. Demand in the foundation<br />

and underground construction industry still seems to be<br />

strong. Both for ourselves and you, dear readers, we hope that<br />

this state of affairs will continue.<br />

In this issue, we would like to continue a story we began to tell<br />

in the past and to introduce you to some of our company‘s important<br />

partners in the field of marketing. From its base near<br />

Manchester, the HamBaker Group deals with our cast iron pipe<br />

business in Britain. HamBaker is totally committed to our highquality<br />

products and is making major efforts to promote sales of,<br />

for example, our thrust-locked BLS ® /VRS-T pipe in a marketing<br />

environment which is not always easy. You can find our portrait<br />

of the company on page 14.<br />

See too the profiles of new, young and promising employees who<br />

work for our group of companies (page 1). With their talents<br />

and abilities they represent the future of our company. We think<br />

you should get to know as many of them as possible.<br />

We hope you will enjoy reading the magazine and would like to<br />

wish you all the best for the forthcoming holiday period and that<br />

you will have a pleasant and relaxing holiday.<br />

We‘ll be back with you with the next issue of inFORM in November<br />

008.<br />

Until then, with best regards, we are<br />

Ulrich Päßler Max Kloger Stefan Weber<br />

Editorial

BGW – Cast iron pipe technology<br />

4<br />

I F A T 2 0 0 8 – T h e i n d u s t r y ‘ s b i g e v e n t<br />

2,560 exhibitors: up 15%<br />

120,000 visitors: up 10%<br />

Foreign participation rises<br />

by a third<br />

Those were the results that once again<br />

demonstrated the significance of IFAT, the<br />

15th International Trade Fair for Water,<br />

Sewage, Refuse and Recycling, held from<br />

the 5th to the 9th of May at the New<br />

Munich Trade Fair Centre, as the world‘s<br />

largest and most important trade fair for<br />

environmental technologies and environmental<br />

services.<br />

There were a total of ,560 exhibitors<br />

from 44 countries showing innovative<br />

products and services in the fields of water,<br />

sewage, refuse and recycling. That figure is<br />

more than 15% up on the figure for IFAT<br />

005. Among the exhibitors, the IFAT Fair<br />

showed a high international participation<br />

of a good third. The marked international<br />

orientation was also reflected in the programme<br />

for the IFAT conference which,<br />

as well as talks by specialists and symposia,<br />

also included Country Specials for Spain,<br />

Eastern Europe, Russia, the Arab regions,<br />

India, China and Japan.<br />

Buderus and TRM set out their stall in Munich<br />

on a 00 square metre stand worthy<br />

of the companies and their products. „The<br />

future is ductile“ was the slogan under<br />

which the cast iron pipe group took the<br />

stage to show what it had: superb products<br />

and good prospects. To learn more,<br />

we interviewed Ulrich Päßler, CEO of<br />

BGW and a member of the executive<br />

board of TRM.<br />

Editor: Herr Päßler, the slogan at IFAT<br />

was „The future is ductile“. Did the success<br />

of the cast iron pipe group at the fair<br />

do anything to demonstrate the truth of<br />

this slogan?<br />

Ulrich Päßler: The answer to that question<br />

is a very definitive „Yes“. More than<br />

ever before, our ductile cast iron pipe for<br />

drinking water supply and sewage disposal<br />

aroused the interest of trade visitors to<br />

the Fair. There were many conversations<br />

in which we found that ductile cast iron<br />

is considered to be the material of the<br />

future because it will carry high loads, is<br />

flexible in how it can be laid, is reliable and<br />

is very long-lived. In today‘s world, these<br />

properties are coming to be increasingly<br />

valuable. „Sustainability“ is the key word<br />

that has become the guiding principle for<br />

many public companies and local public<br />

enterprises.<br />

Editor: It was not just at the IFAT itself<br />

that there was a considerably higher international<br />

participation among both exhibitors<br />

and visitors; on the Buderus stand too<br />

things were more international than ever<br />

before. What is your view of this?<br />

Ulrich Päßler: This is a very welcome<br />

development and is a result of the fact that<br />

BGW and TRM have now moved well beyond<br />

their home markets, and have done<br />

so with great success. The opening out<br />

into European markets and into the world

market has shown that with our products,<br />

and above all the VRS/BLS ® system, we<br />

are well able to meet fresh challenges.<br />

This is why there were delegations from<br />

all parts of Europe, the Near East and Asia<br />

that we welcomed to the stand and why<br />

there were many promising prospects<br />

that we were able to discuss.<br />

Editor: Is the way things went at this<br />

year‘s IFAT proof that the changes in the<br />

cast iron pipe group have had a beneficial<br />

effect?<br />

Ulrich Päßler: Most definitely. There has<br />

been an improvement in our international<br />

sales and marketing structure and we are<br />

focussing on high-grade problem solvers<br />

in the form of our restrained socket joints<br />

and the CMC coating and this has set in<br />

train successes not just at the IFAT but generally.<br />

Last year we were still able to chalk<br />

up a two-digit rise in turnover and there<br />

is every prospect of this trend continuing<br />

in 008. The Russian market is growing<br />

fast, and given that this is another market<br />

where we want to continue establishing<br />

our presence, it is true to say that we are<br />

on the right road and that the slogan for<br />

IFAT 008 was more than justified.<br />

Editor: The next big events for the industry<br />

are the „World Water Congress“<br />

(WWC) in September 008 in Vienna and<br />

„Wasser Berlin“ in 009 and people are<br />

already looking ahead to these. Are they<br />

some more events at which the cast iron<br />

pipe group is going to be represented?<br />

Ulrich Päßler: Yes, the preparations are<br />

already being made and I do not see that<br />

there is going to be any need for us to<br />

change our slogan.<br />

BGW – Cast iron pipe technology<br />

5

BGW – Cast iron pipe technology<br />

6<br />

A c l e a r d e c i s i o n i n f a v o u r<br />

o f d u c t i l e c a s t i r o n<br />

Cast iron veins to carry some of the lifeblood of Berlin-Brandenburg International Airport<br />

For what is currently Germany‘s biggest<br />

transport project, Buderus Giesserei<br />

Wetzlar GmbH is supplying a large part of<br />

the drinking water and sewage systems<br />

for the internal development of the airport<br />

site. There will be 4 kilometres of<br />

cast iron pipe for drinking water and sewage<br />

of nominal sizes from DN 80 to DN<br />

400. Some 60% of these pipe have to be<br />

laid this year and the rest are to follow in<br />

009.<br />

How did the company come to land such<br />

a large and important order?<br />

It was some years ago that the preparatory<br />

work began at the engineering consultants.<br />

In the end, the customer and<br />

the engineering consultants made a very<br />

clear decision in favour of ductile cast iron<br />

as a material. They appreciated the well<br />

known advantages which the material and<br />

the related systems have but there was<br />

more to it than that. They also valued the<br />

good experience there had been with the<br />

construction and operation of large-scale<br />

airport projects in the past, such as Frankfurt<br />

am Main airport for example. Early<br />

in 007, the invitations to tender were<br />

sent out to interested construction companies<br />

all over Europe. As well as being<br />

highly qualified and adequately financed<br />

over the construction period, these companies<br />

also had to draw up a plan of costs<br />

for the project. This was where Buderus<br />

too had to work out prices following comprehensive<br />

costings made in consultation<br />

with its suppliers and had to provide technical<br />

assistance. Then, late in 007, after<br />

extensive re-negotiations, the contract for<br />

this immense construction project, which<br />

covered not only drinking water and sewage<br />

but also other media, was awarded to<br />

a well-known Berlin consortium consisting<br />

of the Karl Weiss construction companies<br />

and the Beton- und Rohrbau company.<br />

Because February 008 was the date set<br />

for construction to begin, regardless of<br />

the weather, negotiations had to be conducted<br />

quickly and conscientiously. For<br />

demanding projects, high-grade products<br />

which are manufactured and looked after<br />

by committed and able employees are a<br />

prerequisite.<br />

Because of the scale of the project, employees<br />

of BGW‘s Applications Engineering<br />

Division and the marketing department<br />

all sat round the same table with the construction<br />

companies in the consortium<br />

right from the start. All these people knew<br />

one another from the many demanding<br />

construction projects they had worked on<br />

in the past and were already convinced of<br />

their partners‘ ability to deliver.<br />

As well as the quality of the product systems<br />

and the flexibility matched to the customer‘s<br />

requirements, what is also particularly<br />

important is logistics and everything<br />

to do with it. Deliveries have to be notified<br />

to BBI by e-mail and have to arrive<br />

punctually within a time slot. For customers<br />

of BGW, it goes without saying that the<br />

field sales force (Lutz Rau, Berlin Sales Division)<br />

will be there to see to their needs<br />

and that if any special questions arise relating<br />

for example to the BLS ® system or<br />

to the unlocking with SIT/Plus then employees<br />

of BGW‘s Applications Engineering<br />

Division will be available to give onsite<br />

instructions. This long-term trust on<br />

the part of customers is the very thing that<br />

Buderus has always worked to develop,

even when prices have to be competitive<br />

and margins are tight. After several rounds<br />

of negotiations, it was BGW that the consortium<br />

finally opted for to be given the<br />

contract for the internal development of<br />

BBI international airport. Following this,<br />

the Karl Weiss company visited BGW in<br />

Wetzlar and satisfied itself that the production<br />

department would perform to the<br />

requisite standard and that the workforce<br />

at the Wetzlar production plant had the<br />

The demands of the future have already<br />

been met: since September 2006, development<br />

work has been underway at the<br />

airport at Schönefeld to turn it into the<br />

new Hauptstadt-Airport BBI (BBI Capital<br />

Airport, a possible alternative name for<br />

BBI). As from 2011, all flights in the Berlin-Brandenburg<br />

region will be concentrated<br />

on this new airport in the southeast<br />

of the city. The airports in the city<br />

centre at Tegel and Tempelhof will be<br />

closed down in parallel.<br />

The design of BBI envisages a modern<br />

airport where distances are short and for<br />

this reason the terminal is situated between<br />

the two takeoff and landing runways,<br />

which are laid out in parallel with<br />

one another. BBI will be one of the new<br />

generation of airports: low-cost, functional,<br />

and cosmopolitan with modernday<br />

industrialised architecture. At BBI,<br />

the region of the German capital will be<br />

able to provide business travellers, tourists<br />

and companies with an airport offer-<br />

right sort of friendly competence.<br />

To safeguard the smooth running of this<br />

important international hub and interchange<br />

point for air travel, it is essential<br />

for it to have a supply system of high quality<br />

and one that can also be expanded to<br />

meet future demands. For this, the customer<br />

and the construction companies are<br />

putting their trust in the ductile cast iron<br />

pipe systems from Wetzlar.<br />

BBI Airport – the new airport for Berlin and Brandenburg<br />

ing excellent connections that handles international<br />

flights, that has its own motorway<br />

junction and that has a railway<br />

station immediately below the terminal.<br />

BBI is fully capable of handling A-380s:<br />

the runways and taxiways will allow even<br />

modern-day jumbos to take off and land<br />

at it.<br />

A takeoff capacity of 22 to 25 million<br />

passengers is planned for 2011. If the<br />

development in passenger traffic demands,<br />

the airport can be developed to<br />

handle up to 40 million passengers. BBI<br />

thus gives the Berlin-Brandenburg region<br />

the capacities it will need in the next few<br />

decades.<br />

A springboard to the east<br />

The outlook is clear: The BBI will become<br />

an airport in the centre of Europe whose<br />

primary focus is point-to-point flights within<br />

Europe and selected long-haul flights.<br />

The airports of Berlin have traditionally<br />

focussed their attention very much on<br />

Eastern Europe. With the expansion<br />

of the EU to the east,<br />

this tendency has become<br />

even more marked. Added<br />

to this there is the strategic<br />

advantage of being<br />

well placed in the centre of<br />

Europe: flight times to Eastern<br />

Europe and Asia are an hour<br />

shorter that they are from established<br />

hub and interchange<br />

airports in the west of continent.<br />

To Berlin in next to no time<br />

With the airport shuttle, the time to travel<br />

into the centre of Berlin will be just 20<br />

minutes and by motorway it will be just<br />

on 30 minutes. BBI will make Berlin the<br />

European capital whose international airport<br />

is the shortest distance away.<br />

BBI Airport City<br />

As well as the attractive flights that will be<br />

available, there will also be an extensive<br />

non-aviation offering at BBI. The plans<br />

are for the businesses and restaurants in<br />

the airport itself, just in front of the terminal,<br />

to be supplemented by the airport‘s<br />

own shopping and office complex – BBI<br />

Airport City. Here there will be businesses,<br />

cafés, bars, restaurants, hotels and<br />

conference centres for passengers and<br />

visitors to the airport.<br />

BGW – Cast iron pipe technology<br />

7

TRM – Cast iron pipe technology<br />

8<br />

S m a l l h y d r o e l e c t r i c g e n e r a t o r<br />

Waterpower plays an important part in<br />

the generation of energy in South Tyrol.<br />

It is a renewable and inexhaustible source<br />

of energy and using it safeguards the energy<br />

supply and at the same time protects<br />

our habitat for future generations.<br />

The environmental balance sheet for waterpower<br />

is the best of all, because the<br />

water from rivers is used and is returned<br />

