A Framework of Medical Equipment Management System for In ...

A Framework of Medical Equipment Management System for In ...

A Framework of Medical Equipment Management System for In ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

32nd Annual <strong>In</strong>ternational Conference <strong>of</strong> the IEEE EMBS<br />

Buenos Aires, Argentina, August 31 - September 4, 2010<br />

Abstract—<strong>Medical</strong> equipment management is an important<br />

issue <strong>for</strong> safety and cost in modern hospital operation. <strong>In</strong><br />

addition, the use <strong>of</strong> an efficient in<strong>for</strong>mation system effectively<br />

promotes the managing per<strong>for</strong>mance. <strong>In</strong> this study, we<br />

designed a framework <strong>of</strong> medical equipment management<br />

system used <strong>for</strong> in-house clinical engineering department. The<br />

system was web-based, and it integrated clinical engineering<br />

and hospital in<strong>for</strong>mation system components. Through related<br />

in<strong>for</strong>mation application, it efficiently improved the operation<br />

management <strong>of</strong> medical devices immediately and continuously.<br />

This system has run in the National Taiwan University Hospital.<br />

The results showed only few examples in the error analysis <strong>of</strong><br />

medical equipment by the maintenance sub-system. The<br />

in<strong>for</strong>mation can be used to improve work quality, to reduce the<br />

maintenance cost, and to promote the safety <strong>of</strong> medical device<br />

used in patients and clinical staffs.<br />

T<br />

A framework <strong>of</strong> medical equipment management system <strong>for</strong> in-house<br />

clinical engineering department<br />

I. INTRODUCTION<br />

ODAY's medical environment is highly dependent on<br />

various types <strong>of</strong> medical equipment to complete the<br />

diagnosis and treatment <strong>for</strong> patients with care. These medical<br />

devices must be kept in good condition to prevent from<br />

injuries occurred in patients as well as in users. Moreover, to<br />

face the tough competition environment and complex health<br />

care system, the hospital should take the appropriate cost<br />

controls in response to that situation. The clinical engineering<br />

department (CED) in the hospital is responsible <strong>for</strong> the<br />

patient and clinical staff safety in using medical devices.<br />

Besides, the cost control in related operational activities <strong>of</strong><br />

medical devices (such as purchase, contract, repair, and<br />

maintenance) is another important job <strong>for</strong> this department<br />

[1]-[3]. For these goals, CED is responsible <strong>for</strong> purchase<br />

assessment, safety installation, warranty assurance,<br />

correcting repair, contrast monitoring, preventive<br />

maintenance, and identifying discard to provide safe,<br />

effective, and economical services and equipment that are<br />

necessary <strong>for</strong> patient care research and community service.<br />

To promote the operating per<strong>for</strong>mance, it is needed with a<br />

Manuscript received April 22, 2010; revised June 22, 2010.<br />

*C. H. Chien is with the Graduate <strong>In</strong>stitute <strong>of</strong> Electrical Engineering,<br />

National Taiwan University, Taipei, Taiwan 100, ROC and also with the<br />

Department <strong>of</strong> Biomedical Engineering, National Taiwan University<br />

Hospital, Taipei, Taiwan 100, ROC (886-2-2356-2092; fax:<br />

886-2-2383-2677; e-mail: d91921022@ ntu.edu.tw).<br />

Y. Y. Huang is with the <strong>In</strong>stitute <strong>of</strong> Biomedical Engineering, National<br />

Taiwan University, Taipei, Taiwan 100, ROC (e-mail: yyhuang@<br />

ntu.edu.tw).<br />

F. C. Chong. is with the the Graduate <strong>In</strong>stitute <strong>of</strong> Electrical Engineering,<br />

National Taiwan University, Taipei, Taiwan 100, ROC (e-mail:<br />

fcchong@cc.ee.ntu.edu.tw).<br />

Chia-Hung Chien * , Yi-You Huang, and Fok-Ching Chong<br />

978-1-4244-4124-2/10/$25.00 ©2010 IEEE 6054<br />

systematic managing strategy [4]-[6].<br />

The <strong>Medical</strong> <strong>Equipment</strong> <strong>Management</strong> <strong>System</strong> (MEMS) is<br />

