with lokring - Ledocom.cz

with lokring - Ledocom.cz

with lokring - Ledocom.cz

- TAGS

- lokring

- www.ledocom.cz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

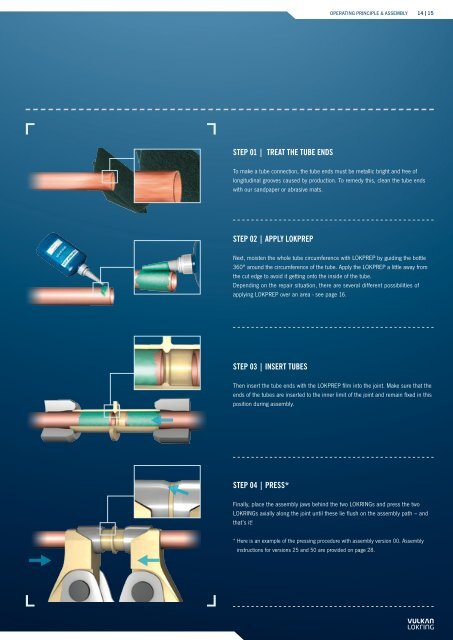

sTEP 01 | TREAT THE TUBE ENDs<br />

OPERATING PRINCIPLE & ASSEMBLY<br />

14 | 15<br />

To make a tube connection, the tube ends must be metallic bright and free of<br />

longitudinal grooves caused by production. To remedy this, clean the tube ends<br />

<strong>with</strong> our sandpaper or abrasive mats.<br />

sTEP 02 | APPLY LOKPREP<br />

Next, moisten the whole tube circumference <strong>with</strong> LOKPREP by guiding the bottle<br />

360° around the circumference of the tube. Apply the LOKPREP a little away from<br />

the cut edge to avoid it getting onto the inside of the tube.<br />

Depending on the repair situation, there are several different possibilities of<br />

applying LOKPREP over an area - see page 16.<br />

sTEP 03 | INsERT TUBEs<br />

Then insert the tube ends <strong>with</strong> the LOKPREP film into the joint. Make sure that the<br />

ends of the tubes are inserted to the inner limit of the joint and remain fixed in this<br />

position during assembly.<br />

sTEP 04 | PREss*<br />

Finally, place the assembly jaws behind the two LOKRINGs and press the two<br />

LOKRINGs axially along the joint until these lie flush on the assembly path – and<br />

that’s it!<br />

* Here is an example of the pressing procedure <strong>with</strong> assembly version 00. Assembly<br />

instructions for versions 25 and 50 are provided on page 28.