to them unchanged. Small hydroelectric<br />

generator stations are particularly good<br />

because not only are they an economical<br />

energy source that is kind to the environment<br />

but they also have beneficial effects<br />

on the habitat of both man and beast.<br />

Turbine pipe including a large number of special structures<br />

“Manhole“ – produced in the form of a DN 600/600 all-flanged tee<br />

s t a t i o n a t W i n n e b a c h<br />

i n S o u t h T y r o l<br />

This is why the largest energy supplier in<br />

South Tyrol, SEL AG, has again invested in<br />

a new small hydroelectric generator station.<br />

The station, which is being built in<br />

the Pustertal in South Tyrol to the most<br />

stringent ecological standards, is to have<br />

an average annual rated output of 1,170<br />

kilowatts. It is permissible for 60 to 480<br />

litres per second of water to be diverted<br />

from the river Winnebach to generate<br />

power. The remaining volume of water<br />

flowing has been measured as 50 litres per<br />

second in winter and 100 litres per second<br />

from April to November. Pipes measuring<br />

a total of , 00 metres in length are being<br />

laid for the generator station. The project<br />

envisages the construction of a water-diverting<br />

generator station with a water intake<br />

structure situated at Ast in the commune<br />

of Terenten. The water is diverted<br />

by an underground pipe constructed from<br />

individual pipes of ductile cast iron. The<br />

turbine building, most of which is above<br />

ground, is situated in the parish of Dörfl<br />

in the commune of Vintl, where the Winnebach<br />

flows into the river Rienz. Having<br />

been used in the turbine, the water is returned<br />

to the Winnebach by a concrete<br />

channel followed by an overflow weir.<br />

Trench holding the feed water pipe and the empty<br />

piping for control cables

So that the landscape is spoiled as little as<br />

possible, the whole of the pressure pipe<br />

has been constructed as a DN 600 underground<br />

pipeline (of wall thickness classes<br />

K9 and K10). The turbine building is being<br />

partly buried in earth bankings.<br />

Nor have the fish been forgotten: so that<br />

there is no risk to their spawning grounds,<br />

a so-called fish ladder has been incorporated<br />

in the water intake structure. What<br />

is more, small hydroelectric stations have<br />

a beneficial effect on fish stocks anyway,<br />

because the eddies from the turbines introduce<br />

oxygen into the water.<br />

The special feature of this project is the<br />

many inspection and connection „manholes“<br />

distributed along the length of the<br />

. kilometre long path followed by the<br />

pipe carrying the feed water. Four inspection<br />

openings (or „manholes“, in the<br />

form of DN 600/600 all-flanged tees) have<br />

been installed to provide access facilities<br />

to the pipe every 600 meters for inspection<br />

work. However, the pipe carrying the<br />

feed water supplies water not only to the<br />

turbine but also to two branch pipes running<br />

to hydrants, which are to be used for<br />

fighting forest fires. There are also four<br />

nearby farms whose sprinkler systems<br />

are being connected to the new pressure<br />

pipe.<br />

For the most part, the route followed by<br />

the pipe is along forest roads and through<br />

areas of forest but there are also two high<br />

points where it crosses the Winnebach.<br />

To avoid any air inclusions in the pipe, it is<br />

necessary for an automatic air supply and<br />

air venting unit to be installed.<br />

Because of the many special structures,<br />

the Winnebach hydroelectric generator<br />

station project involves more fittings than<br />

any other turbine project for the past ten<br />

years – about 110 fittings are being installed.<br />

Another novel feature is the system for<br />

locating leaks by means of fibre optics. To<br />

enable possible leaks to be located as accurately<br />

as possible, a fibre optic cable has<br />

been laid below the bottom of the pipe.<br />

This technique has been developed by<br />

the University of Hydraulic Engineering<br />

at Innsbruck.<br />

(We will be publishing a report on this subject<br />

in the next issue of inFORM.)<br />

Mountains, castles and sundials<br />

The Pustertal in South Tyrol:<br />

a paradise for nature-lovers and<br />

culture-seekers<br />

The Pustertal is a valley whose height<br />

ranges from 700 to approximately<br />

1,600 metres. It is situated mainly in<br />

South Tyrol and it runs between Brixen<br />

and Lienz. It branches off eastwards<br />

from the Eisacktal at a point to the north<br />

of Brixen and the rivers Rienz and Drau<br />

flow through it. In the High Pustertal,<br />

there are the characteristic peaks of<br />

the Sexten and Lienz Dolomites. This<br />

is also the place where the celebrated<br />

Drei Zinnen tower into the sky. Deodat<br />

de Dolomieu was the first man to investigate<br />

the calcareous rocks in the region,<br />

and it is from him that these peaks<br />

take their name. The Dolomites have a<br />

close connection with the history of alpine<br />

mountaineering. A name that will<br />

be remembered in this connection is the<br />

film director and actor Luis Trenker, who<br />

came from the Tyrol and whose films often<br />

„starred“ mountain landscapes.<br />

The Pustertal has some 73,000 inhabitants<br />

living on a good 2,000 square kilometres<br />

of land. The best known towns<br />

are Bruneck, Wengen and Toblach.<br />

From the administrative point of view<br />

it consists of the districts of Hochabtei,<br />

Hochpustertal, Kronplatz and Tauferer<br />

Ahrntal.<br />

A wide range of sporting activities are<br />

available: climbing, hiking, mountainbiking,<br />

paragliding, rafting and much<br />

else besides. In winter, the High Pustertal<br />

is an absolute paradise for skiers.<br />

A special attraction is the micro-climate<br />

tunnel at Prettau. This is a disused mine<br />

gallery in which there are micro-climatic<br />

conditions consisting of a temperature<br />

of about 9° Celsius and a relative<br />

humidity of approximately 95%. These<br />

have a beneficial effect particularly on<br />

people suffering from respiratory prob-<br />

lems. In the Pustertal tourists will find<br />

everything they want from luxury hotels<br />

to family-owned boarding houses. The<br />

charm of the valley comes from the association<br />

of the old and the new, of traditional<br />

country life and modern-day living,<br />

of the Tyrolean and the Italian.<br />

Seeing the well-preserved town walls<br />

and town gates and the castle at Bruneck,<br />

the visitor will find himself transported<br />

into the middle ages. Nowhere<br />

else in Europe are there so many properties<br />

dating from the middle ages situated<br />

so closely together as there are<br />

here. With its 400 or so castles and citadels,<br />

South Tyrol generally is the region<br />

which can boast the largest number of<br />

medieval edifices. There are many romances<br />

from the age of chivalry that<br />

tell the story of those times. Rodeneck<br />

Castle is one of the largest castles in<br />

South Tyrol and is the home of a renowned<br />

cycle of frescoes dating from<br />

the 13th century showing scenes from<br />

Hartmann von Aue‘s Middle High German<br />

epic „Iwein“. The „Gustav Mahler<br />

Music Weeks“ would also seem to<br />

be a byword among lovers of classical<br />

music. Today, handicrafts are still a living<br />

presence in the Pustertal in the form<br />

of its wood-carving, its lace-making, its<br />

weaving and its making of Patschen or<br />

felt shoes. Typical culinary products are<br />

cheese and home-cured bacon.<br />

A special event is the Stegener Market<br />

which is held in autumn every year and is<br />

the biggest food and handicraft market<br />

in the whole of Tyrol. There are booths<br />

there selling mulled wine and the special<br />

little sausages and stalls where you<br />

can buy schnapps and cheeses and all<br />

sorts of handicraft products.<br />

That the people in the Pustertal seem<br />

to have a rather sunny disposition is<br />

shown by one of the other special features<br />

of the region: the many sundials.<br />

What is it that people say? Only count<br />

the happy hours!<br />

TRM – Cast iron pipe technology<br />

9

