Timber Construction

Timber Construction

Timber Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

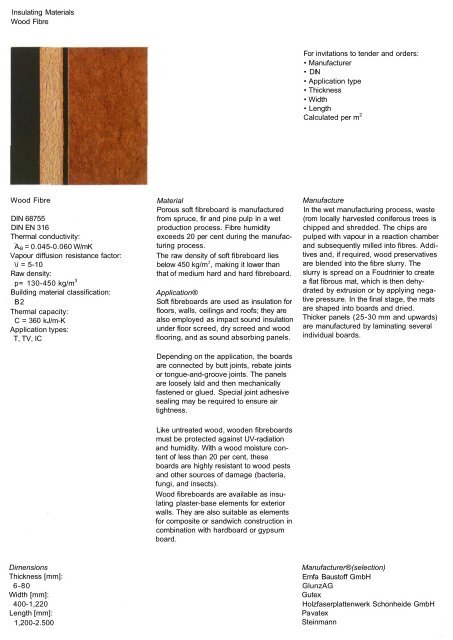

Insulating Materials<br />

Wood Fibre<br />

Wood Fibre<br />

DIN 68755<br />

DIN EN 316<br />

Thermal conductivity:<br />

A.B = 0.045-0.060 W/mK<br />

Vapour diffusion resistance factor:<br />

\i = 5-10<br />

Raw density:<br />

p= 130-450 kg/m 3<br />

Building material classification:<br />

B2<br />

Thermal capacity:<br />

C = 360 kJ/m-K<br />

Application types:<br />

T, TV, IC<br />

Dimensions<br />

Thickness [mm]:<br />

6-80<br />

Width [mm]:<br />

400-1,220<br />

Length [mm]:<br />

1,200-2.500<br />

Material<br />

Porous soft fibreboard is manufactured<br />

from spruce, fir and pine pulp in a wet<br />

production process. Fibre humidity<br />

exceeds 20 per cent during the manufacturing<br />

process.<br />

The raw density of soft fibreboard lies<br />

below 450 kg/m ;i , making it lower than<br />

that of medium hard and hard fibreboard.<br />

Application®<br />

Soft fibreboards are used as insulation for<br />

floors, walls, ceilings and roofs; they are<br />

also employed as impact sound insulation<br />

under floor screed, dry screed and wood<br />

flooring, and as sound absorbing panels.<br />

Depending on the application, the boards<br />

are connected by butt joints, rebate joints<br />

or tongue-and-groove joints. The panels<br />

are loosely laid and then mechanically<br />

fastened or glued. Special joint adhesive<br />

sealing may be required to ensure air<br />

tightness.<br />

Like untreated wood, wooden fibreboards<br />

must be protected against UV-radiation<br />

and humidity. With a wood moisture content<br />

of less than 20 per cent, these<br />

boards are highly resistant to wood pests<br />

and other sources of damage (bacteria,<br />

fungi, and insects).<br />

Wood fibreboards are available as insulating<br />

plaster-base elements for exterior<br />

walls. They are also suitable as elements<br />

for composite or sandwich construction in<br />

combination with hardboard or gypsum<br />

board.<br />

For invitations to tender and orders:<br />

• Manufacturer<br />

•DIN<br />

• Application type<br />

• Thickness<br />

• Width<br />

• Length<br />

Calculated per m 2<br />

Manufacture<br />

In the wet manufacturing process, waste<br />

(rom locally harvested coniferous trees is<br />

chipped and shredded. The chips are<br />

pulped with vapour in a reaction chamber<br />

and subsequently milled into fibres. Additives<br />

and, if required, wood preservatives<br />

are blended into the fibre slurry. The<br />

slurry is spread on a Foudrinier to create<br />

a flat fibrous mat, which is then dehydrated<br />

by extrusion or by applying negative<br />

pressure. In the final stage, the mats<br />

are shaped into boards and dried.<br />

Thicker panels (25-30 mm and upwards)<br />

are manufactured by laminating several<br />

individual boards.<br />

Manufacturer® (selection)<br />

Emfa Baustoff GmbH<br />

GlunzAG<br />

Gutex<br />

Holzfaserplattenwerk Schonheide GmbH<br />

Pa vat ex<br />

Steinmann<br />

Bituminated Fibreboard [Asphalt-<br />

Treated Board; US]<br />

[DIN 68752<br />

lermal conductivity:<br />

^ = 0.056-0.060 W/mK<br />

'apour diffusion resistance factor:<br />

= 5-10<br />

Raw density:<br />

p = 200-350 kg/m 3<br />

Building material classification:<br />

B2<br />

Fhermal capacity:<br />

C - 630 kJ/m ; 'K<br />

\pplication types:<br />

T,TV<br />

"isions<br />

nickness [mm]:<br />

16-25<br />

Wdth [mm]:<br />

[400-1,220<br />

Length [mm]:<br />

[2,440,2,500<br />

Material<br />

Bituminated fibreboards are porous wood<br />

fibreboards, manufactured with a bitumen<br />

additive.<br />

A distinction is made between bituminated<br />

(ibreboards<br />

• with 10-15 per cent bitumen additive<br />

(moisture-proof) and a water absorption<br />

rate of less than 25 per cent (BPH)<br />

• with more than 15 per cent bitumen<br />

additive (increased moisture resistance)<br />

and an average water absorption of less<br />

than 20 per cent (BPH2).<br />

Application®<br />

The primary areas of application ar& exterior<br />

walls, roof extensions and subfloors.<br />

Bitumen-impregnated wood fibreboards<br />

can be used under roof covering as<br />

water- and airtight layers. The bitumen<br />

content renders them resistant to moisture,<br />

rot, fungi and insects.<br />

Insulating Materials<br />

Bituminated Fibreboard<br />

For invitations to tender and orders:<br />

• Manufacturer<br />

•DIN<br />

• Application type<br />

• Thickness<br />

• Width<br />

• Length<br />

Calculated per m /<br />

Manufacture<br />

Bituminated wood fibreboards are manufactured<br />

in the same manner as porous<br />

wood fibreboards; the only difference<br />

being that a bitumen emulsion is added<br />

to the fibre slurry.<br />

Manufacturer® (selection)<br />

Emfa Baustoff GmbH<br />

Gutex<br />

Isofloc Warmedammtechnik GmbH<br />

Pavatex