A N D ' til: p i m i ^ G A t i O N S m 8 & - Clpdigital.org

A N D ' til: p i m i ^ G A t i O N S m 8 & - Clpdigital.org

A N D ' til: p i m i ^ G A t i O N S m 8 & - Clpdigital.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

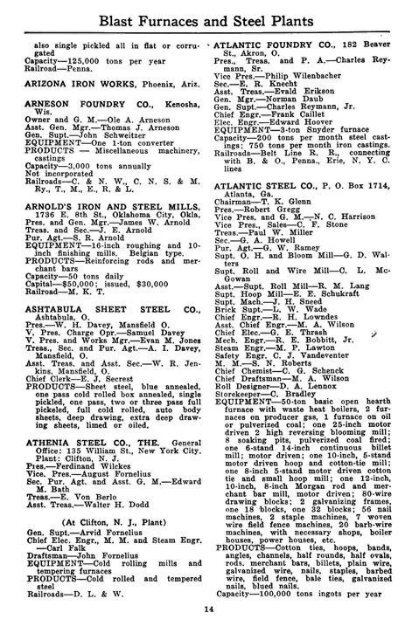

Blast Furnaces and Steel Plants<br />

also single pickled all in flat or corrugated<br />

Capacity—125,000 Ions per year<br />

Railroad—Penna.<br />

ARIZONA IRON WORKS. Phoenix, Arii.<br />

ARNESON FOUNDRY CO., Kenosha,<br />

Wis.<br />

Owner and G. M.—Ole A. Arneson<br />

Assl. Gen. Mgr.—Thomas J. Arncson<br />

Gen. Supt.—John Schweilier<br />

EQUIPMENT—One 1-ton converter<br />

PRODUCTS — Miscellaneous machinery.<br />

castings<br />

Capacity—3,000 Ions annually<br />

Not incorporated<br />

Railroads—C. ft N. W„ C. N. S. 4 M.<br />

Ry., T.. M„ E.. R. ft L.<br />

ARNOLD'S IRON AND STEEL MILLS,<br />

1736 E. 8th St., Oklahoma City. Okla.<br />

Pres. and Gen. Mgr.—James W. Arnold<br />

Treas. and See—J. E. Arnold<br />

Pur. Agt.—S. R. Arnold<br />

EQUIPMENT—16-inch roughing and 10-<br />

Inch finishing mills. Belgian type.<br />

PRODUCTS—Reinforcing rods and merchant<br />

bars<br />

Capacity—50 tons daily<br />

Capital—$50,000; issued, $30,000<br />

Railroad—M. K. T.<br />

ASHTABULA SHEET STEEL CO..<br />

Ashtabula. O.<br />

Pre*.—W. H. Davey, Mansfield O.<br />

V. Pres. Charge Opr.—Samuel Davey<br />

V. Pres. and Works Mgr.—Evan M. Jone*<br />

Treaa., See and Pur. Agt.—A. I. Davey,<br />

Mansfield, 0.<br />

Asal. Treas. and Asst. Sec.—W. R. Jen.<br />

kins, Mansfield, 0.<br />

Chief Clerk—E. J. Secrest<br />

PRODUCTS—Sheel steel, blue annealed.<br />

one pas* cold rolled box annealed, single<br />

pickled, one pass, Iwo or three pass full<br />

picketed, full cold rolled, aulo body<br />

sheets, deep drawing, extra deep drawing<br />

sheets, limed or oiled.<br />

ATHENIA STEEL CO., THE. General<br />

Office: 135 William St., New York City.<br />

Plant: Clifton, N. J.<br />

(Al Pie*.—Ferdinand Vice. See Treas.—E. Asst. Gen. Chief Draftsman—John EQUIPMENT—Cold PRODUCTS—Cold Railroads—D. M. —Carl tempering sleel Clifton, Pur. Supt.—Arvid Treaa.—Waller Bath Elee Pres.—August Falk Agl. Von Engr., furnace* N. L. and Berlo ft J„ Wilrke* Fornelius M. Fornelius Plant) Asst. rolled XV. Fornelius H. M. rolling Dodd and O. and Sleam M.—Edward<br />

mill* tempered Engr. and<br />

14<br />

ATLANTIC FOUNDRY CO.. 182 Beaver<br />

St., Akron, O.<br />

Prea.. Treas, and P. A.—Charles Reyiii.mi.<br />

Sr.<br />

Vieo Pre*.—Philip Wilenbacher<br />

Sec.—E. R. Knecht<br />

Aaat. Treaa.—Evald Erikaon<br />

Gen. Mgr.—Norman Daub<br />

Gen. Supt.—Charles Reymann. Jr,<br />

Chief Engr.—Frank Caillet<br />

Elee Engr.—Edward Hoover<br />

EQUIPMENT—3-ton Snyder furnace<br />

Capacity—200 tons per month ateel castinga;<br />

750 tona per month Iron castings.<br />

Rsilroad*—Belt Line R. R., connecting<br />

with B. ft O., Penna., Erie. N. Y. C.<br />

lines<br />

ATLANTIC STEEL CO., P. 0. Box 1714,<br />

Atlanta. Ga.<br />

Chairman—T. K. Glenn<br />

Pre*.—Robert Gregg<br />

Vice Pres. and G. M.-r-N. C. Harrison<br />

Vice Pre*., Sale*—C. F. Stone<br />

Treaa.—Paul W. Miller<br />

Sec—G. A. Howell<br />

Pur. Agl.—G. XV. Romey<br />

Supt. O. H. and Bloom Mill—G. D. Wallers<br />

Supt. Roll and Wire Mill—0. L. Mc*<br />

Gowan<br />

A**t,—Supt. Roll Mill—R. M. Lang<br />

Supt. Hoop Mill—E. E. Schukraft<br />

Supl. Mach.—J. H. Sneed<br />

Brick Supt.—L. XV. Wade<br />

Chief Engr.—R. H. Lowndes<br />

Aut. Chief Engr.—M. A. Wilson<br />

Chief Elee—G. E. Thrash .,<br />

Mech. Engr.—R. E. Bobbitt, Jr.<br />

Steam Engr,—M. P. Lawton<br />

Safety Engr. C. J. Vandevenier<br />

M. M.—S. N. Roberts<br />

Chief Chemist—C. G. Schenck<br />

Chief Draftsman—M. A. Wllaon<br />

Roll Designer—D. A. Lennox<br />

Storekeeper—C. Bradley<br />

EQUIPMENT—50-ton basic Open hearth<br />

furnace with waste heat boilers, 2 furnaces<br />

on producer gas, 1 furnace on oil<br />

PRODUCTS—Cotton Capacity—100,000<br />

or<br />

driven 8 one mill; motor one tie chant drawing one 10-inch, machine*, wire machlnea, houiea, angle*, rods, galvanised wire, nail soaking<br />

pulverised<br />

a. and field 8-inch 6-stand 18 motor field merchant bar blued driven 2 channel*, power blocks, small block*; 6-inch high 2 with fence mill, 5-stand wire, pit*, driven; fence, nail*. staple 14-inch hoop<br />

coal;<br />

house*, reveraiog hoop bar*, one necessary M<strong>org</strong>an machine*. motor tons half pulverised 2 nails, bale motor and ties, one machine*. 32<br />

one<br />

galvanising mill; bllleta. round*, ingols conlinuous etc. driven; blocks; 10-inch, tie*, colton-tie staple*, blooming rod<br />

25-inch<br />

hoops, driven shop*, 20 one coal plain per half galvanised and barb-wire 7 12-incb, 56 80-wire 6-stand frames, year barbed bands, cotton fired: woven<br />

motor<br />

boiler ovsla, billet mill; wire, mer nail