TRM – Cast iron pipe technology<br />

10<br />

O n f i r m f o u n d a t i o n s<br />

A site measuring 40,000 square metres,<br />

those words alone are enough to give<br />

some idea of how big the project is – Nestling<br />

between the mountains of the Ausseerland<br />

area in Austria‘s Salzkammergut,<br />

the Grimming-Therme thermal spa and its<br />

hotel resort are being built in Bad Mitterndorf.<br />

The project is intended to continue<br />

the development of the region and to be<br />

a driver of year-round tourism. The hot<br />

springs at Bad Mitterndorf, which were<br />

known even in Roman times, will help to<br />

ensure that even greater use is made of<br />

existing tourist attractions such as the<br />

Tauplitz and Loser area for Alpine and<br />

cross-country skiing.<br />

When the ground was broken for this 50<br />

million Euro project in December 007, it<br />

marked a change to the overtaking lane<br />

for the tourist industry in the Salzkammergut.<br />

From the 8,000 square metres of<br />

land that the spa itself will occupy, future<br />

guests and visitors will be able to enjoy the<br />

view they will have of one of the most<br />

impressive panoramas in the Steiermark:<br />

mountains, interspersed with gently roll-<br />

ing hill and knolls and enthroned above<br />

them all the Grimming, the mountain that<br />

personifies the Hinterbergertal, about<br />

which there is such a rich tapestry of legends<br />

and folk-tales. But before that can be<br />

possible there is a lot to do.The whole site<br />

had to be given deep foundations. For<br />

combined environmental and economic<br />

reasons and also in view of the minimal<br />

settlement that is permitted, the decision<br />

that was made in the case of this structurally<br />

demanding building project was to use<br />

the pile system made by TRM. Due to the<br />

existing soil conditions (water table three<br />

metres below the surface of the ground<br />

and a confined aquifer at a depth of 5 to<br />

The TRM pile system<br />

The TRM pile system consists of centrifugally<br />

cast pipe of ductile cast iron with<br />

conical sockets and with spigot ends<br />

which have a matching conical taper. As<br />

a result, the individual lengths of pipe can<br />

be assembled into longer units as the driving<br />

progresses without the need for any<br />

special tools. Due to the rigid joints, they<br />

then form a load-bearing member which<br />

is one continuous unit – the pile A driven<br />

pile is sunk into the soil – by driving – and<br />

then dissipates, or transmits, forces from<br />

the structures situated above it into the<br />

soil. In actual fact, this procedure is a very<br />

old one; in the Neolithic period and the<br />

Bronze Age, piles for constructing dwellings<br />

were already being driven into the<br />

shores of bodies of water or directly into<br />

the bodies of water themselves; this is<br />

how the structures known as lake dwellings<br />

were built.<br />

The piles are made of ductile cast iron,<br />

and this is a very elastic material which is<br />

able to withstand tremendous mechanical<br />

stresses – such as occur in the driving operation.<br />

At a standard length of 5 m, they<br />

Grimming-Therme thermal spa in Bad Mitterndorf – on deep foundations driven with TRM piles<br />

7 metres), the work can only be done if<br />

the springs are kept running or on other<br />

words the deep foundations have to act<br />

to some degree as an additional safeguard<br />

against uplift. That each pile will have the<br />

exterior load-bearing capacity laid down<br />

is demonstrated by the driving criterion<br />

when the pile is being driven. The piles are<br />

pressure-grouted and, in the boggy ground<br />

involved, this rules out any possibility of<br />

the groundwater mixing with polluted<br />

surface water. Hence, the TRM piles have<br />

once again shown themselves to be an efficient,<br />

fast and inexpensive deep foundation<br />

system. If all the piles which have<br />

been delivered to the sites were laid end<br />

to end, they would cover a total distance<br />

of 0 kilometres! Collaboration with the<br />

construction company handling the contract,<br />

Grund-Pfahl und Sonderbau GmbH,<br />

has gone extremely well. The speedy<br />

progress of the construction work and the<br />

absence of any hold-ups (not a single pile<br />

has fractured!) has been the result of good<br />

logistics and of course of efficiency in the<br />

driving operation.

are produced in two sizes (118 and 170<br />

mm) and in different wall thicknesses to<br />

suit the load transmission that is required.<br />

The loads transmitted are between 50<br />

and 140 tons. By plugging the separate<br />

pipe making up the pile into one another,<br />

piles of any desired overall length can<br />

be obtained. The piles can take the form<br />

either of ungrouted end-bearing piles or<br />

of grouted piles which transmit loads by<br />

skin friction. When a grouted pile is used,<br />

liquid concrete (grout) is pumped into the<br />

pile, the interior of which is hollow, at high<br />

pressure during the driving operation and<br />

escapes though an opening at the bottom.<br />

The grout wraps itself round the outside<br />

of the pile as the pile is being rammed<br />

and forms an outer sheath of grout several<br />

decimetres thick. In this way it increases<br />

the surface area of the pile, thus generating<br />

increased friction, and the grout hooks<br />

its claws into the soil. An ordinary grout<br />

pump is used for this pressure grouting.<br />

Ungrouted end-bearing piles are filled<br />

with concrete after they have been driven.<br />

A pressure-distributing plate is mounted<br />

on top of the fully driven pile and this gets<br />

it ready to transmit loads<br />

Near the Andalusian town of Lebrija on<br />

the fruitful plain of the Guadalquivir, one of<br />

Spain‘s biggest solar energy parks, which<br />

will occupy an area of 0,000 square metres<br />

and will produce an output of 6,500<br />

MWh, is being built.<br />

What was selected as the system used for<br />

implementation was the „Mover“ system<br />

developed by Solon Hilber Technologie<br />

GmbH. These are finished modular units<br />

for generating solar electricity which track<br />

the sun as it moves. Because of this tracking<br />

movement by the modules, it is possible<br />

to obtain up to 40 % more electricity<br />

than is the case with modules mounted<br />

in a fixed position. The Mover stands on<br />

a small pedestal and because of this the<br />

P i l e s e n s u r e r e l i a b l e s o l a r e n e r g y<br />

The Lebrija solar energy park – TRM piles safeguard the foundation soil<br />

ground below it can continue to be used<br />

for other purposes, e.g. for raising cattle.<br />

Also, because the large modular panels<br />

move, there is no fear either of the<br />

soil being eroded below the edges from<br />

which rain drips off or of its drying out below<br />

the movers. The structural design and<br />

the control system of the Movers are such<br />

that the panels will pivot to a position in<br />

which their aerodynamics are good if the<br />

wind speed rises to more than about 80<br />

km/h and they will survive winds speeds<br />

of up to 150 km/h without suffering any<br />

damage. To stop any irregular settlement<br />

of the solar panels and hence to prevent<br />

any adverse effects on the pivoting mechanism,<br />

the pedestals were designed to be<br />

carried on pressure grouted TRM piles as<br />

their foundations. Skin friction distributed<br />

over the optimised length of the piles allows<br />

the loads which occur to be transmitted<br />

without any problems into the soft<br />

soil present, as a result of which the use<br />

of these piles forms the least expensive<br />

way of obtaining a foundation. By the use<br />

of lightweight equipment, any adverse effects<br />

on the environment have been minimised<br />

because of the small areas for access<br />

and for doing the work which have<br />

needed to be surfaced. Hence, to allow<br />

an environment-friendly energy generating<br />

system to be produced, what has also<br />

been done is to install the deep foundation<br />

which is kindest to the environment.<br />

TRM – Cast iron pipe technology<br />

11

Places and people<br />

1<br />

C u l t u r a l s p l e n d o u r s a n d a g r e a t q u a l i t y o f l i f e<br />

