Technology Roadmap for Energy Reduction in Automotive

Technology Roadmap for Energy Reduction in Automotive

Technology Roadmap for Energy Reduction in Automotive

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Applications<br />

•Cyl<strong>in</strong>der heads<br />

•Torque converter<br />

hous<strong>in</strong>gs<br />

•Cyl<strong>in</strong>der blocks<br />

•Intake manifolds<br />

•Transmission cases<br />

•Electric motor<br />

hous<strong>in</strong>gs (hybrid vehicle)<br />

•Electric rotors (hybrid<br />

vehicle)<br />

•Chassis components<br />

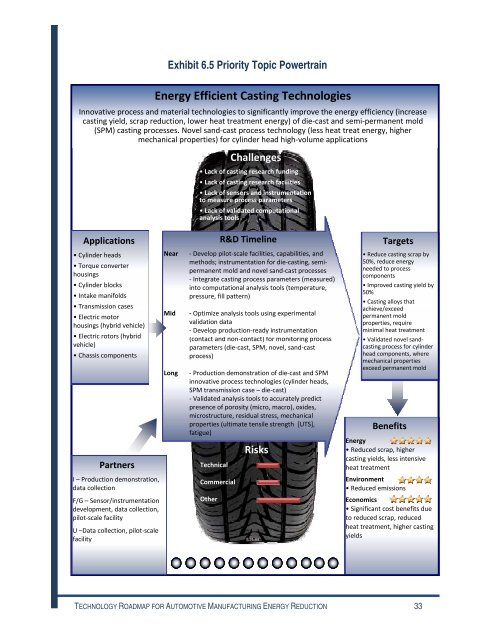

Exhibit 6.5 Priority Topic Powertra<strong>in</strong><br />

<strong>Energy</strong> Efficient Cast<strong>in</strong>g Technologies<br />

Innovative process and material technologies to significantly improve the energy efficiency (<strong>in</strong>crease<br />

cast<strong>in</strong>g yield, scrap reduction, lower heat treatment energy) of die‐cast die‐ cast and semi‐permanent semi‐ permanent mold<br />

(SPM) cast<strong>in</strong>g processes. Novel sand‐cast sand‐ cast process technology (less heat treat energy, higher<br />

mechanical properties) <strong>for</strong> cyl<strong>in</strong>der head high‐volume high‐ volume applications<br />

Partners<br />

I –Productiondemonstration,<br />

–Production demonstration,<br />

data collection<br />

F/G – Sensor/<strong>in</strong>strumentation<br />

development, data collection,<br />

pilot‐scale facility<br />

U –Data collection, pilot‐scale<br />

facility<br />

• Lack of cast<strong>in</strong>g research fund<strong>in</strong>g<br />

• Lack of cast<strong>in</strong>g research facilities<br />

• Lack of sensors and <strong>in</strong>strumentation<br />

to measure process parameters<br />

• Lack of validated computational<br />

analysis tools<br />

R&D Timel<strong>in</strong>e<br />

Near ‐ Develop pilot pilot‐scale ‐ scale facilities, capabilities, and<br />

methods; met hods; <strong>in</strong>strumentation <strong>for</strong> die die‐cast<strong>in</strong>g, ‐ cast<strong>in</strong>g, se semi‐ mi‐<br />

permanent mold and novel sand sand‐cast ‐ cast proces processes ses<br />

‐ ‐ Integrate cast<strong>in</strong>g process parameters (mea (measured) sured)<br />

<strong>in</strong>to com computational putational analysis tools (temperatu (temperature, re,<br />

pre pressure, ssure,<br />

fill pattern)<br />

Mid ‐ Optimize analysis tools us<strong>in</strong>g experimental<br />

validation data<br />

‐ Develop production‐ready <strong>in</strong>strumentation<br />

(conta (contact ct and non non‐contact) ‐ contact) <strong>for</strong> monitor<strong>in</strong>g pr process ocess<br />

parameters parameters (die (die‐cast, ‐ cast, SPM, novel, sand sand‐cast ‐ cast<br />

process)<br />

Long ‐ Production demonstration of die die‐cast ‐ cast and SPM<br />

<strong>in</strong>novative process technologies (cyl<strong>in</strong>der he heads, ads,<br />

SPM transmission case –diecast) –die‐cast) ‐<br />

‐ Validated analysis tools to accurately predic predict t<br />

prese presence nce of porosity (micro, macro), oxides,<br />

mmicrostructure,<br />

icrostructure, residual stress, mechanical<br />

pproperties<br />

roperties (ultimate tensile strength [UTS],<br />

ffatigue)<br />

atigue)<br />

Technical<br />

Commercial<br />

Other<br />

Challenges<br />

Risks<br />

8.31.09<br />

Targets<br />

• Reduce cast<strong>in</strong>g scrap by<br />

50%, reduce energy<br />

needed to process<br />

components<br />

•Improvedcast<strong>in</strong>g •Improved cast<strong>in</strong>g yield by<br />

50%<br />

•Cast<strong>in</strong>galloys •Cast<strong>in</strong>g alloys that<br />

achieve/exceed<br />

permanent mold<br />

properties, require<br />

m<strong>in</strong>imal heat treatment<br />

• Validated novel sand‐<br />

cast<strong>in</strong>g process <strong>for</strong> cyl<strong>in</strong>der<br />

head components, where<br />

mechanical properties<br />

exceed permanent mold<br />

Benefits<br />

<strong>Energy</strong><br />

•Reducedscrap, •Reduced scrap, higher<br />

cast<strong>in</strong>g yields, less <strong>in</strong>tensive<br />

heat treatment<br />

Environment<br />

•Reducedemissions<br />

•Reduced emissions<br />

Economics<br />

• Significant cost benefits due<br />

to reduced scrap, reduced<br />

heat treatment, higher cast<strong>in</strong>g<br />

yields<br />

TECHNOLOGY ROADMAP FOR AUTOMOTIVE MANUFACTURING ENERGY REDUCTION 33