The Stainless Steel Experts - MSTAINLESS

The Stainless Steel Experts - MSTAINLESS

The Stainless Steel Experts - MSTAINLESS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BUSINESS DIVISION<br />

Industrial components<br />

made of stainless steel<br />

22<br />

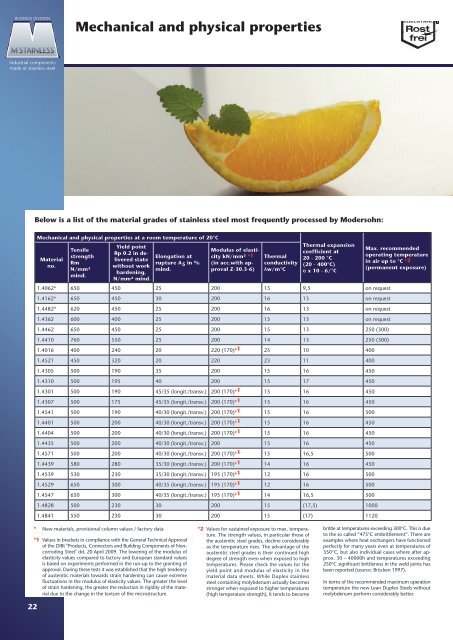

Mechanical and physical properties at a room temperature of 20°C<br />

Material<br />

no.<br />

Mechanical and physical properties<br />

Below is a list of the material grades of stainless steel most frequently processed by Modersohn:<br />

Tensile<br />

strength<br />

Rm<br />

N/mm²<br />

mind.<br />

Yield point<br />

Rp 0.2 in delivered<br />

state<br />

without work<br />

hardening,<br />

N/mm² mind.<br />

Elongation at<br />

rupture A 5 in %<br />

mind.<br />

Modulus of elasticity<br />

kN/mm² *1<br />

(in acc.with approval<br />

Z-30.3-6)<br />

<strong>The</strong>rmal<br />

conductivity<br />

λw/m°C<br />

<strong>The</strong>rmal expansion<br />

coefficient at<br />

20 - 200 °C<br />

(20 - 400°C)<br />

α x 10 - 6/°C<br />

1.4062* 650 450 25 200 15 9,5 on request<br />

1.4162* 650 450 30 200 16 13 on request<br />

1.4482* 620 450 25 200 16 13 on request<br />

1.4362 600 400 25 200 15 13 on request<br />

1.4462 650 450 25 200 15 13 250 (300)<br />

1.4410 760 550 25 200 14 13 250 (300)<br />

1.4016 400 240 20 220 (170)* 1 25 10 400<br />

1.4521 450 320 20 220 23 11 400<br />

1.4305 500 190 35 200 15 16 450<br />

1.4310 500 195 40 200 15 17 450<br />

1.4301 500 190 45/35 (longit./transv.) 200 (170)* 1 15 16 450<br />

1.4307 500 175 45/35 (longit./transv.) 200 (170)* 1 15 16 450<br />

1.4541 500 190 40/30 (longit./transv.) 200 (170)* 1 15 16 500<br />

1.4401 500 200 40/30 (longit./transv.) 200 (170)* 1 15 16 450<br />

1.4404 500 200 40/30 (longit./transv.) 200 (170)* 1 15 16 450<br />

1.4435 500 200 40/30 (longit./transv.) 200 15 16 450<br />

1.4571 500 200 40/30 (longit./transv.) 200 (170)* 1 15 16,5 500<br />

1.4439 580 280 35/30 (longit./transv.) 200 (170)* 1 14 16 450<br />

1.4539 530 230 35/30 (longit./transv.) 195 (170)* 1 12 16 500<br />

1.4529 650 300 40/35 (longit./transv.) 195 (170)* 1 12 16 500<br />

1.4547 650 300 40/35 (longit./transv.) 195 (170)* 1 14 16,5 500<br />

1.4828 500 230 30 200 15 (17,5) 1000<br />

1.4841 550 230 30 200 15 (17) 1120<br />

* New materials, provisional column values / factory data<br />

*1 Values in brackets in compliance with the General Technical Approval<br />

of the DIBt "Products, Connectors and Building Components of Noncorroding<br />

<strong>Steel</strong>" dd. 20 April 2009. <strong>The</strong> lowering of the modulus of<br />

elasticity values compared to factory and European standard values<br />

is based on experiments performed in the run-up to the granting of<br />

approval. During these tests it was established that the high tendency<br />

of austenitic materials towards strain hardening can cause extreme<br />

fluctuations in the modulus of elasticity values. <strong>The</strong> greater the level<br />

of strain hardening, the greater the reduction in rigidity of the material<br />

due to the change in the texture of the microstructure.<br />

*2 Values for sustained exposure to max. temperature.<br />

<strong>The</strong> strength values, in particular those of<br />

the austenitic steel grades, decline considerably<br />

as the temperature rises. <strong>The</strong> advantage of the<br />

austenitic steel grades is their continued high<br />

degree of strength even when exposed to high<br />

temperatures. Please check the values for the<br />

yield point and modulas of elasticity in the<br />

material data sheets. While Duplex stainless<br />

steel containing molybdenum actually becomes<br />

stronger when exposed to higher temperatures<br />

(high temperature strength), it tends to become<br />

Max. recommended<br />

operating temperature<br />

in air up to °C *2<br />

(permanent exposure)<br />

brittle at temperatures exceeding 300°C. This is due<br />

to the so called “475°C embrittlement”. <strong>The</strong>re are<br />

examples where heat exchangers have functioned<br />

perfectly for many years even at temperatures of<br />

350°C, but also individual cases where after approx.<br />

30 – 40000h and temperatures exceeding<br />

250°C significant brittleness in the weld joints has<br />

been reported (source: Brücken 1997).<br />

In terms of the recommended maximum operation<br />

temperature the new Lean Duplex <strong>Steel</strong>s without<br />

molybdenum perform considerably better.