„In Vienna everything was wonderful. Lots<br />

of money and luxury galore.“ Despite what<br />

he called the „Empress‘s sanctimoniousness“,<br />

Giacomo Casanova certainly found<br />

exactly what he liked in Vienna. Yet this<br />

gossipy summing-up of the town that he<br />

gives in his „Memoirs“ is still no more than a<br />

snapshot from the 18th century. There other<br />

conditions too that Vienna experienced.<br />

He was not wrong though. As capital of the<br />

Holy Roman Empire, and particularly under<br />

the regency of the Habsburg emperor,<br />

Vienna became one of the most important<br />

cities in the world, and had an enormous<br />

economic, political and especially cultural<br />

influence. Above all in architecture and music,<br />

for a long time it was Vienna that set the<br />

style – one has only to think of names like<br />

Haydn, Mozart, Johann Strauss the elder<br />

and younger right through to Schönberg.<br />

Innumerable concerts show that even today<br />

Vienna is still one of the world‘s capitals<br />

of music. As well as the music of the Vienna<br />

classical period, the architectural and artistic<br />

works of the Vienna Secession of the<br />

years around 1900 are some of the enduring<br />

witnesses of the city‘s more recent history.<br />

With its .1 million inhabitants, Vienna<br />

was the fourth largest city in the world at<br />

that time. Today the number is about 1.6<br />

million. For the ten million or so tourists<br />

that the city welcomed in 007, it was impossible<br />

to appreciate more than a fraction<br />

of all these cultural achievements. Among<br />

the most popular sights are the Stephans-<br />

The cultural attractions of Vienna are overwhelming<br />

dom (St. Stephen‘s Cathedral), the Schönbrunn<br />

Palace and Zoo, the Kunsthistorisches<br />

Museum, the Hofburg and of course the<br />

Great Wheel on the Prater. The city centre,<br />

with its magnificent buildings along the<br />

Ringstrasse, is designated part of the world<br />

cultural heritage.<br />

What Vienna has a reputation for above<br />

all is a high quality of life. There are many<br />

easy-going coffee houses where one can sit<br />

for hours with one‘s coffee with milk and<br />

read the paper without being bothered by<br />

the waiters. The Heurigen too – the bestknown<br />

of these little wine-drinking locales<br />

can be found in Grinzing − bear witness<br />

to a more relaxed way of life. The Vien-<br />

nese are also said to have an intimate acquaintanceship<br />

with the transitory nature<br />

of things. The author Milo Dor explained<br />

it like this: „People just don‘t take themselves<br />

too seriously here. Of course there<br />

are people who try to play an important<br />

role but everyone knows that it is just playacting.“<br />

In no sense is Vienna just living off its past<br />

splendours. The city is prospering both culturally<br />

and economically. Vienna is the fifth<br />

most wealthy region in the EU. Companies<br />

see Vienna as a springboard to the East.<br />

Particularly in anticipation of the eastward<br />

expansion of the EU, many major foreign<br />

companies made Vienna the hub of their<br />

activities in the countries of central and<br />

eastern Europe or founded a new centre<br />

there to embark on their expansion into<br />

these markets. There are many prestigious<br />

international organisations that have their<br />

headquarters in Vienna. With 147 international<br />

conferences and congresses in 006,<br />

Vienna was the world‘s favourite city for<br />

events of this kind ahead of Paris and Singapore.<br />

One well known conference is for example<br />

the IWA World Water Conference,<br />

which is being held there from the 8th to<br />

the 1 th of September 008. It will be the<br />

big questions of climate change, population<br />

growth and the supply of water that will<br />

be considered there. Tiroler Röhren- und<br />

Metallwerke too will be present and showing<br />

its commitment there (see the article<br />

on page 1 ).

T h e i n t e r n a t i o n a l w a t e r i n d u s t r y i s m e e t i n g i n V i e n n a<br />

