How to Solve Your Process Control Problems in Dispensing

How to Solve Your Process Control Problems in Dispensing

How to Solve Your Process Control Problems in Dispensing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ProCeSS <strong>Control</strong><br />

<strong>How</strong> <strong>to</strong> <strong>Solve</strong> <strong>Your</strong> <strong>Process</strong> <strong>Control</strong><br />

<strong>Problems</strong> <strong>in</strong> Dispens<strong>in</strong>g<br />

By: Scott Beebe, President of Fishman Corporation<br />

Do your results vary, even slightly, dur<strong>in</strong>g a dispens<strong>in</strong>g process? Are you<br />

gett<strong>in</strong>g the consistent performance you need from one system <strong>to</strong> the next?<br />

In dispens<strong>in</strong>g adhesives and solder paste, reliability and quality control problems<br />

— variations <strong>in</strong> viscosity and dot size, dripp<strong>in</strong>g and waste of the material, and<br />

even changes <strong>in</strong> homogeneity — are conditions that challenge the accuracy<br />

and repeatability of fluid dispens<strong>in</strong>g systems. In most cases, problems can be<br />

attributed <strong>to</strong> the use of pneumatics <strong>to</strong> “push” the material out of the syr<strong>in</strong>ge<br />

(aka, barrel reservoir). Fortunately, there is an answer <strong>to</strong> the problems that<br />

plague conventional dispensers. Such a solution elim<strong>in</strong>ates any and all use<br />

of pneumatics. As a result, assemblers can count on consistent and reliable<br />

air-free performance and absolute process control, dot after dot after dot<br />

(or bead after bead after bead). First, consider the downside of pneumatics.<br />

What’s Wrong with Air?<br />

The process of dispens<strong>in</strong>g assembly fluids began with pneumatics. Whether a<br />

hand-held gun, a bench-<strong>to</strong>p dispenser, or an au<strong>to</strong>mated workstation, whether<br />

a diaphragm, spool, needle, or pis<strong>to</strong>n valve, such dispensers are air-driven, <strong>in</strong><br />

that they depend on a column of air under pressure <strong>to</strong> force assembly fluid<br />

through a dispens<strong>in</strong>g tip and on<strong>to</strong> a substrate. Fluctuations <strong>in</strong> air pressure, such<br />

as pressure drops and volumetric displacement, are a result of the plumb<strong>in</strong>g<br />

between the air compressor and workstation. Moisture contam<strong>in</strong>ation,<br />

turbulence, heat, and changes <strong>in</strong> viscosity occur due <strong>to</strong> violent air pulses<br />

com<strong>in</strong>g <strong>in</strong> contact with the assembly fluid... and all can underm<strong>in</strong>e the ability<br />

of air-driven dispensers <strong>to</strong> deliver prescribed amounts of material consistently.<br />

Today, air-driven dispensers — especially where process control is paramount —<br />

are on a decl<strong>in</strong>e, while systems based on air-free technology are ga<strong>in</strong><strong>in</strong>g wider<br />

use <strong>in</strong> dispens<strong>in</strong>g adhesives, solder paste, and other fluids. One <strong>in</strong> particular,<br />

the Fishman Corporation AirFree LDS9000, features a proprietary dispens<strong>in</strong>g<br />

system that offers a superior level of process control without the limitations<br />

of other types of dispensers on the market.<br />

Fishman Corporation 192 South Street, Hopk<strong>in</strong><strong>to</strong>n, MA 01748, United States<br />

US & Canada: 800-433-2115 | United K<strong>in</strong>gdom: 1905 456008 | Europe: +441905 456008<br />