used <strong>for</strong> data collection and management. It incorporates the<br />

equipment inventory, a work order system, the preventive<br />

maintenance schedules/procedures, outsourcing contract<br />

management and all service history records. Besides, it is also<br />

an administrative tool to track equipment, to initiate work<br />

orders, to obtain per<strong>for</strong>mance indicators, to determine<br />

equipment failure trends, to identify training needs, and to<br />

produce management reports.<br />

This paper presents an in<strong>for</strong>mation framework to build and<br />

to enhance CED on the medical equipment management<br />

capabilities. With this method, we will show a framework <strong>of</strong><br />

MEMS from system network architecture to the relationships<br />

between each sub-system model. Few examples on<br />

operational management analysis by the MEMS (such as<br />

failure trends, specific device malfunction analysis) will be<br />

shown in results. These operating data were derived from the<br />

operating results in National Taiwan University Hospital<br />

(NTUH) in 2009. NTUH is a medical center with 2300 beds<br />

and owns more than 30,000 pieces <strong>of</strong> medical equipment. We<br />

will discuss how to use the in<strong>for</strong>mation to improve the<br />

operation quality and to control the potential risk in medical<br />

equipment.<br />

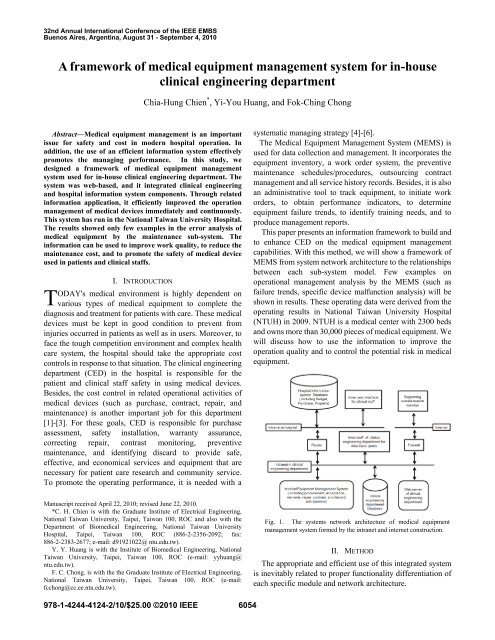

Fig. 1. The systems network architecture <strong>of</strong> medical equipment<br />

management system <strong>for</strong>med by the intranet and internet construction.<br />

II. METHOD<br />

The appropriate and efficient use <strong>of</strong> this integrated system<br />

is inevitably related to proper functionality differentiation <strong>of</strong><br />

each specific module and network architecture.

A. The system network architecture<br />

The system network architecture (Fig. 1) was designed<br />

under the consideration <strong>of</strong> data safety and work per<strong>for</strong>mance.<br />

This was divided into three parts. First, the intranet in hospital<br />

connects the overall operating computers <strong>of</strong> hospital and the<br />

hospital in<strong>for</strong>mation system (HIS). HIS sends some basic<br />

in<strong>for</strong>mation <strong>of</strong> medical equipment (such as budget, purchase,<br />

and property in<strong>for</strong>mation) to the MEMS. The inner users can<br />

also access MEMS through the intranet. Second, the MEMS<br />

was set up in the intranet <strong>of</strong> CED and connected to the<br />

intranet <strong>of</strong> the hospital through a router. The architecture will<br />

increase the work per<strong>for</strong>mance <strong>for</strong> the inner users <strong>of</strong> CED in<br />

input or query data to MEMS and system maintenance. <strong>In</strong><br />

addition to MEMS, the local network also includes a Web<br />

server <strong>of</strong> CED and a database. Third, the Web server <strong>of</strong> CED<br />

connects to the internet through a firewall and provides a<br />

service <strong>for</strong> supporting outside branch member to access the<br />

database <strong>of</strong> CED, which shares related in<strong>for</strong>mation like the<br />

procurement, maintenance, and contract related.<br />

Fig. 2. Relationship between the modules <strong>of</strong> the medical equipment<br />

management system.<br />

B. The medical equipment management system architecture<br />

The MEMS, the main elements is shown in Fig. 2, which<br />

contains ten sub-systems, i.e. the basic in<strong>for</strong>mation,<br />

procurement, acceptance, discard, maintenance, installation<br />

verification, warranty inspection, prevent maintenance, and<br />

contract management. These systems were designed<br />

according to the operational activity <strong>of</strong> CED. On the basis <strong>of</strong><br />

different operating attribution, they can be classified into four<br />

groups.<br />

The first group is the basic in<strong>for</strong>mation, which primarily<br />

provides fixed in<strong>for</strong>mation to other sub-systems such as<br />

inventory in<strong>for</strong>mation, staff data, equipment maintenance<br />

vendors, user department and their cost center code. These<br />

data comes from HIS and automatically updates. When a user<br />

operates other sub-system and inputs a key word, this related<br />

basic in<strong>for</strong>mation will be loaded to an appropriate field. The<br />

mechanic will reduce the user operating time and increase the<br />

data correctness.<br />

The second group contains the procurement, acceptance,<br />

and discard practices. These practices focus on document<br />

6055<br />

assessment. There<strong>for</strong>e, the timing record is crucial to the<br />

daily work activities <strong>of</strong> engineer in CED. Biomedical<br />

managers must be able to correctly assign staffs <strong>for</strong> the right<br />

job and to monitor the rate <strong>of</strong> progress. The administrative<br />

staff needs to record the right date and time at different<br />

conditions such as receipting, dispatching, inspecting, and<br />

closing in service case. Besides, the date and time data will be<br />

automatically reloaded by the system when a user inputs the<br />

case number. Moreover, the engineer needs to key in the<br />

assessing results to the system. The history in<strong>for</strong>mation <strong>of</strong><br />

related equipment could also be queried by these sub-systems.<br />

The maintenance function is used <strong>for</strong> amending the error data<br />

and provides managing authorization <strong>for</strong> a specific user.<br />

The third group is mainly aimed at medical equipment<br />

maintenance and the repair work <strong>of</strong> CED, which is the busiest<br />

in MEMS <strong>for</strong> daily work. <strong>In</strong> NTUH, the repair cases were<br />

around eighty thousand per year. Its users include clinical<br />

staffs <strong>of</strong> the hospital and administrators and biomedical<br />

engineers (BME) in CED. To clinical staffs, its function is<br />

like an order work system when the equipment has a<br />

breakdown. Besides, it also provides user tracing the progress<br />

and content <strong>of</strong> maintenance or repair. For administrators in<br />

CED, their major works focus on inputting the time to the<br />

system when the repair case is in the key point such as receipt,<br />

dispatch, user retrieve, and close moment. For engineers in<br />

CED, they input the repair content, delay reasons, and the<br />

finished time <strong>of</strong> ending repair. Besides, the biomedical<br />

mangers can query related statistics from the sub-system to<br />

obtain per<strong>for</strong>mance indicators, to determine equipment<br />

failure trends, to identify training needs, and to produce<br />

management reports.<br />

The final group includes warranty, maintenance, and<br />

contract management systems. The attribution <strong>of</strong> the group<br />

belongs to managing activities which have the property <strong>of</strong><br />

period plan in advance. So, the system can send a notice to an<br />

engineer according to the important time point <strong>of</strong><br />

predetermined schedule such as warranty expired, executing<br />

prevent maintenance, or carrying out the contract service.<br />

This in<strong>for</strong>mation can be triggered by BME to print a work<br />

order. Besides, the BME can also set and manage related<br />

equipment list and time schedule. The query function shows a<br />

list <strong>of</strong> requesting work orders in the certain period. All the<br />

content <strong>of</strong> per<strong>for</strong>mance in the group will be integrated with<br />

the general maintenance <strong>of</strong> data. To query by inventory<br />

number, the user can easily get related in<strong>for</strong>mation with<br />

different maintenance stratagems <strong>for</strong> certain equipment.<br />

Finally, the maintenance statistic function provides<br />

biomedical managers the in<strong>for</strong>mation about the per<strong>for</strong>mance<br />

