RUN OF THE MILL - Ruskin Mill Trust

RUN OF THE MILL - Ruskin Mill Trust

RUN OF THE MILL - Ruskin Mill Trust

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30<br />

The Forge<br />

by Ryan and Louis, 1st-years<br />

In the forge we first watched a demonstration from<br />

Chris, the Forge Tutor, on how to make a fire poker.<br />

Before we did any work ourselves we had to learn about<br />

health and safety and how to use tools correctly.<br />

We learnt that the metal needed to reach approximately<br />

500 degrees Celsius before it started to change colour.<br />

This meant we had to hold our hand above the metal<br />

before picking it up to check if it was too hot. We also<br />

had to wear an apron, plus a glove on the hand we held<br />

the metal with.<br />

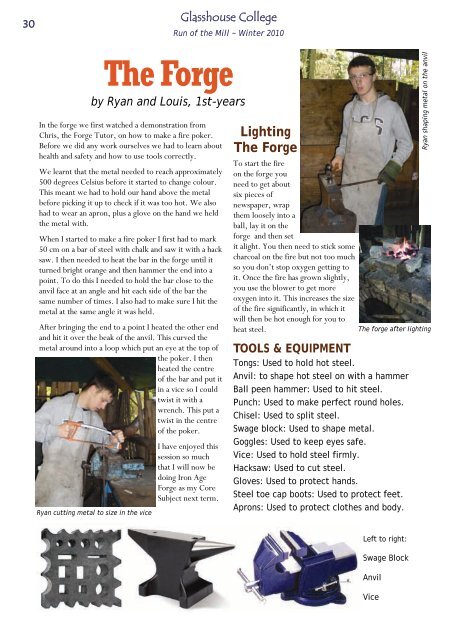

When I started to make a fire poker I first had to mark<br />

50 cm on a bar of steel with chalk and saw it with a hack<br />

saw. I then needed to heat the bar in the forge until it<br />

turned bright orange and then hammer the end into a<br />

point. To do this I needed to hold the bar close to the<br />

anvil face at an angle and hit each side of the bar the<br />

same number of times. I also had to make sure I hit the<br />

metal at the same angle it was held.<br />

After bringing the end to a point I heated the other end<br />

and hit it over the beak of the anvil. This curved the<br />

metal around into a loop which put an eye at the top of<br />

the poker. I then<br />

heated the centre<br />

of the bar and put it<br />

in a vice so I could<br />

twist it with a<br />

wrench. This put a<br />

twist in the centre<br />

of the poker.<br />

Ryan cutting metal to size in the vice<br />

Glasshouse College<br />

Run of the <strong>Mill</strong> ~ Winter 2010<br />

I have enjoyed this<br />

session so much<br />

that I will now be<br />

doing Iron Age<br />

Forge as my Core<br />

Subject next term.<br />

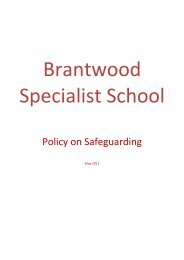

Lighting<br />

The Forge<br />

To start the fire<br />

on the forge you<br />

need to get about<br />

six pieces of<br />

newspaper, wrap<br />

them loosely into a<br />

ball, lay it on the<br />

forge and then set<br />

it alight. You then need to stick some<br />

charcoal on the fire but not too much<br />

so you don’t stop oxygen getting to<br />

it. Once the fire has grown slightly,<br />

you use the blower to get more<br />

oxygen into it. This increases the size<br />

of the fire significantly, in which it<br />

will then be hot enough for you to<br />

heat steel.<br />

TOOLS & EQUIPMENT<br />

Tongs: Used to hold hot steel.<br />

Anvil: to shape hot steel on with a hammer<br />

Ball peen hammer: Used to hit steel.<br />

Punch: Used to make perfect round holes.<br />

Chisel: Used to split steel.<br />

Swage block: Used to shape metal.<br />

Goggles: Used to keep eyes safe.<br />

Vice: Used to hold steel firmly.<br />

Hacksaw: Used to cut steel.<br />

Gloves: Used to protect hands.<br />

Steel toe cap boots: Used to protect feet.<br />

Aprons: Used to protect clothes and body.<br />

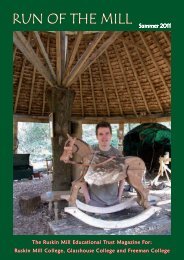

Left to right:<br />

Swage Block<br />

Anvil<br />

Vice<br />

Ryan shaping metal on the anvil<br />

The forge after lighting