World Water Congress and Exhibition, 7th to 12th of September 2008<br />

The international water industry is making<br />

a date with itself for September in Vienna.<br />

The reason is the IWA World Water<br />

Congress and its accompanying Exhibition.<br />

The 008 World Water Congress in Vienna<br />

continues a series of events that<br />

have taken place in Paris ( 000), Berlin<br />

( 001), Melbourne ( 00 ), Marrakech<br />

( 004) und Beijing ( 006) and the series<br />

will continue in Montreal in 010 and in<br />

Busan in 01 .<br />

What decided the choice of Vienna as<br />

the venue for the IWA World Water<br />

Congress in 008 was the wish to give<br />

a prominent place on the programme to<br />

the „Danube Region“, to possible new<br />

countries joining the EU and, basically, to<br />

„Eastern Europe“. The first indication of<br />

this intention was the decision to put the<br />

local organisation of the Congress into<br />

the hands of the „International Association<br />

of Water Supply Companies in the<br />

Danube River Catchment Area“ (IAWD).<br />

This body, together with IWA Conference<br />

President Walter Kling, representing<br />

the Vienna Waterworks, and the IWA<br />

National Committee, will make sure that<br />

there is an appropriate regional flavour to<br />

the event in Vienna. The detailed organisation<br />

of the programme is the responsibility<br />

of the IWA Programme Committee,<br />

on which there are prominent representatives<br />

of the international world of water<br />

professionals.<br />

At the Exhibition, there will be around<br />

00 stands and the ideal conditions offered<br />

by the Austria Center Vienna will<br />

allow attendees to fit these smoothly into<br />

the Congress itself. Special exhibition areas<br />

will be reserved for the most important<br />

sponsors, who are taking part in the<br />

event under a separate partnership.<br />

Tiroler Röhren- und Metallwerke is one<br />

of the so-called Gold Sponsors of the<br />

event and will be showing on an appropriate<br />

stand in the exhibition area.<br />

The organisers are expecting more than<br />

,000 interested professionals from the<br />

water industry who, over the course of<br />

the five-day event, will want to exchange<br />

ideas and accounts of their experiences.<br />

The Congress will offer a wide selection<br />

of technical meetings, opportunities for<br />

networking with business partners and<br />

exciting ancillary events.<br />

These will include for example a gala reception<br />

at the Vienna Town Hall, where<br />

the men and women attending the IWA<br />

World Water Congress will be able to enjoy<br />

an entertaining evening of music and<br />

dancing ranging from the waltz to dancing<br />

to midnight clubbing music.<br />

Jointly with the conference organiser (the<br />

IWA), the Council of European Munici-<br />

Congress President Dr. Walter Kling<br />

palities and Regions will be organising a<br />

„Local Government Day“ as part of the<br />

World Water Congress. The fact that this<br />

is being held at the same time and place<br />

is no accident, because one of the main<br />

concerns for mayors in the European<br />

part of the world is to deal with issues relating<br />

to the subjects of water supply and<br />

sewage disposal. At discussions and medleyed<br />

events there will be an opportunity<br />

to discover subjects and exchange information.<br />

A particular highlight here will<br />

be the talk that will be given to open the<br />

„Local Government Day“ by mayor Dr.<br />

Michael Häupl in his capacity as President<br />

of the CEMR (Council of European Municipalities<br />

and Regions).<br />

On another evening there will be a private<br />

concert by the Vienna Symphony<br />

Orchestra in the celebrated Musikvereinssaal<br />

exclusively for guests of the IWA.<br />

Also waiting for the men and women attending<br />

the conference will be a choice<br />

range of lunches and evening meals and<br />

of sightseeing tours and tour of places<br />

of professional interest. Added to this of<br />

course there will be the important technical<br />

meetings at which the latest trends<br />

and developments in the worldwide water<br />

industry will be presented, ranging<br />

from the design and operation of water<br />

systems or the planning and provision<br />

of water services through to measures<br />

to combat the effects of climate change.<br />

The latest and most innovative technologies<br />

from all over the world and from the<br />

Danube region will be shown at the exhibition.<br />

Places and people<br />

1

Places and people<br />

14<br />

DUCTILE IRON<br />

„ O u r a i m s a r e t h e s a m e “<br />

HamBaker – a sales and marketing partner who can be relied<br />

on in Britain<br />

HamBaker Pipelines is the Cast Iron Pipe<br />

Group‘s sales and marketing partner in<br />

Great Britain. A part of the HamBaker<br />

group, the company was the outcome<br />

of a merger between the Zyron company,<br />

Buderus‘s former sales and marketing<br />

partner in Britain, and the Olympic Pipeline<br />

Products and Roban Ductile Welding<br />

companies.<br />

As Buderus‘s sales and marketing partner<br />

and a producer of flanged pipe, Ham<br />

Baker has the expertise and competencies<br />

needed to supply customers with a<br />

comprehensive range of ductile pipe and<br />

accessories. Market conditions in Britain<br />

have not been easy, but despite this Ham<br />

Baker, under the leadership of managing<br />

director Stew Bailie backed by his committed<br />

team, has managed to double the<br />

sales of Buderus pipe since the merger<br />

in 005. Where the company is making a<br />

particular effort is in the marketing of pipe<br />

with BLS ® restrained joints.<br />

Together with Buderus Giesserei Wetzlar<br />

GmbH, HamBaker founded Buderus Pipe<br />

Systems FZCO in Dubai in 007 and thus<br />

strengthened the already well-established<br />

contacts that existed in the Middle East.<br />

Ed Howard, Ham Baker‘s Group Manag-<br />

ing Director, has this to say: „Our company<br />

is pleased to have an unusually good<br />

business relationship with Buderus and to<br />

have had this for quite some years now.<br />

Our aims are the same as far as the quality<br />

of our products is concerned and – something<br />

that we consider particularly important<br />

– service to our customers is our<br />

number one concern, because we are only<br />

satisfied when our customers are too.<br />

The object of our common strategies is,<br />

by our commitment and with the help of<br />

the Buderus team, for us to continue the<br />

increase in sales in Great Britain“.<br />

As well as the company headquarters near<br />

Manchester United‘s „Theatre of Dreams“<br />

in Manchester, HamBaker Pipelines also<br />

has a production site for flanged pipes at<br />

Stoke-on Trent in the „Potteries“ – an area<br />

of England which is world famous for<br />

the production of china and porcelain.<br />

Well known brand names such as Royal<br />

Doulton, Spode, Wedgwood and Minton<br />

had their home there. Although nowadays<br />

there are also a number of modern factories<br />

to be found in Stoke, the distinctive<br />

feature of the townscape is still the old<br />

„bottle kilns“.<br />

L. to r.: Louisa Haritonow, Lee Bennett, Matt Phillips, Sal Hussain, Steve Balf, Stewart Bailie, Ed Howard,<br />

Daniel Carnera and Lee Vickers

Blue impressions in the Erzgebirge mountains<br />

DN 600 Buderus pipe with BLS ® joints<br />

maintain the water supply in the Zwickau region<br />

In the region south of Zwickau, the<br />

sure, the interim pipeline had to be<br />

water supply company Zweckver-<br />

designed for an operating pressure<br />

band Fernwasser Südsachsen of<br />

(PFA) of 5 bars. Before being put<br />

South Saxony has a DN 1 00 long-<br />

into service, the interim pipeline<br />

distance water pipeline of steel<br />

was pressure tested at a test pres-<br />

which was laid some years before<br />

sure of 0 bars. This generated a<br />

re-unification. The pipeline, which<br />

thrust of approximately 95 tonnes<br />

is showing its age, was causing seri-<br />

at the end of the pipeline and a reous<br />

problems because the bitumen<br />

sultant force of approximately 7<br />

coating on the inside had gradual-<br />

tonnes at a 45° bend. Because the<br />

ly become detached from the wall<br />

renovation is being carried out in<br />

of the pipe and pieces of detached<br />

three sub-sections, the pipes used<br />

material were being carried along in the water. To stop frag- have to be capable of standing the strain of being connected<br />

ments of bitumen from finding their way to the end users via the three times and then disconnected again three times. These are<br />

distribution network, the company had to find a solution which demanding requirements, and it was possible to convince the<br />

would meet public health requirements. It had no choice but customer that the only ideal way of meeting them was by using<br />

to shut the steel pipeline down, a section at a time, and com- DN 600 Buderus pipe of ductile cast iron connected by BLS<br />

pletely renovate it from the inside. However, there were some<br />

00,000 people in the area affected by the renovation whose<br />

supply of drinking water had to be maintained, so it was essential<br />

for a safe and reliable interim pipeline to be laid on the surface<br />

of the ground.<br />

The first section that had to be renovated is 6,000 metres long.<br />

It runs from the point where the pipeline crosses the Zwickauer<br />

Mulde river in the Grünau district to low point 8 in the Hartenstein<br />

district. The renovation is being carried out in three subsections<br />

each approximately ,000 metres long. Because of the<br />

differences in height (1 0 metres) and the existing supply pres-<br />

®<br />

joints with restrained socket joints. The laying of a pipeline of<br />

this kind using ductile cast iron pipe was unknown territory for<br />

the construction company doing the work, Umwelttechnik und<br />

Wasserbau GmbH of Jena. BGW‘s Applications Engineering Division<br />

therefore did everything it could to help and provided the<br />

company with effective assistance. This made a crucial contribution<br />

and as a result the pipeline, which winds through the Erzgebirge,<br />

south of Zwickau, like a gigantic blue snake, has been in<br />

trouble-free operation since the beginning of April. Once again,<br />

ductile cast iron pipe using BLS ® Wolfgang Rink, head of BGW‘s Applications Engineering Division, appraises<br />

