Materials Annual Report - Friends of Imperial College

Materials Annual Report - Friends of Imperial College

Materials Annual Report - Friends of Imperial College

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

group is assigned an artefact (i.e. a kettle, toaster,<br />

golf club, etc.) and is expected to dismantle it,<br />

assess the design and function <strong>of</strong> the individual<br />

components, and then conduct tests to identify<br />

the material and production method used. In<br />

the third year students conduct a group design<br />

study. The project is initiated by a design brief,<br />

which can be to design a product or process.<br />

The team <strong>of</strong> students independently plans how<br />

to address the brief; including how to o acquire<br />

the knowledge needed to carry out the design,<br />

how to organise the work as a team effort and<br />

how progress will be monitored. In addition<br />

to technical content the final report should<br />

contain a business plan for commercialisation<br />

<strong>of</strong> the design and address IP and QA issues.<br />

The MEng students spend the summer between<br />

their third and fourth year on placement before<br />

returning to join one <strong>of</strong> the research groups<br />

to carry out an individual project conducted<br />

over both the Autumn and Spring terms.<br />

The Department also provides teaching to other<br />

<strong>College</strong> Departments. Courses in Biomaterials<br />

are <strong>of</strong>fered to students in the School <strong>of</strong> Medicine<br />

and the Department <strong>of</strong> Bioengineering and<br />

Introductory <strong>Materials</strong> Science and Engineering<br />

is taught to first and second year Aeronautical<br />

Engineering students.<br />

Industrial experience and work placements<br />

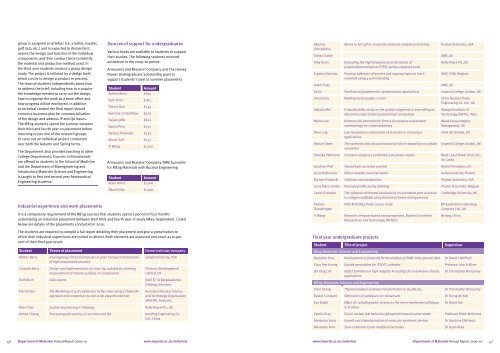

Sources <strong>of</strong> support for undergraduates<br />

Various funds are available to students to support<br />

their studies. The following students received<br />

assistance in the 2009–10 period:<br />

Armourers and Brasiers’ Company and The Harvey<br />

Flower Undergraduate Scholarship grant to<br />

support students’ travel to summer placements<br />

Student Amount<br />

Ashton Berry £394<br />

Ruth Birch £183<br />

Patrick Burr £749<br />

Katerina Christ<strong>of</strong>idou £529<br />

Sajjad Jaffer £600<br />

Daniel Price £757<br />

Bartosz Polomski £539<br />

Anwar Sufi £757<br />

Yi Wang £1,000<br />

Armourers and Brasiers’ Company/AWE bursaries<br />

for MEng <strong>Materials</strong> with Nuclear Engineering<br />

Student Amount<br />

Arjon Vohra £1,000<br />

Adam Foley £1,000<br />

It is a compulsory requirement <strong>of</strong> the MEng courses that students spend a period <strong>of</strong> four months<br />

undertaking an industrial placement between their third and fourth year <strong>of</strong> study (May–September). Listed<br />

below are details <strong>of</strong> the placements conducted in 2010.<br />

The students are required to compile a full report detailing their placement and give a presentation to<br />

which their industrial supervisors are invited to attend. Both elements are assessed and count as 10 per<br />

cent <strong>of</strong> their final year result.<br />

Student Theme <strong>of</strong> placement Home institute/company<br />

Ashton Berry Investigating critical mechanisms in grain transport mechanisms<br />

<strong>of</strong> high-temperature ceramics<br />

Coranda Berry Design and implementation <strong>of</strong> a test-rig, suitable for allowing<br />

measurement <strong>of</strong> internal surfaces on components<br />

Lehigh University, USA<br />

Finsbury (Development)<br />

Limited, UK<br />

Ruth Birch Glass foams (IASTE) TU Bergakademie<br />

Freiberg, Germany<br />

Patrick Burr FAE Modelling <strong>of</strong> cyclic behaviour <strong>of</strong> P91 steel using a Chaboche<br />

approach and comparison to real-scale experimental test<br />

Australian Nuclear Science<br />

and Technology Organisation<br />

(ANSTO), Australia<br />

Alvin Chan Surface engineering in tribology Rolls-Royce Plc., UK<br />

Adrian Chiang Processing and casting <strong>of</strong> cast irons and QA Kai Ming Engineering Co.<br />

Ltd., China<br />

46 Department <strong>of</strong> <strong>Materials</strong> <strong>Annual</strong> <strong>Report</strong> 2009–10 www.imperial.ac.uk/materials www.imperial.ac.uk/materials Department <strong>of</strong> <strong>Materials</strong> <strong>Annual</strong> <strong>Report</strong> 2009–10 47<br />

Katerina<br />

Christ<strong>of</strong>idou<br />

Atoms to Aircraft in composite materials analysis and testing Purdue University, USA<br />

Tobias Clarke AWE, UK<br />

Toby Davis Evaluating the high temperature performance <strong>of</strong><br />

polytetrafluoroethylene (PTFE) spring-energised seals<br />

Evgeniy Donchev Practical adhesion <strong>of</strong> barriers and capping layers to low-k<br />

materials using 4-point bending<br />

Adam Foley AWE, UK<br />

Rolls-Royce Plc.,UK<br />

IMEC VZW, Belgium<br />

Ge Jin Synthesis <strong>of</strong> graphene for optoelectronic applications <strong>Imperial</strong> <strong>College</strong> London, UK<br />

Shuojie Gu Welding metal quality control China Nuclear Power<br />

Engineering Co. Ltd., UK<br />

Sajjad Jaffer A machinability study on the surface roughness in end milling <strong>of</strong><br />

discontinuously reinforced aluminium composites<br />

Mabel Lew Remnant life deterministic fitness-for-purpose assessment<br />

methodology for subsea pipelines<br />

Zhen Ling Low temperature assessment <strong>of</strong> materials in oil and gas<br />

applications<br />

Alistair Owen The synthesis and characterisation <strong>of</strong> silicon-doped boron carbide<br />

nanowires<br />

Manipal Institute <strong>of</strong><br />

Technology (IASTE), India<br />

Wood Group Integrity<br />

Management, UK<br />

Shell UK Limited, UK<br />

<strong>Imperial</strong> <strong>College</strong> London, UK<br />

Shanika Pathirane Corrosion study <strong>of</strong> a combined cycle power station West Coast Power (Pvt) Ltd.,<br />

Sri Lanka<br />

Jonathan Peel Toward best corrosion practice British Petroleum, UK<br />

Lucia Podhorska Silicon dioxide characterisation Aalto University, Finland<br />

Bartosz Polomski Cellulose nanocomposites Purdue University, USA<br />

Luisa Riera Lamela Pressure pr<strong>of</strong>ile during labelling Procter & Gamble, Belgium<br />

Carlos Schuster The influence <strong>of</strong> thermal conductivity on orientated pore structure<br />

in collagen scaffolds using directional freeze-drying process<br />

Kisharn<br />

Thanalingam<br />

Cambridge University, UK<br />

Field M drilling fluids, losses study BP Exploration Operating<br />

Company Ltd., UK<br />

Yi Wang Research on epoxy based nanocomposites, National Centre for<br />

Nanoscience and Technology (NCNST)<br />

Final year undergraduate projects<br />

Beijing, China<br />

Student Title <strong>of</strong> project Supervisor<br />

BEng <strong>Materials</strong> Science and Engineering<br />

Benjamin Foss Development <strong>of</strong> protocols for the analysis <strong>of</strong> SIMS mass spectral data Dr David S McPhail<br />

Chun Ann Huang Double perovskites for ITSOFC cathodes Pr<strong>of</strong>essor John A Kilner<br />

Zhi Yang Lim Defect formation in high integrity Al castings for automotive chassis<br />

applications<br />

MEng <strong>Materials</strong> Science and Engineering<br />

Dr Christopher M Gourlay<br />

Chen Chang Thermal analysis <strong>of</strong> phase transformation in (Cu,Ni)6Sn5 Dr Christopher M Gourlay<br />

Ruskin Constant Fabrication <strong>of</strong> cantilevers for biosensors Dr Yeong Ah-Soh<br />

Zoe Dobel Effect <strong>of</strong> crystallographic texture on the micro-mechanism <strong>of</strong> fatigue<br />

in Zr alloys<br />

Dr David Dye<br />

Carolin Ecsy Future nuclear fuel behaviour/phosphate based nuclear waste Pr<strong>of</strong>essor Robin W Grimes<br />

Alexandru Enica Growth and characterisation <strong>of</strong> molecular spintronic devices Dr Sandrine EM Heutz<br />

Alexander Ford Semi-conductor Q-dot modified electrodes Dr Jason Riley