- Page 1: Ali Reza Kharazipour, Christian Sch

- Page 4 and 5: erschienen in der Reihe der Univers

- Page 6 and 7: Bibliographische Information der De

- Page 8 and 9: Contents Nina Ritter, Alireza Khara

- Page 10 and 11: IV S. E. Sadeghi et al. Insects ass

- Page 12 and 13: 2 1. Initial situation and problem

- Page 14 and 15: 4 climate- friendly and resource-ef

- Page 16 and 17: 6 Figure 2: Different fractions of

- Page 18 and 19: 8 7. Results The following chapter

- Page 20 and 21: 10 9. Literature Deppe, H.J., Ernst

- Page 22 and 23: 12 Introduction The use of natural

- Page 24 and 25: 14 Pilot plant particle board produ

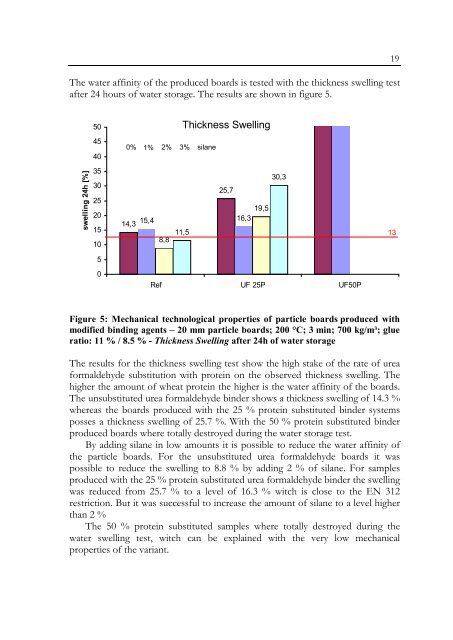

- Page 26 and 27: 16 Results and Discussion Mechanica

- Page 30 and 31: 20 Conclusion The executed research

- Page 32 and 33: Development and production of innov

- Page 34 and 35: 24 Construction Engineering (DIBt)

- Page 36 and 37: 26 Production of pilot scaled mediu

- Page 38 and 39: 28 N/mm² 45 40 35 30 25 20 15 10 5

- Page 40 and 41: 30 mg HCHO/100 g 8 7 6 5 4 3 2 1 0

- Page 42 and 43: 32 References Boehme, C. (2000): Ü

- Page 44 and 45: 34 Introduction At the end of the l

- Page 46 and 47: 36 the genome is not able to rovide

- Page 48 and 49: 38 tolerance mechanisms should take

- Page 50 and 51: 40 Ma, S. S., Gong, Q. Q., & Bohner

- Page 52 and 53: How does fertilization influence tr

- Page 54 and 55: 44 Nitrous oxide Natural sources fo

- Page 56 and 57: 46 Therefore methane oxidation does

- Page 58 and 59: 48 the use of an autosampler system

- Page 60 and 61: 50 variant (140 kg N ha -1y -1) the

- Page 62 and 63: 52 CH4-C uptake [g ha -1 y -1 ] 0 -

- Page 64 and 65: 54 Loftfield, N., Flessa H., August

- Page 66 and 67: 56 Introduction Wood Polymer Compos

- Page 68 and 69: 58 Polypropylene is a high-volume,

- Page 70 and 71: 60 Sisal 8.43 67 / 12 300 -800 2.9

- Page 72 and 73: 62 compounder and the die (currentl

- Page 74 and 75: 64 Subsequently in the project desc

- Page 76 and 77: 66 References Al-Qureshi H.A. (1999

- Page 78 and 79:

68 Mai C, Militz H (2004a), „Modi

- Page 80 and 81:

Integration concept of Non Timber F

- Page 82 and 83:

72 Introduction This paper gives a

- Page 84 and 85:

74 the trees where numbered from th

- Page 86 and 87:

76 Due to the strong economical dev

- Page 88 and 89:

78 The logging ban of the NFPP had

- Page 90 and 91:

80 global level. This means e.g. re

- Page 92 and 93:

82 • Plantation conversion • St

- Page 94 and 95:

84 • Storm damages (Hainan situat

- Page 96 and 97:

86 C Slow transforming Situation: T

- Page 98 and 99:

88 References Bennet, M. T.; Xu, J.

- Page 100 and 101:

90 Sprenger, T. 2007: A strategic f

- Page 102 and 103:

92 Introduction Energy- and matter-

- Page 104 and 105:

94 The Boundary Layer and turbulenc

- Page 106 and 107:

96 F C = w′ C′ Results should l

- Page 108 and 109:

98 Fig. 4: Eddy-covariance measurem

- Page 110 and 111:

100 Fig. 6: Bowen ratio for the Bar

- Page 112 and 113:

102 Fig. 8: Daily course of CO2-con

- Page 114 and 115:

104 Fig. 10: Normalized storage flu

- Page 116 and 117:

Criteria for the assessment of fore

- Page 118 and 119:

108 conference, the Helsinki proces

- Page 120 and 121:

110 Assessment of forest naturalnes

- Page 122 and 123:

112 or even impossible to describe

- Page 124 and 125:

114 naturalness of the vegetation c

- Page 126 and 127:

116 Discussion Knowledge about natu

- Page 128 and 129:

118 Hanstein, U. & Sturm, K. (1986)

- Page 130 and 131:

The fall webworm, Hyphantria cunea

- Page 132 and 133:

122 1. Geographical distribution Th

- Page 134 and 135:

124 3. Life cycle In the native are

- Page 136 and 137:

126 investigating pheromone gland e

- Page 138 and 139:

128 9. Conclusions To effectively m

- Page 140 and 141:

130 Ito, Y., Miyashita, K. (1968) B

- Page 142 and 143:

132 Table 1 Chemical compositions a

- Page 144 and 145:

134 Figure 2 Different development

- Page 146 and 147:

136 Abstract Secale montanum is one

- Page 148 and 149:

138 content so that both freezing i

- Page 150 and 151:

140 In all of the experiments, the

- Page 152 and 153:

142 Table 3: Analysis of variance e

- Page 154 and 155:

144 (a) (b) Figure 4: a) The cold-d

- Page 156 and 157:

146 References Barabanova EA, Banni

- Page 158 and 159:

148 Touchell DH, Chiang VL, and Tsa

- Page 160 and 161:

150 Abstract Bromus L. is one of th

- Page 162 and 163:

152 therefore, be very important re

- Page 164 and 165:

154 gains in short- and long-term b

- Page 166 and 167:

156 B. sterilis species (44.84). Th

- Page 168 and 169:

158 ploidy levels showed lower DRL,

- Page 170 and 171:

160 Mirzaie-Nodoushan H., A.R. Zeba

- Page 172 and 173:

The effects of Poplar clones age va

- Page 174 and 175:

164 homogenous material. In this ca

- Page 176 and 177:

166 content and press time of 6 min

- Page 178 and 179:

168 3- Results Anatomical character

- Page 180 and 181:

170 4 5 11 15.9 1474 0.27 29.18 32.

- Page 182 and 183:

172 Fig 3: The effect of resin cont

- Page 184 and 185:

174 Fig 5: The effect of resin cont

- Page 186 and 187:

176 Fig 7: The effect of clones' ag

- Page 188 and 189:

178 Fig 11: The effect of resin con

- Page 190 and 191:

180 Table 10 - Duncan's grouping te

- Page 192 and 193:

182 Increasing resin content increa

- Page 194 and 195:

184 particleboard / composite mater

- Page 196 and 197:

186 �������� In thi

- Page 198 and 199:

188 dbh>65cm). The spatial coordina

- Page 200 and 201:

190 a b Persentage 90 80 70 60 50 4

- Page 202 and 203:

192 Distance between trees were mea

- Page 204 and 205:

194 - Shugart, H. H., 1984. A theor

- Page 206 and 207:

196 Abstract Termites damage and de

- Page 208 and 209:

198 Fig 2- Cut lumber stored in lab

- Page 210 and 211:

