Case Study - Seele Covertex - Gerber Technology

Case Study - Seele Covertex - Gerber Technology

Case Study - Seele Covertex - Gerber Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

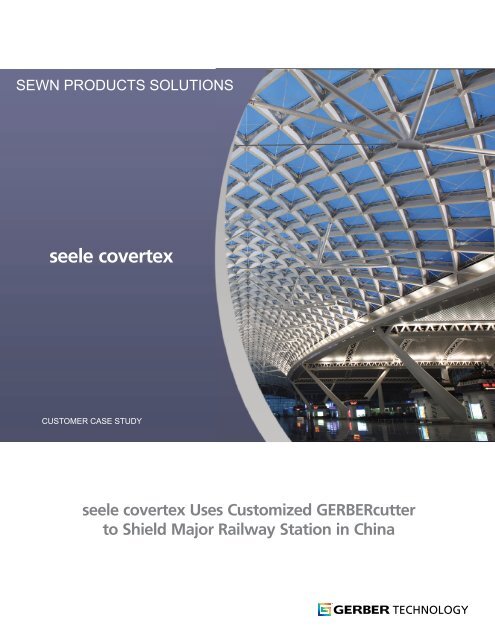

SEWN PRODUCTS SOLUTIONS<br />

seele covertex<br />

CUSTOMER CASE STUDY<br />

seele covertex Uses Customized GERBERcutter<br />

to Shield Major Railway Station in China

1<br />

seele covertex membranes Shanghai Co., Ltd. deals in the fabrication, engineering and<br />

installation of membrane structures and offers premier engineering, design, manufac-<br />

turing and construction solutions. These structures are created by using ETFE (ethylene<br />

tetrafluoroethylene), PTFE (polytetrafluoroethylene), PVDF (polyvinylidene fluoride),<br />

PVC (polyvinyl chloride) materials. seele covertex has production capacity of 500,000<br />

square meters of material per year. Over the years, the company has created mem-<br />

brane structures for both private and public sector projects, which range from sports<br />

and entertainment venues to train stations.<br />

The company began its first operation in 2004 and operates under its parent company,<br />

seele holding GmbH & Co. KG in Germany

Guangzhou’s Largest Railway Station<br />

The Guangzhou South Railway Station is the largest metro<br />

station in Guangzhou and one of the four largest railway pas-<br />

senger transportation hubs in China, serving 300,000 pas-<br />

sengers per day. seele covertex was hired to manufacture and<br />

install the membrane structure that covers the station. A total<br />

of 20,000 square meters of single- and double-ply EFTE<br />

material was used for the roof covering, the first time such<br />

material was used in a China railway station. Daylight enters<br />

the station through the rooflights – which are fitted with a<br />

total of 13,000 square meters of PTFE.<br />

The Guangzhou South Railway Station is<br />

one of the four largest railway passenger<br />

transportation hubs in China, serving<br />

300,000 passengers per day.<br />

seele covertex purchased a GERBERcutter ® DCS2500 in 2008<br />

and has used it to accomplish several high-profile projects.<br />

To meet the needs of seele covertex, <strong>Gerber</strong> customized a<br />

DCS2500 cutter expanding the width of the cutting sur-<br />

face to four meters and the length to 18 meters to provide<br />

a surface big enough to carry out large cutting tasks.<br />

According to both Bjoern Beckert, seele covertex’s general<br />

manager and the company’s cutter operators, the cutter<br />

delivers highly accurate cut parts by creating better patterns<br />

and more efficient nests. The cutter also helped reduce mate-<br />

rial costs and has increased daily output of cut materials from<br />

300 square meters to 1,500 square meters. The cutter has<br />

also been praised for its vacuum and air flotation systems<br />

which are integral to the successful cutting of the materials<br />

used by seele covertex.<br />

A total of 20,000 square meters of single- and double-ply EFTE<br />

material was used for the roof covering, the first time such material<br />

was used in a China railway station.<br />

2

Sky Canopy at Suzhou’s Harmony Times Square<br />

The GERBERcutter DCS2500 system is a highspeed,<br />

single- or low-ply, static table cutting<br />

system designed to cut a wide variety of<br />

technical textiles. It cuts at speeds up to 1.1<br />

meters per second to significantly improve an<br />

operation’s throughput.<br />

<strong>Gerber</strong> <strong>Technology</strong> customized the size of its<br />

DCS2500 cutter to enable seele covertex to easily<br />

cut massive panels. The cutting system helped<br />

reduce material costs and has increased output<br />

of cut materials from 300 square meters to 1,500<br />

square meters per day.<br />

Harmony Times Square, located in Suzhou, China, is a new landmark for the city. It includes office buildings, riverfront cafes and<br />

a state-of-the-art shopping mall. seele covertex constructed a 9,500-square-meter canopy that covers much of it. The sky canopy<br />

is constructed of an ETFE (ethylene tetrafluoroethylene) fabric on which approximately 20 million LED (light-emitting diode)<br />

lamps are installed, to form what is claimed to be the world’s largest LED display screen. The project won a 2009 Award of<br />

Excellence in IFAI’s annual International Achievement Awards program.<br />

3

seele covertex has also used the GERBERcutter DCS2500 in the cutting of membranes for several other large projects in<br />

Europe, Asia and the other regions of the world. With a team of expert technical engineers, the company now ranks as one<br />

of the leaders in the field of membrane structures.<br />

Beijing National Olympic Stadium<br />

Standing 70 meters high and covering 38,000 square meters in<br />

area, the Bird’s Nest National Stadium in Beijing will forever be<br />

remembered as the focal point of the 2008 Olympic Games.<br />

During the opening ceremony, much of the world was transfixed<br />

by this brilliant structure as China hosted one of the world’s<br />

biggest opening ceremonies in the history of the Olympics.<br />

This massive stadium was an example of how far architectural<br />

integrity has come in recent years. A closer look at<br />

the stadium reveals that it is covered with a single layer of<br />

ETFE (Ethylene tetrafluoroethylene) film, a type of plastic<br />

film designed to have high corrosion resistance and<br />

strength over a wide temperature range. The ETFE film on<br />

the stadium’s roof provides weather resistance while allowing<br />

for adequate sunlight to reach the lawn inside the stadium.<br />

At the same time, the structure collects rain water<br />

for other uses. This idea of new technology combined with<br />

environmental sustainability was the work of Shanghaibased<br />

seele covertex.<br />

The Beijing National<br />

Olympic stadium is covered<br />

with a single layer of ETFE<br />

(Ethylene tetrafluoroethylene)<br />

film, a type of plastic<br />

designed to have high corrosion<br />

resistance and<br />

strength over a wide temperature<br />

range. The total<br />

membrane area of 38,000<br />

square meters is made up<br />

of 880 individual panels,<br />

each measuring 216 square<br />

meters.<br />

4

Corporate Headquarters<br />

<strong>Gerber</strong> <strong>Technology</strong><br />

24 Industrial Park Road West<br />

Tolland, CT 06084, USA<br />

Phone: +1 860 871 8082<br />

www.gerbertechnology.com<br />

February 2011

![Download Fast Facts [PDF] - Gerber Technology](https://img.yumpu.com/8694541/1/190x245/download-fast-facts-pdf-gerber-technology.jpg?quality=85)

![Descargar información de la empresa [PDF] - Gerber Technology](https://img.yumpu.com/8670734/1/190x245/descargar-informacian-de-la-empresa-pdf-gerber-technology.jpg?quality=85)