the first section of the interim pipeline in the Hartenstein district.<br />

joints have demonstrated their<br />

wide versatility when used for special applications.<br />

News<br />

15

News<br />

16<br />

SMAGuA 2008 in Zaragoza –<br />

the technological shop-window for the<br />

water industry<br />

The 18th Smagua (International Water Exhibition) took place in<br />

Zaragoza in Spain from the 11th to the 14th of March 008<br />

When it closed its doors, the biggest trade fair in the field of<br />

water technology on the Iberian peninsula could boast the best<br />

figures in its history: 1,7 5 exhibitors and more than 5,000<br />

trade visitors. These numbers underline the importance that<br />

SMAGUA has in the European part of the world. At the same<br />

time as the exhibition, preparations were also underway in<br />

Zaragoza for EXPO 008, and it was under the general theme<br />

of „Water and Sustainable Development“ that this exhibition<br />

was opened to the public on the 14th of June.<br />

In association with Construtec, Buderus Giesserei Wetzlar<br />

GmbH exhibited a range of pipes specifically designed for<br />

trenchless laying. Applications to snowmaking facilities were<br />

also shown.<br />

The large number of trade visitors who took an interest in<br />

Buderus‘s BLS ® system and in the CMC pipe was a clear sign of<br />

how special solutions are moving increasingly to the forefront<br />

of people‘s attention. Construtec successfully completed the<br />

snowmaking projects at Formigal and La Covatilla last year, so it<br />

was no surprise that there should be a considerable increase in<br />

the interest shown by skiing resorts in the Buderus solutions.<br />

Generally speaking, the entire Spanish market is of interest at<br />

the moment because the demand for more efficient up-to-date<br />

water technology of the very best quality holds out the promise<br />

of good opportunities for doing business over the next few<br />

years and beyond. Long spells when there is little rain and increasing<br />

water consumption triggered by an economy that is<br />

growing well, combined with an unprecedented boom in building<br />

in Spain, mean that large amounts of money are having to be<br />

invested in water supply and sewage disposal.<br />

Together with its Spanish partner Construtec, the Cast Iron Pipe<br />

Group has long seen these signs of the times and, logically, has<br />

established a good position for itself by showing at SMAGUA.<br />

WETEX 2008<br />

In the near future, the Gulf region is going to be faced with the<br />

problem of increasing shortages of raw material resources and<br />

will thus be compelled to adopt fresh approaches if it is to maintain<br />

economic power and prosperity in its countries. Alternative<br />

energy sources, environmental protection and the subject of<br />

water will be of growing importance.<br />

This being so, the WETEX exhibition, which was held for the<br />

tenth time in succession at the Dubai International Convention<br />

and Exhibition Centre from the 17th to the 19th of March, is an<br />

important procurement platform for national and international<br />

companies giving them, as it does, wide-ranging access to the<br />

latest technologies and management solutions. The exhibition<br />

provides representatives of the industry with an opportunity to<br />

bring themselves right up to date on the subject of water, energy<br />

and the environment in the Gulf region and, together with<br />

their strategic partners, to set innovative solutions off on the<br />

road to success. As it was last year, Buderus Pipe Systems was<br />

among the exhibitors and concentrated on showing the CMC<br />

pipe and the successful BLS ® joint.<br />

H. H. Sheikh Hamdan bin Rashid Al Maktoum opens WETEX, the 10th Water<br />

Technologies, Energy and Environment Exhibition.

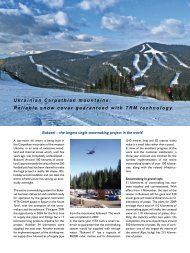

Winter as an economic factor: SAM<br />

ALPEXPO in Grenoble and ALPITEC in<br />

Bozen<br />

This year, the SAM, the International Exhibition of Mountain Regions<br />

Planning and Development, was open to visitors for the<br />

eighteenth time from the rd to the 5th of April in Grenoble.<br />

BGW and TRM had decided that they would show at the SAM<br />

for the first time. As they found when the exhibition closed its<br />

doors, this was a wise decision. The exhibition confirmed its<br />

position as an essential meeting point for professionals from all<br />

over the world in the field of skiing resorts. This was clear from<br />

the sharp rise in the number of visitors and foreign delegations<br />

(15%), who came chiefly from Spain, Portugal, Italy, Switzerland<br />

and the countries of Central and Eastern Europe, but also from<br />

South America, Australia, China and Russia.<br />

Among the factors contributing to the success of the exhibition<br />

were the facts that the winter season from 007 to 008 had<br />

been a very successful one and that „manufactured snow“ was<br />

the very area where a strong demand could be expected for<br />

facilities for making it. What counts in snowmaking is, above all,<br />

the quality of the manufactured snow. Nowadays, there is hardly<br />

a single skiing area one can think of that does not have snowmaking<br />

facilities. The BGW/TRM stand was the biggest in the field of<br />

„snow-pipes“ and it triggered feedback to match. Many planners<br />

and operators of skiing resorts were able to satisfy themselves as<br />

to the quality of the well presented product range and new and<br />

important contacts were made. In a word: ductile pressure pipe<br />

and their secure traction-resistant joints hit the spot.<br />

The position was much the same when the „winter professionals“<br />

got together in Bozen in the South Tyrol. Not long before<br />

– from the 9th to the 11th of April – ALPITEC 008 had taken<br />

place there. 1 4 exhibitors from 15 nations took the opportunity<br />

to show their products and services to the almost 10,000<br />

trade visitors on stands which were all very lavish. In the field of<br />

snowmaking facilities TRM, showing its well-tried range of cast<br />

iron pipe, had a strong presence as the only pipe manufacturer.<br />

The response from visitors was very positive and showed that<br />

ductile cast iron pipe have established an excellent position for<br />

themselves in the skiing resort sector.<br />

The TRM team at the Alpitec in Bozen.<br />

L. to r.: Stefan Sterr, Claudia Mair, Sieghart Berktold and Julia Berkmann<br />

WOD-KAN 2008<br />

WOD-KAN, the International Fair of Machines and Facilities for<br />

Water Supply and Sewage Systems, took place from the 7th to<br />

the 9th of May 008 in Bydgoszcz in Poland. BGW‘s sales and<br />

marketing partner Tyco Waterworks Polska Sp. z o.o. presented<br />

exhibits providing an overview of all the types of coating and<br />

socket that can be supplied. This year, it was the open-air site<br />

that had been selected for the company‘s attractive exhibition<br />

stand. The stand, measuring about 50 square metres in size, was<br />

constructed in the style of an Upper Silesian coalmine. Manfred<br />

Hoffmann, head of export sales at BGW, was very happy with<br />

the show put on at WOD-KAN: „It was not just WOD-KAN,<br />

which is the most important fair of its kind in the central and eastern<br />

European part of the world, which chalked up a rise in the<br />

numbers of exhibitors and visitors; we too noted an increase in<br />

interest among visitors belonging to the industry“.<br />

It was time once again on the 0th of May. That was when VO-<br />

DOVODY-KANALIZACE, the International Water Management<br />

Exhibition, opened its doors in Brno in the Czech Republic, and<br />

on the following two days more than 8500 trade visitors flooded<br />

into the exhibition centre. The majority of foreign exhibitors<br />

were from western industrialised countries, whereas the bulk<br />

of the foreign trade visitors came from post-Soviet and near<br />

eastern countries, from the Balkans and from North Africa, or<br />

in other words from the countries that are still waiting for the<br />

crucial investments to be made in water management, in the<br />

infrastructure for water and sewage management and in environmental<br />

protection. On an area of about 60 square metres,<br />

BGC presented „a mini-IFAT“. The same exhibits as had already<br />

stirred up lively interest in Munich did the same in Brno. They<br />

were supplemented by the commercial range of fittings. Ivana<br />

Drozdová, chief executive officer of BGC, was very positive in<br />

the view she expressed of the company‘s showing: „Once again,<br />

it has been seen that Brno is a centre for exhibitions where new<br />

trading partnerships are born. We were able to make contacts<br />

that promise to be successful and we were widely praised for our<br />

first class presentation which, as we did at IFAT, we gave under<br />

the slogan „The future is ductile“.<br />

News<br />

17

News<br />

18<br />

BLS ® and PuR TOP – the tailor-made solution to problems<br />

Culverting of a canal between the Neuwieser and Partwitzer Lakes in the Lausitz<br />

Between Berlin and Dresden, in the Lausitz, there is a landscape<br />

that was produced by open cast mining and this is being changed<br />

into a lake landscape that will extend into more than one of the<br />

federal states. This will offer a long-term potential for creating a<br />

special and attractive environment in which there will be a new<br />

and close togetherness between home life, leisure and work. The<br />

lakes, which are on three different levels, are being connected together<br />

into a „lake chain“ by navigable canals.<br />

As part of this work, the Neuwieser Lake (the lake left by the Bluno<br />

mine) and the Partwitzer Lake (the lake left by the Skado mine)<br />

are to be connected by a navigable canal in which there will be<br />

a lock. In 00 , in line with the development aim for the Lausitz<br />

lake chain, namely the conversion into a water-oriented tourist<br />

region of more than purely regional significance, a connecting waterway<br />

had already been created between what were termed<br />

the „holes“ left by the Koschen and Skado mines. In 004, this<br />

was followed by the building of a canal between the holes left by<br />

the Koschen, Sedlitz and Skado mines. For the planned construction<br />

of a canal between Bluno and Skado, the company responsible<br />

for all the rehabilitation work, Lausitzer und Mitteldeutsche<br />

Bergbau- und Verwaltungsgesellschaft mbH (LMBV), had to relay<br />

a main drinking water supply pipe of DN 500 diameter belonging<br />

to the Zweckverband Kamenz water supply company. So that<br />

the pipe would be situated two metres below the canal, it had to<br />

be laid at a depth of 15 metres. The floor of the culvert runs in a<br />

protective tube of polymer concrete, which was connected below<br />

water by divers working in a sheet-piling box. The DN 500<br />

water-carrying pipe, running for a length of 180 metres, are fitted<br />

with the well tried BLS ® restrained joints. Where the pipe had to<br />

be laid in an area below the water table, a PUR TOP coating was<br />

selected for them to allow for the very high pH of the ground<br />

water. At the depth of 15 metres and given that the soil would<br />

be loosened when the sheet piling boxes were withdrawn, stress<br />

analysis indicated that a wall thickness well above standard – K14<br />

in fact – would have to be used in the bottom region of the ascending<br />

sides of the culvert. The fittings and the areas occupied<br />

by the sockets were enclosed in addition in shrink-on material.<br />

The PUR TOP coating, a development<br />

of Tiroler Röhren- und<br />

Metallwerke AG, means a polyurethane<br />

coating of increased<br />

thickness (4 0 µ), which is also<br />

wrapped in an impact-resistant<br />

tape. PUR TOP pipe are used<br />

mainly in corrosive soils.<br />

This was another special case<br />

where the technical problems<br />

could be quickly, safely and reliably<br />

solved by the use of the<br />

BLS ® restrained joint and PUR<br />

TOP pipe of a special wall thickness<br />

of K14. The company laying<br />

the pipe was very happy with the smooth way in which the BLS ®<br />

joints could be assembled even under the difficult conditions created<br />

by the ascending sides of the culvert and the trenches leading<br />

to the protective tubes. In the sections clear of the ground<br />

water, normal epoxy-blue cast iron pipe and fittings of the new<br />

generation equipped with BLS ® joints were laid.<br />

The land can now rest by its lake shores<br />

A new water-filled paradise in the Lausitz<br />

A landscape is being given a face-lift. Where lignite had previously<br />

been mined for some 160 years, a landscape of water<br />

is now coming into being and this will change the character of<br />

the Lausitz. In the region between Senftenberg, Spremberg and<br />

Hoyerswerda, more than 2,000 million tons of lignite had been<br />

open-cast mined from depths of up to 60 metres since the middle<br />

of the 19th century. LMBV‘s last working open-cast mine in<br />

the region, the Mero mine at Großäschern, became exhausted<br />

in 1999. What were left were gigantic „holes“ which have been<br />

filled with water to become lakes. The main object of transforming<br />

the landscape in this way is to develop an unusual new landscape<br />

whose character is formed by its bodies of water. At the<br />

heart of the Lausitz lakeland will be a world of water comprising<br />

ten lakes with a total surface area of 7,000 hectares connected<br />

by navigable canals and locks.

The important thing was always water<br />

An excursion during the sales force conference in April 2008 at Blankenburg am Harz<br />

A report by ursula Mandler<br />

The conference opened with Friedhelm Kleinblotekamp, head<br />

of sales for Germany, introducing the new member of our field<br />

sales force in the German Sales Department, Heinz-Jörg Weimer.<br />

Ulrich Päßler, sales director, then provided an overview of<br />

how the company‘s sales and turnover had been developing. A<br />

point he stressed as particularly important was the way the price<br />

of scrap had been shooting up, a development which, he said,<br />

was making it necessary for the price of products to be adjusted<br />

to match. This means that there are special demands on the field<br />

sales force to explain why this has to be done and to make sure<br />

that it can be done successfully.<br />

To provide a little variety, there was a break in the process of<br />

working though the many points on the agenda in the form of<br />

an excursion to the Wienrode waterworks and the Wendefurth<br />

dam. Our colleague Uwe Hoffmann, whose area covers the<br />

Harz/Saxony-Anhalt region, was the man responsible for organising<br />

this.<br />

We first went to the Wienrode waterworks, which is situated<br />

below the Rappbode dam and which is able to supply 180,000<br />

cubic metres of drinking water a day. At the waterworks, we<br />

were welcomed by Dipl.-Ing. Klaus-Peter Faber, head of pipe and<br />

facilities maintenance for the Eastern Harz Supply Area. During<br />

the guided tour, he explained the operations that have to be<br />

performed if good drinking water is to be obtained.<br />

The waterworks are supplied with water from the Rappbode<br />

dam. Intake of the water is through two intake towers and the<br />

depth of intake can be varied to six different levels. The water<br />

reaches the Wienrode waterworks though a . kilometre long<br />

tunnel. In the waterworks themselves, the soft water of the Harz<br />

region is processed into drinking water by a process which is a<br />

close copy of what happens in nature. The soft water from the<br />

dam is cleaned and freed of algae and microscopic lifeforms by<br />

48 open fast filter beds covering an area of , 00 square metres.<br />

Carbon dioxide and limewater are used to harden the water<br />

and stabilise its pH. The addition of small doses of chlorine and<br />

chlorine dioxide ensures that the quality of the water remains<br />

unchanged as it travels through the pipe system to the customer.<br />

Via the Eastern Harz pipeline, the waterworks, which belong<br />

to the Verband Fernwasserversorgung Elbaue-Ostharz supply<br />

company, supply large areas of Saxony-Anhalt out as far as the<br />

Halle region. The company supplies a total of some two million<br />

people through a pipe network totalling around 750 kilometres<br />

in length, which is fed by seven waterworks.<br />