<strong>of</strong> BME and outsourcing.<br />

C. Developing tools<br />

The developing tools are used <strong>for</strong> web page design and<br />

database building. First, the web pages <strong>of</strong> MEMS were<br />

designed by the Visual studio C# and the web server <strong>of</strong> CED<br />

by the FrontPage and Dreamweaver, because the s<strong>of</strong>tware is<br />

easy to get and easy to use. The C# was adopted by the IT

department <strong>of</strong> NTUH and used <strong>for</strong> the HIS programming,<br />

because the web page designed by C# is more efficient than<br />

FrontPage in processing the complex operating environment.<br />

About the database tools, the Micros<strong>of</strong>t SQL server was<br />

adopted <strong>for</strong> local database <strong>of</strong> CED, and Oracle Database was<br />

used <strong>for</strong> HIS. The factors <strong>of</strong> selecting different databases<br />

were considered with the using volume, cost, per<strong>for</strong>mance<br />

and efficiency. Sometimes, the Micros<strong>of</strong>t ACCESS was also<br />

used <strong>for</strong> preliminary verification <strong>for</strong> the programming test <strong>of</strong><br />

dynamic web page.<br />

It seems that Micros<strong>of</strong>t s<strong>of</strong>tware products were used <strong>for</strong><br />

deployment because they are standby <strong>for</strong> us. Developers can<br />

choose familiar tools to construct their system. <strong>In</strong><br />

consideration <strong>of</strong> the developing cost, they may use<br />

open-source solutions such as Linux.<br />

III. RESULT<br />

The user interface <strong>of</strong> MEMS is shown in Fig.3. The left<br />

side <strong>of</strong> the graph shows the working menu and the right is the<br />

executing result. It was designed by Visual studio C# and<br />

users operate the function on their computer browser.<br />

Different roles (such as clinical staffs, administrator,<br />

biomedical engineer etc.) have different authorities to open<br />

different functions.<br />

Fig. 3. The user interface <strong>of</strong> medical equipment management system<br />

Fig. 4. The statistic graphic <strong>for</strong> the failure items <strong>of</strong> medical equipment<br />

repair cases come from National Taiwan University Hospital in 2009<br />

<strong>In</strong> the maintenance data, we not only look into a general<br />

cause <strong>of</strong> the malfunction but also analyze the causes by<br />

6056<br />

specific types <strong>of</strong> equipment or user behavior. Fig. 4 shows the<br />

twelve types <strong>of</strong> error code and the statistic graph <strong>for</strong> the<br />

failure items <strong>of</strong> medical equipment repair cases. The statistic<br />

data was explored from the MEMS in NTUH around 6000<br />

pieces.<br />

Among them the number 8 (outdated parts) has the biggest<br />

amount. It means that it had a lot <strong>of</strong> repair cases due to the<br />

outdated equipment. Moreover, the specific types <strong>of</strong><br />

equipment failure analysis can be exploried from repair<br />

records.<br />

Fig. 5. The failure analysis <strong>of</strong> portable physiological monitors<br />

Fig. 5 shows the statistic graph with regard to the failure<br />

analysis <strong>of</strong> portable physiological monitors that are<br />

commonly used in nursing department. The data was<br />

collected from the repair records <strong>of</strong> this type instrument<br />

around three years with total <strong>of</strong> 2538 cases. The common<br />

failures include sensor, probe, null function, replacement cuff,<br />

power supply, battery, fittings, manufacturers, panel module,<br />

replacing bag, corrector, scrapped, and other issues. The<br />

sensor, probe, and cuff account <strong>for</strong> most <strong>of</strong> these failure items.<br />