200 Table 1-Average charge retentio

- Page 212 and 213:

202 Demolition average grades No. o

- Page 214 and 215:

204 Fig 9-In control samples of E.

- Page 216 and 217:

206 Fig 12- Control samples of E. s

- Page 218 and 219:

208 Fig 16- Treated with Celcure sa

- Page 220 and 221:

210 camaldulensis samples, impregna

- Page 222 and 223:

212 Abstract For identification of

- Page 224 and 225:

214 Pedology There are 11 types of

- Page 226 and 227:

216 5- Seashores up to 1250 meters

- Page 228 and 229:

218 The climate of the site of thes

- Page 230 and 231:

220 10- Erodium sp. 11- Meidcago sp

- Page 232 and 233:

222 Semeng associations(Tecomella u

- Page 234 and 235:

224 Figure 10: Calotropis procera,

- Page 236 and 237:

226 Acacia tortilis associations: T

- Page 238 and 239:

228 7- Calotropis procera Acacia al

- Page 240 and 241:

230 Figure 15: Populus euphratica,

- Page 242 and 243:

232 8- Lycium shawii 9- Medicago sp

- Page 244 and 245:

234 1- Amygdalus iranshahrii 2- Con

- Page 246 and 247:

236 Olive associations (Olea ferrug

- Page 248 and 249:

238 animals in forest constantly an

- Page 250 and 251:

No. 1 2 3 4 240 Forest association

- Page 252 and 253:

10 11 242 Acacia nubica A. ehrenber

- Page 254 and 255:

Effects of drought stress on Eucaly

- Page 256 and 257:

246 livelihood of farmers. The succ

- Page 258 and 259:

248 sample were representative of t

- Page 260 and 261:

�����������

- Page 262 and 263:

252 Our data, while providing furth

- Page 264 and 265:

254 Roozitalab, M.H., National soil

- Page 266 and 267:

256 Abstract Iran is a unique count

- Page 268 and 269:

258 performed using shoot number, s

- Page 270 and 271:

260 Season Time of Treatment (M) pe

- Page 272 and 273:

262 Rooting% Fig 3: Rooting of E.gr

- Page 274 and 275:

264 References: 1-Assareh, M.H. 199

- Page 276 and 277:

266 Abstract Based on outcome of se

- Page 278 and 279:

268 categorized as woodlands. Most

- Page 280 and 281:

270 country were determined and res

- Page 282 and 283:

272 Fig 1: Insect abundance in any

- Page 284 and 285:

274 1-Oak 1- 1- Oak gall wasps Faun

- Page 286 and 287:

276 and Adeli in 1983 collected and

- Page 288 and 289:

278 Table 4- Important poplar pests

- Page 290 and 291:

280 Farashiani M. E., Sama G., Yarm

- Page 292 and 293:

282 Salehi M. and Babmorad M. 1998.

- Page 294 and 295:

National Park Hainich - Primeval Be

- Page 296 and 297:

286 dominated the utilisation and a

- Page 298 and 299:

288 wind direction is south-west wi

- Page 300 and 301:

290 The acquisitions of animals and

- Page 302 and 303:

292 The “Treetop-Pathway” (leng

- Page 304 and 305:

294 Introduction Plant development

- Page 306 and 307:

296 were set to the value of 10, ex

- Page 308 and 309:

298 Figure 1. A) Phylogenetic tree

- Page 310 and 311:

300 Figure 2. Scales log(2). A) Exp

- Page 312 and 313:

302 Schrader J, Nilsson J, Mellerow

- Page 314 and 315:

304 1 Abstract Mushroom-forming Aga

- Page 316 and 317:

306 One species cultured and eaten

- Page 318 and 319:

308 manifold different compatible m

- Page 320 and 321:

310 conditions. In ectomycorrhizal

- Page 322 and 323:

312 conditions and to introduce in

- Page 324 and 325:

314 promoter). Laccase production b

- Page 326 and 327:

316 Standrige S, Oberwinkler F, Par

- Page 328 and 329:

318 Rühl M and Kües U (2007) Mush