Worldwide: 1-508-435-2115 | www.fishmancorp.com<br />

AirFree White pAper<br />

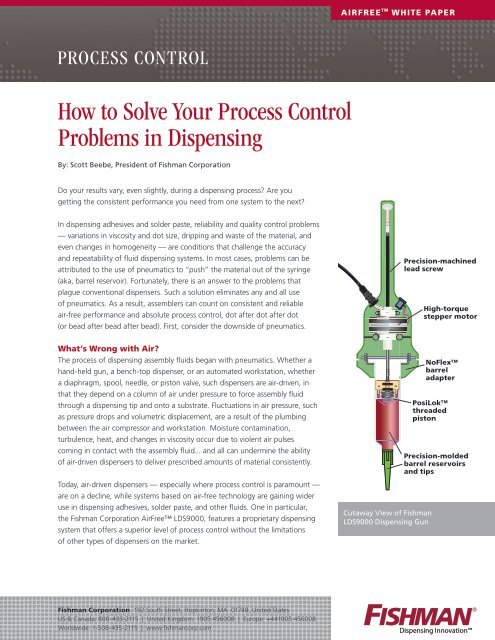

Cutaway View of Fishman<br />

LDS9000 Dispens<strong>in</strong>g Gun<br />

precision-mach<strong>in</strong>ed<br />

lead screw<br />

high-<strong>to</strong>rque<br />

stepper mo<strong>to</strong>r<br />

NoFlex<br />

barrel<br />

adapter<br />

posiLok<br />

threaded<br />

pis<strong>to</strong>n<br />

precision-molded<br />

barrel reservoirs<br />

and tips<br />

Dispens<strong>in</strong>g Innovation

ProCeSS <strong>Control</strong><br />

Fishman LDS9000<br />

With the LDS (l<strong>in</strong>ear drive system) 9000, a notable difference over other dispensers,<br />

<strong>in</strong>clud<strong>in</strong>g valves, is the <strong>in</strong>telligence programmed <strong>in</strong><strong>to</strong> the control unit. The opera<strong>to</strong>r<br />

<strong>in</strong>puts the size of the reservoir (syr<strong>in</strong>ge), the dispense volume, the dispense rate,<br />

and the amount of snuff-back <strong>in</strong> numeric format. The LDS9000 calls for no guess<br />

work or play<strong>in</strong>g with knobs, as is required by air-driven systems. The software<br />

calculates the amount of forward and reverse motion needed <strong>to</strong> displace the<br />

exact amount of assembly fluid. The air-free l<strong>in</strong>ear drive system (LDS) is repeatable<br />

with<strong>in</strong> ±5%, ensur<strong>in</strong>g the same amount of material is dispensed each and every<br />

time the system is cycled. (See cutaway figure.)<br />

The electronic control unit <strong>in</strong>corporates a universal power supply and connects<br />

directly <strong>to</strong> the LDS gun via an electrical cable assembly. The programmable<br />

<strong>in</strong>telligence comb<strong>in</strong>ed with a patentprotected drive system ensures the ultimate<br />

<strong>in</strong> process control. In fact, the design and functionality of the LDS9000 is such<br />

that a system dispens<strong>in</strong>g material <strong>in</strong> the United States will perform exactly as<br />

a system <strong>in</strong> Ch<strong>in</strong>a, as long as the same program, assembly fluid, reservoir, and<br />

dispense tip are employed <strong>in</strong> both locations.<br />

Furthermore, if multiple systems are used on the same production l<strong>in</strong>e (see pho<strong>to</strong>),<br />

the performance will be exactly the same, from the beg<strong>in</strong>n<strong>in</strong>g of the production<br />

run <strong>to</strong> the end. We guarantee it!<br />

For further <strong>in</strong>formation, check out the Fishman website at www.fishmancorp.com.<br />

# # #<br />

Fishman Corporation 192 South Street, Hopk<strong>in</strong><strong>to</strong>n, MA 01748, United States<br />

US & Canada: 800-433-2115 | United K<strong>in</strong>gdom: 1905 456008 | Europe: +441905 456008<br />

Worldwide: 1-508-435-2115 | www.fishmancorp.com<br />

AirFree White pAper<br />

Production L<strong>in</strong>e with Fishman<br />

LDS9000 Dispens<strong>in</strong>g Systems<br />

Assembl<strong>in</strong>g Medical Devices<br />

Dispens<strong>in</strong>g Innovation