These three parts are usually connected to patients, which are<br />

easy to damage due to pulling or tension. By contrast, the<br />

panel module and battery are two frequently encountered<br />

problems that are related to the machine.<br />

Fig. 6. The failure analysis <strong>for</strong> a specific type <strong>of</strong> patient monitor<br />

If we want to know what the error behavior <strong>for</strong> certain<br />

brand and model, we can set specific field on the query<br />

function <strong>of</strong> MEMS to get related in<strong>for</strong>mation. The<br />

in<strong>for</strong>mation can be used to prevent maintenance schedule or

purchase assessment. Fig.6 shows a failure analysis <strong>for</strong> a<br />

specific type <strong>of</strong> patient monitor. The failure item <strong>of</strong> power<br />

supply occurred more frequently than that on the portable<br />

monitor (14% vs. 7%). Whether the problem comes from the<br />

original design or is due to improper operation <strong>of</strong> users awaits<br />

further exploration.<br />

IV. DISCUSSION<br />

Our results demonstrated the ability <strong>of</strong> data analysis <strong>for</strong><br />

maintenance history records with MEMS. It just uses the<br />

partial function <strong>of</strong> the MEMS in all operating activities <strong>of</strong><br />

CDE. Fig. 4 shows an error analysis <strong>of</strong> one-year maintenance<br />

records in 2009. It revealed a major problem that the<br />

equipment was too old to be maintained and repaired in the<br />

hospital. To reduce the idle time during equipment shutdown,<br />

a stock plan is needed <strong>for</strong> some parts in general use. Once the<br />

maintenance frequency <strong>of</strong> the equipments increases or the<br />

related parts are not available, a proposal <strong>for</strong> a new budget<br />

plan is needed.<br />

Fig. 5 and Fig. 6 reveal an error analysis <strong>for</strong> specific type<br />

device. These results provide useful in<strong>for</strong>mation <strong>for</strong><br />

managing strategies to medical equipment. For example,<br />

sensors and probes were the major problems happened in the<br />

cases <strong>of</strong> malfunction devices. To prevent the problems, a<br />

safety stock <strong>of</strong> these consumables should be kept to reduce<br />

the breakdown time during repair. Besides, education <strong>for</strong><br />

users is needed to reduce the malfunction factor <strong>of</strong> human<br />

errors, such as no charging battery, plugging error site <strong>for</strong><br />

power cord, and breaking probe wire etc. Moreover, when<br />

users purchase the same type device, the in<strong>for</strong>mation can<br />

assist users to define a proper specification and brand.<br />

<strong>In</strong> many cases the CED is managed according to three<br />

approaches: totally internal, totally external and a<br />

combination between internal and external resources. <strong>In</strong> the<br />

initial design <strong>for</strong> developing the management system, it is<br />

necessary to consider the real operation mode <strong>of</strong> CED. <strong>In</strong> our<br />

system, which is designed <strong>for</strong> a combination type, the<br />

function <strong>of</strong> contract management is a sub-system <strong>for</strong><br />

managing the outsourcing service especially <strong>for</strong> high value<br />

equipment, such as CT and MRI. <strong>In</strong> the sub-system, the<br />

service response time and the maintenance quality are the two<br />

important monitoring items.<br />

<strong>In</strong> this study, the MEMS covers all activities in CED on<br />

medical equipment management. Through systematic data<br />

collection in each stage (such as purchase, contract, repair,<br />

and maintenance), it provides useful in<strong>for</strong>mation to advance<br />

the management ability in CED more effectively and<br />

efficiently. With regard to how to run data into useful<br />

in<strong>for</strong>mation, however, the data <strong>for</strong>mat and operating interface<br />

