Timber Construction

Timber Construction

Timber Construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Timber</strong> Structures<br />

Built Examples<br />

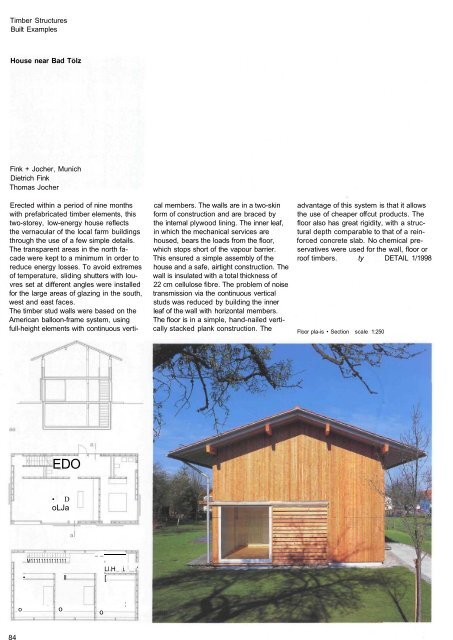

House near Bad Tolz<br />

Fink + Jocher, Munich<br />

Dietrich Fink<br />

Thomas Jocher<br />

Erected within a period of nine months<br />

with prefabricated timber elements, this<br />

two-storey, low-energy house reflects<br />

the vernacular of the local farm buildings<br />

through the use of a few simple details.<br />

The transparent areas in the north facade<br />

were kept to a minimum in order to<br />

reduce energy losses. To avoid extremes<br />

of temperature, sliding shutters with louvres<br />

set at different angles were installed<br />

for the large areas of glazing in the south,<br />

west and east faces.<br />

The timber stud walls were based on the<br />

American balloon-frame system, using<br />

full-height elements with continuous verti-<br />

84<br />

o<br />

•<br />

EDO<br />

• D<br />

oLJa<br />

M11111111111111<br />

• —<br />

o<br />

II<br />

__<br />

o<br />

Ll.H<br />

[<br />

i. ,'<br />

:<br />

cal members. The walls are in a two-skin<br />

form of construction and are braced by<br />

the internal plywood lining. The inner leaf,<br />

in which the mechanical services are<br />

housed, bears the loads from the floor,<br />

which stops short of the vapour barrier.<br />

This ensured a simple assembly of the<br />

house and a safe, airtight construction. The<br />

wall is insulated with a total thickness of<br />

22 cm cellulose fibre. The problem of noise<br />

transmission via the continuous vertical<br />

studs was reduced by building the inner<br />

leaf of the wall with horizontal members.<br />

The floor is in a simple, hand-nailed vertically<br />

stacked plank construction. The<br />

advantage of this system is that it allows<br />

the use of cheaper off cut products. The<br />

floor also has great rigidity, with a structural<br />

depth comparable to that of a reinforced<br />

concrete slab. No chemical preservatives<br />

were used for the wall, floor or<br />

roof timbers. ty DETAIL 1/1998<br />

Floor pla-is • Section scale 1:250<br />

<strong>Timber</strong> Structures<br />

Built Examples<br />

Horizontal section First floor • vertical section<br />

scale 1:20<br />

1 roof construction: concrete roof tiles<br />

30/50 mm battens, 24/46 mm counter-battens<br />

moisture-diffusing roof sheeting<br />

24 mm sawn tongued-and-grooved boarding<br />

160 mm cellulose-fibre thermal insulation<br />

between 60/160 mm ratters<br />

aluminium foil vapour barrier<br />

40 mm thermal insulation<br />

between 40/60 mm battens<br />

12.5 mm plasterboard<br />

2 wall construction:<br />

30/50 mm untreated larch strips<br />

insect screen, 30/50 mm battens<br />

moisture-diffusing wind proof building paper<br />

24 mm softwood tongued-and-grooved boarding<br />

160 mm cellulose-fibre thermal insulation<br />

between 60/160 mm timber studs<br />

12 mm plywood construction board<br />

polythene sheet vapour barrier<br />

60 mm thermal insulation between 60/60 mm<br />

timber battens, 12.5 mm plasterboard<br />

3 larch strips splay cut on both edges;<br />

white glazed on edges and rear lace<br />

85