Acrylic Resins - The Freedonia Group

Acrylic Resins - The Freedonia Group

Acrylic Resins - The Freedonia Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

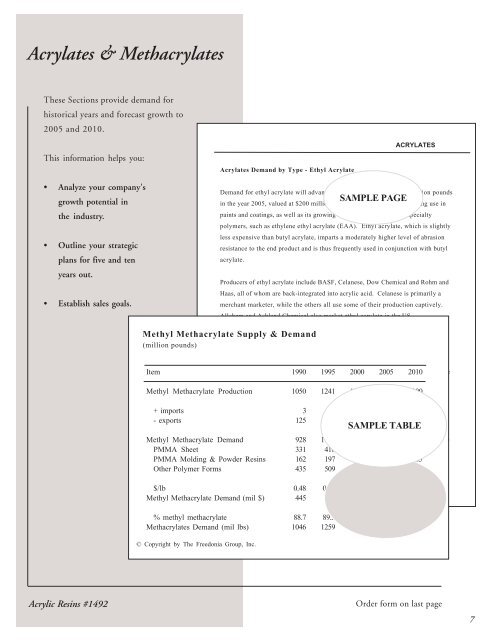

Acrylates & Methacrylates<br />

<strong>The</strong>se Sections provide demand for<br />

historical years and forecast growth to<br />

2005 and 2010.<br />

This information helps you:<br />

• Analyze your company's<br />

growth potential in<br />

the industry.<br />

• Outline your strategic<br />

plans for five and ten<br />

years out.<br />

• Establish sales goals.<br />

Acrylates Demand by Type - Ethyl Acrylate<br />

ACRYLATES<br />

Demand for ethyl acrylate will advance 3.8 percent per year to 315 million pounds<br />

SAMPLE PAGE<br />

in the year 2005, valued at $200 million. Gains will result from increasing use in<br />

paints and coatings, as well as its growing use as an intermediate in specialty<br />

polymers, such as ethylene ethyl acrylate (EAA). Ethyl acrylate, which is slightly<br />

less expensive than butyl acrylate, imparts a moderately higher level of abrasion<br />

resistance to the end product and is thus frequently used in conjunction with butyl<br />

acrylate.<br />

Producers of ethyl acrylate include BASF, Celanese, Dow Chemical and Rohm and<br />

Haas, all of whom are back-integrated into acrylic acid. Celanese is primarily a<br />

merchant marketer, while the others all use some of their production captively.<br />

Allchem and Ashland Chemical also market ethyl acrylate in the US.<br />

Methyl Methacrylate Supply & Demand<br />

Ethylhexyl Acrylate<br />

(million pounds)<br />

Demand for ethylhexyl acrylate will increase 3.2 percent annually to 145 million<br />

pounds in the year 2005, valued at $100 million. Gains will result primarily from<br />

Item the increased production of 1990 paints and 1995 coatings. 2000 In particular, 2005 ethylhexyl 2010 acrylate<br />

is used in automotive clearcoats. In addition to being the acrylic base resin in<br />

Methyl Methacrylate Production automotive clearcoats, ethylhexyl 1050 acrylate 1241 also 1510 helps to 1780 protect the 2100 finish from<br />

+ imports<br />

damage and fading caused by ultraviolet (UV) rays.<br />

3 38 45 55 60<br />

- exports 125 155 90 80 60<br />

Ethylhexyl acrylate is somewhat more specialized SAMPLE than either TABLE butyl or ethyl<br />

Methyl Methacrylate Demand acrylate. <strong>The</strong> relatively low 928 level of 1124 production 1465 eliminates 1755 economies 2100 of scale, so<br />

PMMA Sheet that selling prices for ethylhexyl 331 acrylate 418 are higher 573 than 675 other commodity 800<br />

PMMA Molding & Powder acrylates. <strong>Resins</strong><br />

Other Polymer Forms<br />

162<br />

435<br />

197<br />

509<br />

255<br />

637<br />

305<br />

775<br />

365<br />

935<br />

$/lb<br />

Manufacturers of ethylhexyl acrylate include BASF, Celanese and Dow Chemical.<br />

0.48 0.68 0.65 0.72 0.77<br />

Methyl Methacrylate Demand (mil $) 445 764 952 1265 1620<br />

% methyl methacrylate 88.7 89.3 90.1 90.2 90.1<br />

Methacrylates Demand (mil lbs) 1046 1259 1626 1945 2330<br />

© Copyright by <strong>The</strong> <strong>Freedonia</strong> <strong>Group</strong>, Inc.<br />

<strong>Acrylic</strong> <strong>Resins</strong> #1492 Order form on last page<br />

7