Product catalogue 2012 - SILADENT Dr. Böhme & Schöps GmbH

Product catalogue 2012 - SILADENT Dr. Böhme & Schöps GmbH

Product catalogue 2012 - SILADENT Dr. Böhme & Schöps GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

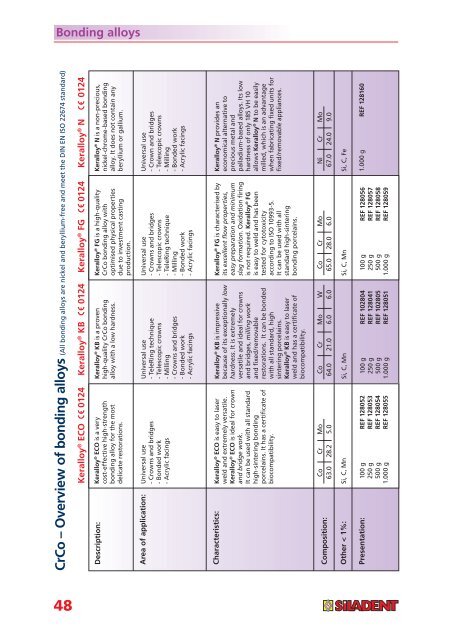

Bonding alloys<br />

CrCo – Overview of bonding alloys (All bonding alloys are nickel and beryllium-free and meet the DIN EN ISO 22674 standard)<br />

48<br />

Keralloy ® FG 0124 Keralloy ® N 0124<br />

Keralloy ® KB 0124<br />

Keralloy ® ECO 0124<br />

Keralloy ® N is a non-precious,<br />

nickel-chrome-based bonding<br />

alloy. It does not contain any<br />

beryllium or gallium.<br />

Keralloy ® FG is a high-quality<br />

CrCo bonding alloy with<br />

optimised physical properties<br />

due to investment casting<br />

production.<br />

Keralloy ® KB is a proven<br />

high-quality CrCo bonding<br />

alloy with a low hardness.<br />

Keralloy ® ECO is a very<br />

cost-effective high-strength<br />

bonding alloy for the most<br />

delicate restorations.<br />

Description:<br />

Universal use<br />

- Crown and bridges<br />

- Telescopic crowns<br />

- Milling<br />

- Bonded work<br />

- Acrylic facings<br />

Universal use<br />

- Crowns and bridges<br />

- Telescopic crowns<br />

- TeleRing technique<br />

- Milling<br />

- Bonded work<br />

- Acrylic facings<br />

Universal use<br />

- TeleRing technique<br />

- Telescopic crowns<br />

- Milling<br />

- Crowns and bridges<br />

- Bonded work<br />

- Acrylic facings<br />

Universal use<br />

- Crowns and bridges<br />

- Bonded work<br />

- Acrylic facings<br />

Area of application:<br />

Keralloy ® N provides an<br />

economical alternative to<br />

precious metal and<br />

palladium-based alloys. Its low<br />

hardness of only 185 VH 10<br />

allows Keralloy ® N to be easily<br />

milled, which is an advantage<br />

when fabricating fixed units for<br />

fixed/removable appliances.<br />

Keralloy ® FG is characterised by<br />

its excellent flow properties,<br />

easy preparation and minimum<br />

slag formation. Oxidation firing<br />

is not required. Keralloy ® FG<br />

is easy to weld and has been<br />

tested for cytotoxicity<br />

according to ISO 10993-5.<br />

It can be used with all<br />

standard high-sintering<br />

bonding porcelains.<br />

Keralloy ® KB is impressive<br />

because of its exceptionally low<br />

hardness. It is extremely<br />

versatile and ideal for crowns<br />

and bridges, milling work<br />

and fixed/removable<br />

restorations. It can be bonded<br />

with all standard, high<br />

sintering porcelains.<br />

Keralloy ® KB is easy to laser<br />

weld and has a certificate of<br />

biocompatibility.<br />

Keralloy ® ECO is easy to laser<br />

weld and extremely versatile.<br />

Keralloy ® ECO is ideal for crown<br />

and bridge work.<br />

It can be used with all standard<br />

high-sintering bonding<br />

porcelains. It has a certificate of<br />

biocompatibility.<br />

Characteristics:<br />

Mo<br />

9.0<br />

Cr<br />

24.0<br />

Ni<br />

67.0<br />

Mo<br />

6.0<br />

Cr<br />

28.0<br />

Co<br />

65.0<br />

W<br />

6.0<br />

Mo<br />

6.0<br />

Cr<br />

21.0<br />

Co<br />

64.0<br />

Mo<br />

5.0<br />

Cr<br />

28.2<br />

Co<br />

63.0<br />

Composition:<br />

Si, C, Fe<br />

Si, C, Mn<br />

Si, C, Mn<br />

Si, C, Mn<br />

Other < 1%:<br />

1.000 g REF 128160<br />

100 g REF 128056<br />

250 g REF 128057<br />

500 g REF 128058<br />

1.000 g REF 128059<br />

100 g REF 102804<br />

250 g REF 128041<br />

500 g REF 102805<br />

1.000 g REF 128051<br />

100 g REF 128052<br />

250 g REF 128053<br />

500 g REF 128054<br />

1.000 g REF 128055<br />

Presentation: