Technology Roadmap for Energy Reduction in Automotive

Technology Roadmap for Energy Reduction in Automotive

Technology Roadmap for Energy Reduction in Automotive

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Body <strong>in</strong> White and<br />

Components<br />

Pa<strong>in</strong>t<br />

Powertra<strong>in</strong> and<br />

Chassis Components<br />

F<strong>in</strong>al Assembly<br />

Plant Infrastructure<br />

<strong>Energy</strong> Efficient<br />

Manufactur<strong>in</strong>g &<br />

Production <strong>for</strong> Exist<strong>in</strong>g<br />

Materials<br />

<strong>Energy</strong> Efficient<br />

Manufactur<strong>in</strong>g &<br />

Production <strong>for</strong> New<br />

Materials<br />

<strong>Energy</strong> Efficient Design<br />

of Products and<br />

Processes<br />

Organization of the Report<br />

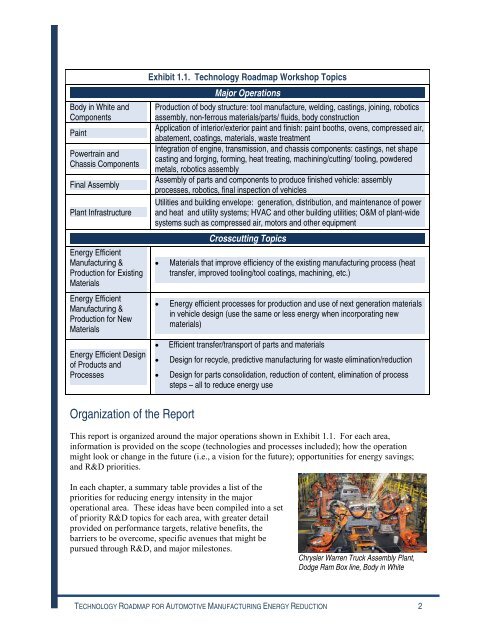

Exhibit 1.1. <strong>Technology</strong> <strong>Roadmap</strong> Workshop Topics<br />

Major Operations<br />

Production of body structure: tool manufacture, weld<strong>in</strong>g, cast<strong>in</strong>gs, jo<strong>in</strong><strong>in</strong>g, robotics<br />

assembly, non-ferrous materials/parts/ fluids, body construction<br />

Application of <strong>in</strong>terior/exterior pa<strong>in</strong>t and f<strong>in</strong>ish: pa<strong>in</strong>t booths, ovens, compressed air,<br />

abatement, coat<strong>in</strong>gs, materials, waste treatment<br />

Integration of eng<strong>in</strong>e, transmission, and chassis components: cast<strong>in</strong>gs, net shape<br />

cast<strong>in</strong>g and <strong>for</strong>g<strong>in</strong>g, <strong>for</strong>m<strong>in</strong>g, heat treat<strong>in</strong>g, mach<strong>in</strong><strong>in</strong>g/cutt<strong>in</strong>g/ tool<strong>in</strong>g, powdered<br />

metals, robotics assembly<br />

Assembly of parts and components to produce f<strong>in</strong>ished vehicle: assembly<br />

processes, robotics, f<strong>in</strong>al <strong>in</strong>spection of vehicles<br />

Utilities and build<strong>in</strong>g envelope: generation, distribution, and ma<strong>in</strong>tenance of power<br />

and heat and utility systems; HVAC and other build<strong>in</strong>g utilities; O&M of plant-wide<br />

systems such as compressed air, motors and other equipment<br />

Crosscutt<strong>in</strong>g Topics<br />

• Materials that improve efficiency of the exist<strong>in</strong>g manufactur<strong>in</strong>g process (heat<br />

transfer, improved tool<strong>in</strong>g/tool coat<strong>in</strong>gs, mach<strong>in</strong><strong>in</strong>g, etc.)<br />

• <strong>Energy</strong> efficient processes <strong>for</strong> production and use of next generation materials<br />

<strong>in</strong> vehicle design (use the same or less energy when <strong>in</strong>corporat<strong>in</strong>g new<br />

materials)<br />

• Efficient transfer/transport of parts and materials<br />

• Design <strong>for</strong> recycle, predictive manufactur<strong>in</strong>g <strong>for</strong> waste elim<strong>in</strong>ation/reduction<br />

• Design <strong>for</strong> parts consolidation, reduction of content, elim<strong>in</strong>ation of process<br />

steps – all to reduce energy use<br />

This report is organized around the major operations shown <strong>in</strong> Exhibit 1.1. For each area,<br />

<strong>in</strong><strong>for</strong>mation is provided on the scope (technologies and processes <strong>in</strong>cluded); how the operation<br />

might look or change <strong>in</strong> the future (i.e., a vision <strong>for</strong> the future); opportunities <strong>for</strong> energy sav<strong>in</strong>gs;<br />

and R&D priorities.<br />

In each chapter, a summary table provides a list of the<br />

priorities <strong>for</strong> reduc<strong>in</strong>g energy <strong>in</strong>tensity <strong>in</strong> the major<br />

operational area. These ideas have been compiled <strong>in</strong>to a set<br />

of priority R&D topics <strong>for</strong> each area, with greater detail<br />

provided on per<strong>for</strong>mance targets, relative benefits, the<br />

barriers to be overcome, specific avenues that might be<br />

pursued through R&D, and major milestones.<br />

Chrysler Warren Truck Assembly Plant,<br />

Dodge Ram Box l<strong>in</strong>e, Body <strong>in</strong> White<br />

TECHNOLOGY ROADMAP FOR AUTOMOTIVE MANUFACTURING ENERGY REDUCTION 2