are very important. They will influence the in<strong>for</strong>mation<br />

whether is accurate and comprehensive. Data quality<br />

initiatives can help to insure the accuracy <strong>of</strong><br />

clinical/biomedical engineering data. Some important key<br />

fields in designing database may be considered. The basic<br />

6057<br />

in<strong>for</strong>mation <strong>of</strong> medical equipment should include:<br />

nomenclature, manufacturer, nameplate model, serial number,<br />

acquisition cost, condition code, and maintenance assessment.<br />

To record key date in working condition includes: accepting,<br />

assigning, ending, and retrieving case. To record related<br />

person in these operating activities includes: user, engineer,<br />

manager, department chief, contact phone number, and<br />

related cost center code. The cost data is also important <strong>for</strong><br />

modern enterprise, so the related cost value like purchase,<br />

installation, training, consumables, operating, maintenance,<br />

contract, and disposal needs to be involved. Other useful data<br />

could include: warranty, location, other contractor agencies,<br />

scheduled maintenance due dates, and intervals.<br />

V. CONCLUSION<br />

<strong>Medical</strong> equipment has become an important component <strong>of</strong><br />

modern health services. But the related management or<br />

maintenance is particularly weak in the districts. The growth<br />

in capabilities to manage or maintain medical equipment has<br />

lagged far behind the rate <strong>of</strong> deployment <strong>of</strong> equipment. <strong>In</strong><br />

addition to the traditional operation management, the patient<br />

safety, operation per<strong>for</strong>mance in cost/efficient analysis, and<br />

risk evaluation and control are the important issues <strong>for</strong> using<br />

medical equipment in hospital [7][8]. A framework <strong>of</strong><br />

medical equipment management system has been proposed in<br />

the paper <strong>for</strong> assisting in-house CE department early to<br />

confront the potential risk.<br />

REFERENCES<br />

[1] Andreas Lenel,Caroline Temple-Bird,Willi Kawohl,Manjit Kaur ,<br />

“How to Organize a <strong>System</strong> <strong>of</strong> Healthcare Technology <strong>Management</strong>”,<br />

World Health Organization,2009<br />

[2] David Y. and Jahnke E.G., “Planning Hospital <strong>Medical</strong> Technology<br />

<strong>Management</strong>”, IEEE Engineering in Medicine and Biology Magazine,,<br />

vol. 23, no. 3, pp. 73-79, May-June ,2004.<br />

[3] Y David and Thomas M. Judd, “<strong>Management</strong> and Assessment <strong>of</strong><br />

<strong>Medical</strong> Technology, Clinical Engineering (Principles and<br />

Applications in Engineering)”, CRC, New York, 2003.<br />

[4] David W. Feigal, M.D., M.P.H., “Total Product Life Cycle, Center <strong>for</strong><br />

Devices and Radiological Health”, FDA Available: www.fda.gov.<br />

[5] <strong>Medical</strong> <strong>Equipment</strong> Planning Guidance article, Health Devices, vol. 26,<br />

no. 1, pp. 4-12, 1997<br />

[6] Iyad Mobarek, Tarawneh, Al Waleed, Francois Langevin, Mohammad<br />

Ibbini, “Fully Automated Clinical Engineering Technical <strong>Management</strong><br />

<strong>System</strong>”, Journal <strong>of</strong> clinical engineering , vol. 31, no. 1 ,pp. 46-60,2006<br />

[7] Wang, B. Eliason, R.W. Richards, S.M. Hertzler, L.W. Moorey, R. ,<br />

“Financial impact <strong>of</strong> medical technology”, IEEE Engineering in<br />

Medicine and Biology Magazine, vol. 27, no. 4, pp. 80-85,<br />

JULY/AUGUST, 2008.<br />

[8] David W. Feigal, Susan N. Gardner, and Mark McClellan, “Ensuring<br />

Safe and Effective <strong>Medical</strong> Devices”, The new England journal <strong>of</strong><br />

medicine, vol. 348, no.16 ,pp. 191-192, 2003.